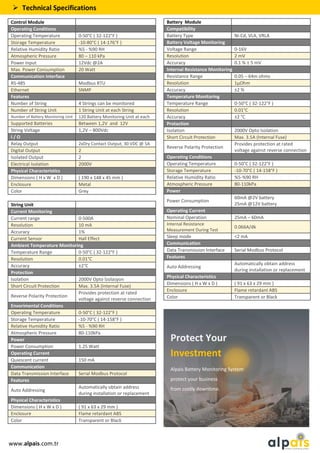

The Alpais battery monitoring system allows businesses to monitor battery infrastructure from a single control center. It measures various parameters of individual batteries like voltage, temperature, and internal resistance. The data is sent to the control unit via modules and then analyzed by Alpais software. This helps businesses optimize battery usage, reduce costs, and avoid downtime from undetected battery issues.