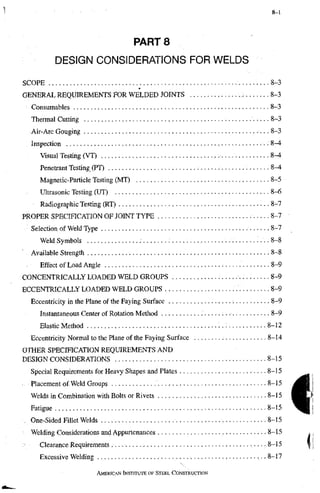

This document is the 14th edition of the Steel Construction Manual published by the American Institute of Steel Construction (AISC). It provides design guidance and specifications for structural steel buildings and bridges. The manual consists of 17 parts covering dimensions and properties of steel sections, design of members under various loading conditions, and design of bolted and welded connections. It includes the AISC Specification for Structural Steel Buildings and the RCSC Specification for structural joints using high-strength bolts.

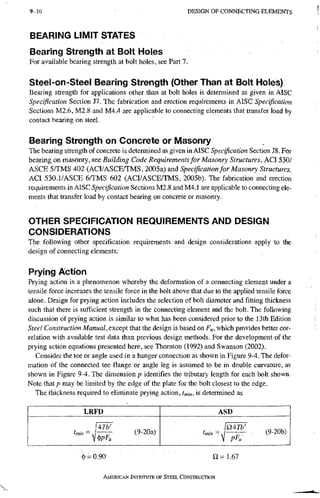

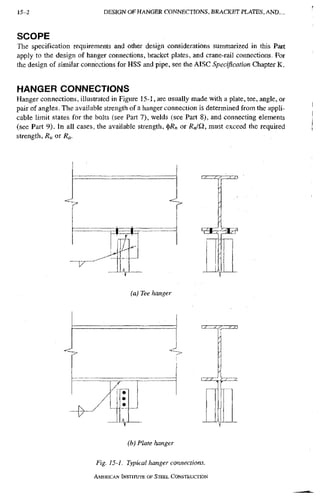

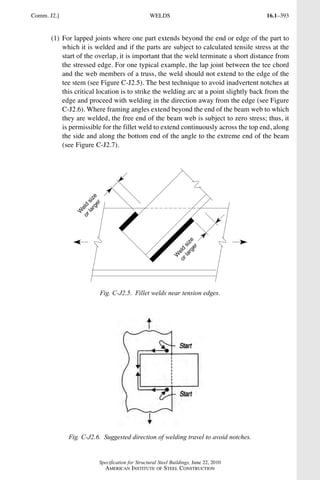

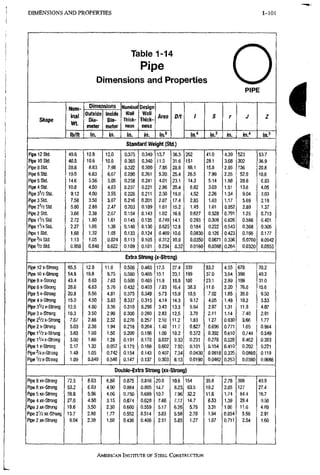

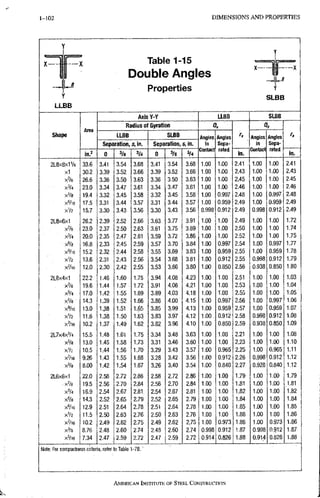

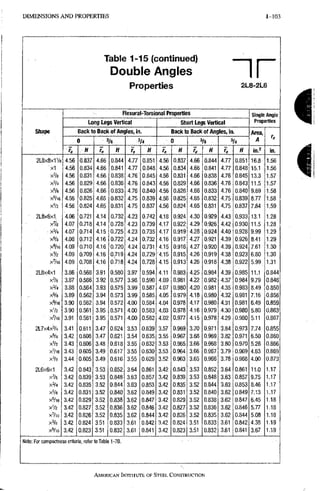

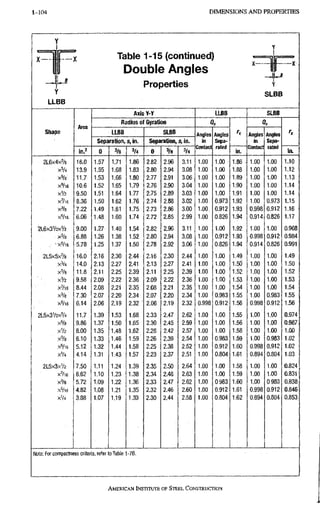

![SCOPE

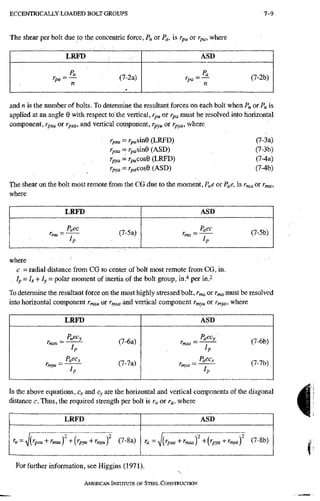

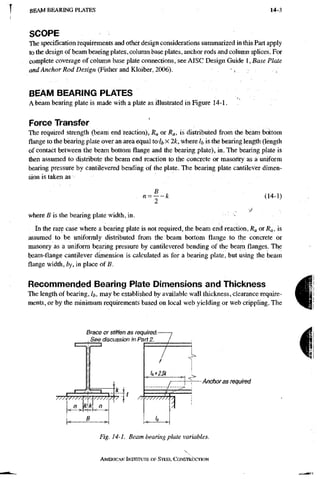

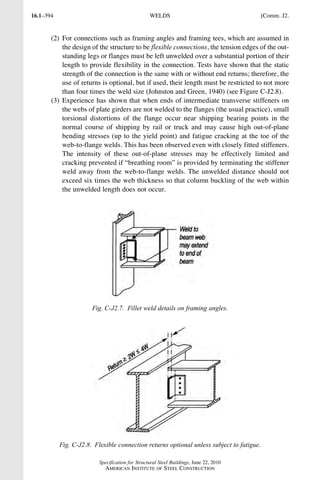

The specification requirements and other design recommendations and considerations sum-

marized in this Manual apply in general to tlie design and construction of steel buildings and

other structures.

The design of seismic force resisting systems also must meet the requirements in the

AISC Seismic Provisions for Structural Steel Buildings, except in the following cases for

which use of the AISC Seismic Provisions is not required;

• Buildings and other structures in seismic design category (SDC) A

• Buildings and other structures in SDC B or C with R = 3 systems [steel systems not

specifically detailed for seismic resistance per ASCE/SEI7 Table 12,2-1 (ASCE,2010)]

• Nonbuilding structiu-es similar to buildings with i? = 1 Va braced-frame systems or

R = 1 moment-frame systems; see ASCE/SEI 7 Table 15.4-1

• Nonbuilding structures not similar to buildings (see ASCE/SEI 7 Table 15.4-2), which

are designed to meet the requirements in other standards entirely

Conversely, use of the AISC Seismic Provisions is required in the following cases:

• Buildings and other structures in SDC B or C when one of the exemptions for steel

seismic force resisting systems above does not apply

• Buildings and other structures in SDC B or C that use composite seismic force resist-

ing systems (those containing composite steel-and-concrete members and those

composed of steel members in combination with reinforced concrete members)

• Buildings in SDC D, E or F

• Nonbuilding structures in SDC D, E or F when the exemption above does not apply

The AISC Seismic Design Manual provides guidance on the use of the AISC Seismic

Provisions.

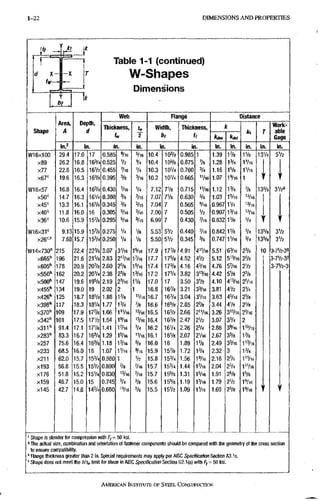

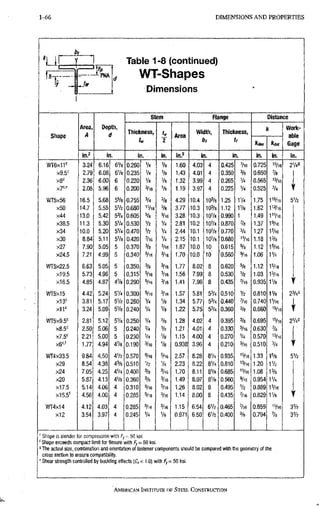

The Manual consists of seventeen parts addressing various topics related to steel build-

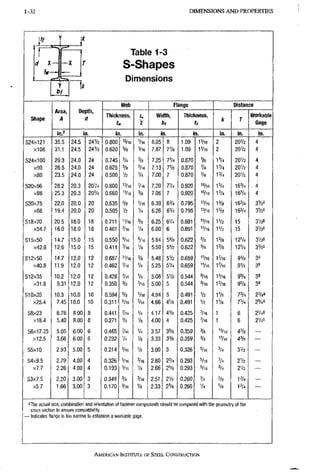

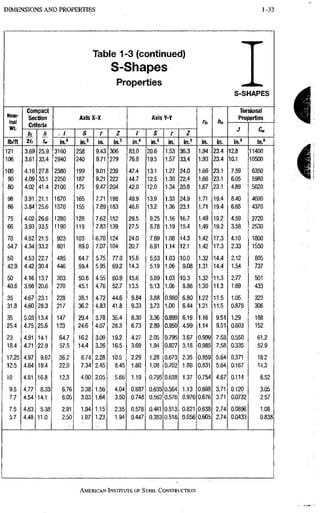

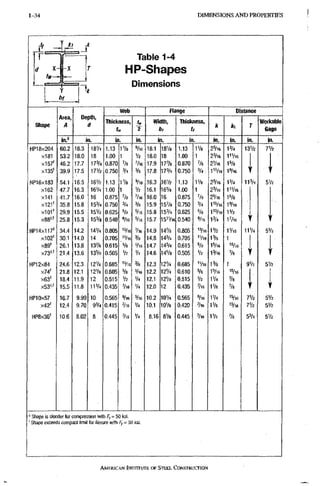

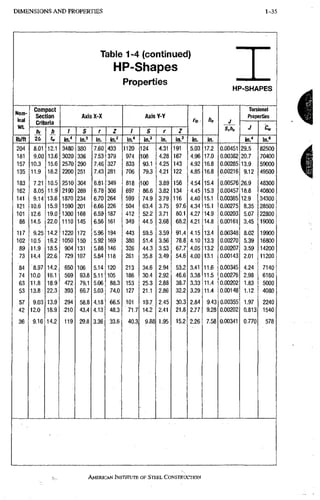

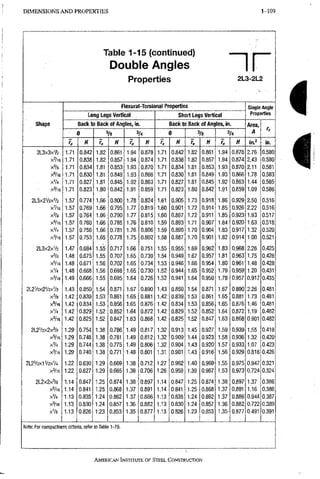

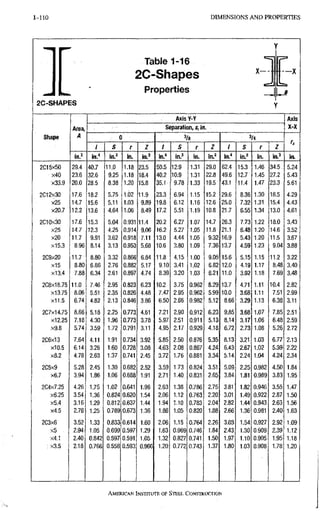

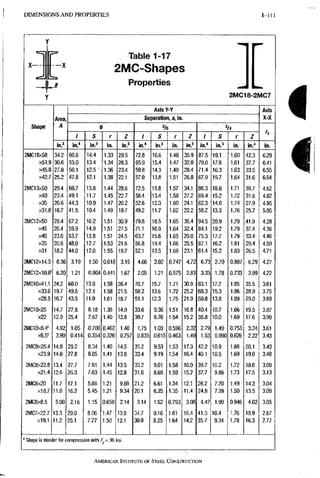

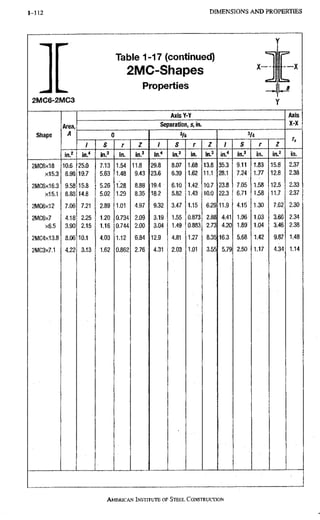

ing design and construction. Part 1 provides the dimensions and properties for structural

products commonly used. For proper material specifications for these products, as well as

general specification requirements and other design considerations, see Part 2. For the

design of members, see Parts 3 through 6. For the design of connections, see Parts 7 through

15. For AISC Specifications and Codes, see Part 16. For other miscellaneous information,

see Part 17.

REFERENCE

ASCE (2010), Minimum Design Loads for Buildings and Other Structures, ASCE/SEI 7-10,

American Society of Civil Engineers, Reston, VA.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-8-320.jpg?cb=1684244800)

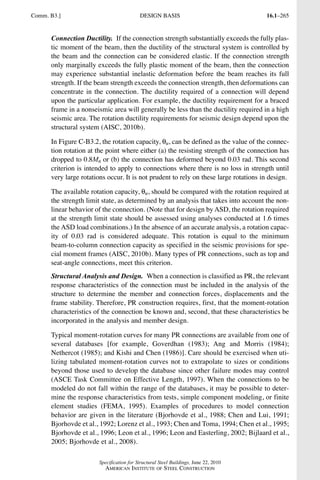

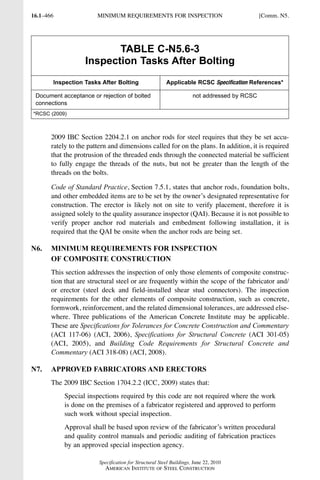

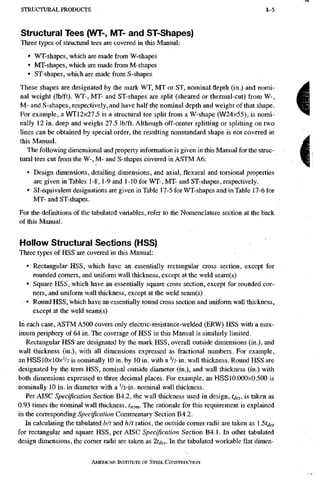

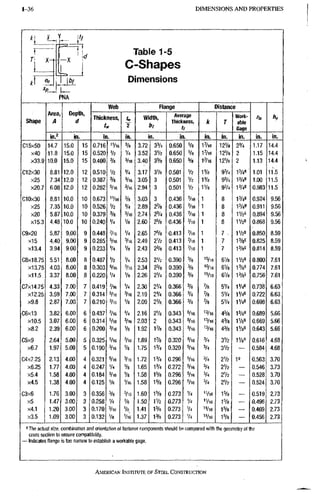

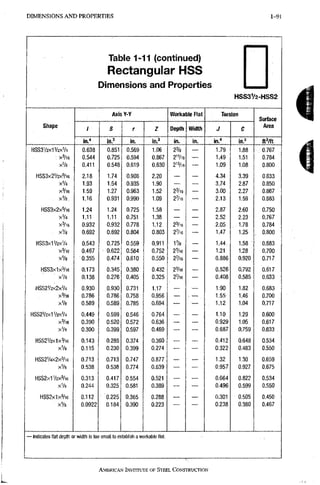

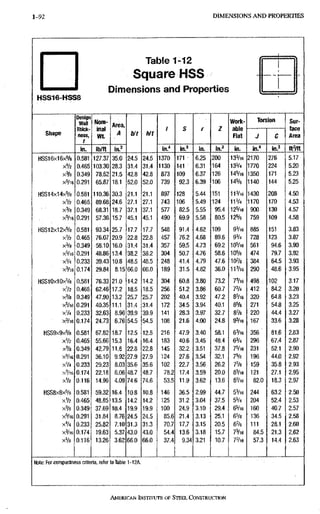

![1-94 D I M E N S I O N S A N D PROPERTIES

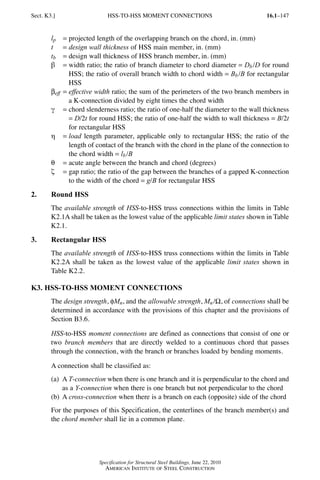

HSS4-HSS2

Table 1-12 (continued)

Square HSS

Dimensions and Properties

Shape

Design

Wall

•Piick-

ness,

f

Nom-

inal

W t

Area,

A b/t h/t

1 S r Z

Work-

able

Flat

Torsion Sur-

face

Area

Shape

Design

Wall

•Piick-

ness,

f

Nom-

inal

W t

Area,

A b/t h/t

1 S r Z

Work-

able

Flat J C

Sur-

face

Area

Shape

in. ll]/ft in.2

b/t h/t

in." in.3 in. in. in." in.^ ft=/ft

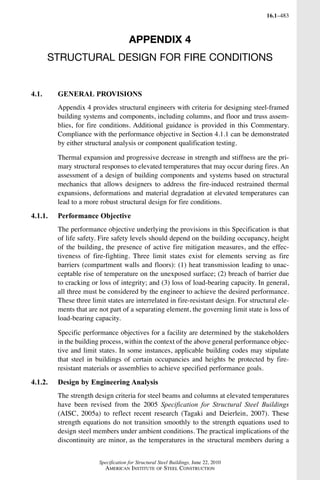

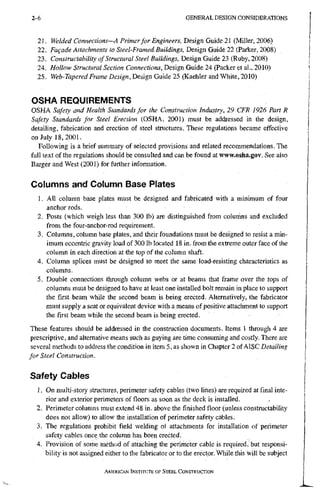

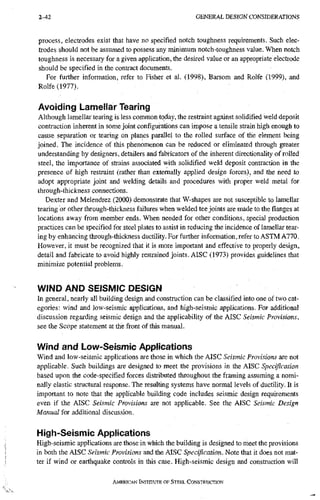

HSS4X4XV2 0.465 21.63 6.02 5.60 5.60 11.9 5.97 1.41 7.70 — 21.0 11.2 1.20

x % 0.349 17.27 4.78 8.46 8.46 10.3 ^ 5.13 ,1.47 6.39 25/iu 17.5 9.14 1.23

x^/ie 0.291 14.83 4.10 10.7 10.7 9.14 4.57 1.49 5.59 2% 15.3 7.91 1.25

.xV4 0.233 12.21 3.37 14.2 14.2 7.80 3.90 1.52 4.69 2% 12.8 6.56 1.27

0.174 9.42 2.58 20.0 20.0 6.21 3.10 1.55 3.67 3^/16 10.0 5.07 1.28

xVs 0.116 6.46 1.77 31.5 31.5. 4.40 2.20 i:58 2,56 3^/16 6,91 3.49 1.30

HSS3V2X3V2X% 0.349 14,72 4.09 7,03 7.03 6.49 3.71 1.26 4,69 — 11.2, 6.77 1.07

X 5 / I 6 0.291 12.70 3.52 9.03 9,03 5.84 3.34 1.29 4.14 2V8 9.89 5.90 1.08

xV4 0.233 10.51 2.91 12,0 12.0 5.04 2.88 1,32 3.50 2% 8,35 4.92 1.10

X 3 / I 6 0.174 8.15 2.24 17.1 17.1 4.05 2.31 1,35 2.76 2'VI6 6,58 3.83 1.12

xVs 0.116 5.61 1.54 27.2 27,2 2.90 1.66 1.37 1.93 • 215/16 4,58 2.85 1.13

HSS3x3x% 0.349 12.17 3.39 5.60 5.60 3.78 2.52 1.06 3.25 — 6,64 4.74 0.900

X=/L6 0,291 10.58 2.94 7.31 7.31 3.45 2.30 1.08 2.90 5.94 4.18 0.917

XV4 0.233 8.81 2.44 9.88 9.88 3.02 2,01 ,1.11 2,48 — . 5,08 3.52 0.933

xVn 0.174 6.87 1.89 14:2 14.2 2.46 1,64 1.14 1.97 2^/16 4,03 2.76 0.950

xVa 0.116 4.75 1.30 22.9 22.9 1.78 1,19 1.17 1.40 2VI6 2,84 1.92 0.967

HSS2V2X2V2X5A6 0.291 8.45 2.35 5.59 5.59 1.82 1.46 0.880 i.88 , — 3,20 2.74 0.750

X V 4 0,233 7.11 1.97 7.73 7.73 1.63 1.30 0.908 1.63 — 2,79 2.35 0.767

0.174 5.59 1.54 11.4 11.4 1,35 1.08 0.937 1.32 2.25 1.86 0.784

xVa 0.116 3.90 1.07 18.6 18.6 0.998 0.799 0.965 0.947 . — • 1.61 1.31 0.800

HSS2V4X2V4XV4 0.233 6.26 1.74 6.66 6.66 1.13 1.01 0.806 1.28 — 1,96 1.85 0.683

x3/ie 0.174 4.96 1.37 9.93 9.93 0.953 0.847 0.835 1.04 1.60 1.48 0.700

xVa 0,116 3.48 0.956 16.4 16.4 0.712 0.633 0.863 0,755 1.15 1.05 0.717

HSS2X2XV4 0,233 5.41 1.51 5.58 5.58 0.747 0.747 0.704 0.964 — 1.31 1.41 0,600

xVw 0,174 4.32 1.19 8.49 8.49 0.641 0.641 0.733 0.797 1.09 1.14 0,617

xVs 0.116 3.05 0.840 14.2 14.2 0.486 0.486 0.761 0.584 0.796 0.817 0,633

Note; For compactness criteria, refer to Table 1-12A.

Indicates flat depth or width is too small to establish a workable flat.

AMERICAN INSTRRUTE OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-102-320.jpg?cb=1684244800)

![U S I N G T H E 2010 A I S C SPECIFICATION 2-9

The required strength of structural members and connections may be determined by elas-

tic, inelastic or plastic analysis for the load combinations associated with LRFD and by

elastic analysis for load combinations associated with ASD and as stipulated by the appli-

cable building code. In all cases, the available strength must exceed the required strength.

The AISC Specification gives provisions for determining the available yucngih ;is summa-

rized below.

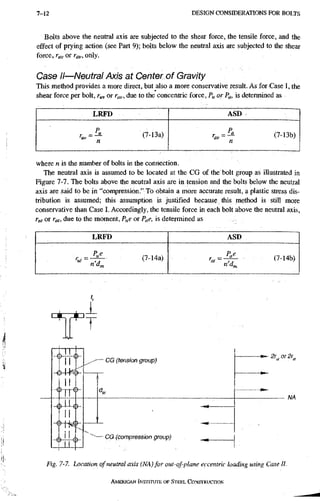

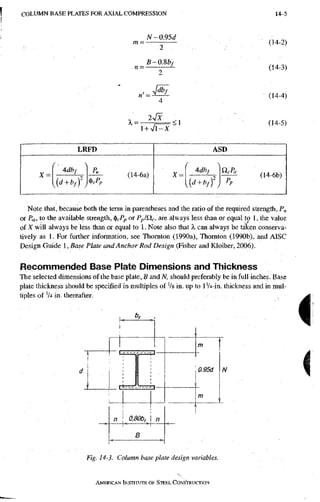

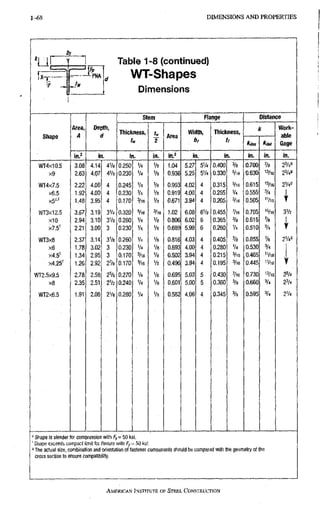

Load and Resistance Factor Design (LRFD)

The load combinations appropriate for LRFD are given in the applicable building code or,

in its absence, ASCE/SEI 7 Section 2.3. For LRFD, the available strength is referred to as

the design strength. All of the LRFD provisions are structured so that the design strength

must equal or exceed the required strength. This is presented in AISC Specification Section

B3.3 as

R u < ( l f R . ( 2 - 1 )

In this equation, is the required strength determined by analysis for the LRFD load

combinations, R^ is the nominal strength determined according to the AISC Specification

provisions, and <

]

) is the resistance factor given by the AISC Specification for a particular

limit state. Throughout this Manual, tabulated values of (])/?„, the design strength, are given

for LRFD. These values are tabulated as blue numbers in columns with the heading LRFD.

If there is a desire to use the LRFD provisions in the form of stresses, the strength provi-

sions can be transformed into stress provisions by factoring out the appropriate section

property. In many cases, the provisions are already given directly in terms of stress.

Allowable Strength Design (ASD)

Allowable strength design is similar to what is known as allowable stress design in that they

are both carried out at the same load level. Thus, the same load combinations are used. The

difference is that for strength design, the primary provisions are given in terms of forces or

moments rather than stresses. In every situation, these strength provisions can be trans-

fonned into stress provisions by factoring out the appropriate section property. In many

cases, the provisions are already given direcdy in terms of stress.

The load combinations appropriate for ASD are given by the applicable building code or,

in its absence, ASCE/SEI 7 Section 2.4. For ASD, the available strength is referred to as the

allowable strength. All of the ASD provisions are structured so that the allowable strength

must equal or exceed the required strength. This is presented in AISC Specification Section

B3.4as

3 (2-2)

In this equation, R^ is the required strength determined by analysis for the ASD load com-

binations, R„ is the nominal strength determined according to the AISC Specification

provisions and Q, is the safety factor given by the Specification for a particular limit state.

Throughout this Manual, tabulated values of k„fQ, the allowable strength, are given for

ASD. These values are tabulated as black numbers on a green background in columns with

the heading ASD.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

i](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-145-320.jpg?cb=1684244800)

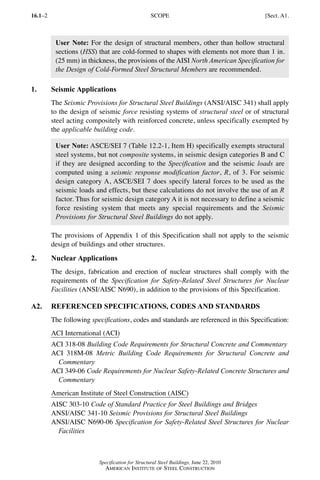

![D E S I G N F U N D A M E N T A L S 2-15

1-

Fe

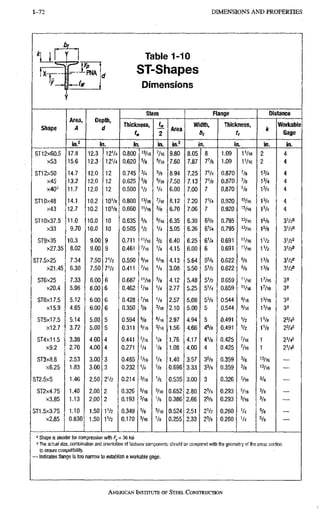

found in the interaction equation. In past LRFD Specifications, the factors B] and Bi from

Chapter C of those specifications were used to amplify moments to account for second-

order effects. was used to account for.the second-order effects due to member curvature

and Bz was used to account for second-order effects due to sidesway. In both Specifications,

more exact methods were permitted.

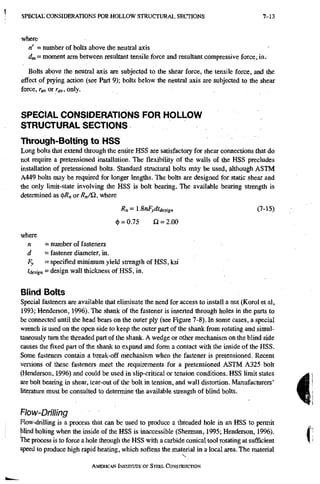

AISC Specification Section CI and Appendix 7 provide three approaches that niay be

followed.

• The direct analysis method is provided in Chapter C. This is the most comprehensive

and, as the name suggests, most direct approach to incorporating all necessary factors

in the analysis. Through the use of notional loads, reduced stiffness, and a second-

order analysis, the design can be carried out with the forces and moments from the

analysis and an effective length equal to the member length, K - 1.0. Section C2 of

the AISC Specification details the requirements for determination of required

strengths using this method.

• The effective length tnethod is given in AISC Specification Appendix 7, Section 12. In

this method, all gravity-only load cases have a minimum lateral load equal to 0.2% of

the story gravity load appHed. A second order analysis is carried out and the member

strengths of columns and beam-columns are determined using effective lengths, deter-

mined by elastic buckling analysis, or more commonly, the alignment charts in the

Commentary to the Specification when the associated assumptions we satisfied. The

Specification permits A

T = 1.0 when the ratio of second order drift to first order drift is

less than or equal to 1.1.

• The first-order analysis method is given in AISC Specification Appendix 7, Section 7.3.

With this approach, second-order effects are captured through the application of an

additional lateral load equal to at least 0.42% of the story gravity load applied in each

load case. No further second-order analysis is necessary. The required strengths are

taken as the forces and moments obtained from the analysis and the effective length

factor is/<:= 1.0.

When a second-order analysis is called for in the above methods, AISC Specification

Section CI allows any method that properly considers P-delta effects. One such method is

amplified first-order elastic analysis provided in Specification Appendix 8. This is a modi-

fied caixy over of the Bi-Bj approach used in previous LRFD Specifications, which was an

extension of the simple approach taken in past ASD Specifications.

The AISC Specification fully integrates the provisions for stability with the specified

methods of design. For all framing systems, when using the direct analysis method, AISC

Specification Section C3 provides that the effective length factor, K, for all members can be

taken as 1.0 unless a lesser value can be justified by analysis. For the effective length

method, AISC Specification Appendix 7, Section 7.2.3(a) provides that in braced frames, the

effective length factor, K, may be taken as 1.0. For moment frames, Appendix 7, Section

7.2.3(b) requires that a critical buckling analysis to determine the critical buckling stress, Fe,

be performed or effective length factors, K, be used. For the first-order analysis method.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

i](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-151-320.jpg?cb=1684244800)

![C O N T R A C T D O C U M E N T I N F O R M A T I O N 2-27

that the product will be used in rigging or similar applications subject to dynamic loading.

The manufacturer's safe working load may be overly conservative for permanent installa-

tions and similar applications subject to static loading only.

If desired, the published safe working load can be converted into an available strength

with reliability consistent with that of other statically loaded structural materials. In this

case, the nominal strength, R„, is determined as:

Rn - (safe working load) X (manufacturer's safety factor) (2-8)

and the available strength, ^Ra or /?„/0, is determined using

(

]

) = 0.50 (LRFD) £2 = 3.00(ASD)

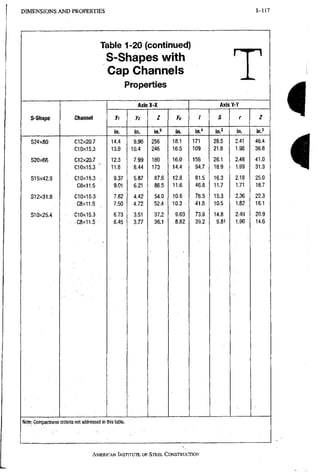

Crane Rails

Crane rails are furnished to ASTM A759, ASTM A l , and/or manufacturer's specifications

and tolerances.

Most manufacturers chamfer the top and sides of the crane-rail head at the ends unless

specified otherwise to reduce chipping of the running surfaces. Often, crane rails are

ordered as end-hardened, which improves the resistance of the crane-rail ends to impact

that occurs as the moving wheel contacts it during crane operation. Alternatively, the entire

rail can be ordered as heat-treated. When maximum wheel loading or controlled cooling is

needed, refer to manufacturers' catalogs. Purchase orders for crane rails should be noted

"for crane service."

Light 40-lb rails are available in 30-ft lengths, 60-lb rails in 30-, 33- or 39-ft lengths, stan-

dard rails in 33- or 39-ft lengths and crane rails up to 80 ft. Consult manufacturer for

availabihty of other lengths. Rails should be arranged so that joints on opposite sides of the

crane runway will be staggered with respect to each other and with due consideration to the

wheelbase of the crane. Rail joints should not occur at crane girder splices. Odd lengths that

must be included to complete a run or obtain the necessary stagger should be not less than

10 ft long. Rails are furnished with standard drilling in both standard and odd lengths unless

stipulated otherwise on the order.

CONTRACT DOCUMENT INFORMATION

Design Drawings, Specifications and

Other Contract Documents

CASE Document 962D, A Guideline Addressing Coordination and Completeness of

Structural Construction Documents (CASE, 2003), provides comprehensive guidance on

the preparation of structural design drawings.

Most provisions in the AISC Specification, RCSC Specification, AWS D l . l , and the

AISC Code of Standard Practice are written in mandatory language. Some provisions

require the communication of information in the contract documents, some provisions are

inyoked only when specified in the contract documents, and some provisions require the

approval of the owner's designated representative for design if they are to be used.

Following is a summary of these provisions in the AISC Specification, RCSC Specification,

and AISC Code of Standard Practice.

AMERICAN iNSTrruTE OF STEEL CONSTRUCTION

I](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-163-320.jpg?cb=1684244800)

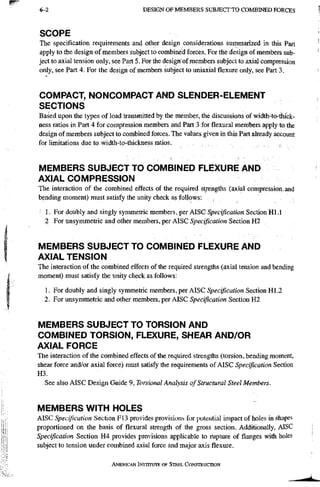

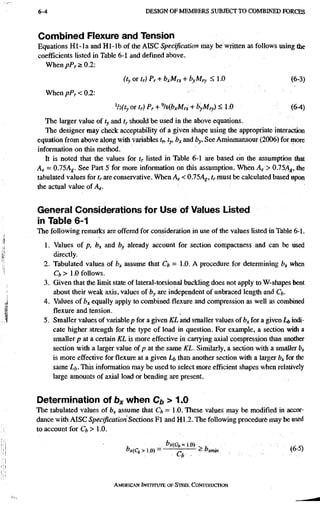

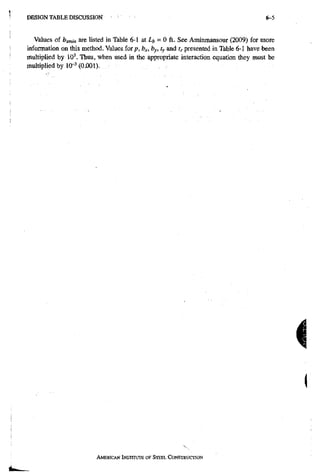

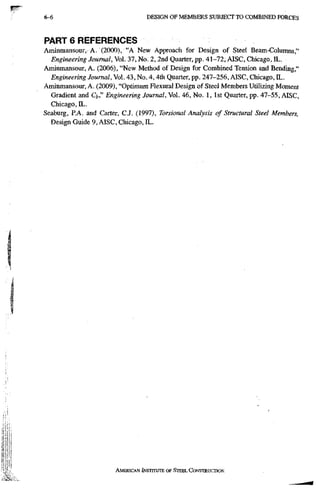

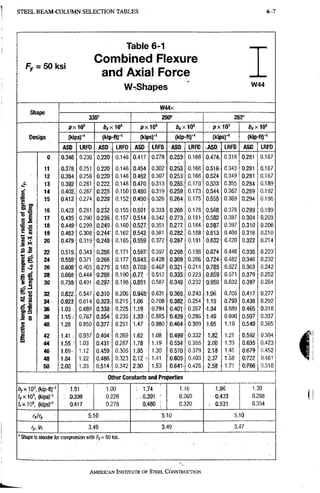

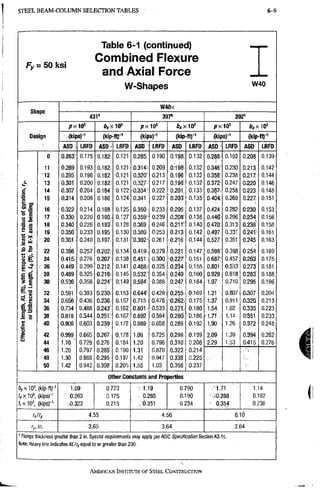

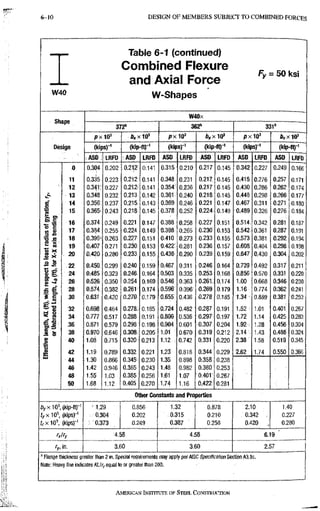

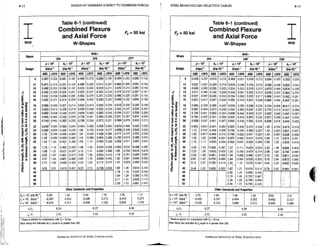

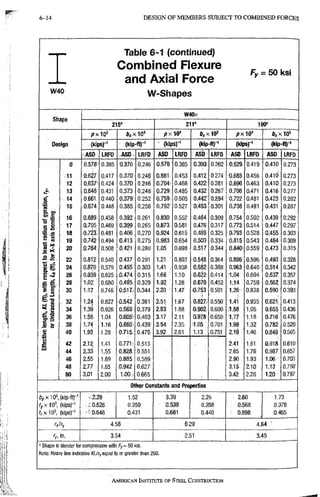

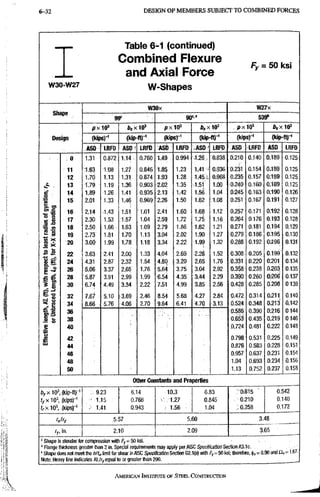

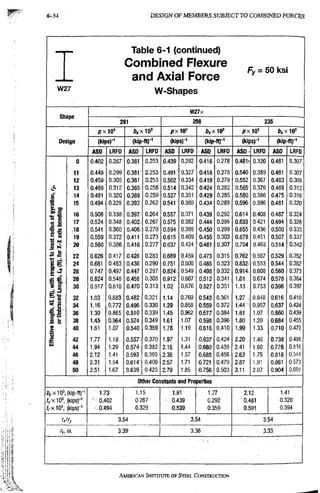

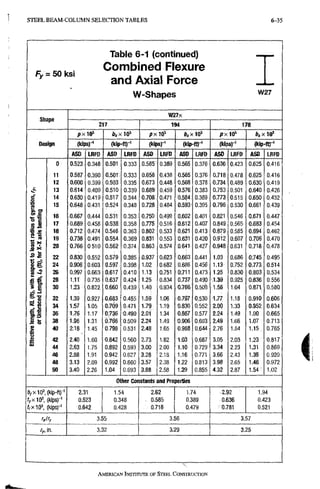

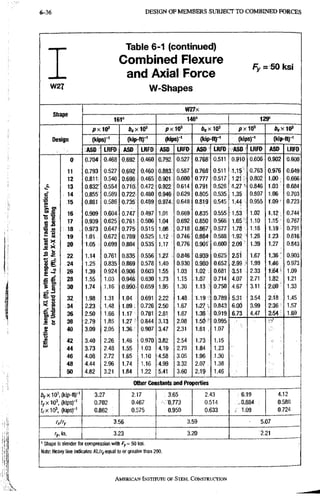

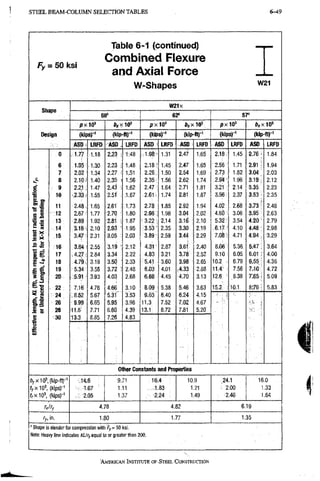

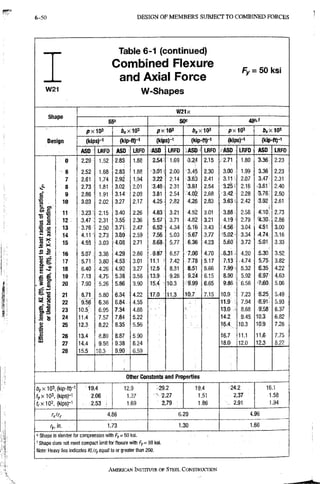

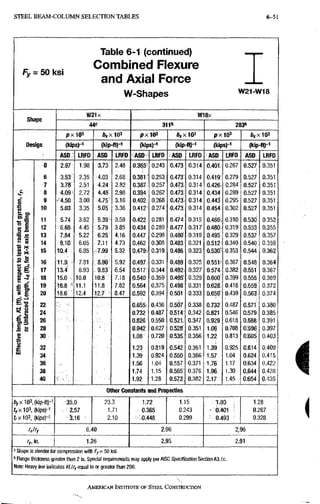

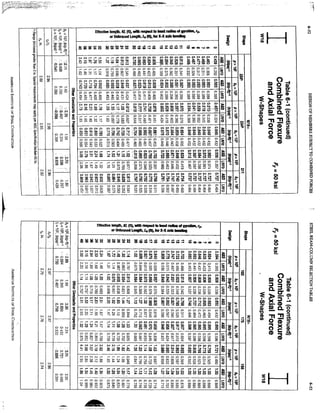

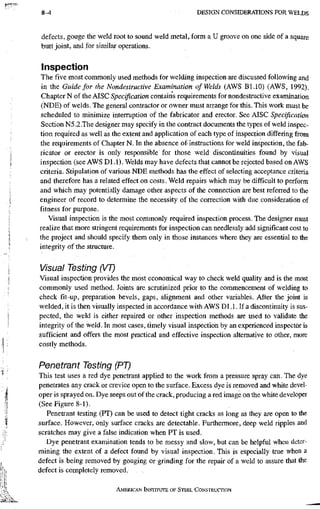

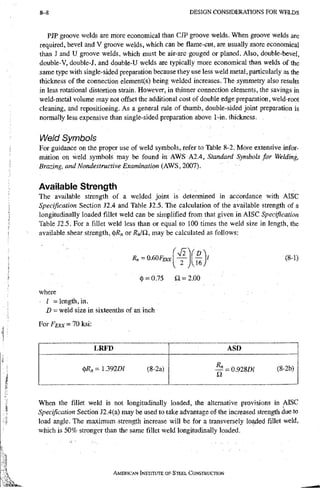

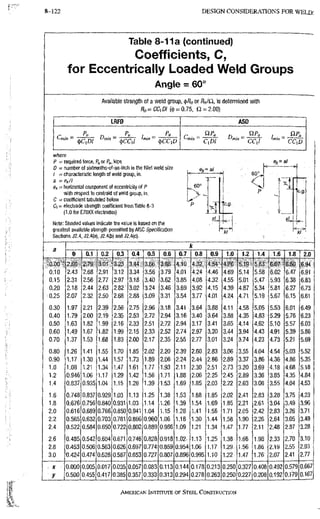

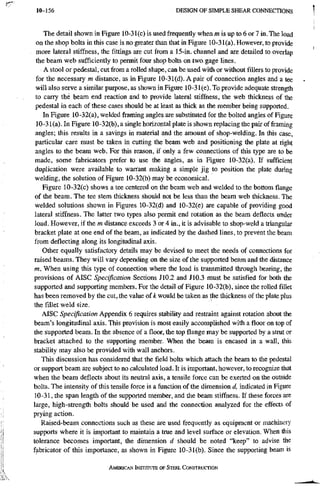

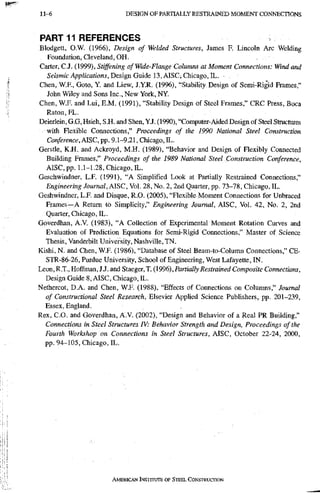

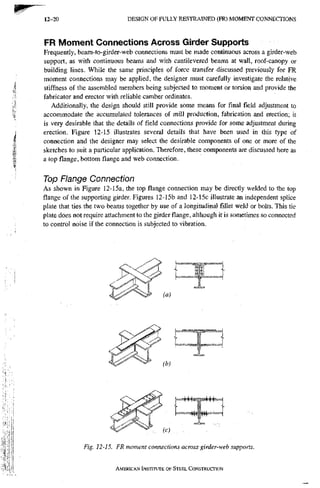

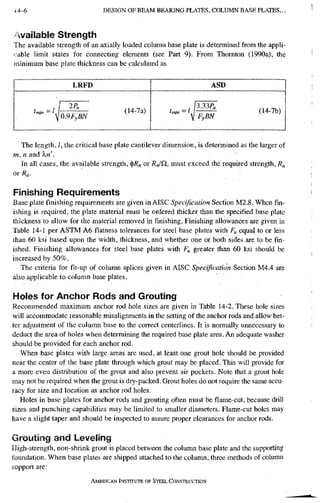

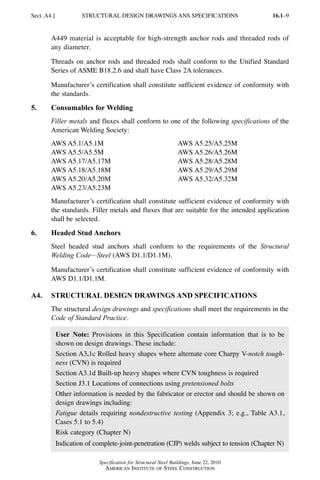

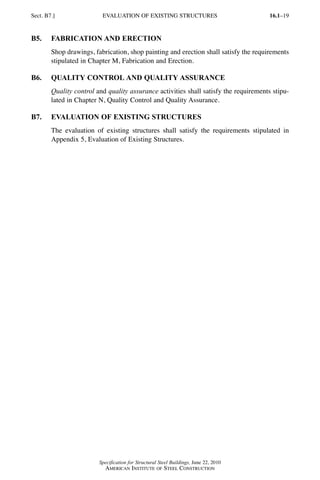

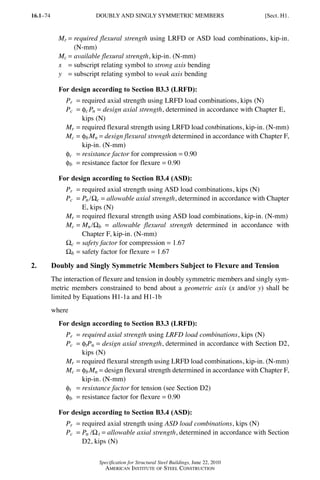

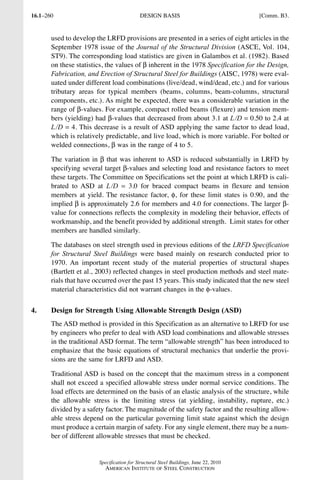

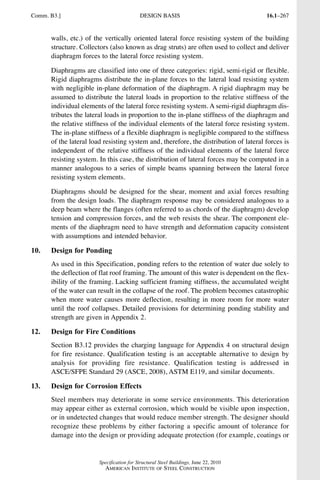

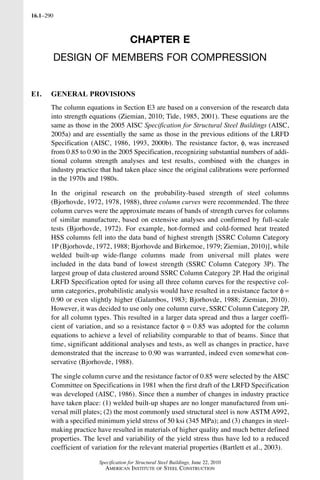

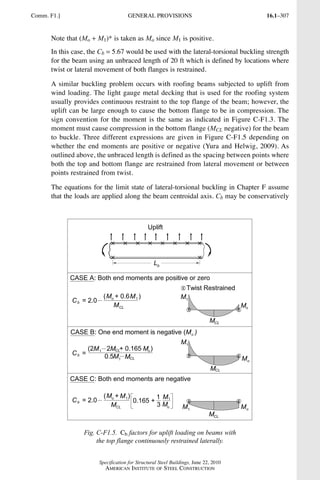

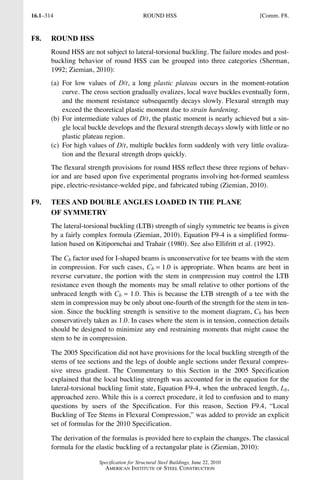

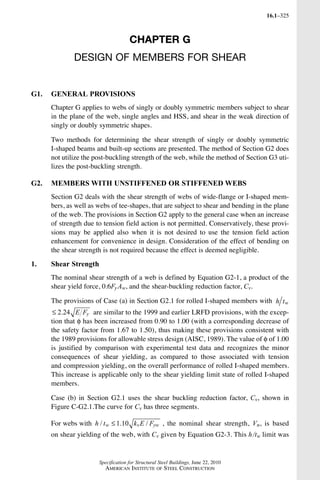

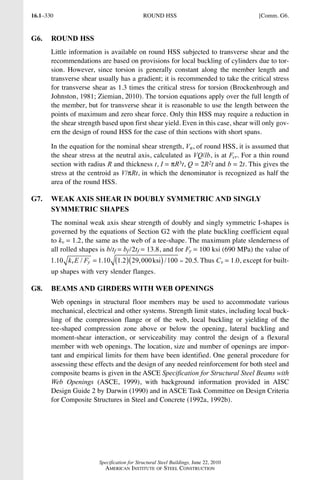

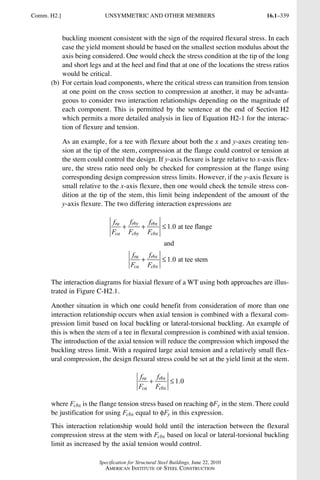

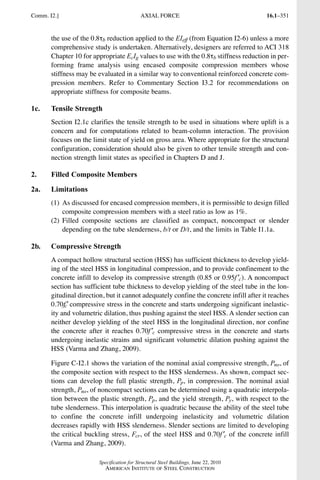

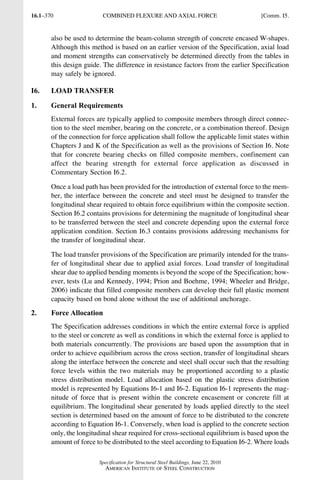

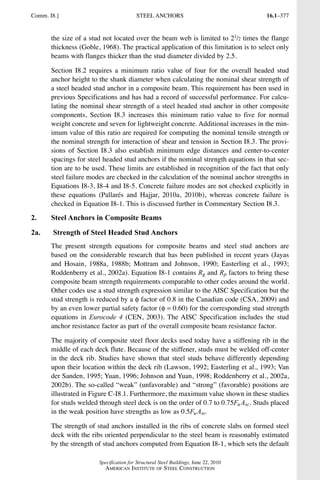

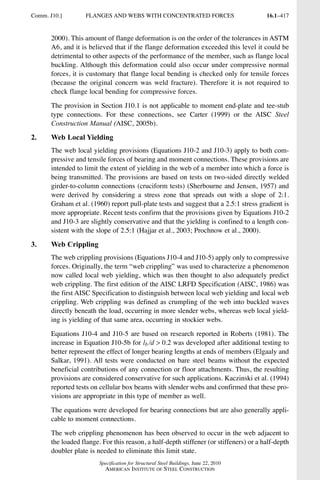

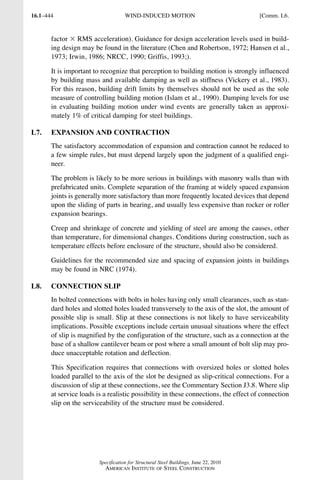

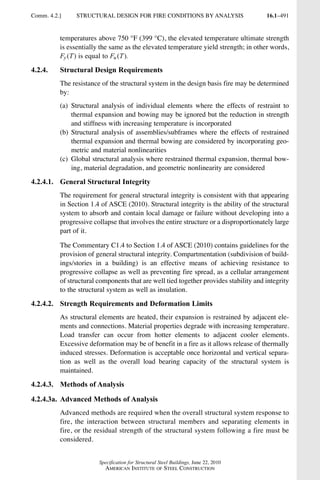

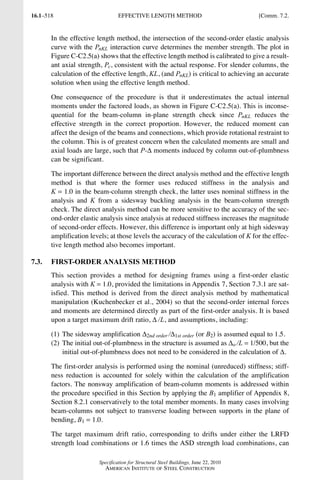

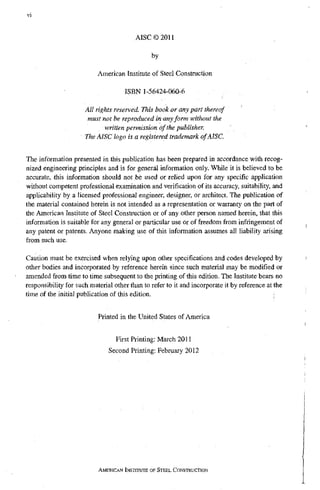

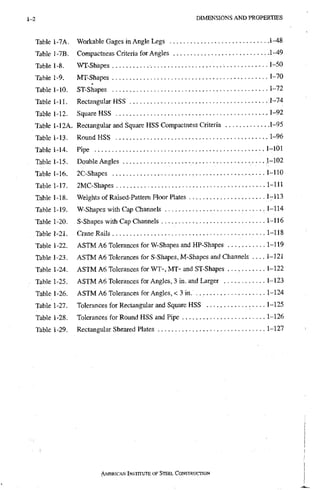

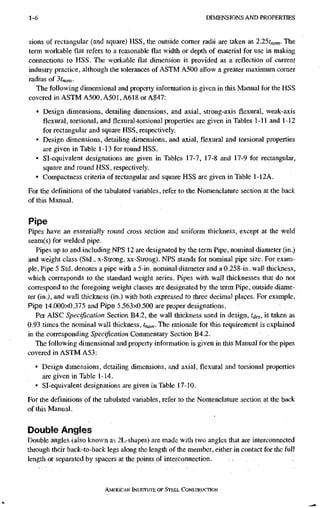

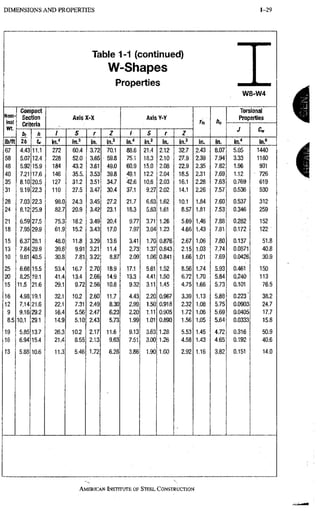

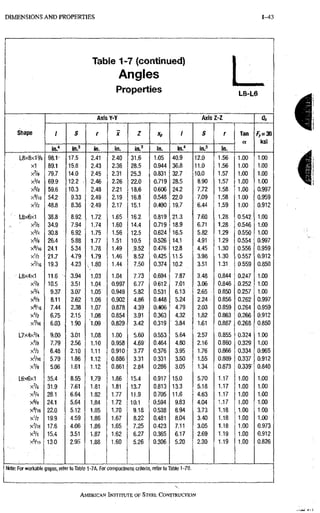

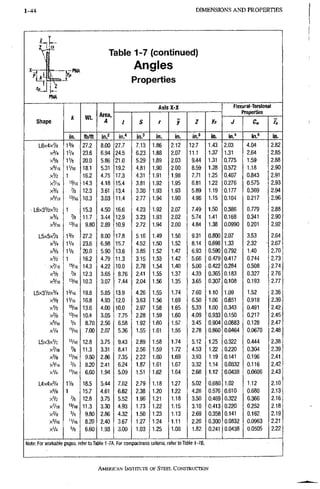

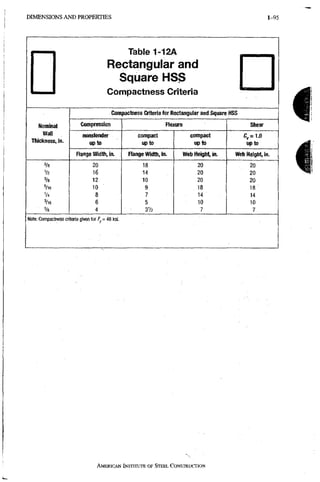

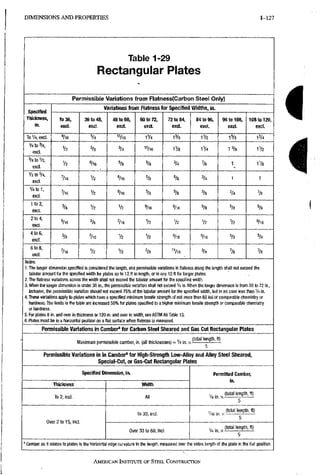

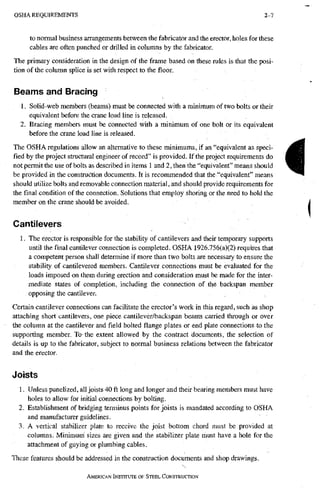

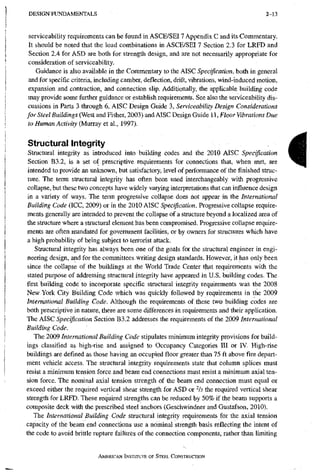

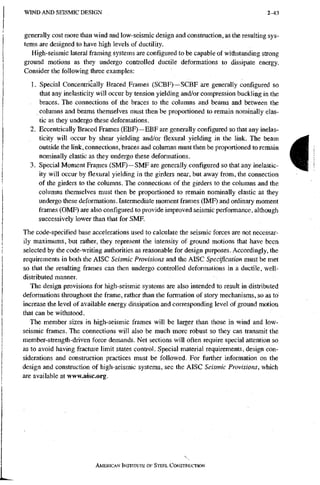

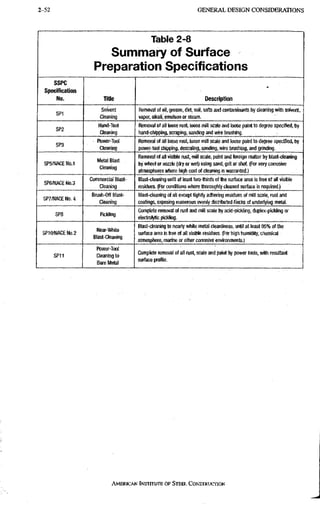

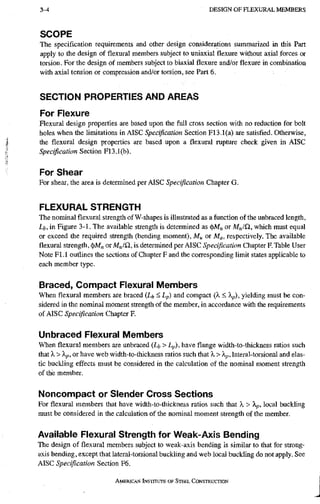

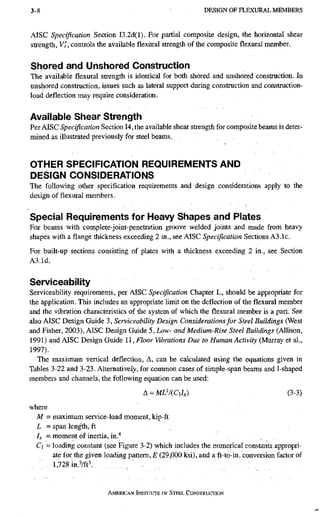

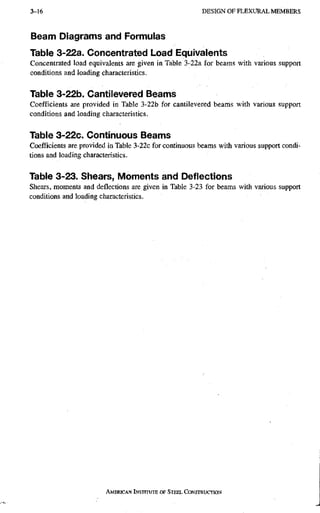

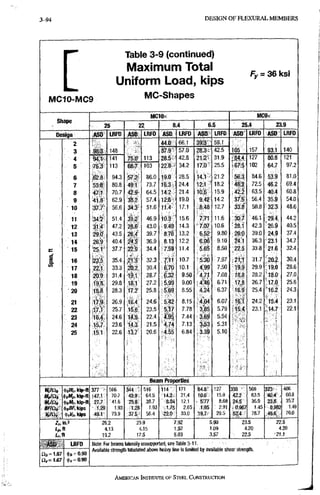

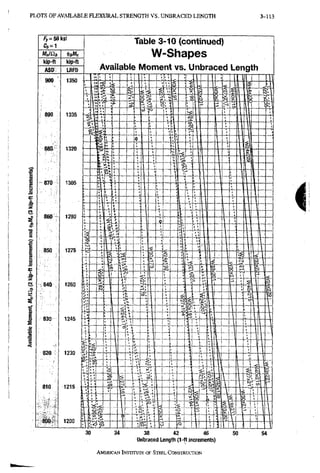

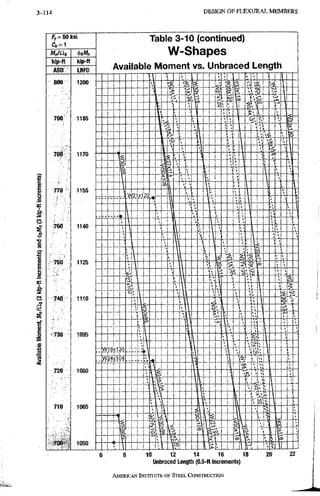

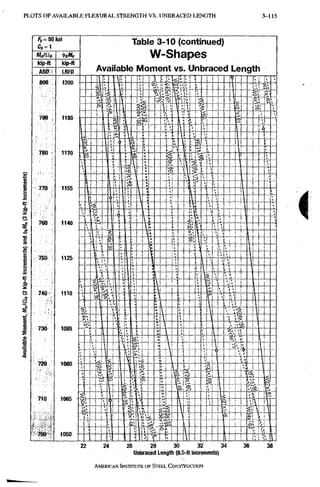

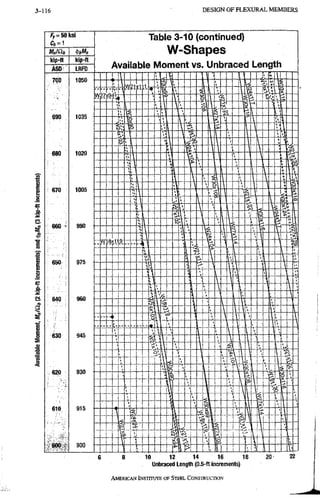

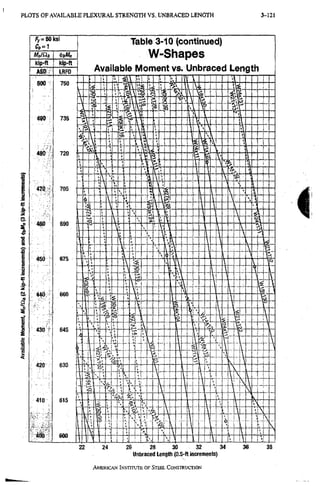

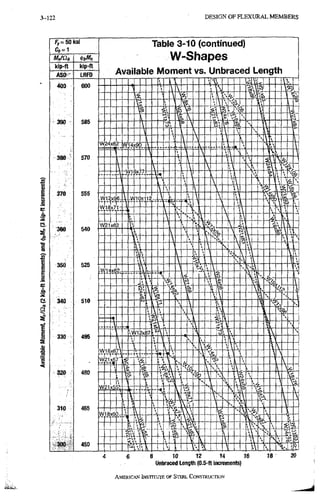

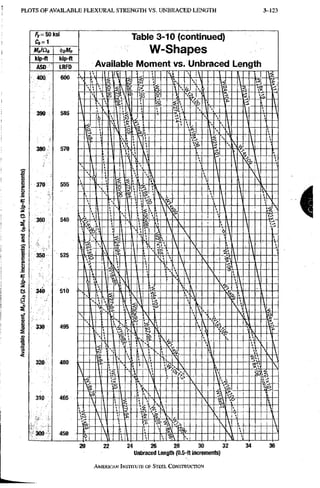

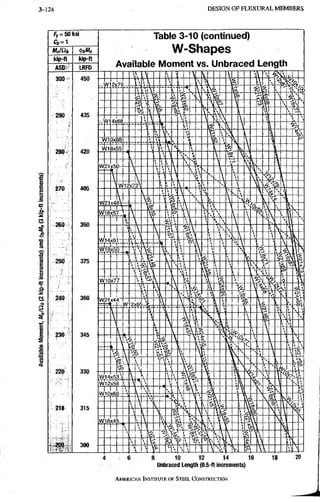

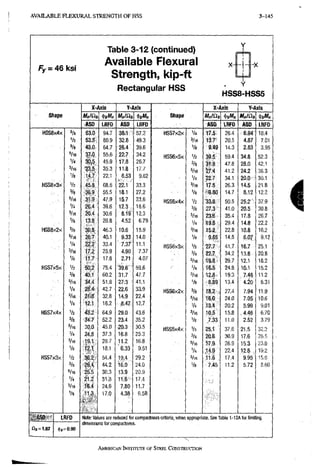

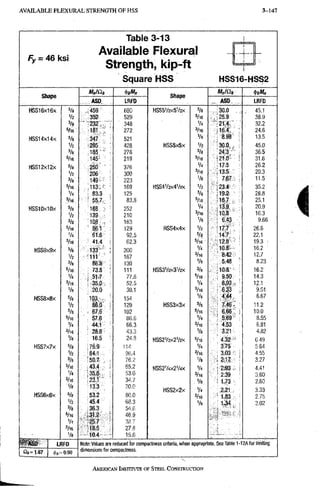

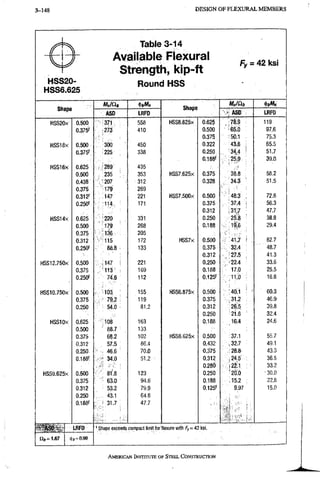

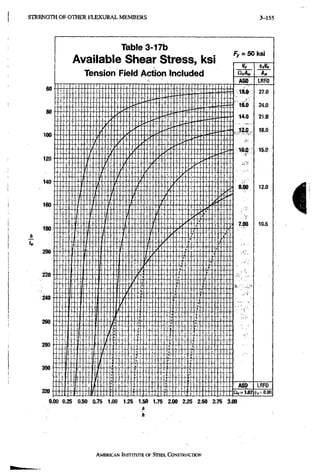

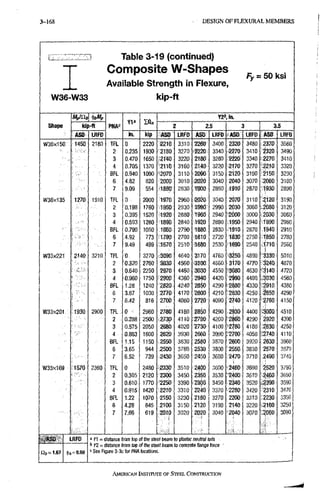

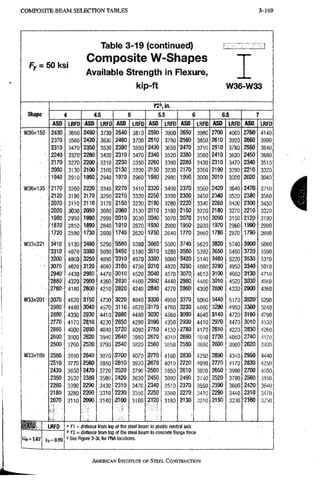

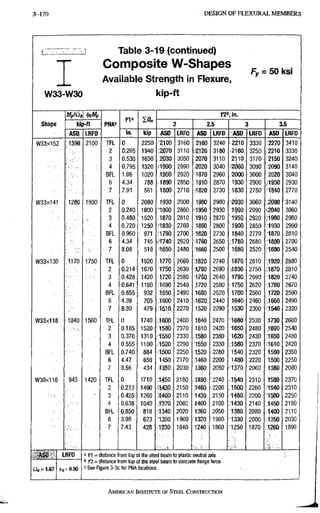

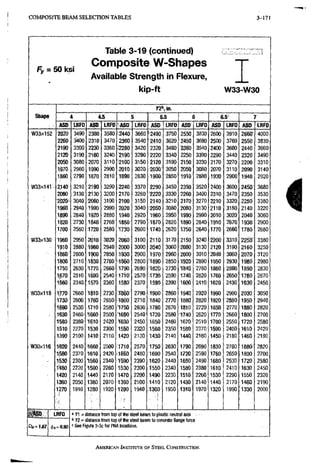

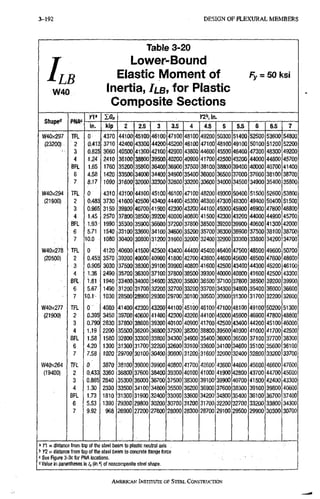

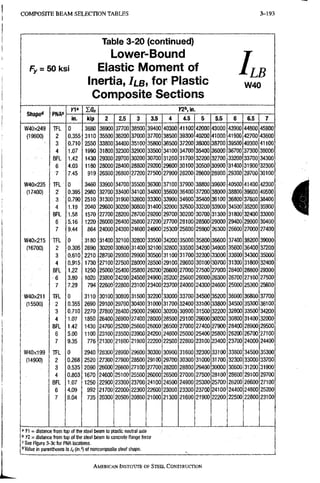

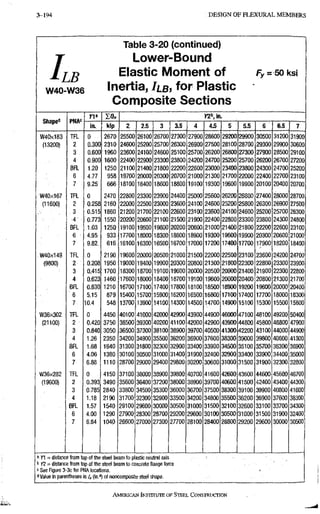

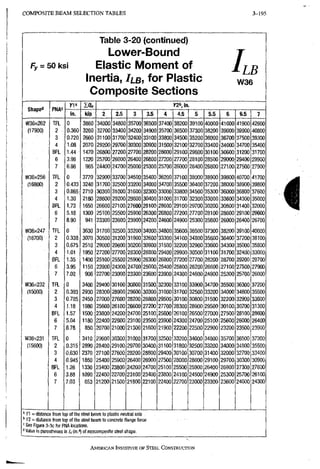

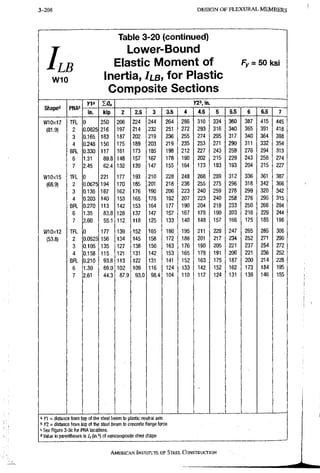

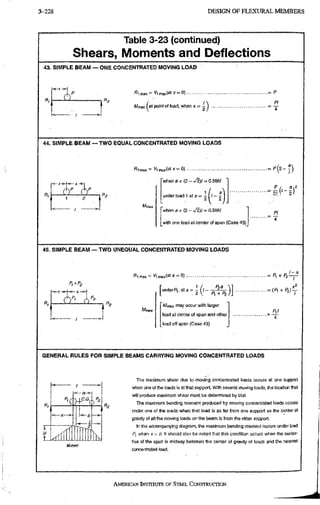

![D E S I G N T A B L E D I S C U S S I O N 3-9

DESIGN TABLE DISCUSSION

Flexural Design Tables

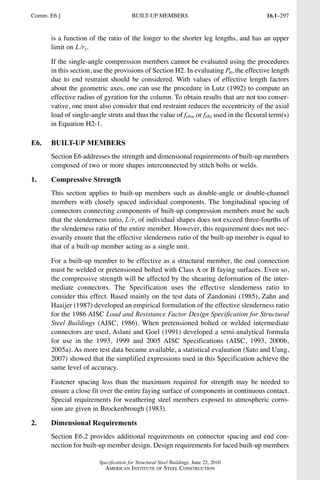

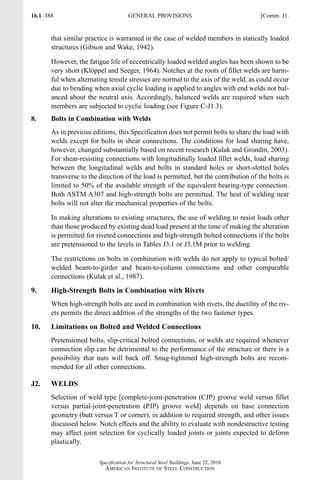

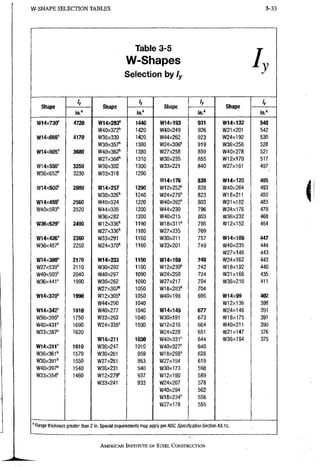

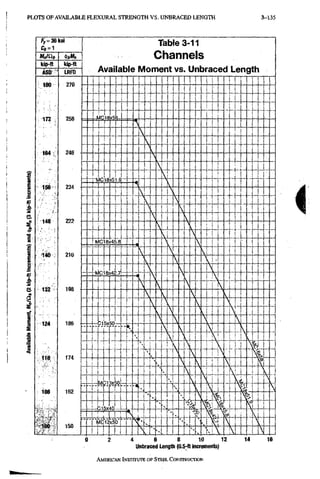

Table 3-1. Values of Cb for Simply Supported Beams

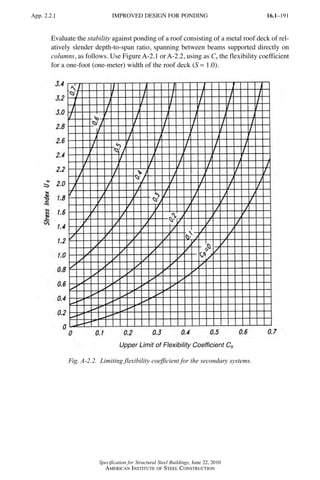

Values of the LTB modification factor, Cb, are given for various loading conditions on sim-

ple-span beams in Table 3-1. -

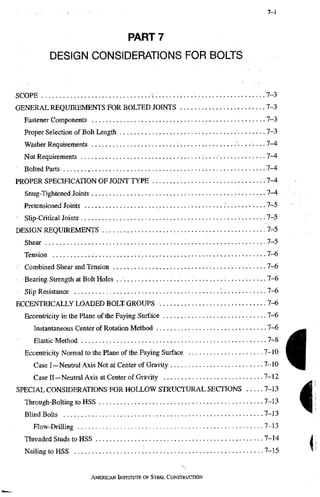

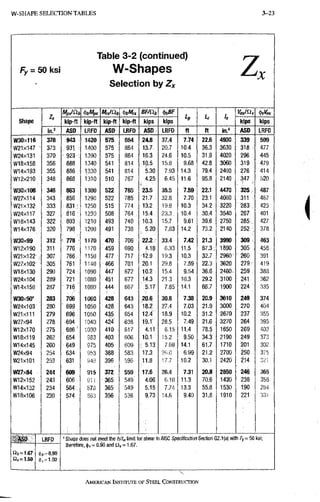

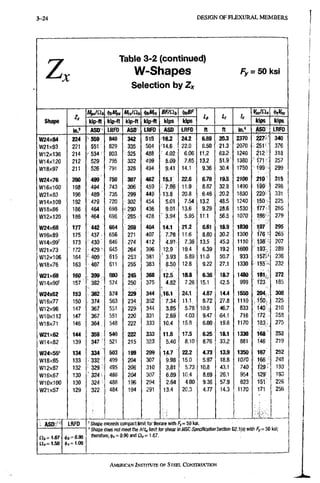

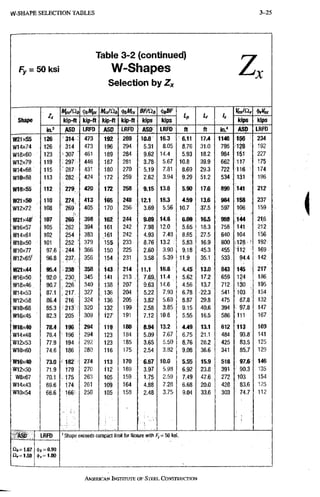

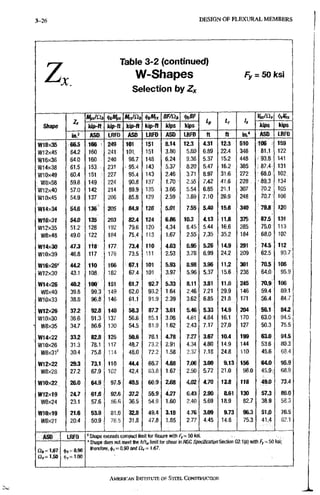

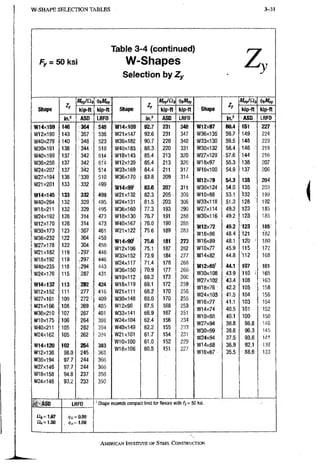

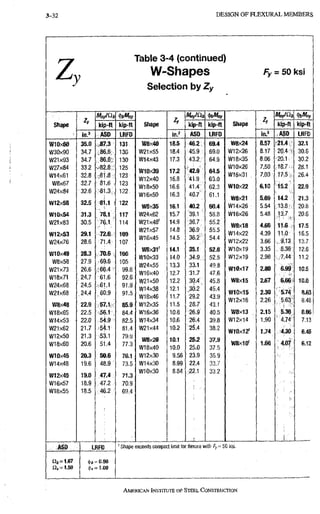

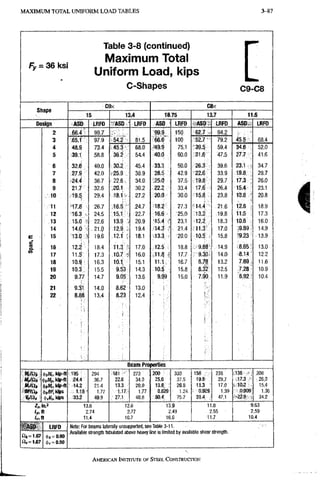

W-Shape Selection Tables

Table 3-2. W-Shapes—Selection by Zx

W-shapes are sorted in descending order by strong-axis flexural strength and then grouped

in ascending order by weight with the lightest W-shape in each range in bold. Strong-axis

available strengths in flexure and shear are given for W-shapes with Fy = 50 ksi (ASTM

A992). Cb is taken as unity.

For compact W-shapes, when L ^ i L p , the strong-axis available flexural strength, ^i^Mpx

or Mpx/£lb, can be determined using the tabulated strength values. When Lp < Lf, < Lr,

linearly interpolate between the available strength at Lp and the available strength at Lr

as follows;

LRFD ASD

i^bMn = Cb [mpx - ^bBF{Lb - Lp)]

<^bMpx .(3-4a)

Mn ^ [Mpx BF,^ , J

(3-4b)

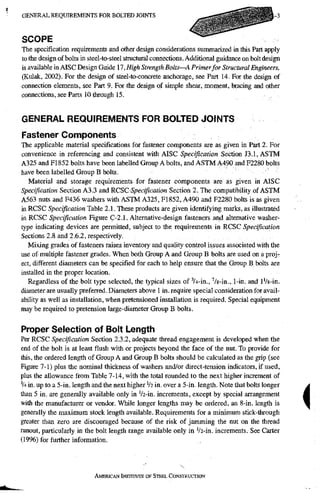

I 1 Ci=201

P P P

t

q=158 Cr170

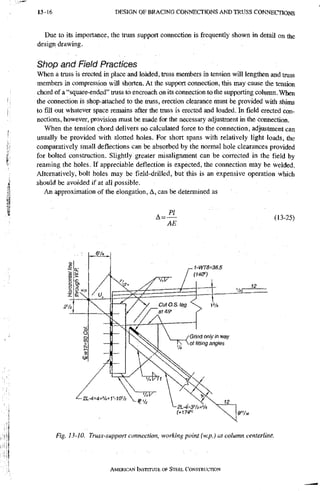

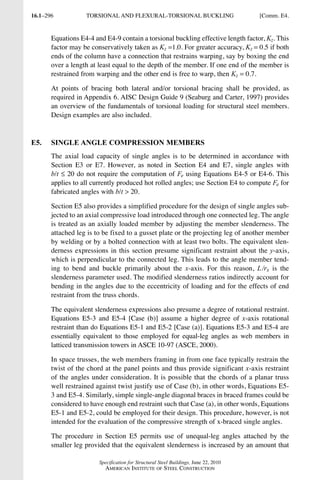

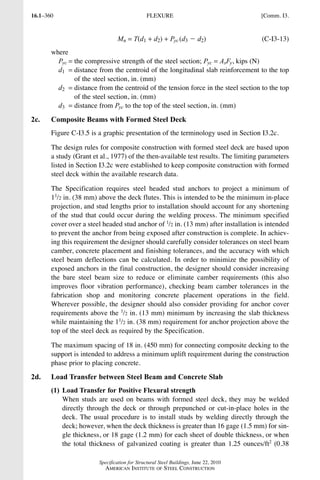

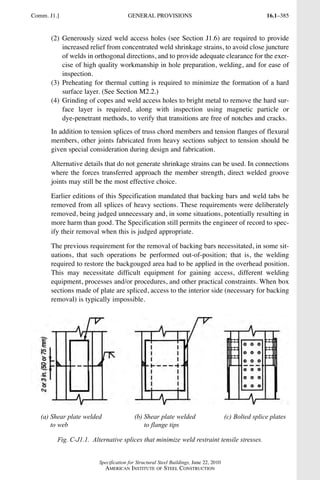

Fig. 3-2. Loading constants for use in determining simple beam deflections.

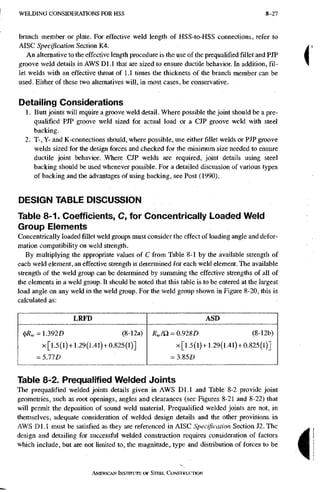

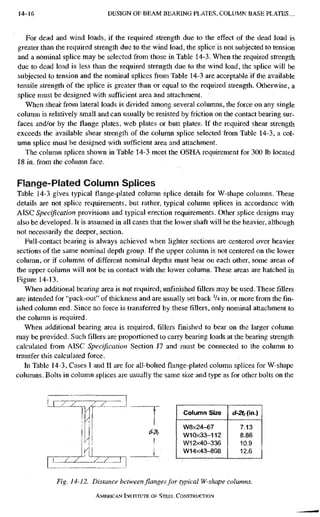

AMERICAN INSTITUTE OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-197-320.jpg?cb=1684244800)

![3-10 D E S I G N O F H L E X U R A E M E M B E R S

where

[Lr-Lp]

Lp = for compact sections, see Figure 3-1, AISC5peayiC(2//on Equation F2-5

= for noncompact sections, Lp-L'p, see Figure 3-1, Equation 3-2

Lr = see Figure 3-1, AlSCSpeci/iCfjrfon Equation F2-6

Mpj, - FyZj, for compact sections (Spec. Eq. F2-1)

= M'p as given in Figure 3-1, AISC Specification Equation F3-1, for noncompact

sections

= Mr, see Figure 3-1

= 0.90

Qi, =1.67

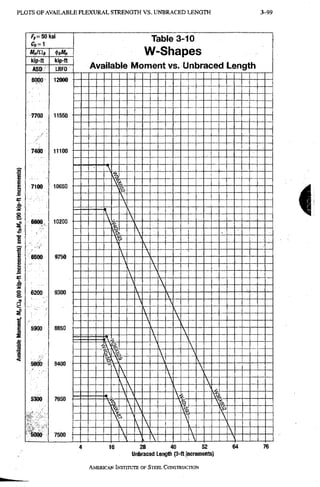

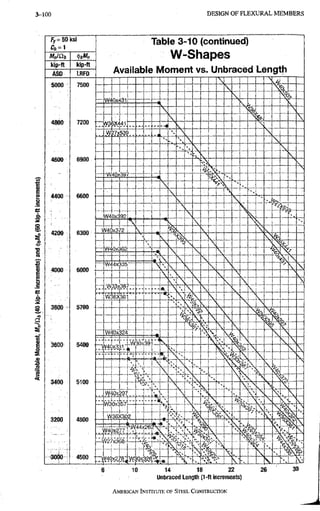

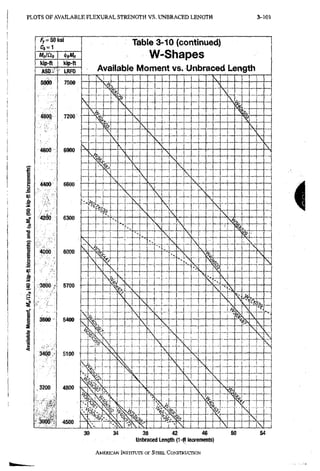

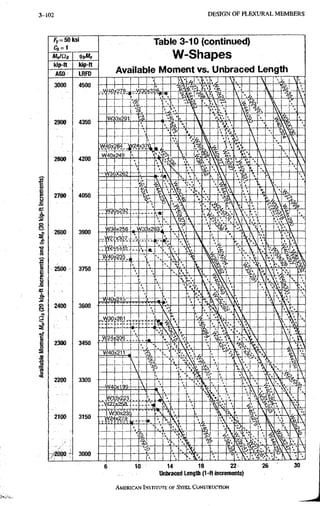

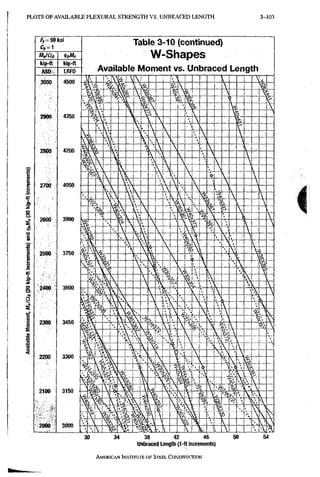

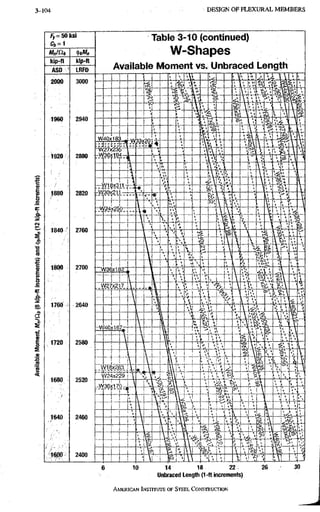

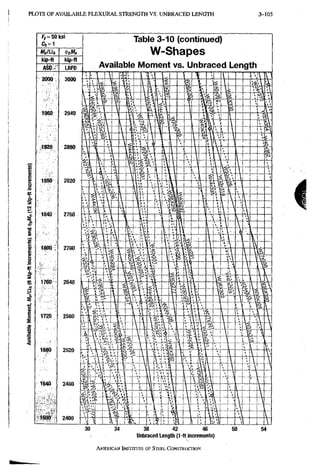

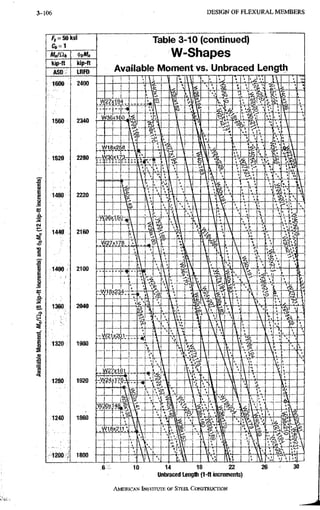

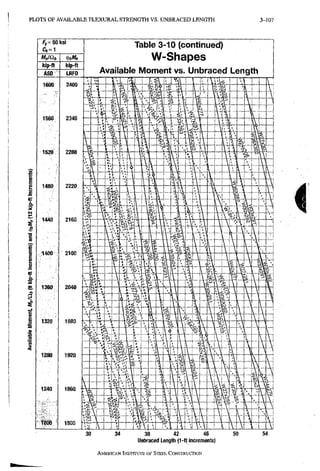

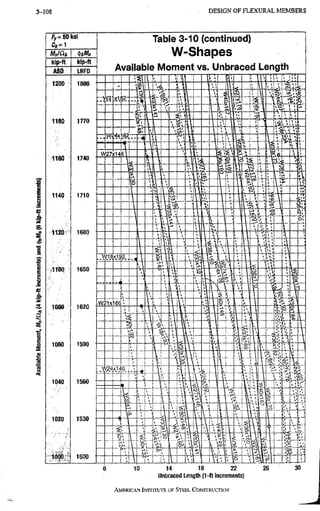

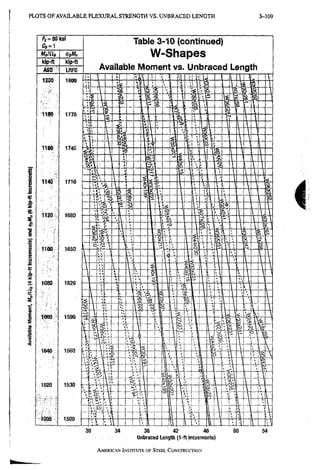

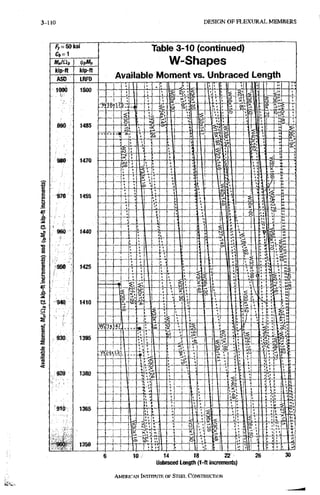

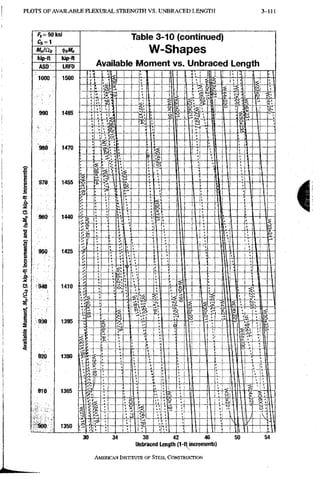

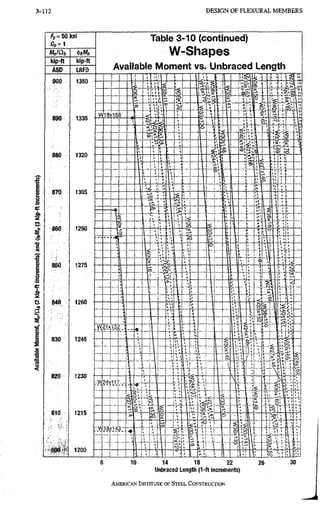

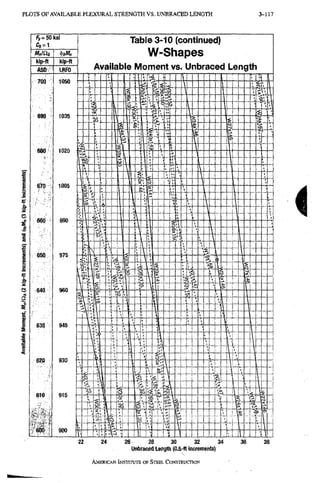

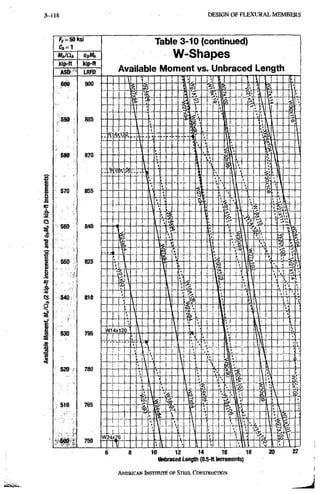

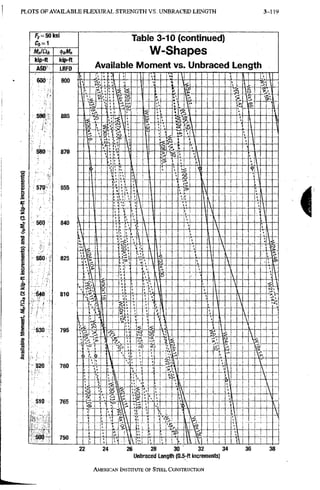

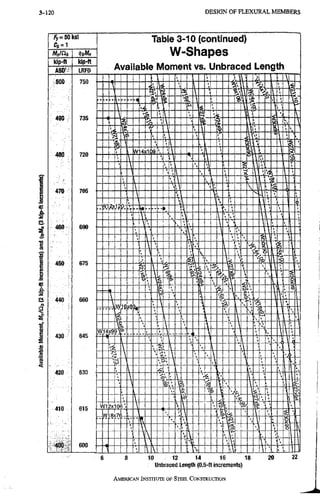

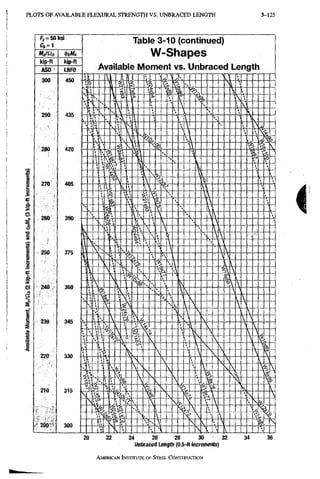

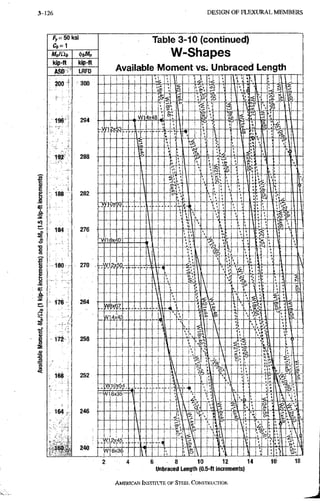

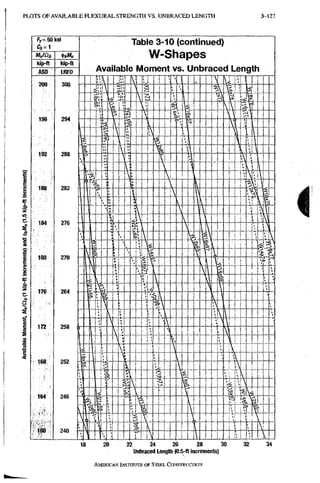

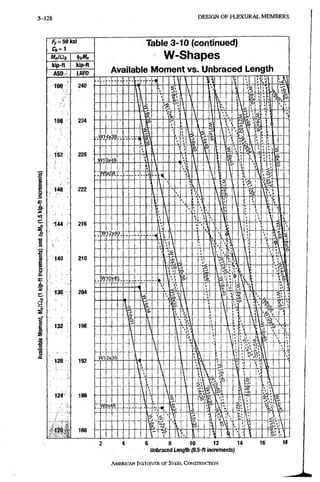

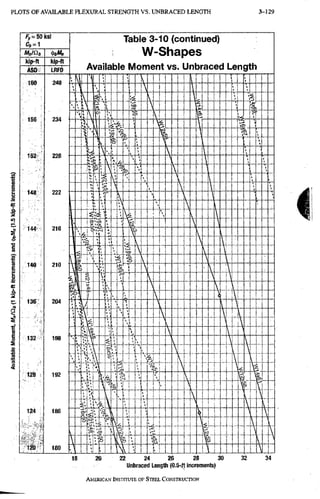

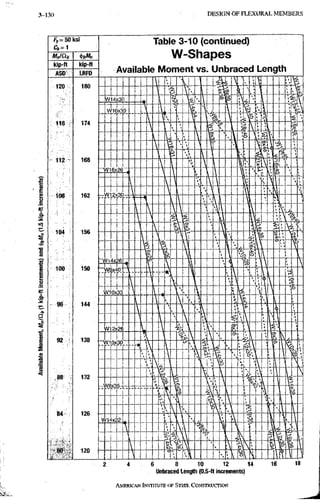

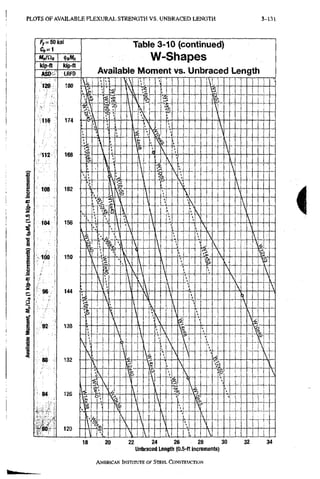

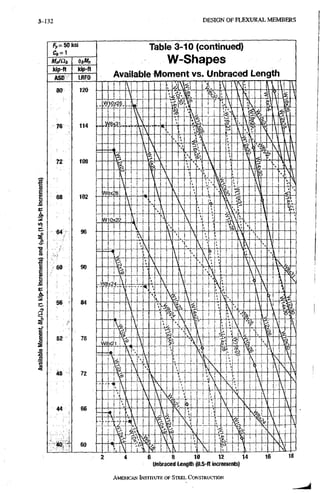

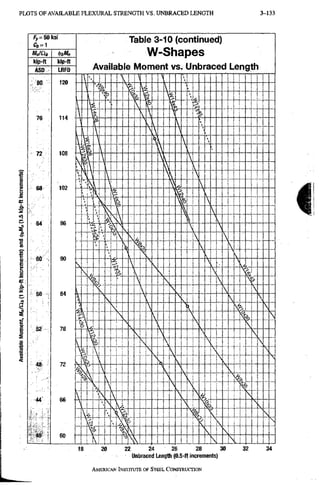

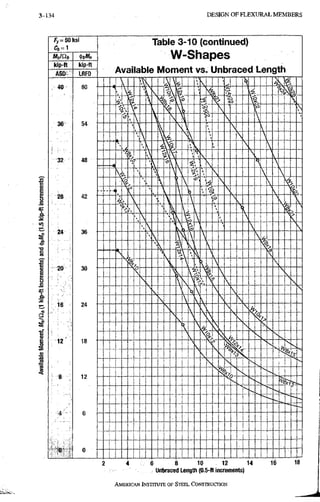

When Lfe > Lr, see Table 3-10.

The strong-axis available shear strength, or can be determined using the

tabulated value.

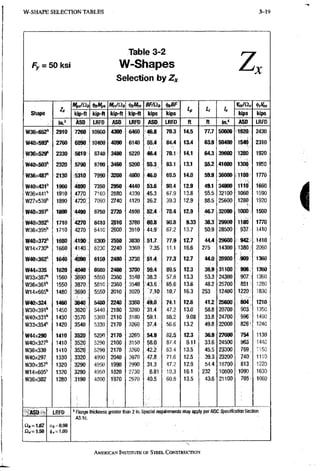

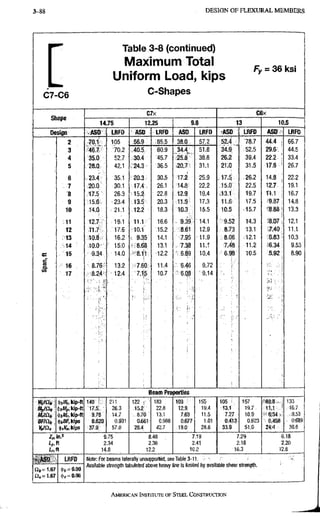

Table 3-3. W-Shapes—Selection by Ix

W-shapes are sorted in descending order by strong-axis moment of inertia, /x. and then

grouped in ascending order by weight with the lightest W-shape in each range in bold.

Table 3-4. W-Shapes—Selection by Zy

W-shapes are sorted in descending order by weak-axis flexural strength and then grouped in

ascending order by weight with the lightest W-shape in each range in bold. Weak-axis avail-

able strengths in flexure are given for W-shapes with Fy = 50 ksi (ASTM A992). Ch is taken

as unity.

For noncompact W-shapes, the tabulated values of Mny/Sit and ^i,Mny have been adjusted

to account for the noncompactness.

The weak-axis available shear strength must be checked independently.

Table 3-5. W-Shapes—Selection by ly

W-shapes are sorted in descending order by weak-axis moment of inertia, ly, and then

grouped in ascending order by weight with the lightest W-shape in each range in bold.

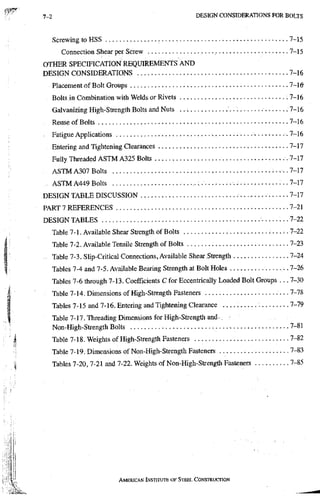

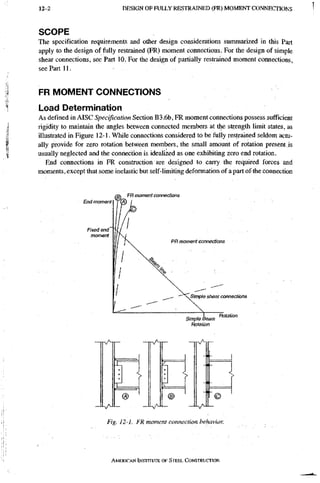

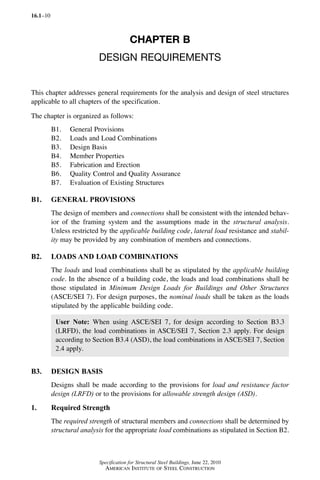

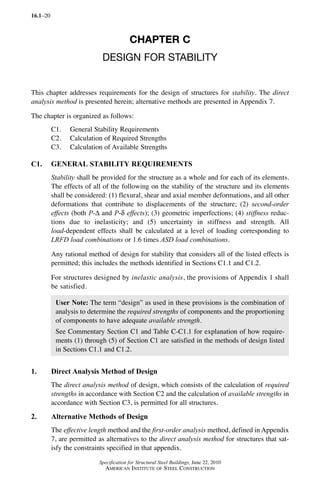

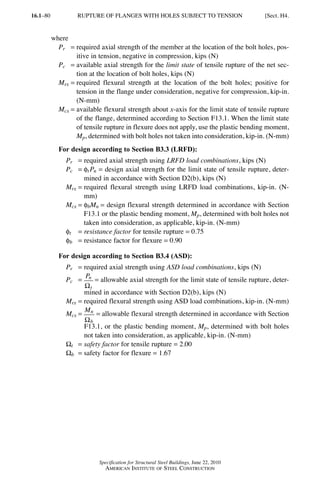

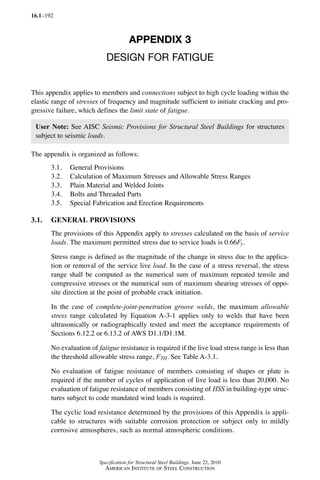

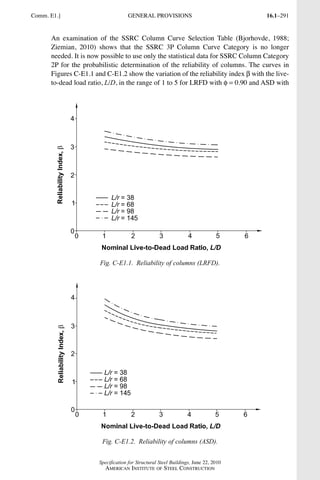

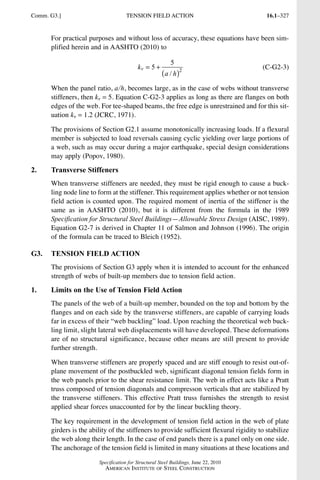

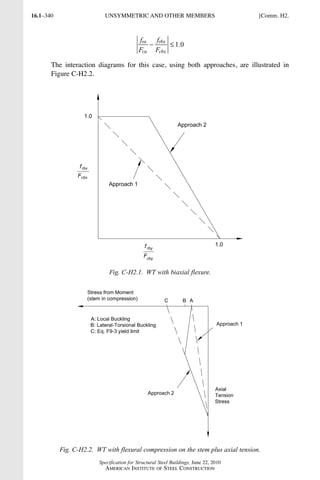

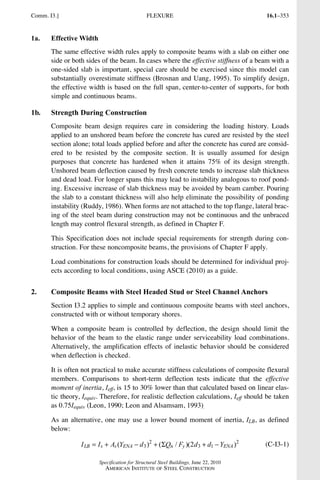

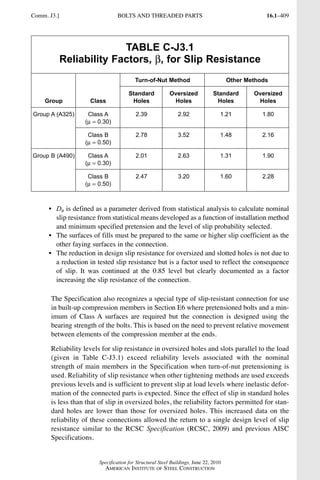

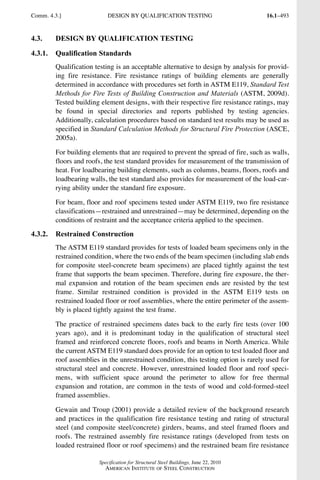

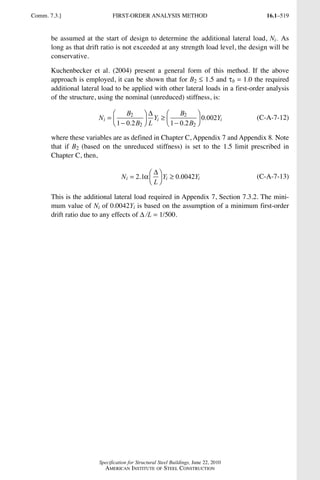

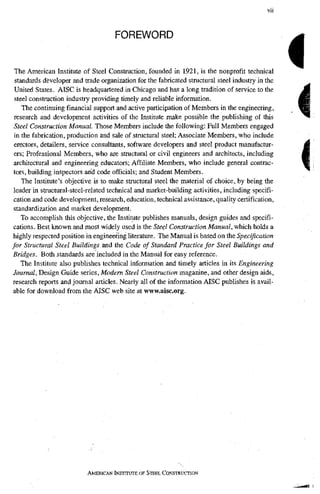

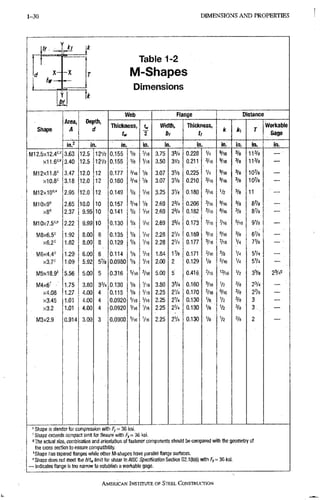

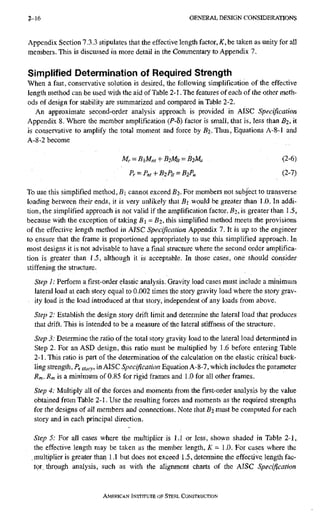

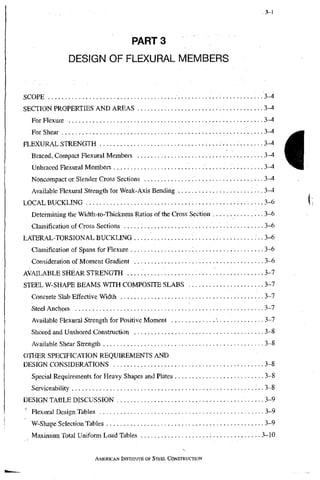

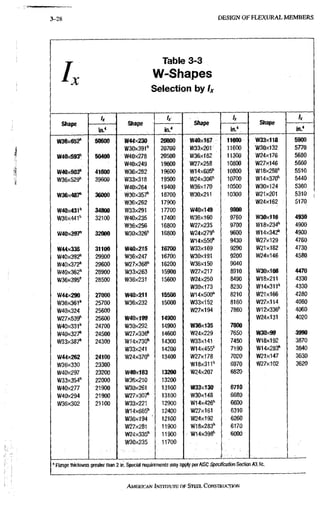

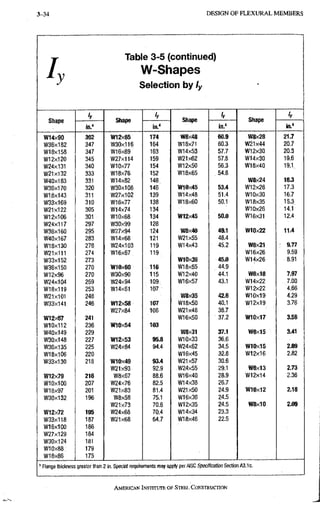

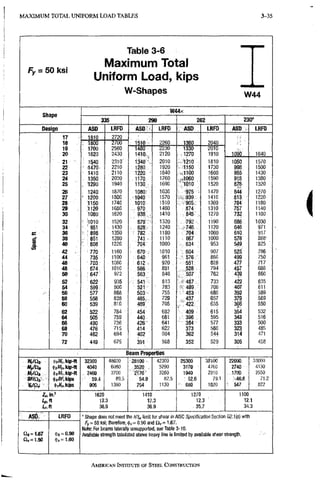

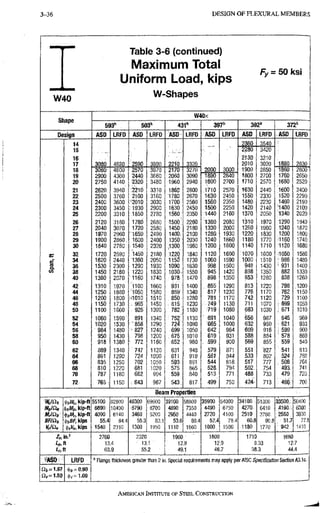

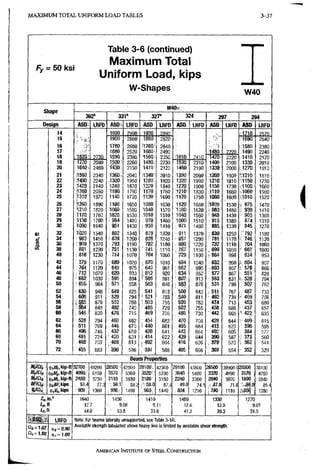

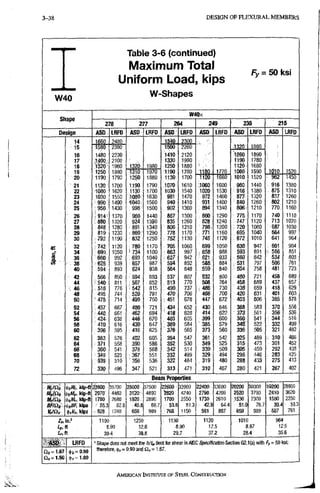

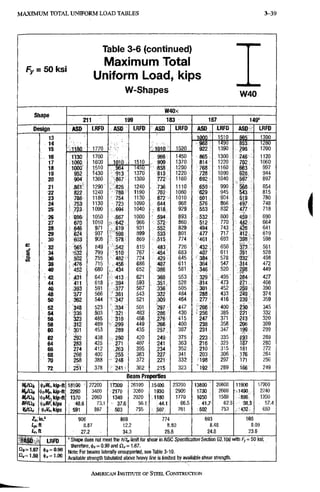

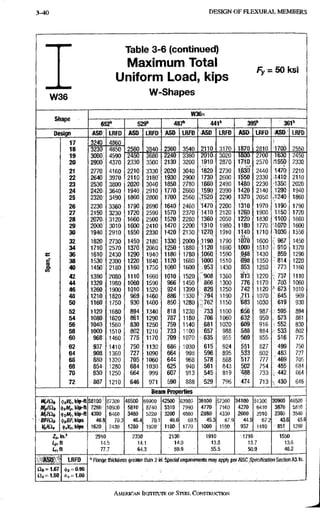

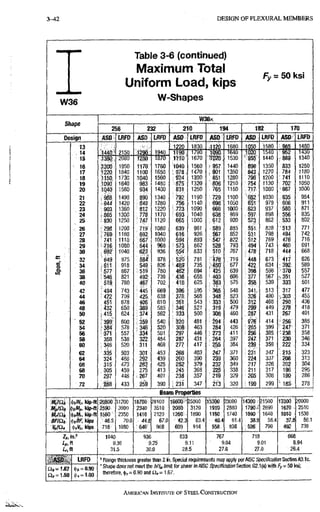

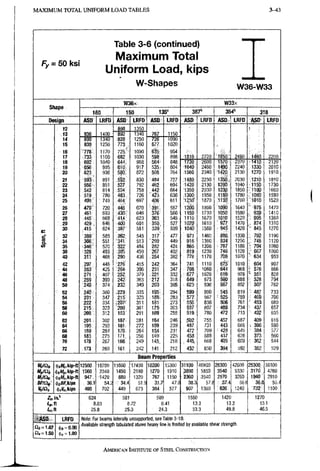

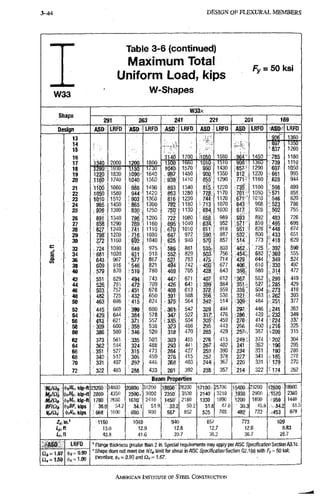

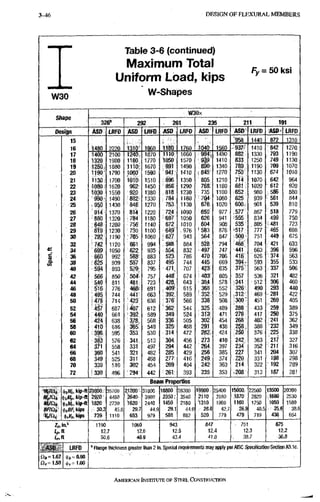

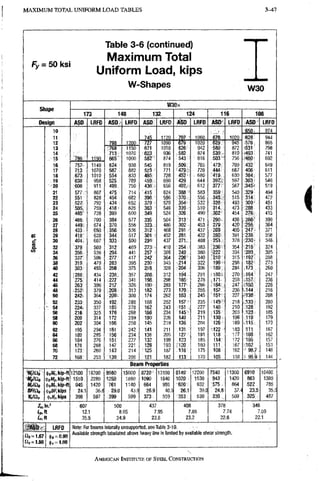

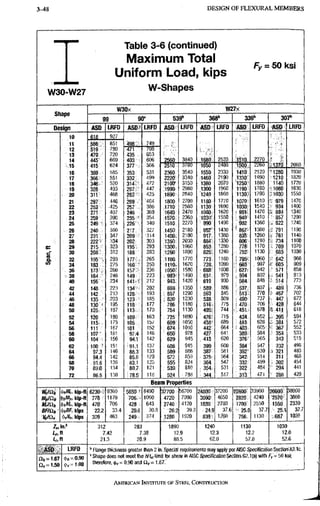

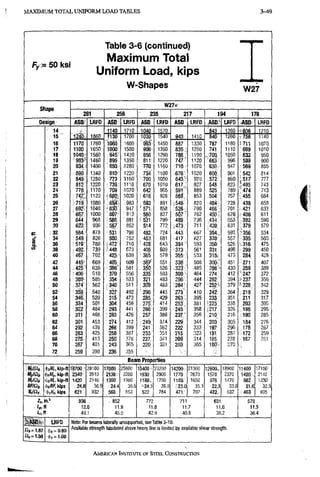

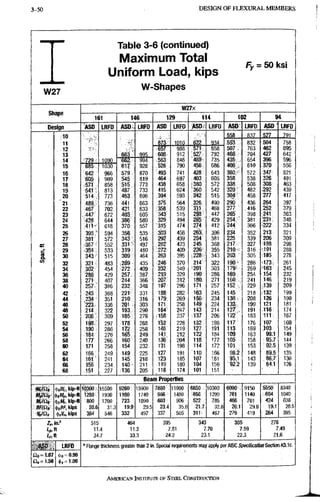

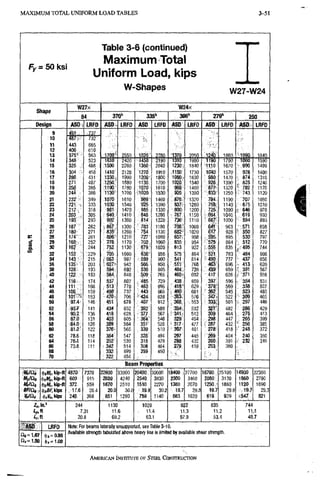

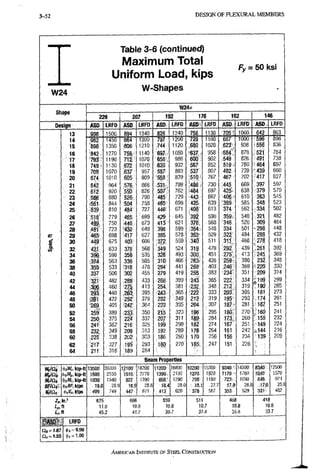

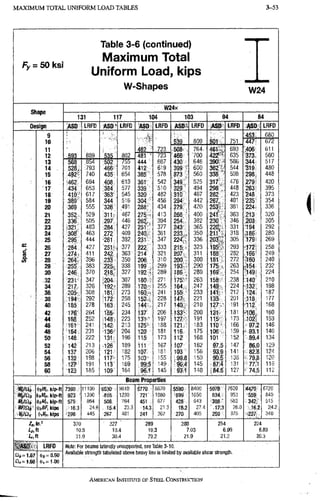

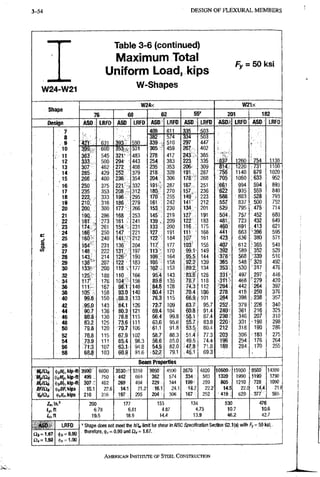

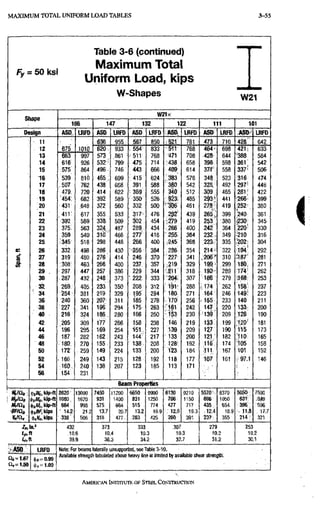

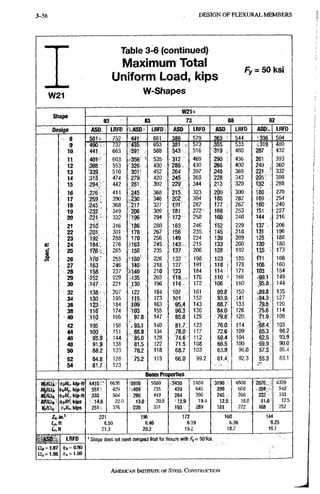

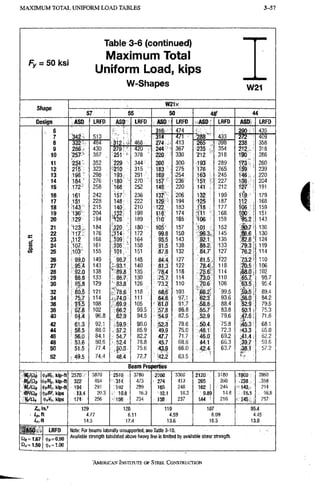

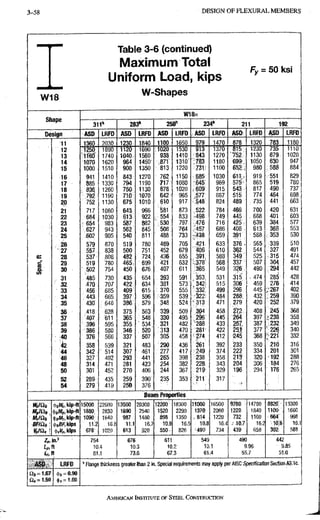

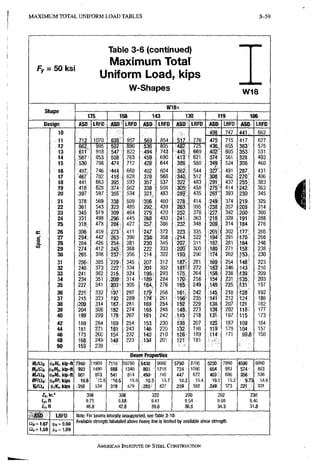

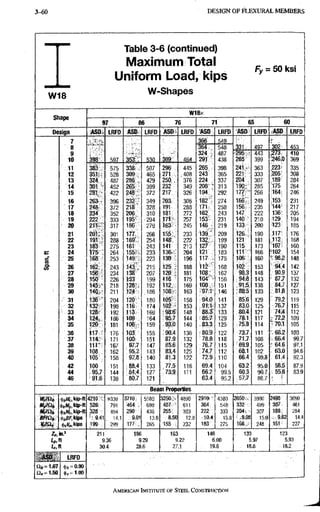

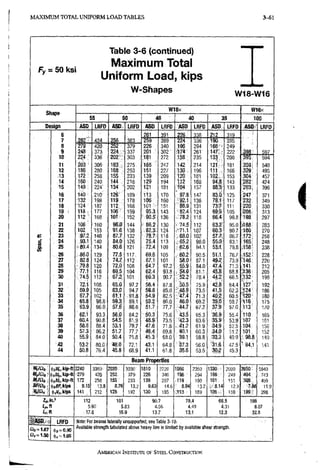

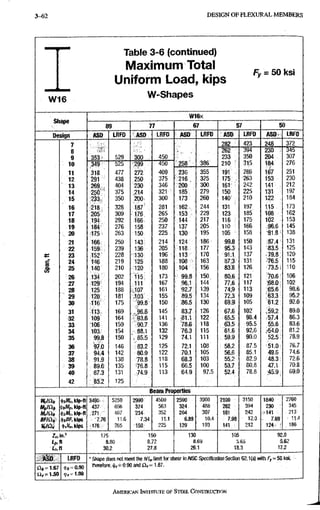

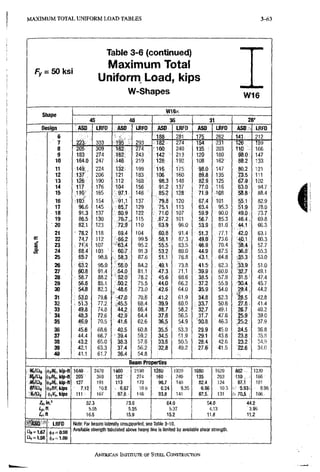

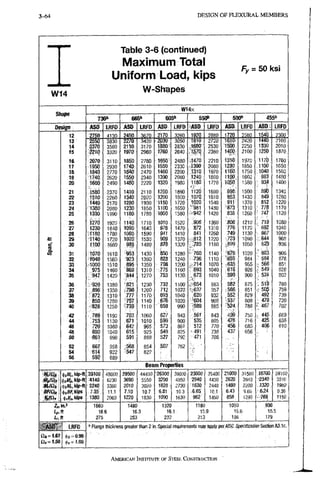

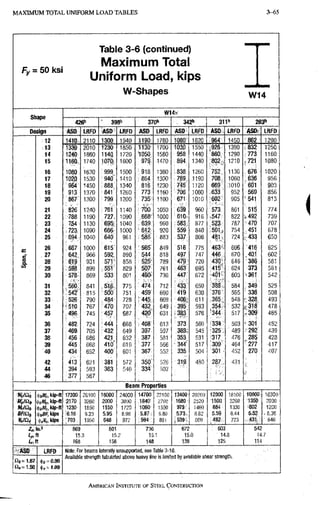

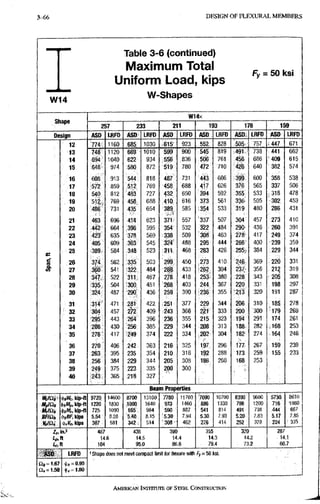

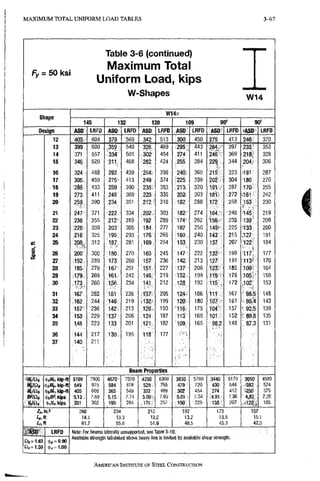

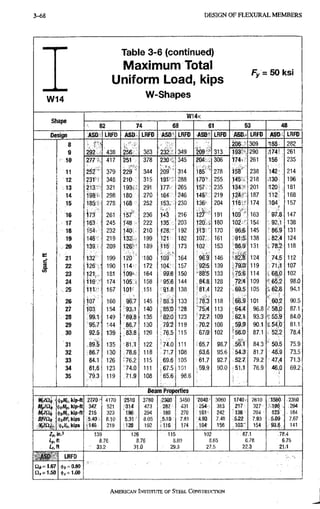

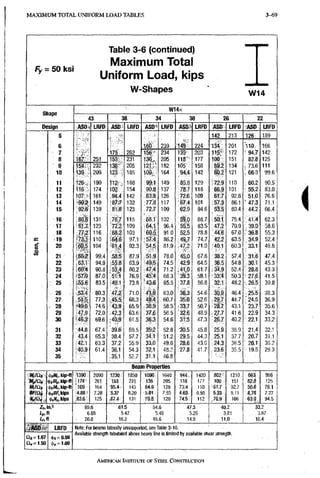

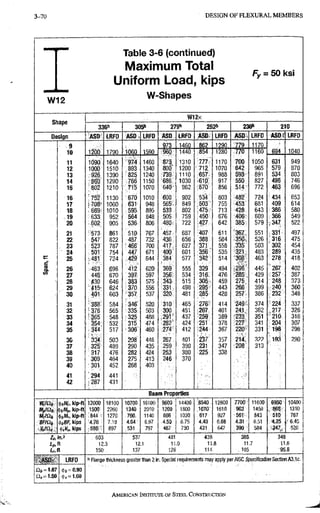

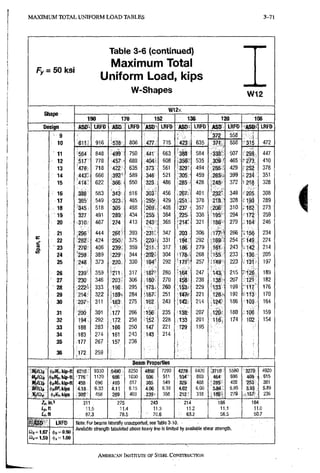

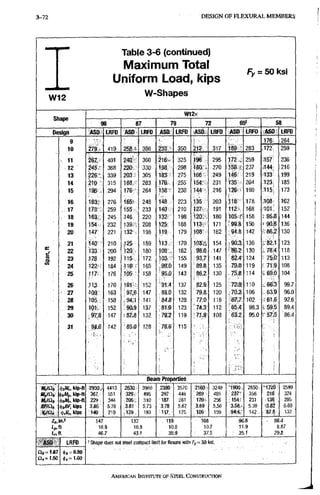

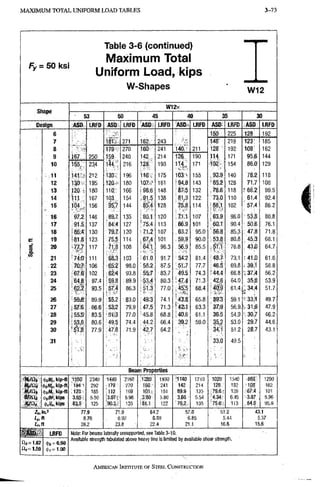

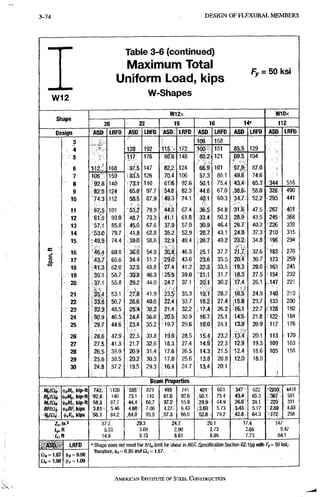

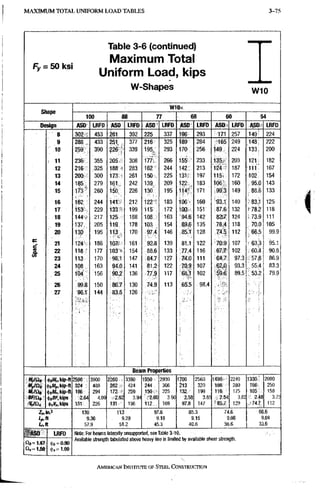

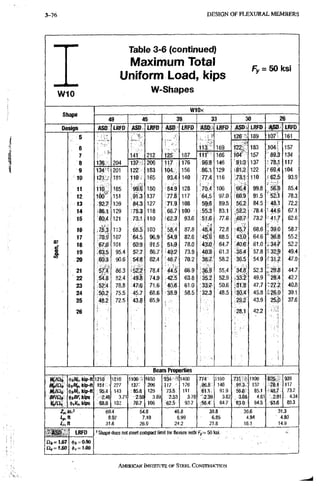

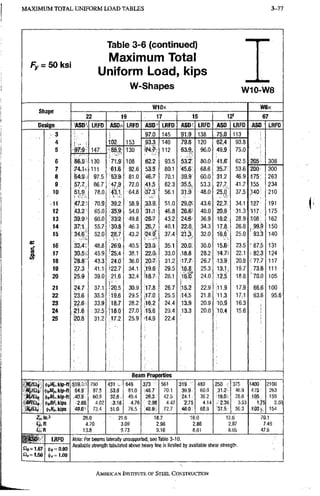

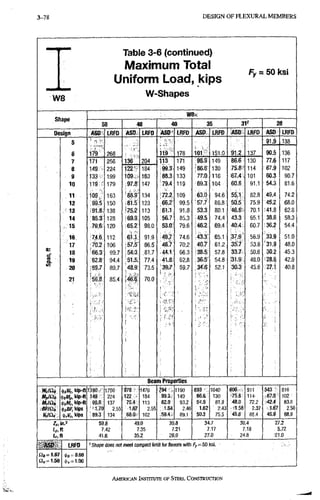

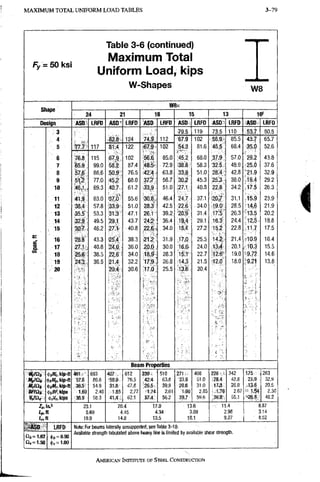

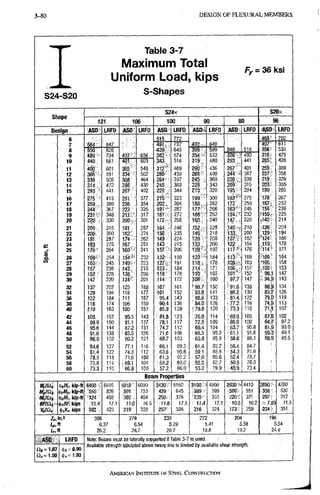

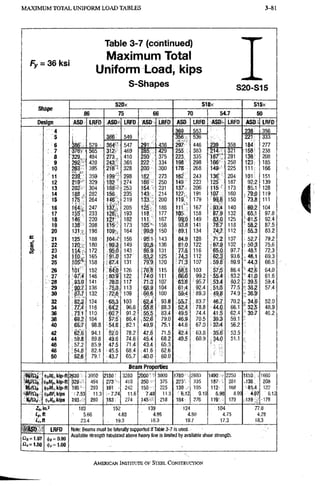

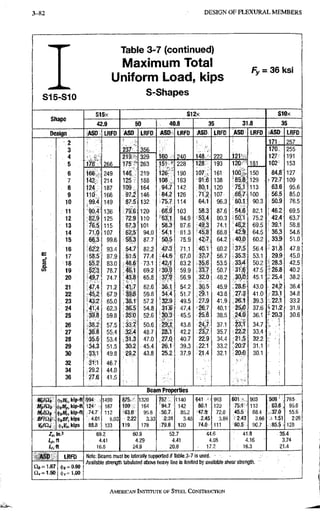

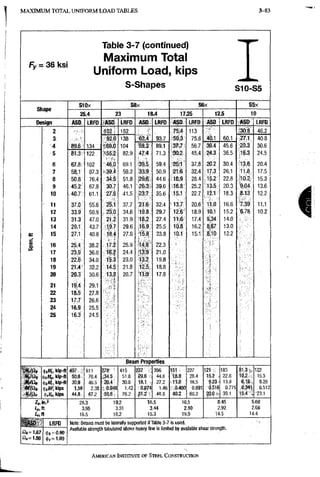

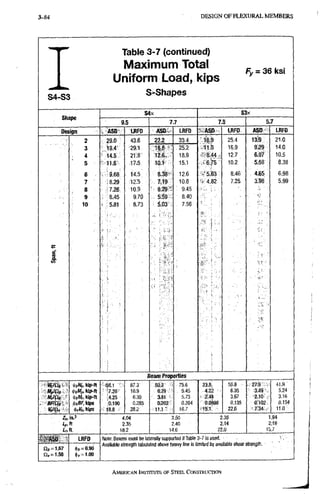

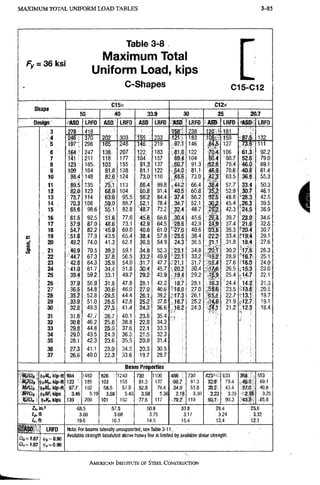

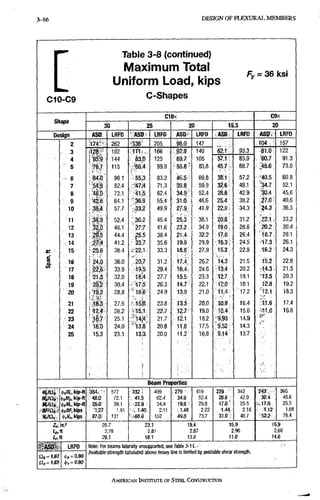

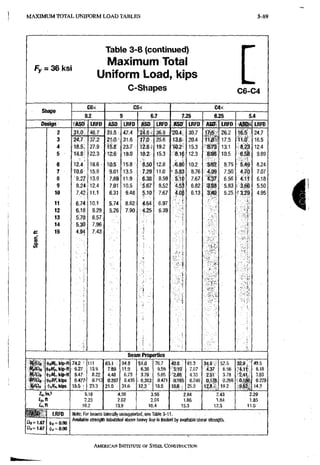

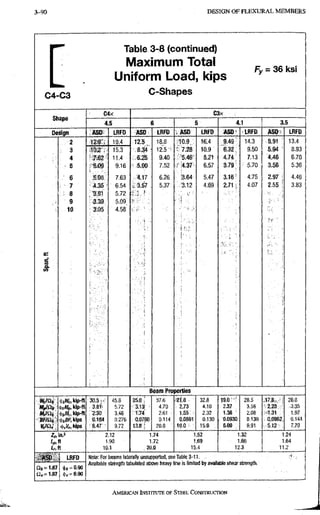

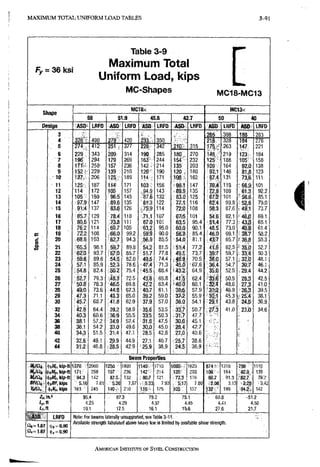

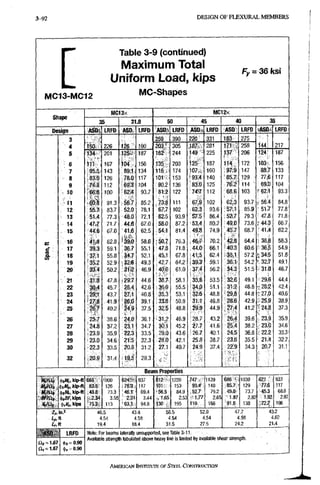

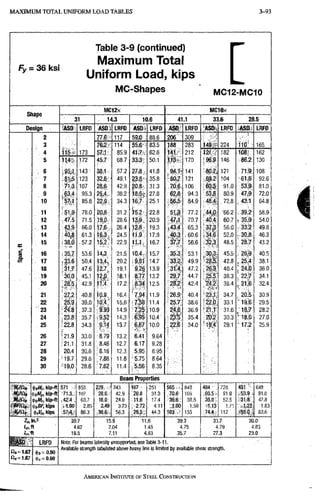

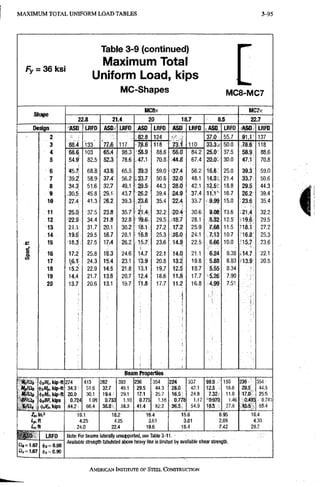

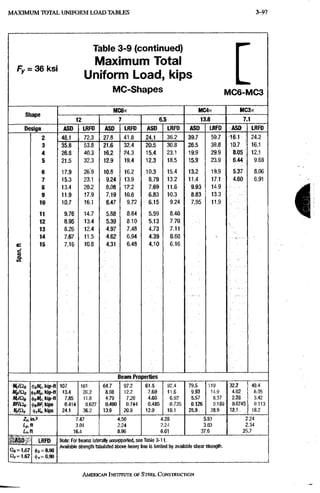

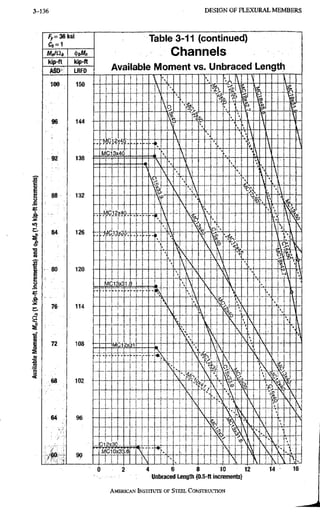

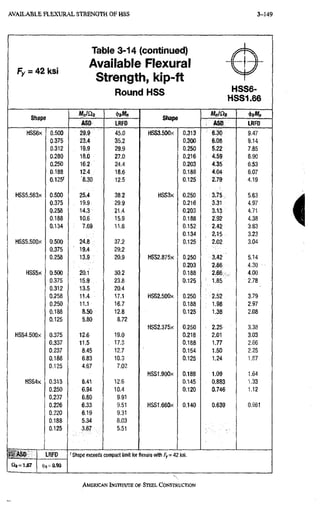

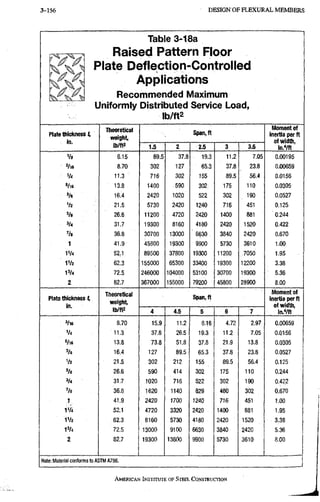

Maximum Total Uniform Load Tables

Table 3-6. W-Shapes~Maximum Total Uniform Load

Maximum total uniform loads on braced (Lt, < Lp) simple-span beams bent about the strong

axis are given for W-shapes with Fy = 50 ksi (ASTM A992). The uniform load constant,

^bWc or Wc/Qfc (kip-ft), divided by the span length, L (ft), provides the maximum total uni-

form load (kips) for a braced simple-span beam bent about the strong axis. This is based on

the available flexural strength as discussed for Table 3-2.

AMERICAN INSTITUTE OF STIEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-198-320.jpg?cb=1684244800)

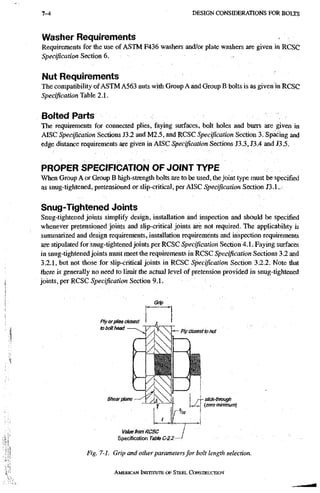

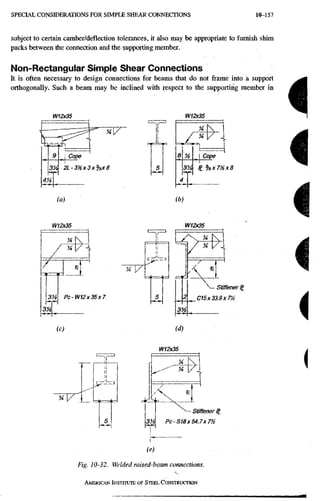

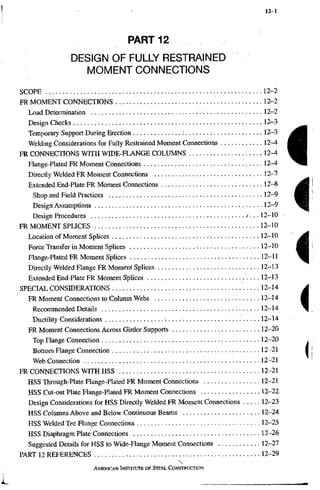

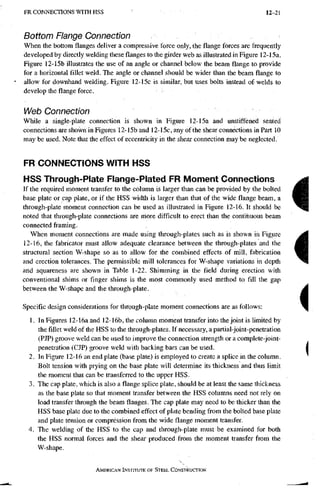

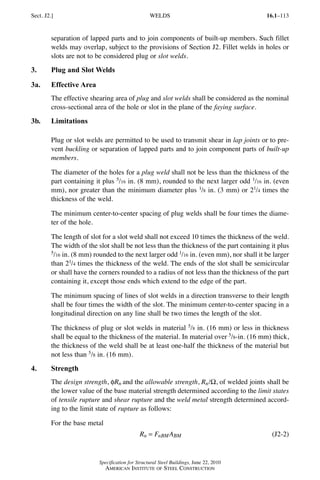

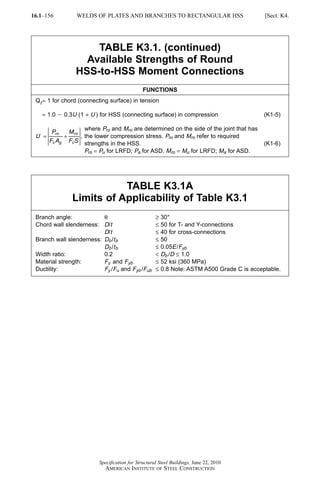

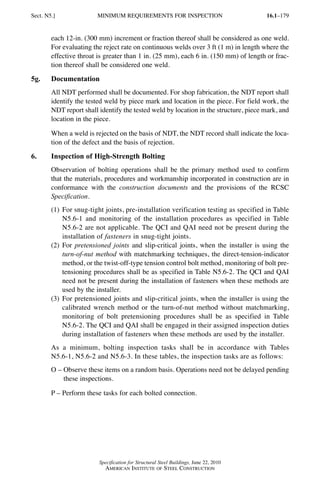

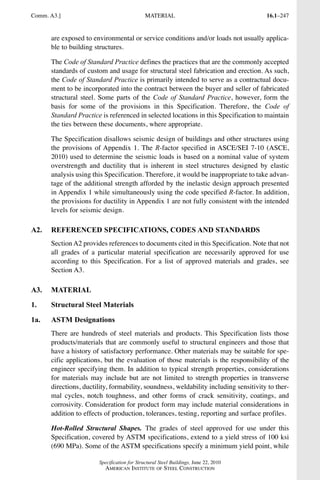

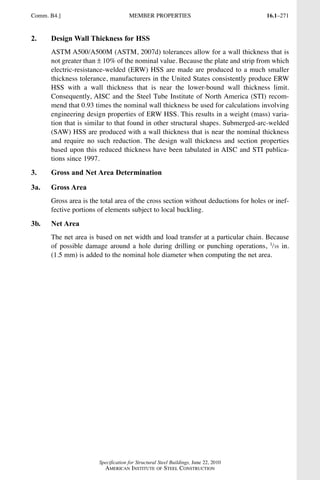

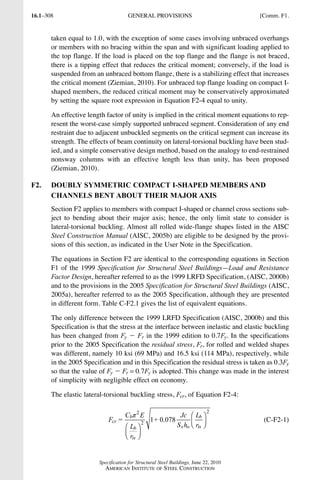

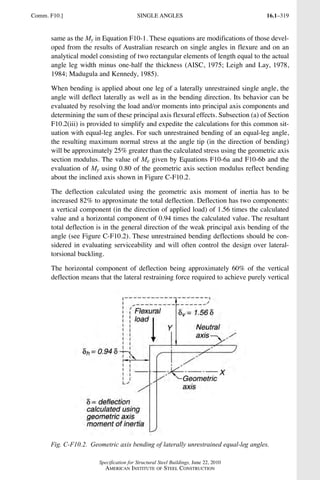

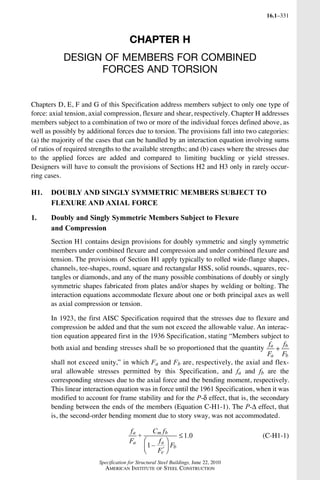

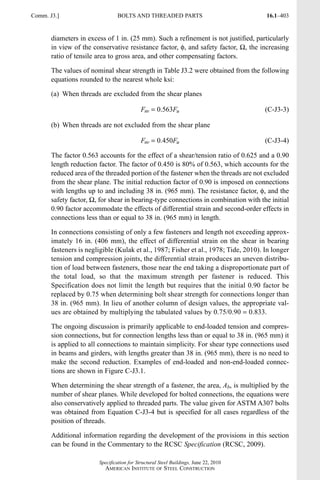

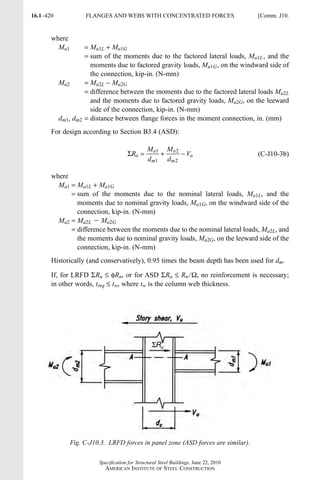

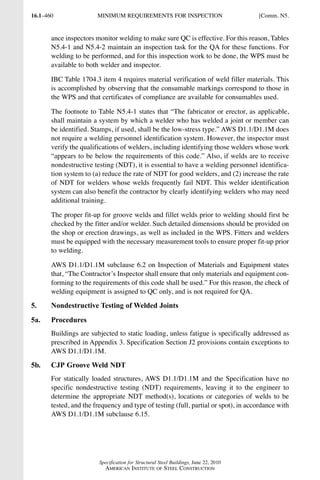

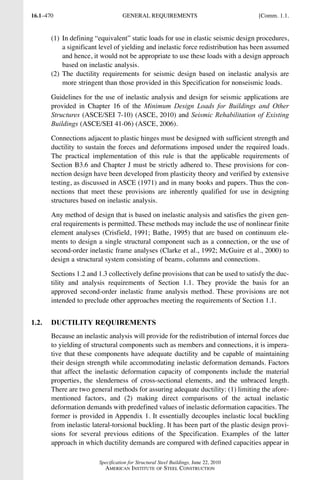

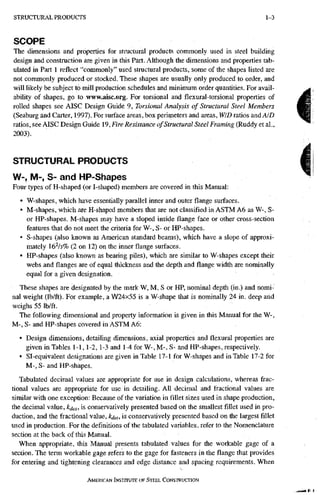

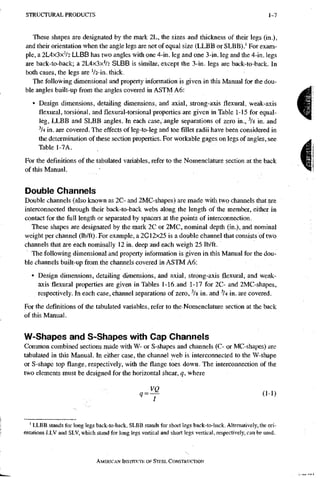

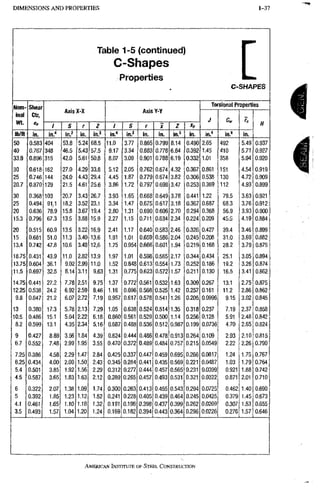

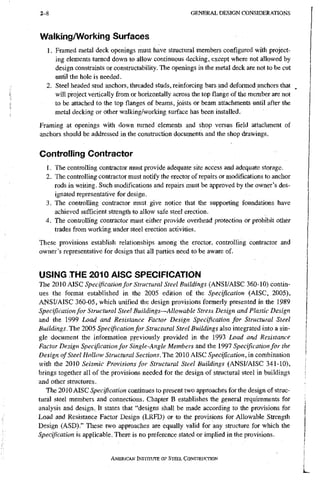

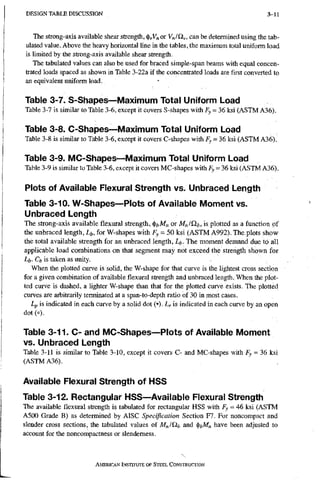

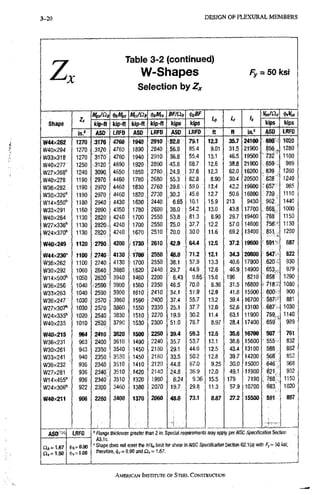

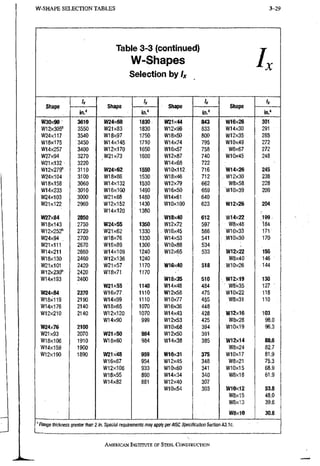

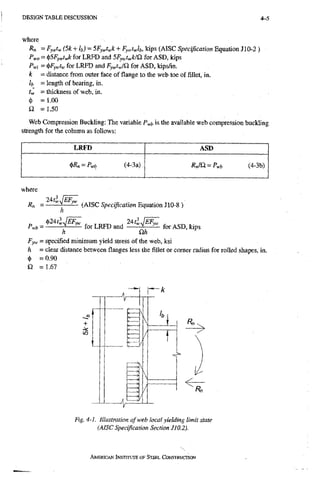

![3-18 D E S I G N O F F L E X U R A L M E M B E R S

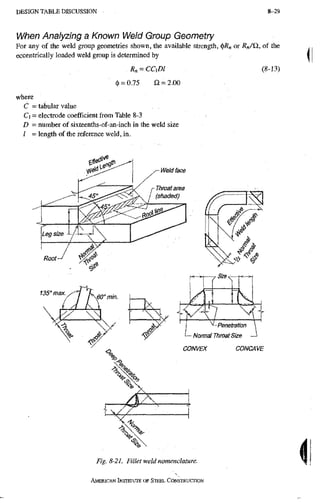

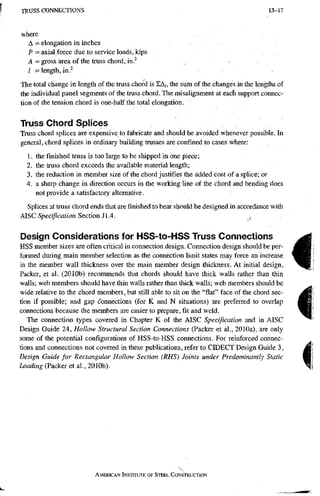

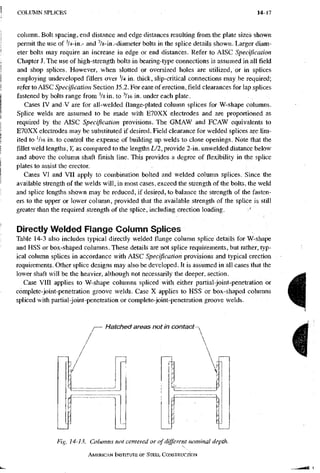

Table 3-1

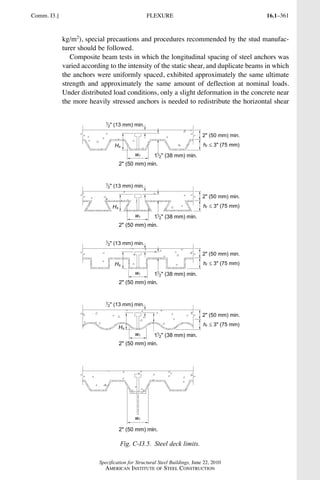

Values of Cb for Simply Supported Beams

Load

Lateral Bracing

Along Span

None

Load at midpoint

At load point

1.32

1.67 1.67

P |P None

Loads at third points

At load points

L o a d s s y m m e t r i c a t l y p l a c e d P .67 1.00 1.67

P P jP

m

None

Loads at quarter points

At load points

Loads at quarter points

1

1.14

1

] r i . 6 7 ^ 1 . l j ' l . 1 1 ^ 1 . 6 7 |

None

At midpoint

At third points

At quarter

points

At fifth points

1.30 1.30

rxn

1.4S 1.01 1.45

1.62 1.06 1.06 1.52

1.66 1-12 1.00 1.12 1.56

Note; Lateral bracing must always be provided at points of support per AISC Specification Chapter F.

AMERICAN INSTITUTE OF STEEI. CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-206-320.jpg?cb=1684244800)

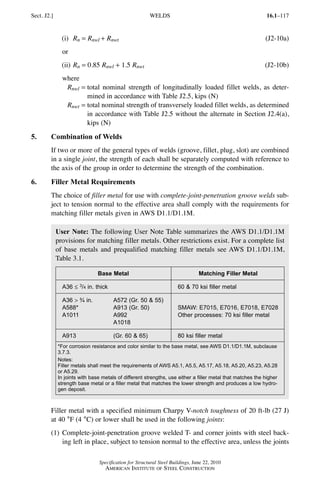

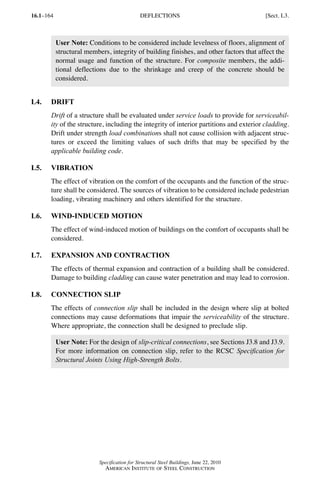

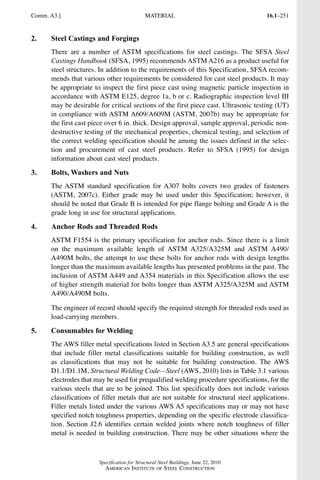

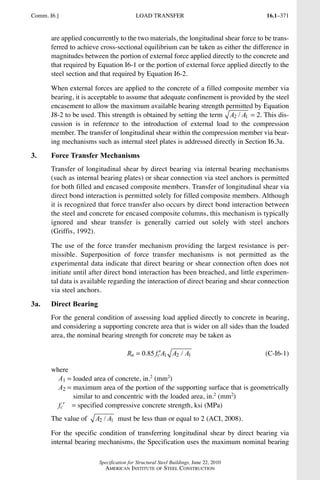

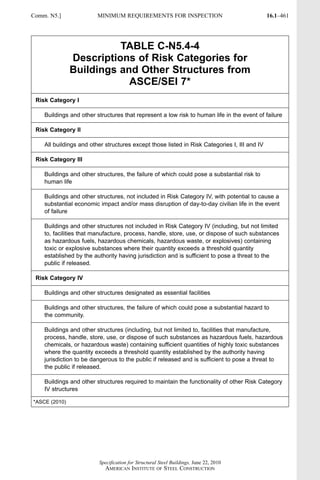

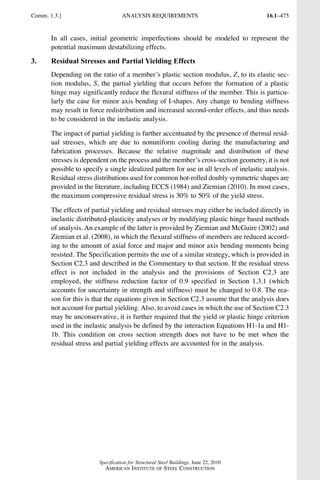

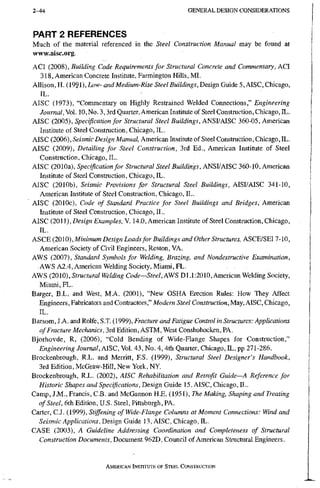

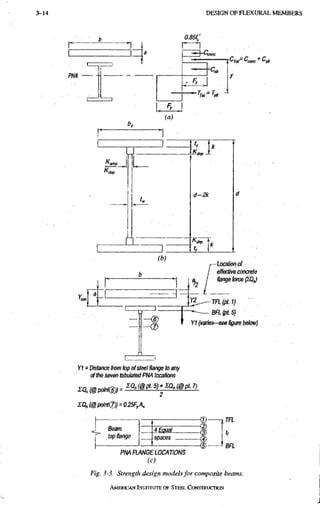

![M A X I M U M TOTAL U N I F O R M L O A D TABLES 3-41

F y = 50 ksi

Table 3-6 (continued)

Maximum Total

Uniform Load, kips

W-Shapes W36

W36x

siidfje

330 302 282 262 247 231

Design ASD LRFD ASD LRFD ASD LRFD ASD LRFD ASD LRFD ASD LI^FD

17

1410.

1240 isfin 1170 I7fi0 1110 IBfiO

18 540, p.sin 1410. ?1?n 1970 1220 1830 1140; 1720 .1070 1610

19 480 2230 1340' 2020 1.250^ 1880 1160 1740 l i a o : 1630 1010 1520

20 1410 2120 1280 1920 1190: 1790 1100 1650 1030; 1550 i 961 1440

21 l340 2010 1220 1830 Ma 1700 1050. 1570 979' 1470 915 1380

22 1280 1920 1160 1750 1080 1620 998 1500 934 1400 874 1310

23 1220 1840 1110 1670 1030 1550 955 1430 894 1340 836 1260

24 1170 1760 1060 ,1600 :990 1490 915 1380 857 1290 801 1200

25 iisti 1690 1020 1540 : 950 1430 878, 1320 822 1240 • 769 1160

28 1080 1630 983 1480 914 1370 844 1270 791 1190 739 1110

27 1040 1570 ; 946 1420 880 1320 813 1220 761 1140 712 1070

28 10T0 1510 912 1370 : 848 1280 i 784 1180 7'34 1100 686 1030

29 970 1460 '881: 1320 1 819 1230 757 1140 : 709 1070 663 996

30 938 1410 852 1280 792 1190 732 1100 685 1030 . 641 963

32 879' 1320 798 1200 ,742 1120 686 1030 642 966 601 903

34 828 1240 751 1130 '699 1050 646 971 ^ 60?. 909 565 850

36 ! 782 1180

w 1070 860 992 : 610 917 571 858 534 803

c" 38 741 1110 6

7

2 1010 625 939 578 868 541 813 : 506 760

CL

00 40 7p4 1060 639 960 594 893 S49 825 514 773 481 722

42 6^70 1010 608 914 566 850 523 786 489 736 • 458 688

44 6ifO 961 581 873 i 5^0 811 499 750 467 702 437 657

46 612 920 555 835 , 516 776 477 717 447 672 418 628

48 586 881 >532 800 495 744 457 688 4.28 644 40P 602

K 50 563 846 511 768 475 : 714 43^ 660 i4t1 618 384 578

52 5.41 813 491 738 457 687 4'22 635 '395 594 . 370 556

54 52:1 783 473 711 440 661 407 611 381 572 - 356 535

56 5b3 755 456 686 4^4 638 : 392 589 367 552 343 516

58 485 729 440 662 •410 616 379 569 '354 533 331 498

60 469 705 426 640 ; 396 595 366 550 343 515 320 482

62 454 682 4f2 619 i S83 576 ' 354 532 332 498 31D 456

64 440 661 399 600 i 371 558 343 5 1 6 321 483 300 451

66 426 641 387 582 360 5 4 1 333 5 0 0 ; 311 468 291 4 3 8

68 414 622 376 5 6 5 : 349 525 323 485 302 4 5 4 283 425

70 402 604 ;365 549 : ?39 510 314 471 294 4 4 1 , 275 4 1 3

72 391 588 355 533 330 496 305 458 286 4 2 9 r 267 4 0 1

Beam Properties

<|>s(%,kip-ft 28100 4 2 3 0 0 25500 , 3 8 4 0 0 23800 3 5 7 0 0 22000 3 3 0 0 0 2b6oa. 3 0 9 0 0 19200 2 8 9 0 0

3520 5 2 9 0 3190 4 8 0 0 2970 4 4 6 0 2740 4130 257,0: 386C 2400 3610

21.70 3 2 6 0 1970 , 2 9 7 0 1830. 2 7 6 0 17.00:). 2550 1590 240C 1490 2 2 4 0

'BF/Qb 42 2 63.4 40 5 60.S ! 39.6 59.0 38.1 57.9 ' 37.4 55 367 53.7

763 1150 705 1 0 6 0 i653t 9 8 5 620: 9 3 0 "587 881 555 8 3 2

1410 1280 1190 1100 1030 963

13.5 13.5 13.4 13.3 13.2 13.1

feft • 4 5 . 5 43.6 4 2 . 2 40.6 39.4 38.6

116=1.67

LRFD

(!>(, = 0.90

!]),= 1.00

NoterFor beams laterally unsupported, see Table 3-10.

Available strength.tabulated above heavy,line is limited by available shear strength.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-229-320.jpg?cb=1684244800)

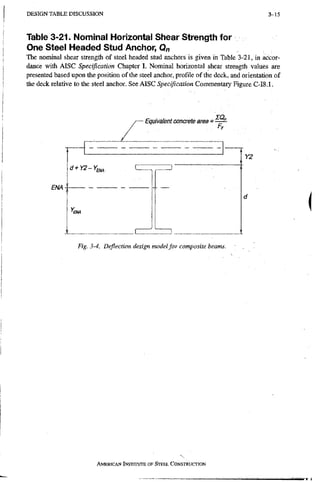

![M A X I M U M TOTAL U N I F O R M L O A D TABLES 3-45

Fy = 50 ksi

Table 3-6 (continued)

Maximum Total

Uniform Load, kips

W-Shapes W33-W30

W33x

oiidfjt;

152 141 130 118" 391" 357"

Design ASD LRFD ^SD LRFD ASO LRFD ASD LRFD ASD LRFD A$D> LRFD

12 B 1210 768 150 :i650 977 ; i

13 851 280 - f •TfSo- b W '637 , 958

14 iiOU 733 1100 ' 666.. 1000 592.: 889

15 744 1120 684 1030 621:; 934 ;552;' 830

16 697 1050 964 583t 876 :'5i8: 778 i M ' 2710 1630 2440

17 656 986 603 907 i548: 824 :487 :732 I M O , 2560 -1550 2330

18 i620 932 5570 857 5T8' 778 '460. 692 1610' 2420 1460 2200

19 ,587 883 540 812 491 737 436.:: 655 :i52ff. 2290 ^1390 2080

20 558 839 '513 771 466: 701 4:14: 623 :i45a:: 2180 £1320 1980

21 531 799 489 734 4*44 667 394i 593 13®" 2070 '1250 1890

22 507 762 '4136 701 :424 637 377' 566 '1320' ,1980 Si 200 1800

23 485 729 446 670 :40S. 609 3'60: 541 1260 1890 ':nso 1720

24 465 699 427 643 :388 584 345 519 1210 1810 1100 1650

25 446, 671 41D 617 ;373-. 560 '333^ 498 ;ii6o: 1740 SI 050 1580

26 1429. 645 395 593 35ff 539 319' 479 1140. 1670 ^idio 1520

27 '413 621 380 571 34j5-i 519 :307:. ,461 :1070 1610 , 976 1470

28 ,398 > 599 366 551 i333' 500 :296: 445 ,1030 1550 " 94i 1410

29 385- 578 354 . 532 : 3 a : 483 286: 429 9 ® 1500 . 909 ,1370

30 '372'- 559 i3.i2 514 -i3#' 467 276: 415 •

1450 ft 878 1320

G 32 349: 524 321 482 438 259, 389 9 ® 1360 : 823 1240

a 34 328 493 302 454 ;274 412 244 366 8^1; 1280 :: 776 1160

W : 36 310 466 2i35 428 :259, 389 ,230 346 ..80f 1210 732 •1100

38 294 441 t 70' 406 245 369 328 ,m 1140. 693 1040

40 2/9 419 ;256 386 ' 233. 350 ':20:7.: :311 ; 724 1090 65? 990

42 266 399 244 367 334 197 296 ' te 1040 ^ 627 943

44 254 381 233 350 121-2-' 318 :1«8: 283 658 989 ? 599 900

46 !243;. 365 223" 335 i203; 305 180 271 ,629 946 1 573 861

48 232 349 214 321 194 292 173- 259 ^ 603. , 906 : 549 825

50 223 335 '205, 308 186. 280 166: 249 5 1 , 870 : , 527 792

52 215 323 197 297 1;7i9 269 ' 159 239 557 837 507 762

54 207 311 190 286 173' 259 153 231 . ' 806 488 733

56 ;i9S; 299 183: 275 ;166 250 M48; 222 im 777 ; 470 707

58 192 289 ;177 266 i 16T 242 i143 215 : 499 750 454 633

60 '186 280 171 257 1B5 234 138 208 482 725 ' 439 660

62 180 270 165: 249 1.50 226 h34 201 : 4 S 702 425 639

64 174 262 160 241 :r46. 219 129. 195 452 680 412 619

66 i169' 254 155 234 I4i- 212 126 189 439 659 399 600

68 164 247 151 227 f37 206 122 183 426 640 : 387 582

70 159 240 147 220 1.33- 200 , r i 8 „ 178 413 621 376 566

72 155 233 142 214 129' 195 'lis:; 173 • 402 604 366 550

Beam Properties

^blUfc, kip-tf lit 200? 16800 103B0:-f 15400 9320 14000 5280 12500 28900:' 43500 26300 39600

Wpiat ^1,11/lp, kip-ft 1390 2100 1280:- 1930 1170 1750 1040 1560 3620: 5440 3290 4950

Kiai, •iMr.kip-ft 851 : 1280 782 1180 709 i 1070 627 942 2180 3280 1990 2990

BF/Qi,.(ftSf, kips W 31.7 48.3 30.3 45.7 •29.3 43.1 27.2 40,6 : 31.4 47.2 31.3 47.2

425 638 ; 403: 604 1384 ! 576 325 489 903 1350 813 1220

^t, in.' 559 514 467 415 1450 1320

• 8.72 8.58 . 8.44 8.19 13.0 12.9

ir,ft 25.7 25.0 24.2 ; 23.4 58.8 54.4

ASD LRFD Note: For beams laterally unsupported, see Table 3-10.

(])/,= 0.90

Available strength tabulated above heavy line is limited by available shear strength.

1,50 ^>,= 1.00

mox

(

AMERICAN INSTITUTE OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-233-320.jpg?cb=1684244800)

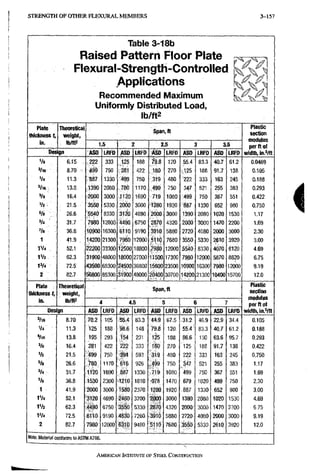

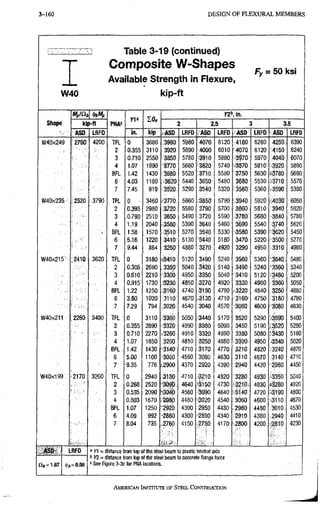

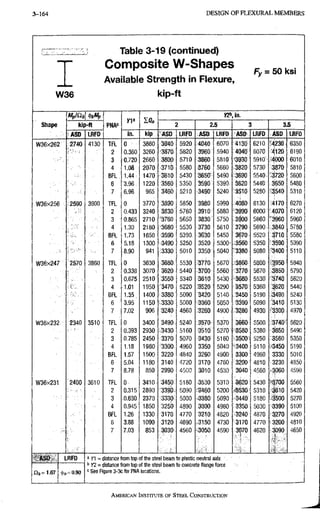

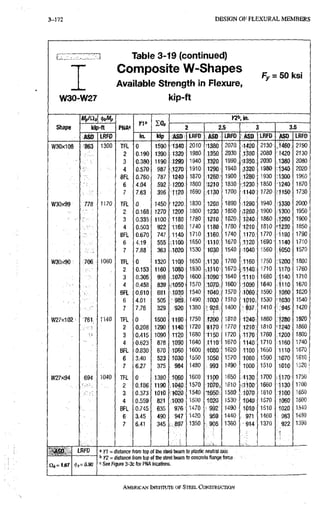

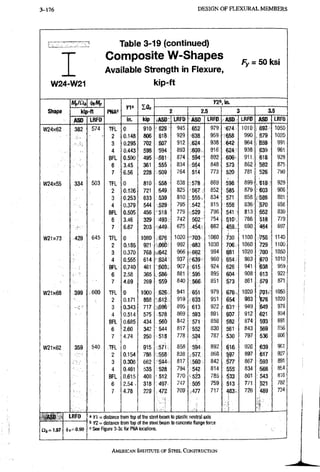

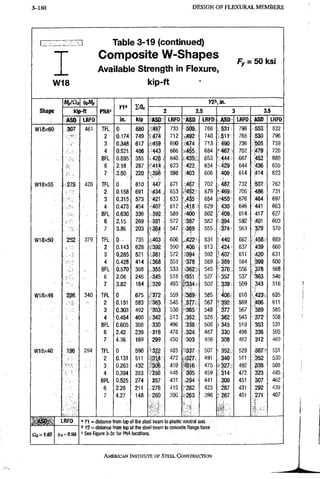

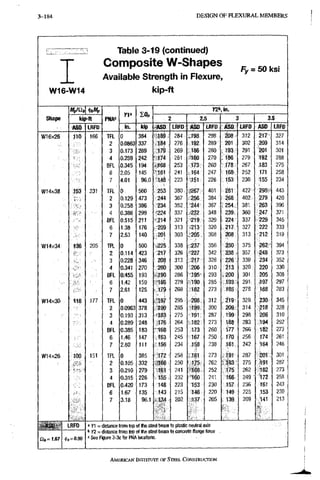

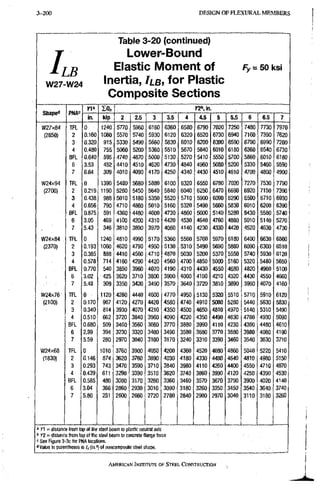

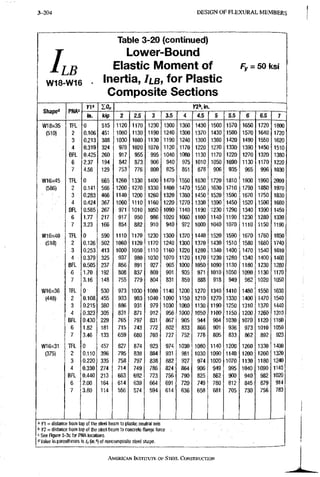

![C O M P O S I T E B E A M S E L E C T I O N T A B L E S 3-159

f>-50ksi

Table 3-19 (continued)

Composite W-Shapes

Available Strength in Flexure,

kip-ft W40

3 ]

Shape

Shape 4 4.S S 5.5 6 6.5 7

Shape

ASD LRFD ASD LRFD ASD LRFD ASD LRFD ASO LRFD ASD LRFD iASD LRFD

W40X297 5210 7820 5310 7990 5420 8150 5530 8320 5640i 8480 5750 8640 5860 8810

5070 7620. 5160' 7760. •5250 7900. 5350 8040 5440 8180 5530; 8310 i5620 8450

4920 7390 5000 7510 5070 7620 5150 7740 5220; 7850 5300 7970 5380 8080

4760 7150 4620 7240 4880 7330 4940 7420 5000; 7510 5060 7600 •5120 7690

•4580 6880 4620 6950 •4670 7010 '•4710 7080 4750! 7140 4800 7210 4840 7280

4460 6 7 1 0 4500 6760 4530 6810 4570 6870 4600^ 6920 4640 6970 14670 7030

4290 6450 4320 6490 •4340 6530. -4370 6570 4400' 6610 4430 6650 14450 6690

W40X294 5200 7820 5310 7980 5420 8150 5530 8310 5630 8470 5740 8630: 5850- 6790

5080- 7640 5i:80 7780 5270 7920 5360 8060 5450 8200 5550 8340 •5640 8480

4950 7430 .5020 7550 5100 7670 5180 7790 5260 7910 5340 8020 5420 8140

4800 7210: 4860 7300 4920 7400. 4990 7500 5050i 7590 5120 7690 5180 7790

4630- 6960 4680 7030 4730 7110 4780 7180 4830; 7260 4880 7330 .'4930 7410

4460 6700 4490 6760 4530 6810 4570 6870 4610i 6930 4650 6990 4690 7040

4190 6290 4210 6330 4240 6370 4270 6410 4290 6450 4320 6500 4350 6540

W40X278 4950 7440 5050 7590 5150 7750 5260 7900 5360; 8060 5460 8210 5560 8360

•4830- 7270 4920 7400 •5010 7530, •5100 7670 :5190 7800 5280 7940 5370 8070

4710 7080 •4780 7190 4860 7300- 4930 7420 5010 7530 5090 7640 5160 7760

4570 6870 4630 6960 4690 7050 4750 7150 '4820: 7240 4880 7330 4940 7430

4420 6640 4470 6710 4510 6780 4560 6860 461.0; 6930 4660 7000 4710 7080

4250 6380 4280 6440 4320 6490 4360 6550 4390; 6600 4430 6660 ,4470 6720

3970 5970 4()00 6010 4030 6050 4050 6090 4080: 6130 4100 6170 4130 6200

W40x277 4850 7290 51950 7440 5050 7590 5150 7750 5260' 7900 5360 8050 5460, 8210

.4720 7090 4810 7220 4890 7350 4980 7480 :;5060; 7610 5150 7740 5240 7870

-4580 6880 •4650 6980 4720 7090 '4790 7200 •4660 7300 4930 7410 :5000 7510

^4420 6640 4480 6730 4530 6810 .4590 6890 4640; 6970 4700 7060 4750 7140

4250 6390 4290 6450 4330 6510 4370 6570 4410: 6630 4450 6690 4490 6750

4160 6250 4190 6300 4220 6350 4260 6400 4290 6450 4320 6500 J4350 6540

4020 6040 4050 6080 4070 6120 4100 6160 4120 6200 4150 6230 4170 6270

W40X264 4630 6970 4730 7110 -4830 7260. 4920 7400 5020 7550 5120 7690 5210 7840

;4530- 6800 4610 6930 ,4690 7060 54780 7180 ?4860; 7310 4950 7430 5030 7560

4410 6620 4480 6730 4550 6840 4620 6940 '4690 7050 4760 7160 4830 7260

4280 6430 4330 6520 4390 6600 4450 6690 4510 6780 4570 6860 4630 6950

4130 6210 4180 6280 4230 6350 4270 6420 4320 6490 4360 6550 4410 6620

3980' 5980 4010 6030 4050 6080 4080 6140 4120 6190 4150 6240 4190 6290

3730 5610 3760 5640 3780 5680 •3800 5720 383Di 5750 3850 5790 iSSBO 5830

ASD

aj=i.67

LRFD

(l>t=0.90

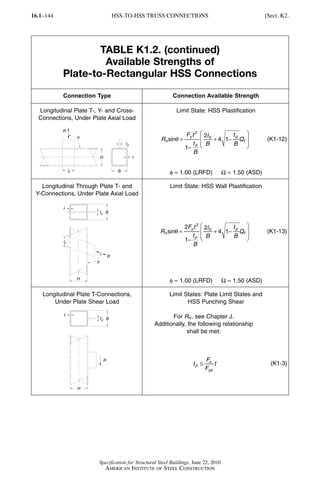

= K1 = distance from top of the steel beam to plastic neutral axis

fc Y2 ~ distance from top of the Steel beam to concrete flange force

See Rgure 3-3c for PNA locations.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-347-320.jpg?cb=1684244800)

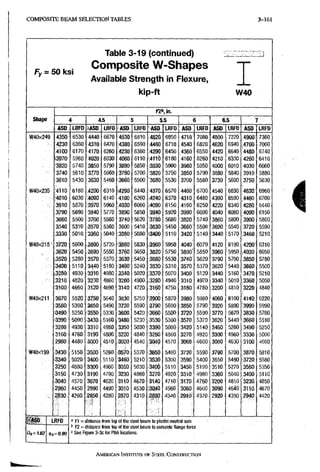

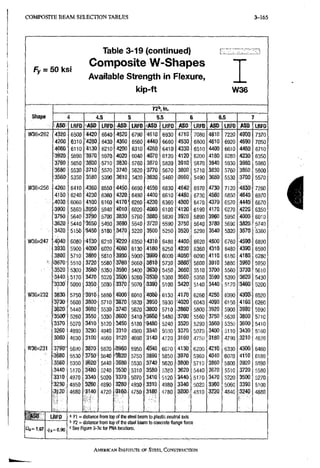

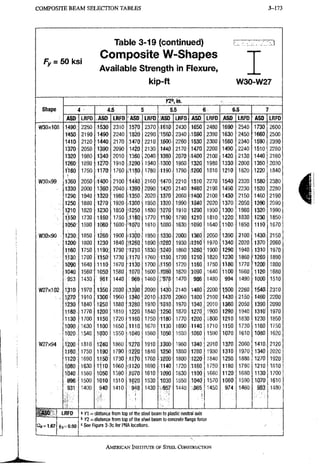

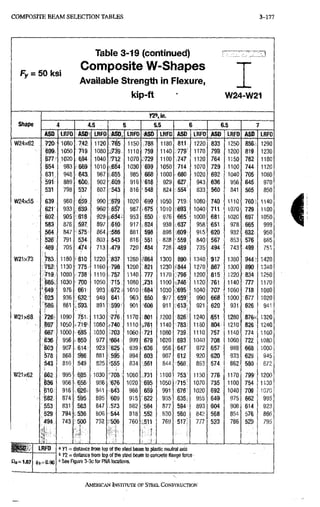

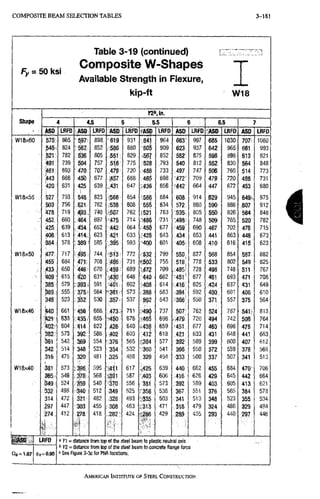

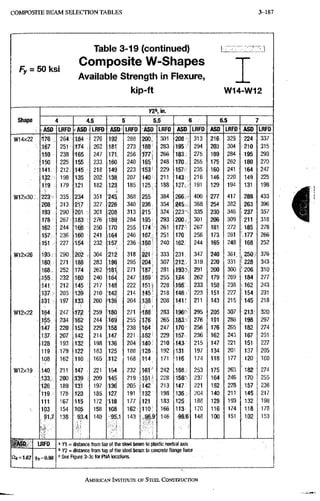

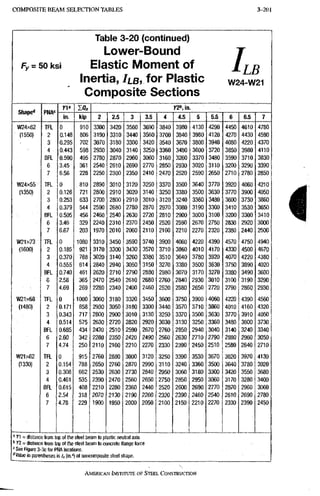

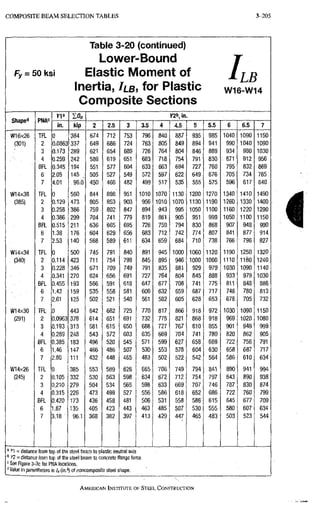

![COMPOSITE B E A M SELECTION TABLES 3-185

Fy = 50 ksi

Table 3-19 (continued)

Composite W-Shapes

Available Strength in Flexure,

kip-ft

E I Z

W16-W14

Shape

Shape 4 4.5 5 5.5 6 6.5 7

Shape

ASD LRFD ASD LRFD ASD LRFD ASD LRFD ASD LRFD lASD LRFD ASD LRFD

W16x26 227, 341. 237 356 -246 370 256 384 265 399 .275 413 285 428

218 327 226 340 234 352 243 365 im' 377 259 390 268 403

208 312 215 323 222 334 ,-229 345 •m] 356 244 366 251 377

198 297 •204 306 210 315 216 324 ;222 333 228 343 234 352

188 282 192 289 197 296 202 304 k207; 311 212 318 217 326

175 263 179 268 182 274 186 279 189 285 193 290 197 296

158 237 160 241 •163 244 165 248 .31671 252 170 255 172 259

W14x38 309 464 -323 485 •337 506 351 527 365! 548 379 569 393.- 590

291 438 303 455 315 473 327 491 338 508 350 526 362 : 544

' 273 410 283. 425 >2£(2 439 302 454 :m 468 321 482 331 497

254 382 . 262 393 269 404 276 416 284 427 291 438 299 449

235 353 •240 361 245 369 -250 376 .>•256' 384 261 392 266 400

226 340 230 346 235 353 239 360 366 248 373 252 379

215 324 219 329 2212 334 . 226 340 229' 345 233 350 236 355

W14x34 '274 413 .287 431 <2£I9 450 312 469 324! 488 337 506 349 525

259' 389 -269 405 r280 421 291 437 sSOji 453 312 468 322 484

243 365 252 378 '260 391 269 404^ •<277; 417 286 430 295 443

227 340 •233 351 ;24'0 361 247 371 " 381 260 391 267 401

210 315 214 322 219 330 .224 337 •829! 344 234 351 239 359

201 303. 205 309 209 315 213 321 2.17 327 221 333 225 338

191 287 194 292 ',197 297 201 301 •204; 306 207 311 210 316

W14x30 241 362 •252 378 -263. 395 274 412 285; 428 296 445 307 461

-•228 342 237 356 .•246 370 256 385 265 399 275 413 284 427

214 322 •222 334 ..230 345 288 357 245 369 253 381 261 392

201 301 207 311 ^213 320 219 329 225 339 231 348 238 357

186 280 191 287 Id6 294 200 301 ;.208: 308 209 315 214 321

178 267 181 273 185 278 189 284 192 289 196 295 200 300

167 250 169 255 172 259 •175 263 178 267 180 271 183 275

W14x26 ?10 316 220 330 529 345 ,239 359 248 i 373 258 388 268; 402

199 300 208 312 •216 325 -224 337 .i2S3i 349 241 362 249 374

.188 283 ,195 294 '202 304 209 315 216 325 223 336 230 346

177 266 . -183 275 188 283 194 292 JOO^ 300 205 309 211 317

166 249 170 256 174 262 179 269 183 275 187 282 192 288

. 156 235 160 240 •163 245 166 250 170 255 173 260 176 265

144

_ s

216 146 220 ,'149 223 151 227 231 156 234 158 238

LRFD

(|)s=a9o

3 Y^ = distance from top of the steel beam to plastic neutral axis

!> Y2 = distance from top of the steel beam to concrete flange force

See Figure 3-3c for PNA locations.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-373-320.jpg?cb=1684244800)

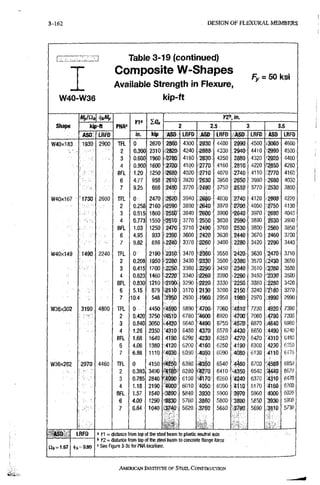

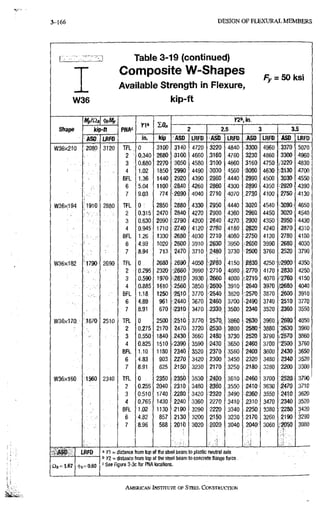

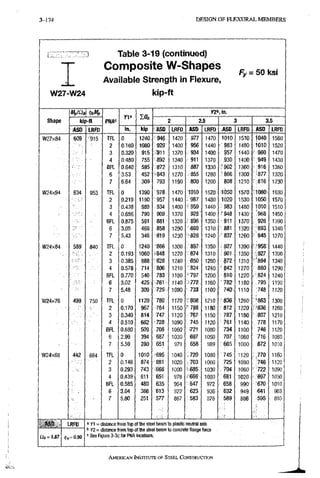

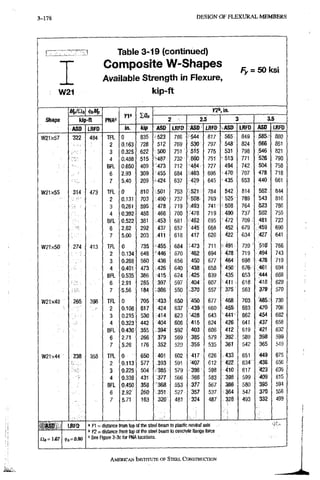

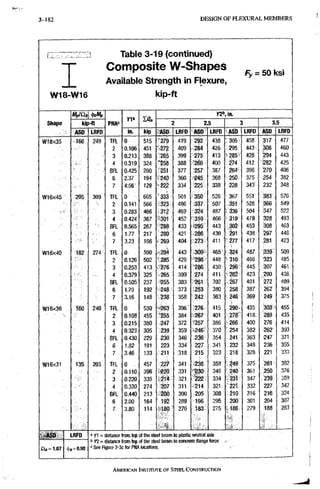

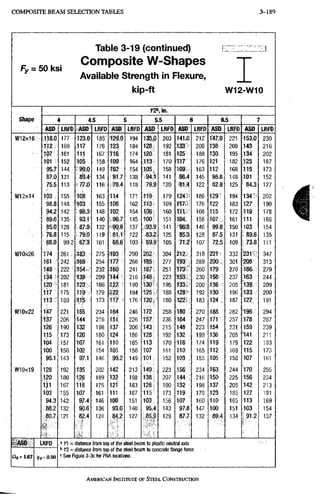

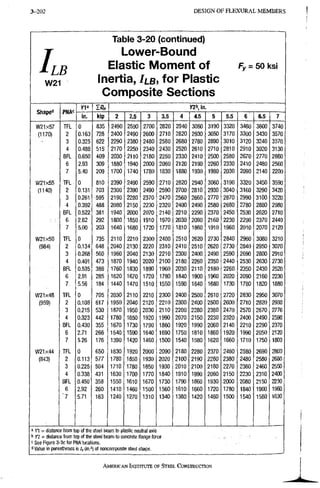

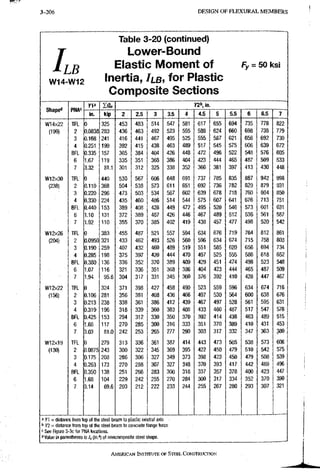

![3-186 DESIGN OF FLEXURAL MEMBERS

F Z Z Z Z I Z 3 1

W14-W12

Table 3-19 (continued)

Composite W-Shapes

Available Strength in Flexure,

kip-ft

Fy = 50ksi

Shape

Mp/Qi <t>(,Mp

PMA«

Kl' I Q n

in.

Shape kipift PMA«

Kl' I Q n

2 j 2.5 j ^ 3 3.5

Shape

ASO LRFD

PMA«

in. Wp ASD LRFD ASD U?FD "ASD piiljjilfi^-jill.lilail

W14X22 : 82.8 125 TFL 0 325 1143 215 151 228 159 240 1.68 c: 252

2 0.0838 283 i139 209 •146 220 153 230 160 241

3 0,168 241 "135 . 202 141 211 147 220 153 229

4 0.251 199 1*30 195 •135 203 140 210 1,45 218

BFL , 0.335 157, 125 188 129 194'^ 133 200 137 206

6 1.67 119 120 180 n 2 3 184 126 189: 129 193

7 3;32 81.1 -111

I

- • •

167 113 170 115 173 f l 7 176

W12x30 108 162 TFL 0' 440 |179 269 190 285 201 302. 212 318

2 ,10.110 368 171 258 '481 271 190 285 199 299

3 0.220 296 164 246 1171 257 178 268: 186 279

4 0.330 224 155" 234 1161 242 167 251 172 259

BFL 0:440 153 147. 221 ,151 227 •155 232 158 238

6 ,1 i;io i 131 •144 1 216 147 221 151 226. .154 231

7 .|1:92 i 110 • u o ! 211 143 215 m 219 149 223

W12x26: . 92;8 ' rto: TFL|O

'

-

-

- ! 383: 155 232 164 247 174 261 183 . 275

2 j0.0950: 321 •148 223^ .156 -1 235 164 247 172 259

3 0.190 259 142 213 i-48 223 155 232 161 242

4 10.285 198 135 203 140 210 145 217 150 225

BFL 1

0:380 136 128 192 131 197 134 202 •: 138 207

1 6 1.07 i 116 •125 188 128 - 192 131 197 .Ii34 201

7 1.94 95.6 •121 183 124 186 126 190 1:29 193

W12x22 73.1 110 TFL 0 , 324 132 198: 140 210 148 222 1:56 d 234

•. . 1 2 0.106 281 127' 191 -134 202 141 213 ^48 1 223

3 0.213 238 123' 185 129 193 135 202 141 1 211

I 4 0.319 196 1.18 177 123 185 128 192 133 199

i BFL 0.425 153 'J13 170 117 175 120 181 124 : 187

!

6 1.66 117 107 162 .110 166 113 170 116 175

j

7 '1 3.03 81.0 99.8 150 102 1 153 ,104 156 1106 159

W12x19 61;6 ! 92.6 • TFL,! 0 279 113 169 1 120 ' 180 126 190 133?. 201

i

, ^r,.-;. j 2 10.0875 243 109 164 ] l i s 1 173 . -121 182 127 191

3 j0.175 203 105 158 1110 1 166 •116 174 ,{121 182

4 : 0.263 173 101 ' 152 106 159 110 165 114 172

j

i BFL 1

0.350 138 97.3 146 101 151 ! 104 157 ' 108 182

6 1 1.68 104 92.3 139 , 94.9 143 ! 97.4 146 100 150

3

1 7

1

3.14 69.6 - 84.7

!

- —

127 •86.4 130 88.2 133 89.9 135

.ASD

£24 = 1.67

LRFD

<l>j=0.90

' n = distance from top of the steel beam to plastic neutral axis

1

= YZ = distance from top of ttie steel beam to concrete flange force

See Rgure 3-3c for PNA locations.

AMERICAN INSTITUTE, OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-374-320.jpg?cb=1684244800)

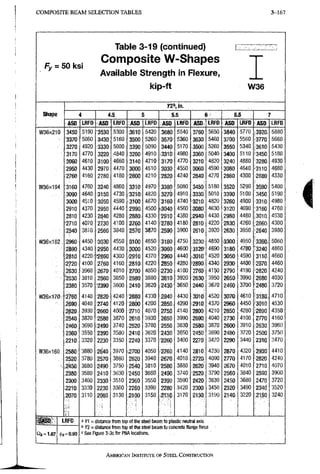

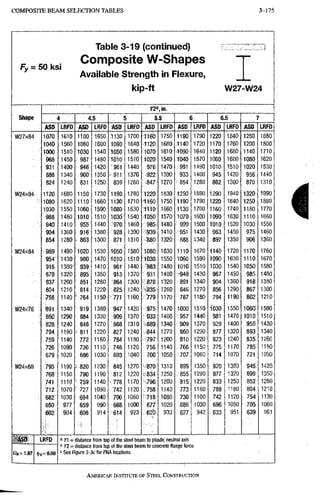

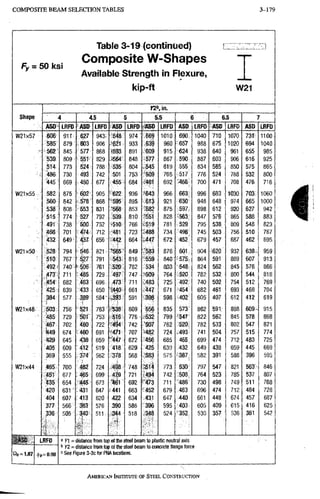

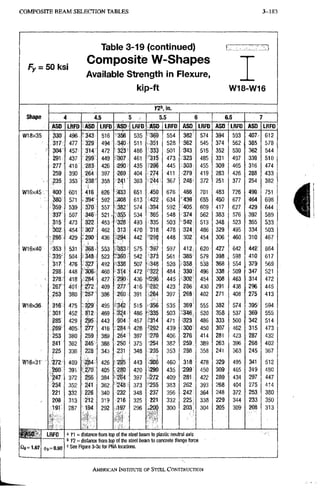

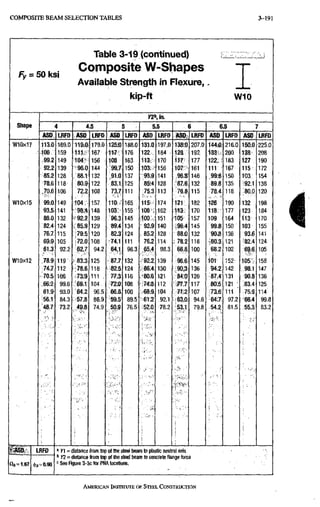

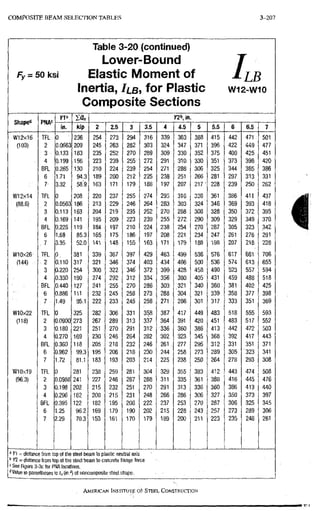

![3-379 DESIGN OF F L E X U R A L M E M B E R S

W12-W10

Table 3-19 (continued)

Composite W-Shapes

Available strength in Flexure,

kip-ft

Fy -50 ksi

Shape PNA"

i o r

yji'.in.

Shape kip-ft PNA"

i o r

2 2.5 3 3.5

Shape

ASO LRFD

PNA"

in. kip ASD LRFD ASO LRFD ASD LRFD ASO LRFD

W12X16 50.1 ?S.4 TFL : 0 236 5«4.0 141 99.9 150 - ;t06 159 112':, 168

2 0.0663 209 91.3 137 .i96.5 145 m 153 107 161

3 0.133 183 ?88.'6 133 93.1 140 .•.SI7.7 147 102 154

4 0.199 156 .'85.7 129 89.6 135 .93.5 141 ]37,4 146

BFL 0.265 130 f82i8 124 . 86.0 129 -:89.2 134 'S2,5 139

6 1.71 94.3 .77.6 117 79.9 120 • 82.3 124 84.6 127

7 3.32 58.9 ••69,6 105 107 72.5 109. - 74.0 111

W12x14 43.4 65.3 TFL 0:: 208 '82.5 124 87.7 132 92.9 140 > 98.1: 147

2 0.0563 186 80.3 121 84.9 128 •-89.5 135 ; 94.2 142

3 o ; i i 3 163 77.^ 117 •'82.0 123 86.1 129 '90.2 135

4 0.169 141 '75.5 114 •79.1 119 • 82.6 124 86.1 129

. - BFL 0.225 119 J 73.1 110 76.1 114 79.0 119 82.0 123

6 1.88 85.3 V68.3 103 70.4 106 ' 72.6 109 74.7 112

7 3.35 52.0 ,'60.8 91.4 62.1 93.3 '63.4 95,3 .64.7 97.2

W10X26 78.1 117 TFL 0 ' 381 136 204 .145 218 155 233^ 164 • 247

2 0.110 317 194 .137 206 U5 218 153 230

3 . 0.220 254 122' 184 193 135 203. 1'41 213

4 0.330 190 145 173 120 180 c125 187 129 195

BFL 0.440 127 108, 162 : t l i 167 . 114 171 .117 176

6 0.886 111 106 159 .108 163 111 187 •1,14 171

7 1.49 95.1 103 155 105 158 •08 . 162 110 166

W10x22 . '64.i9 97.5 TFL 0 325 315' 173 .I2S ' 185 ^ 131 197 139 209

2 0.0900 273 110' 165 ?16 175 185 .130 196

3 0.180 221 104 157 T10 165 115 ' 173 121 181

4 0.270 169 98.4 148 103 154 '-107 161 111 167

BFL 0.360 118 "92.5 139 95.4 143 • 98.3 148 1D1 152

6 0.962 99.3 •SO.I 135 92.5 139 95.0 143 97.5 147

7 1.72 81.1 87.0 131 89.1 134 •91.1 137 93.1 140

W10X19 53.9 81.0 TFL 0 281 !09.6 150 107 160 •T14 171 121 181

2 0.0988 241 -a5)5 144 m 153 • m 162 .i;i4 171

3 0.198 202 137 96.3 145 '401 152 .106 160

4 0.296 162 86.8 130 90.8 13/ • 94.9 143 •98.9 149

BFL 0.395 122 82.1 123 '85.2 128 • .88.2 133 ' 91.3 137

6 1.25 96.2 78.5 118 80.9 122 •83.3 125 85.8 129

7 2:29 70.3 ,-73.7 111 75.4 113 77.2 116 78.9

^

119

1

^ K1 = distance from top of the steel beam to plastic neuiral axis

' n = distance from top of the 'steel beam to concrete flange force

' See Rgure 3-3c for PMA locatioris.

AMERICAN INSTITUTE, OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-376-320.jpg?cb=1684244800)

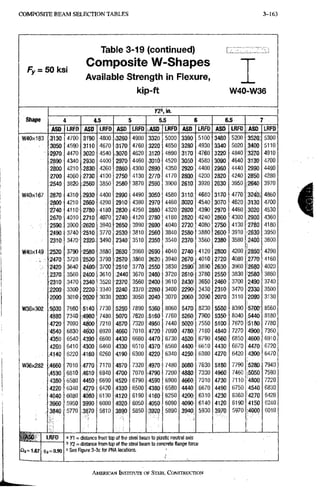

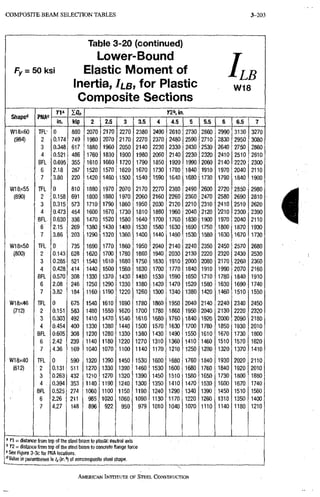

![3-190 DESIGN OF FLEXURAL M E M B E R S

W10

Table 3-19 (continued)

Composite W-Shapes

Available Strength in Flexure,

kip-ft

Fv = 50 ksi

Shape

Mp/dn

PNA=

K1« tOn

Y2>>, in.

Shape kip-ft PNA=

K1« tOn

2 2.5 3 3.5

Shape

ASO LRFD

PNA=

in. kip ASD- LRFD ASD LRFD ASD LRFD ASO LRFD

W10x17 . 46.7 70.1. TFL 0 250 .B7.8 132 94:0 141.' 100 151 ' 106 ,1 160

2 0:0825 216 '84.4 127 89.8 135 95.2 143- 101 151

3 0.165 183 80.9 122 85.5 128 ' '90,0 135 •94.6 142

4 0.248 150 77.2 116: 81.0 122 84,7 127 •88.5 133

BFL 0:330 117 c73.5 110 .76.4 115 -79,3 119 124

6 1.31 89.8 69.7 105 71,9 108 : 74.2 111 >6,4 115

7 2,45 62.4 64.4 96:8 65.9 99,1 • 6V.5 101 69,1 104

W 1 0 X 1 5 39.9 60.0 TFL 0 221 77.0 116 82,5 124 88.0 132 • , 93,5 140

2 0.0675 194 •74.2 112 79.1 119 . •;83.9 126 88.7 133

3 0.135 167 -71.4 107 75.6 114 79.7 120 83.9 126

4 0.203 140 68.5 103 72.0 108 .. 75.5 113 78.9 119

BFL 0i270: 113 •65.5 98.4 ••68.3 103 71.1 107 73.9 111

6 1.35 83.8 .•61^ 92,5 63.6 95:6' 65.7 98.7 67,8 102

7 2.60 55.1 ,S5.8 83.9 57.2 86:0 58.6 88.0 59.9 90.1

W 1 0 X 1 2 • 31.2 46.9 TFL 0 177 •.61.? 92.1 65,7 98.7 ;70.1 105 74.5 112

2 0:0525 156 •59.1 88.9 •63:0 94.8 •,-66.9 100 70.8 106

3 0.105 135 57.0 85.7 60,4. 90.7 ,^3.7 95.8 •67.1 101

4 0.158 115 ••54.8. 82,4 57.7 86.7 ,j6'0.5 91.0. 95.3

BFL 0.210 93.8 152.5 78.9 "54.9 82.4 J57.2 86.0 .'69.5 89.5

6 1.30 69.0 49r2 73,9 50.9 76.5 '52.6 79.1 ^54.4 81.7

7 2.61 44.3 .44.3 66.6 45.4 68.2 : 146.5' 69.9 47.6 71.5

^ , i '

r:

; J

* i i

i ..

i-

1 ' i f i S S 1 W f S f

lifssf^

ASD

Q4=i.e7

LRFD

(])4=0.90

' Kl = distance from top ofrthe steel beam to plastic neutral axis:

!> Y2 = distance from top of. the steel team to concrete flange force.

' See Figure 3-3c for PNA locations.

AMERICAN INSTITUTE, OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-378-320.jpg?cb=1684244800)

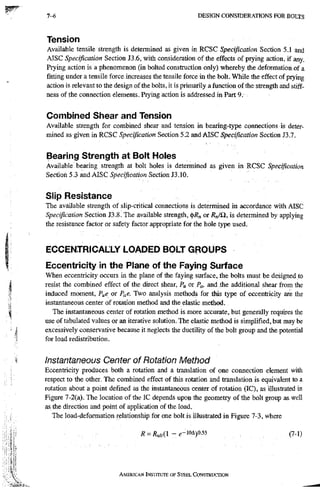

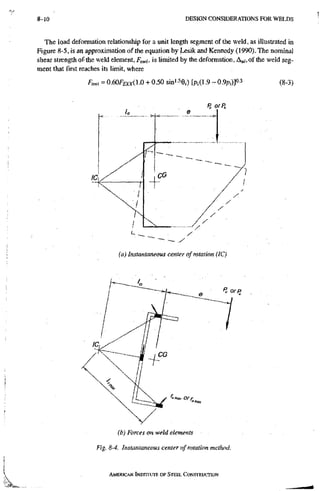

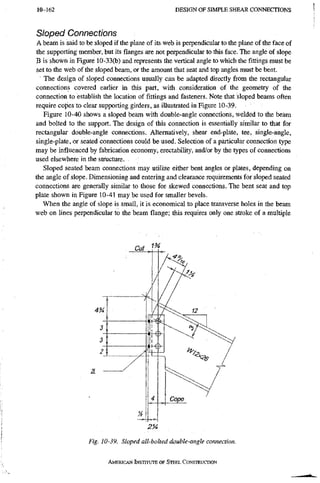

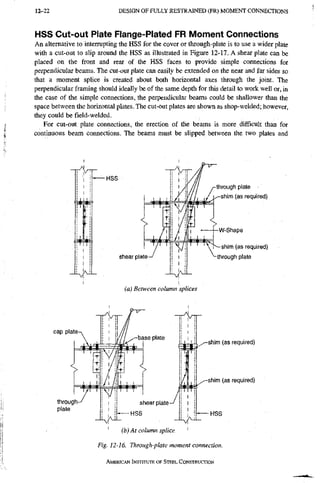

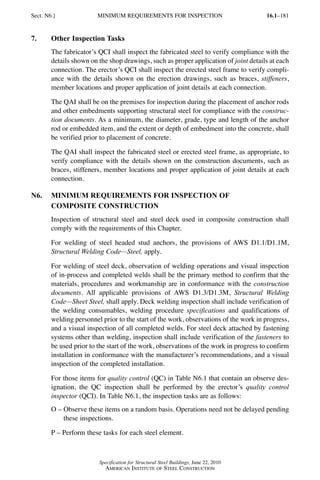

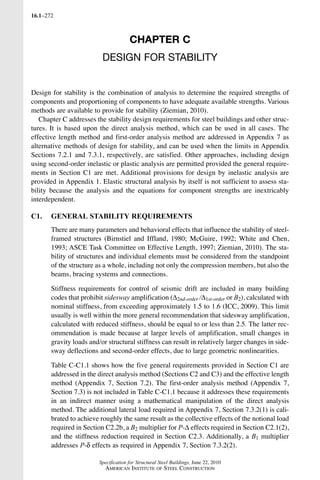

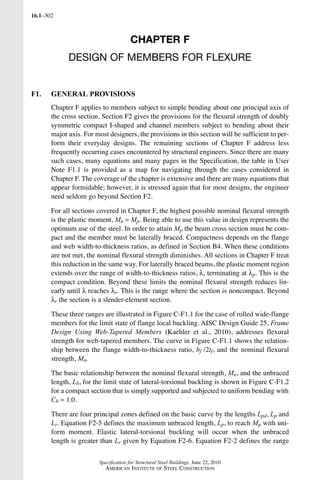

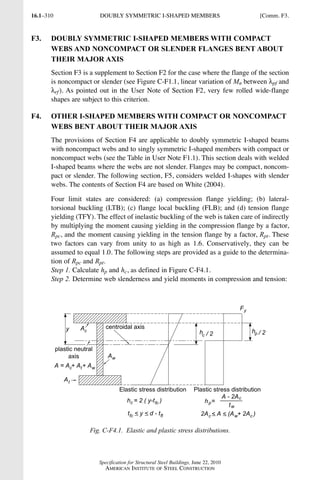

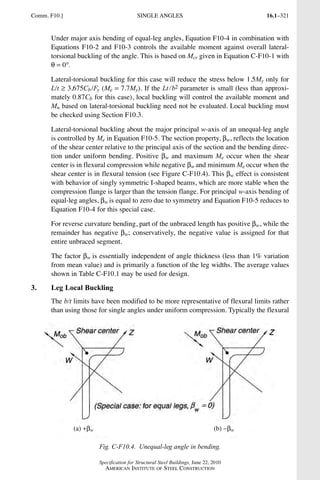

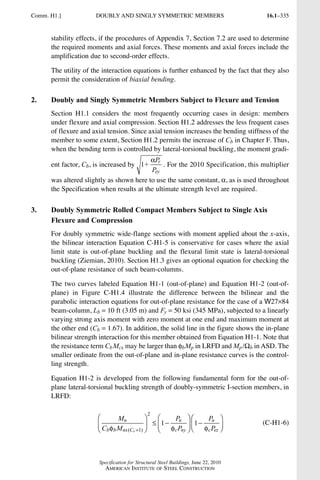

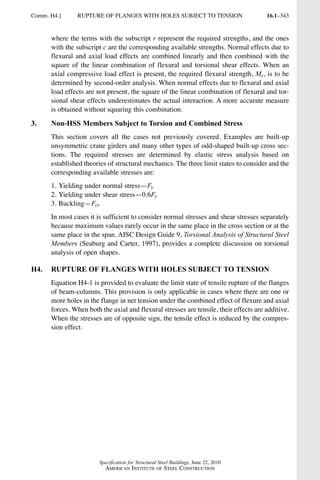

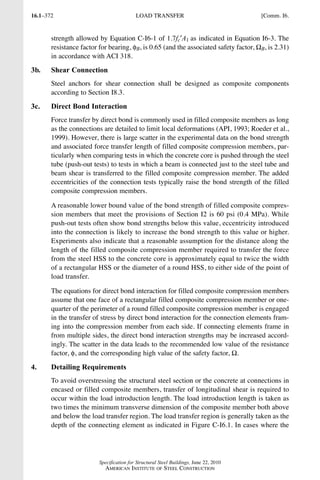

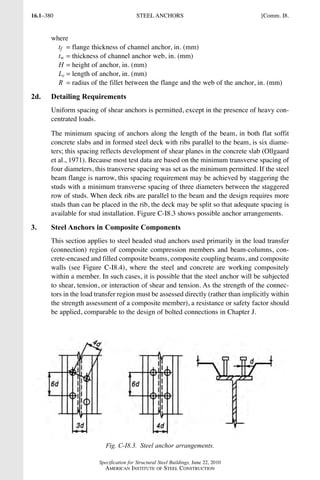

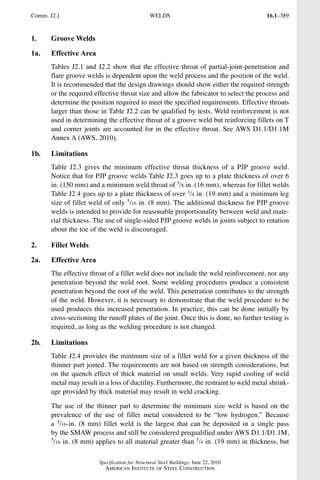

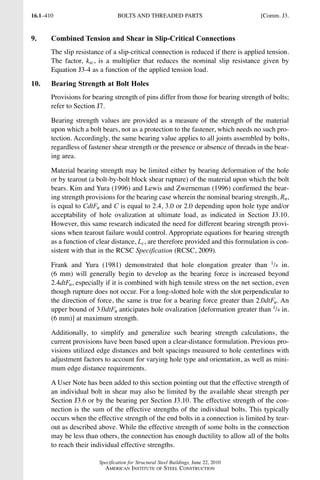

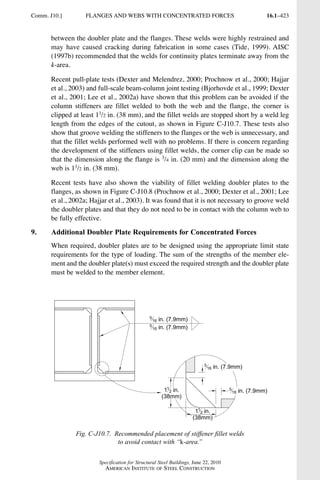

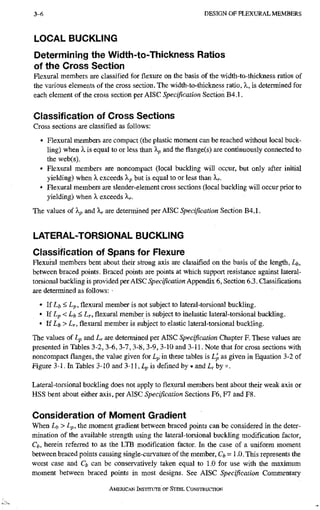

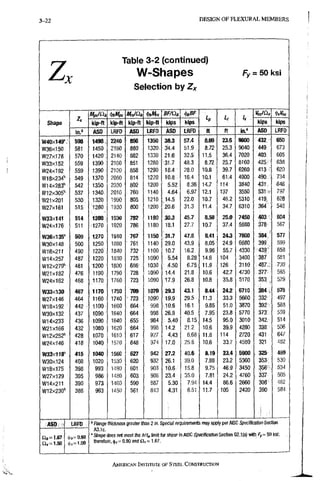

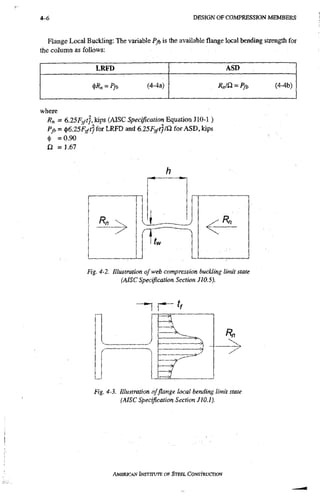

![3-212 D E S I G N O F F L E X U R A L M E M B E R S

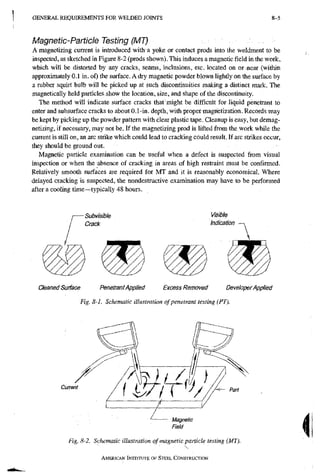

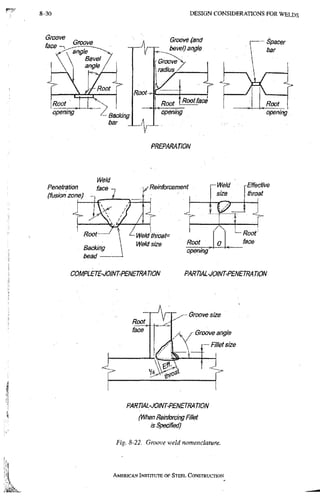

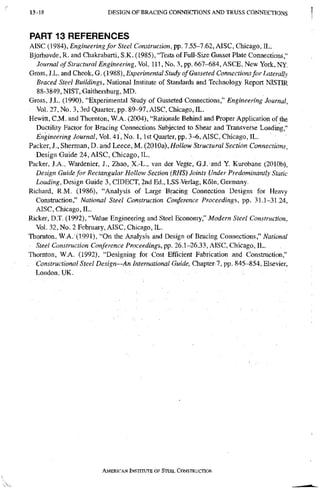

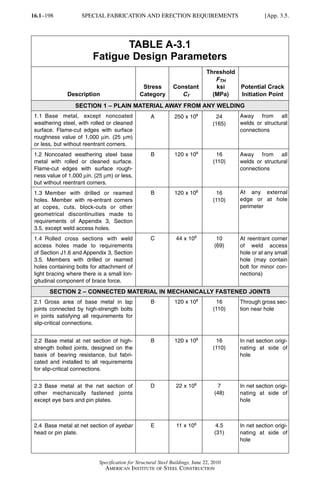

Table 3-22c

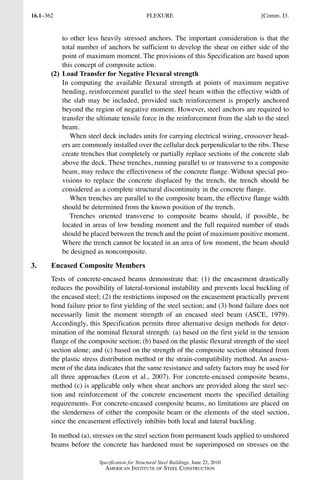

Continuous Beams

Moments and Shear Coefficients—

Equal Spans, Equally Loaded

M o m e n t

in terms of

T'

.077 +

.

0

3

6 +

.

0

3

6 +

.

0

7

7

Shear

in terms of wl

Uniform Load

f T T T T 7 t

o f i — f ^

gg m 31 22

10 10 10 10

0fl5 23t20 letlS i9tl8 2

O

T

M Tsto

•W -35~ IT -ST IT -ir

wTw 45]61 S3tS3 Sit 49 ^

1

0

4 ToT 104 TM^ TW^ TBT ^TK

r w w w w i F W i

M o m e n t

in terms of P/

+.156 +.156

V.187 ,

Concentrated Loads

at center

Shear

in terms of P

+.175 +.10 +.175

+.171 +.11 +.13 +.11 +.171

* ]

P • P

t 1 I

1,31 .691.69 .311

P P

1.35 .651.50 .501.65 .351

P P P P P

t 1 t ^ t ' t ' t * t

T.34 .661.54 .461.60 .60',46 ,541,66 ,34'

M o m e n t

in terms of Pi

Concentrated Loads

at third points

Shear

in terms of P

'•222 .,111 -,111 -.222 P P p p

, n . n ,

1.67 1,3311,33 ,671

•,156 +,066+ 066+,156 -

-,267 - 267

.,2f,146 • 076*<'?9 ',122 M22 >,099',076 .,01.46 i24

P P P P P P

, 1 1 . n n

1.73 1.2711.0 1.011.27 .731

P P P P P P P P P P

, 1 1 . 1 1 , 1 1 . 1 1 , 1 1 .

1.72 1.28^1.07 .9311.0 1.01.93 1.07ll.2B .72(

M o m e n t

in terms of P/

..267 .267

• 258 >.022 -.022 ..25(

Concentrated Loads

at quarter points

Shear

in temis of P

-.465

..314 ,128 ..314

..282 ..097 ,003 ,,003 >.097 ..282

',,372 ,.372

:04 ,155

..079,054 ,006 .,079 , m

-.296 -.394

.,303 ,155 +

,

2

0

4 ,155 *,303

,054 ,079 .,079 ,054 ,006 .,079 . j

tl,03 1,9711,97 l,03l

P P P P P P P P P

. 1 1 1 , H i 1 1 1

11,13 1,8711,50 1,501,87 1,131

P P P P P P P P P : P P P P P P

, 1 1 1 : 1 1 1 , 1 1 1 , 1 1 1 . I l l ,

11.11 1.8911,60 1.40Ti.50 i:50tl.40 1.60)1:69 1.111

AMERICAN INSTITUTE, OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-400-320.jpg?cb=1684244800)

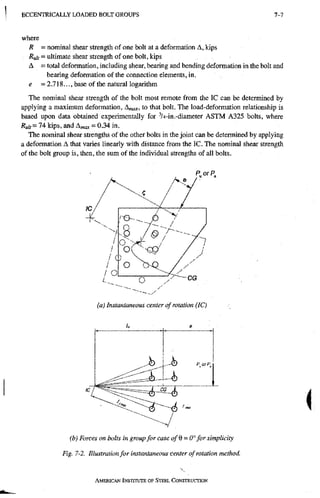

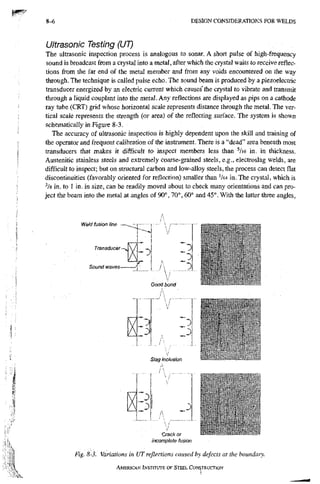

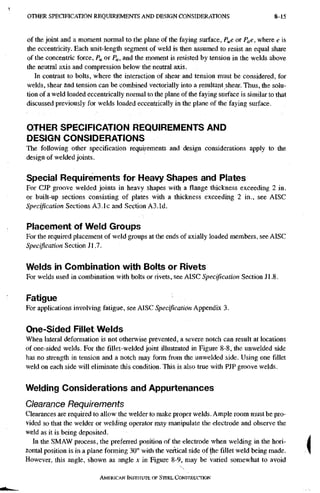

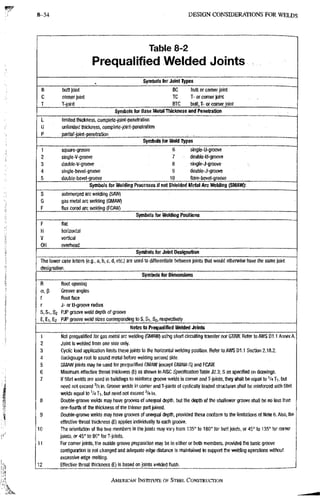

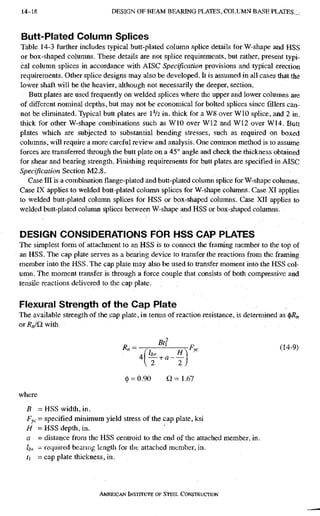

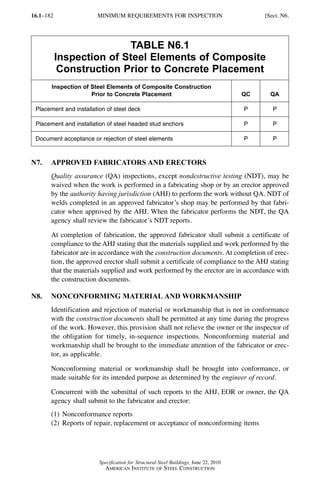

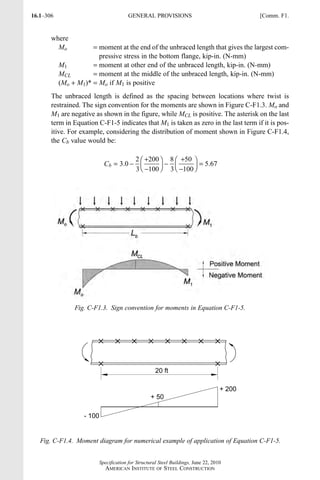

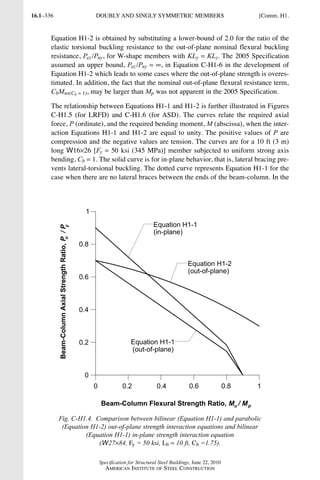

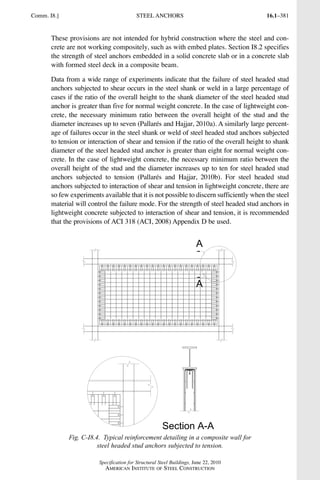

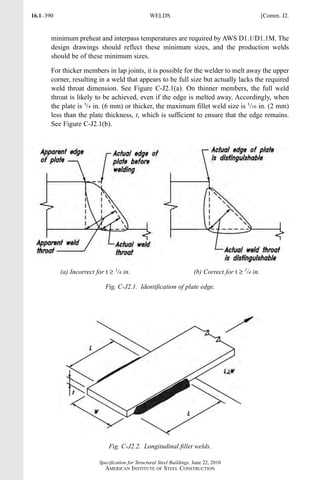

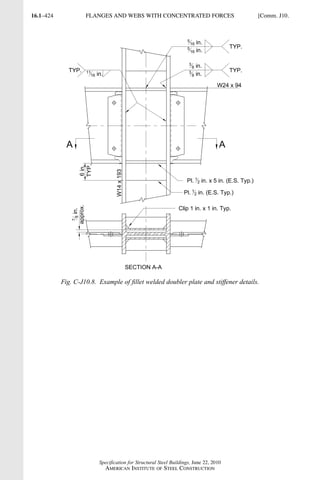

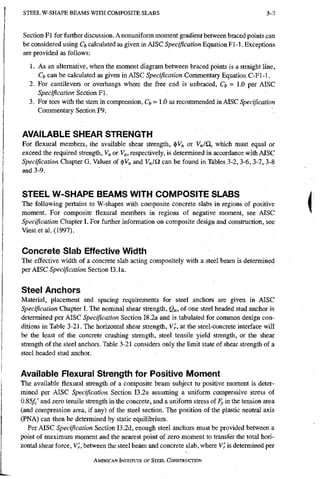

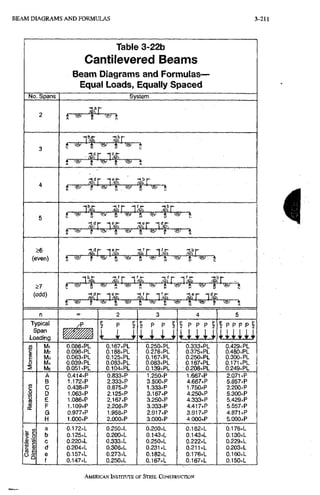

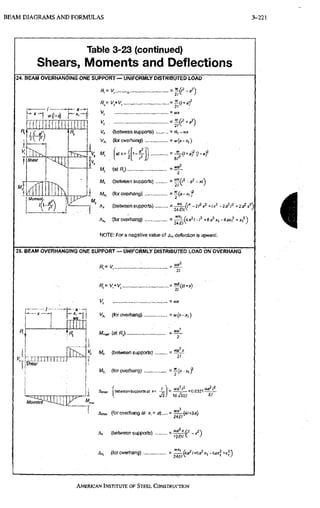

![3-216 DESIGN OF F L E X U R A L M E M B E R S

Table 3-23 (continued)

Shears, Moments and Deflections

10. SIMPLE BEAM - TWO EQUAL CONCENTRATED LOADS UNSYMMETRICALLY PLACED

Shear

V, ( = V™, when a < t>)

V™,whena>6).,

V, (when

1

K M, ( = M™, when a>b)....

T (= Mrac when a < b)....

Q-a+b)

(i-a)

M,

Moment

M, (when x< a) = *

M„ (whena < x < ( / - 6 ) j = R.,x~P(x-e

11. SIMPLE BEAM — TWO UNEQUAL CONCENTRATED LOADS UNSYMMETRICALLY PLACED

P,(/-a)+Pab

M

- I -

71

.11,

Shear

R = v..

m r

I D I

P K

V, (when a < * < ( / - & ) ) = R i - P i

M, ( = when R, < P,) = Rta

H ( = M™, when R, < PJ = flj6

Moment

Mj M, ( w h e n * < a ) =fl,x

1

J,

M, (when a < x c ( / - t i ) ) =fl^x-ftx~^

12. BEAM FIXED AT ONE END, SUPPORTED AT OTHER — UNIFORMLY DISTRUBTED LOAD

Wl

• I ]

—

•

:

• X

Shear

I Morhent

i

Total Equiv. Uniform Load = wl

1

V,

T

1 M,

i

M,

1

1

} A,

= Rl ~wx

wf

t ^ (at X = ^ ( U o.«2 () =

AMERICAN INSTTRUTE OF STBEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-404-320.jpg?cb=1684244800)

![3-222 DESIGN OF F L E X U R A L M E M B E R S

Table 3-23 (continued)

Shears, Moments and Deflections

26. BEAM OVERHANGING ONE SUPPORT — CONCENTRATED LOAD AT END OF OVERHANG

PS

I

R , = I / , . .

1

] 111111l u U I

Shear

Moment

w™, (atR,) =Pa

M, (between supports)

M,, (for overtiang)

Amiix between supports at X=

H

_ Par

Am,, (for ovettiang at X, = a)

A, (between supports)

A,

aei

((-.a)

(for overhang) = ~ (2a/ t3ax, - x,^)

27. BEAM OVERHANGING ONE SUPPORT — UNIFORMLY DISTRIBUTED LOAD BETWEEN SUPPORTS

Total Equiv, Uniform Load = w!

R = V

H I ~-^.-a-r-

-f-Xi-H

h i i i i i i

-^.-a-r-

-f-Xi-H

R

^ m r r ^

1

2

R

1 Shear V

-IM 1 TTTN

V

_ wl

2

Moment

V,

A W (atcenter)..

/W,

Am,, (atcenter)..

Ax

A,,

240

240

28. BEAM OVERHANGING ONE SUPPORT — CONCENTRATED LOAD AT ANY POINT BETWEEN SUPPORTS

Total Equlv. Uniform Load

- £ ?

~ I

- l - V, (= IWwtien a< b)

VJ= l/„»when a > 6)

i

b

Shear

MIfflJ

. l U l i J

(at point of toad)

Mx (whenx<a)..

i-2b)

atx= J-^-j—^ wtien

(at point of load)

- Ptix

I

Pab(a^

Momont

A, ( w h e n x o )

A, (When a).: =

_ Pai)*i

(i.a)

AMERICAN INSTITUTE, OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-410-320.jpg?cb=1684244800)

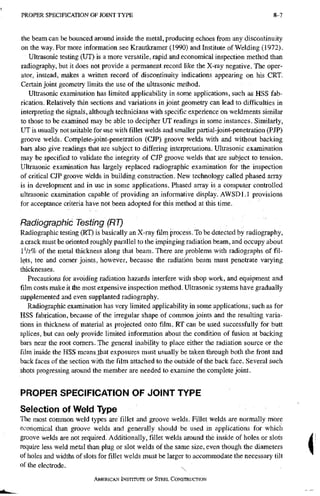

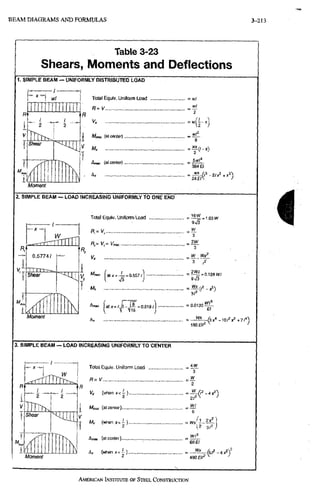

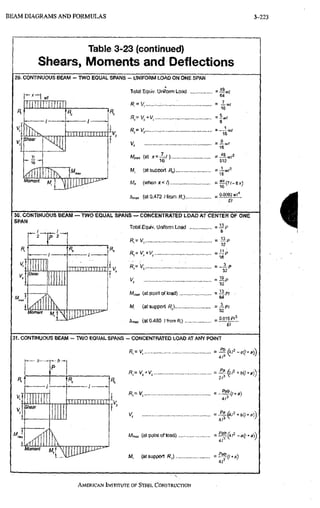

![B E A M D I A G R A M S A N D FORMULAS 3-225

Table 3-23 (continued)

Shears, Moments and Deflections

34. SIMPLE BEAM — LOAD INCREASING UNIFORMLY FROM CENTER

r-T ' -

- /

• 2

W

2

Shear

Total Equiv, Uniform Load

R=V

3

2

V. ( W h e n x < i )

Mb^ (atcenter).,

y Mx ( w h e n * < i ) . .

I

Amax (at center)

Ax (when i ) . .

~ 12

2

_

~ 320 £/

- J I L

" 12S

Moment

35. SIMPLE BEAM — CONCENTRATED MOMENT AT END

(M-

SImr

Total Equiv. Uniform Load

R=V :

M^

M,

_ 8M

I

I

i

-i^-7}

t Jf= 0.423 /)... =:0.0e42

Ml'

Moment A,

36, SIMPLE BEAM ~ CONCENTRATED MOMENT AT ANY POINT

X 1

Total Equiv. Unifomn Load ...

M =

I

R - t

, a

] 1111 M 11

Sltesr

N

K

H H ^ Moment

R

R'V

Mj, (whence a) = Rx

(when x > a) =fi(/-X)

A, (when x< a) =:.iL.

6 0 i '

A, (when X > a) _ M

6 El

X"

/

I.,.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-413-320.jpg?cb=1684244800)

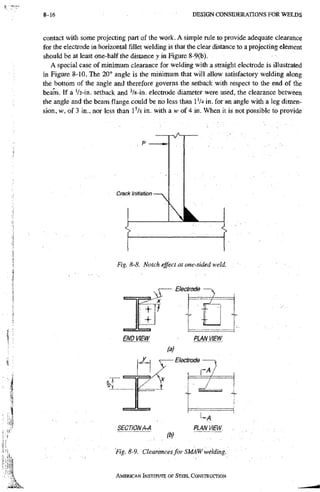

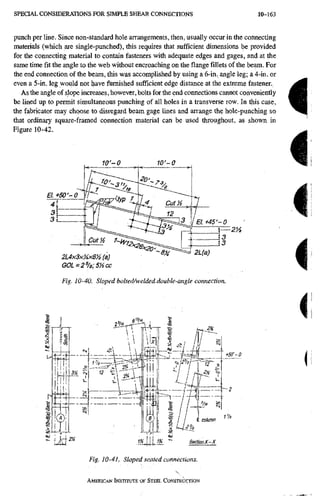

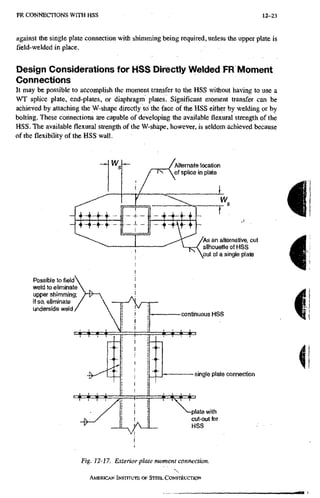

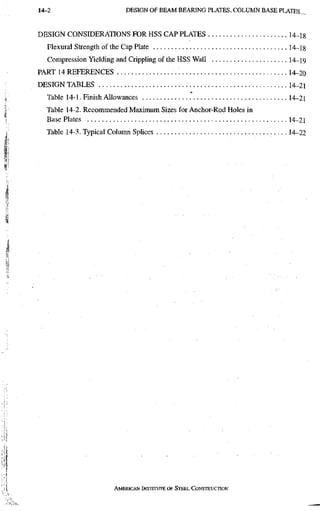

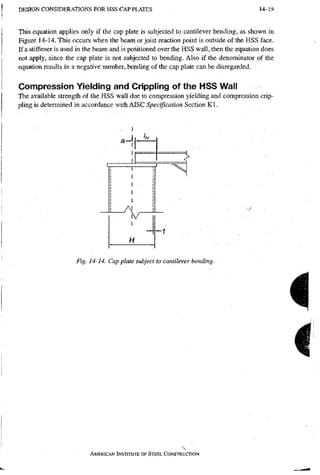

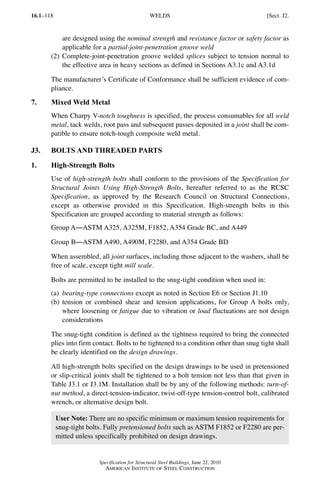

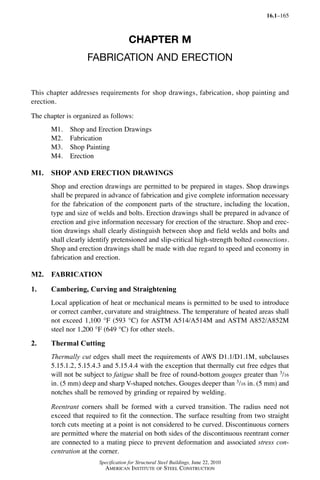

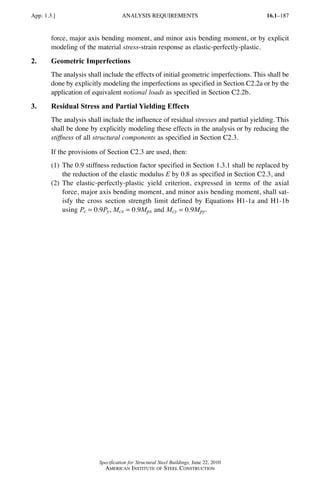

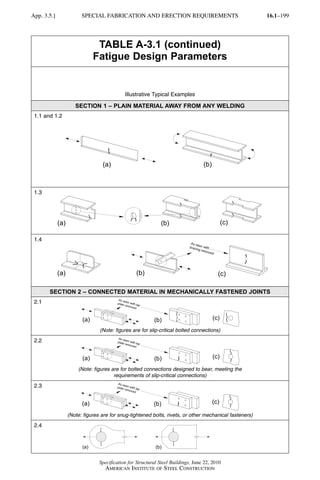

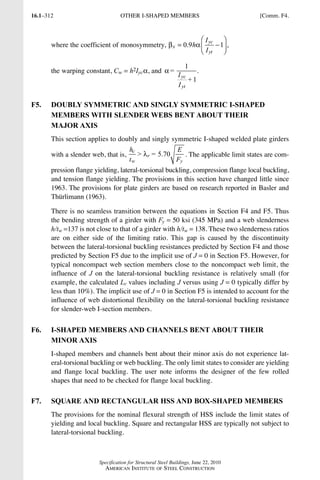

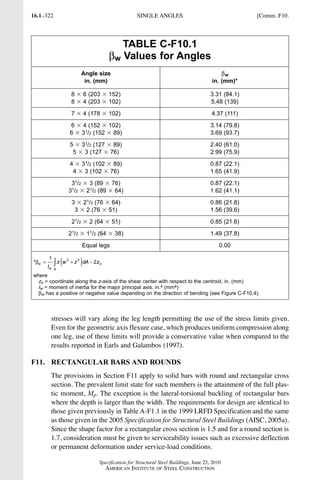

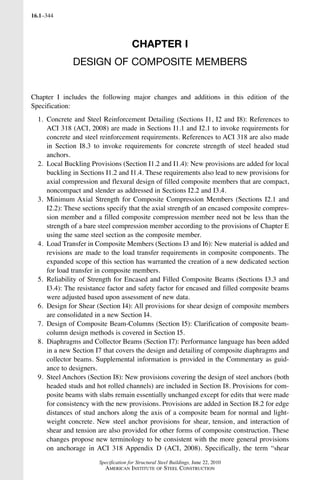

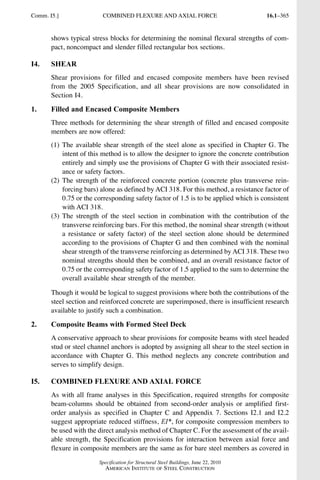

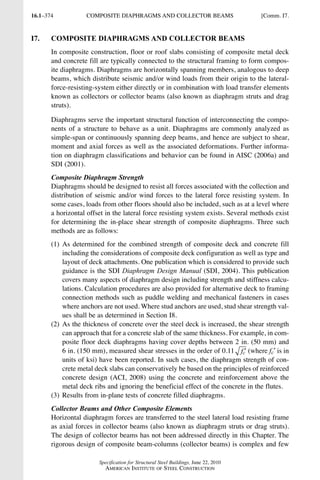

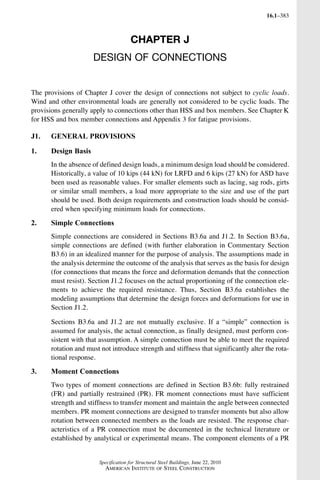

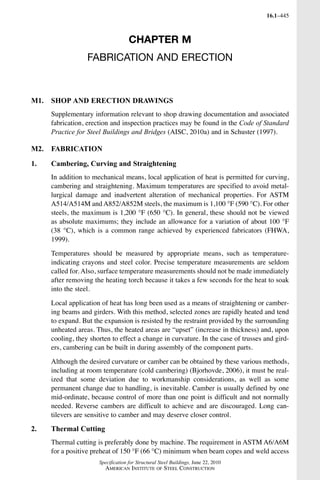

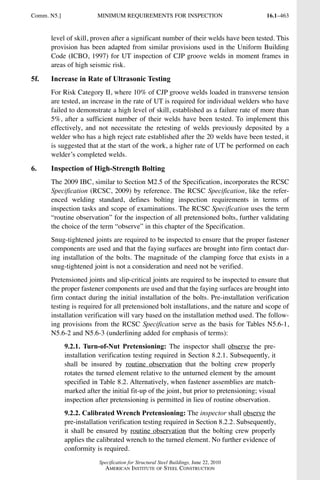

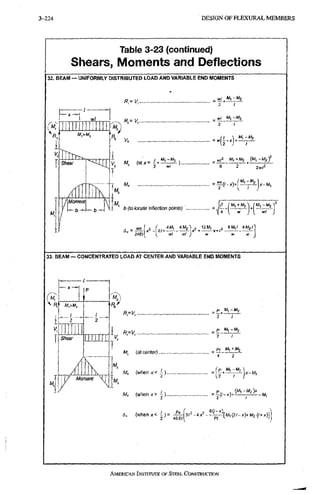

![BEAM DIAGRAMS AND FORMULAS 3-227

Table 3-23 (continued)

Shears, Moments and Deflections

40. CONTINUOUS BEAM — FOUR EQUAL SPANS — THIRD SPAN UNLOADED

/ c I D (

0.380 wl

Shear

o.mwiTTTTrrr^

0.558 wl

T r n r m ^ .

^.omwi'

"^'•'-i-! 1 1

0.620 Wl 0.397 wl

'79 wl' -0.056

0.0400 wl

*-0.09

—'-UL

77 wl'

^ >10.380/

Rt= 0.442wl

A^(0.475!fromE} = 0.0094 wl'/EI

41. CONTINUOUS BEAM — FOUR EQUAL SPANS — LOAD FIRT AND THIRD SPANS

1

I Dl I

0.0180wl 0.482 wl

-

>

0

.

0

-<mTTl

-^-'-^uiiLL

996 wf

rrrrrrv.-^-^^-

0.554 wl

i$wl' • -0.035

+

0

.

0

8

0

5 wf

05)8 wl

5

3

6 wj*

0.44ei

j j j j j X L L L U - u ^

A„„(0.477ifFmiA} " O.OogTwl'/EI

42. CONTINUOUS BEAM — FOUR EQUAL SPANS — ALL SPANS LOADED

m i - " " '

I C] I 0] I

= Rc^0.92ewl Ra=1.14wl R^==0.393wl

0.536 wl 0.464 wl

rm-T^. TTTrm-r^.

•H}.07?2 wl'

scaxtrr

0.60? wl ^^

wp *o.o3etwi'

^

r

-

r

T

T

T

T

T

-

r

-

T

^ i

0.46.WI

1 r-rv.

0.S36WI

•K).0772

0.3931 0.6361

•

0.5361 ^

0.3931

(0.4401 from A and£) ~ 0.0065 wlfai

AMERICAN iNSTrruTE OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-415-320.jpg?cb=1684244800)

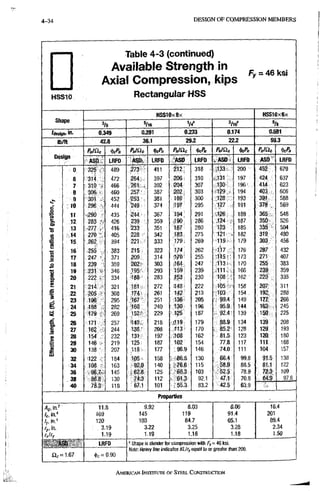

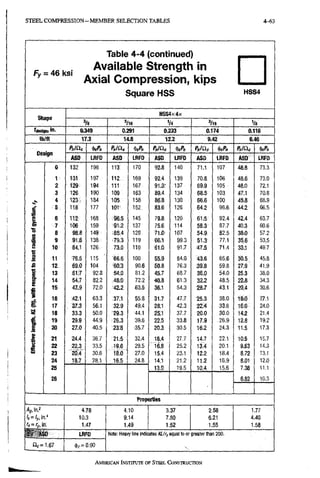

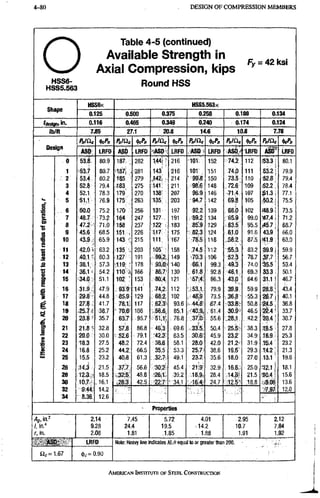

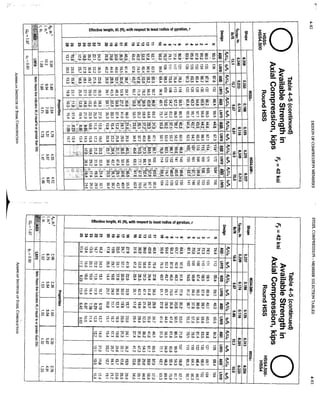

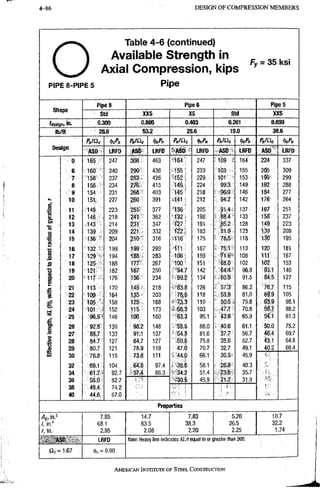

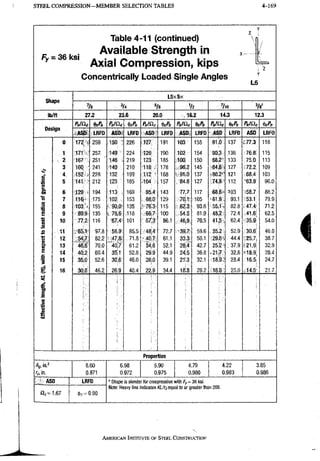

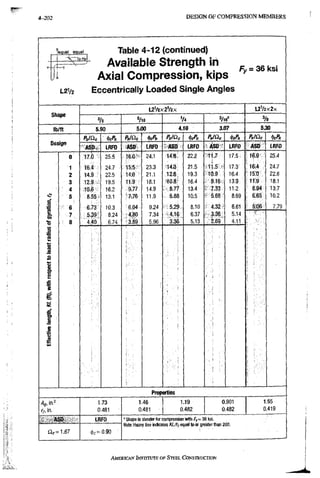

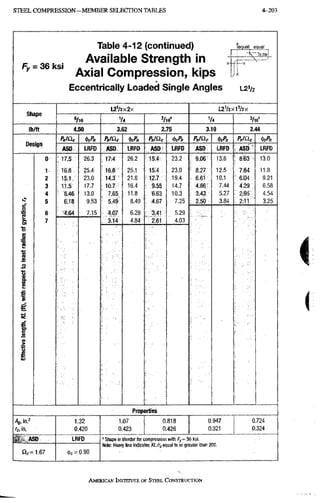

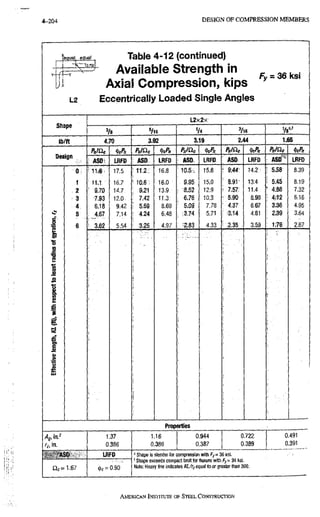

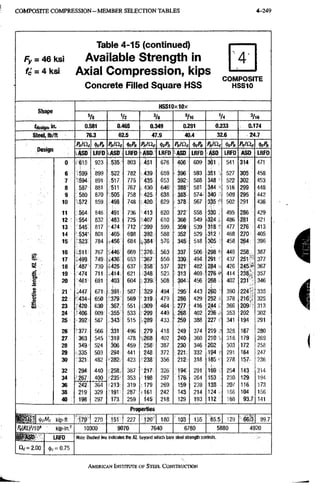

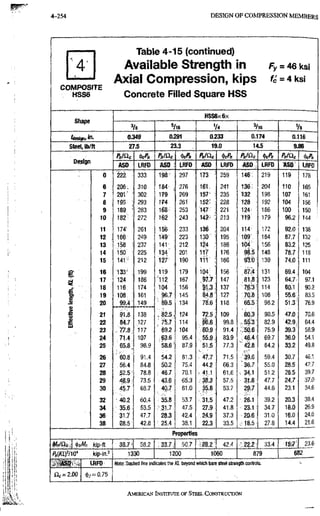

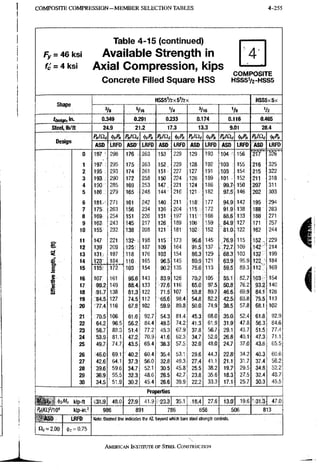

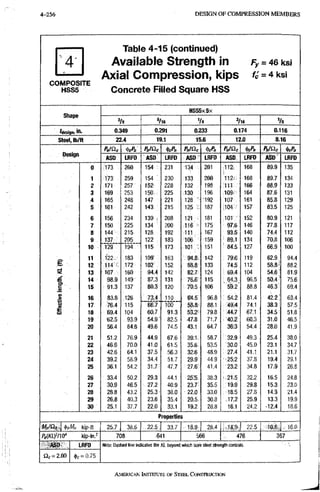

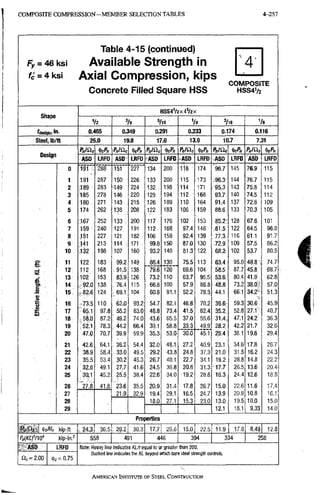

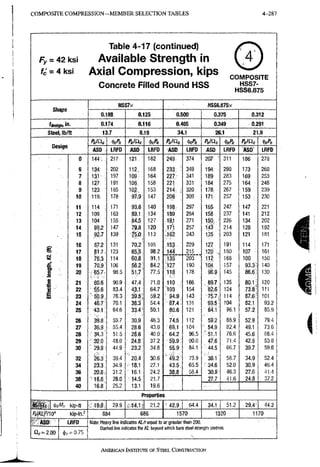

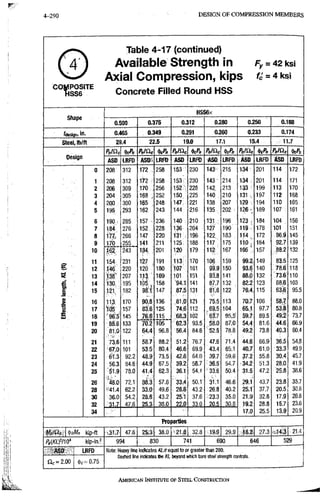

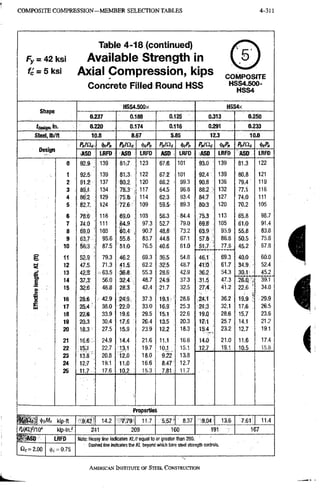

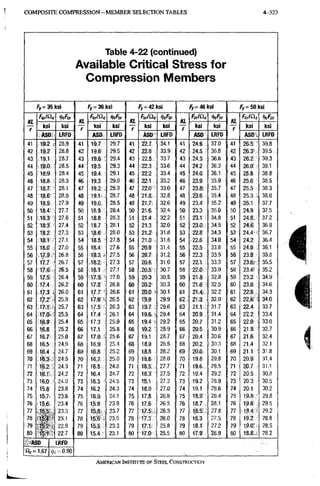

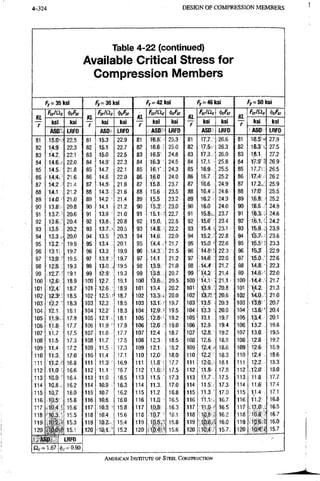

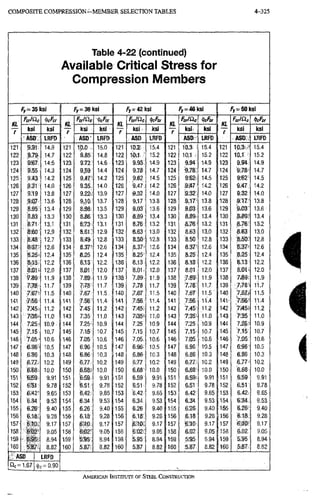

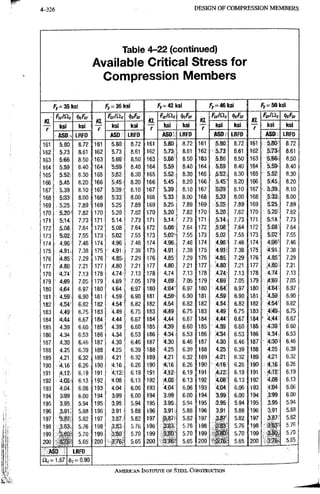

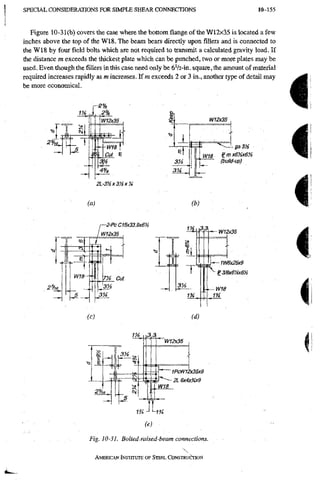

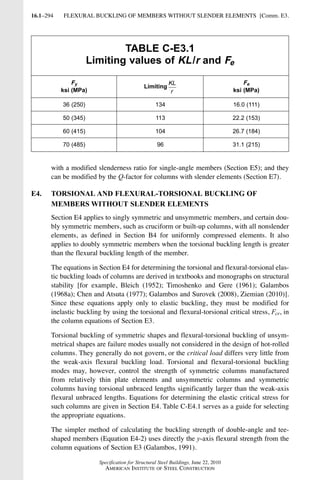

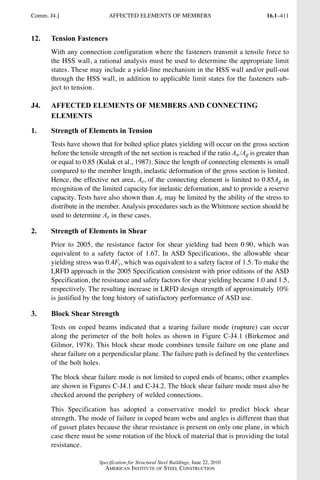

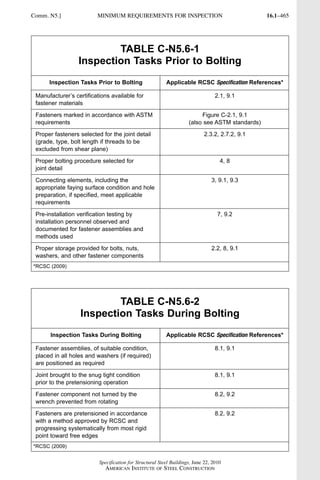

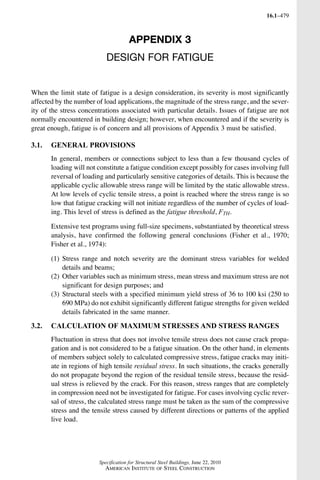

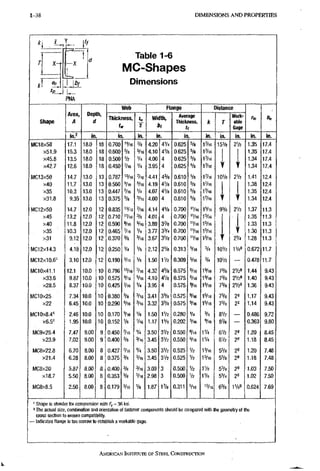

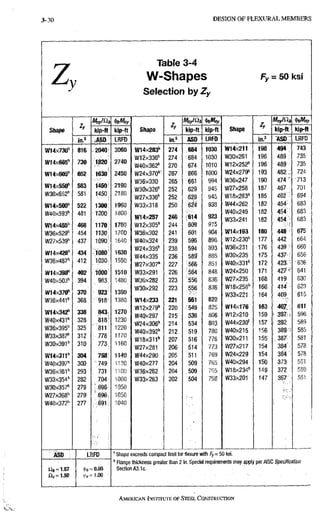

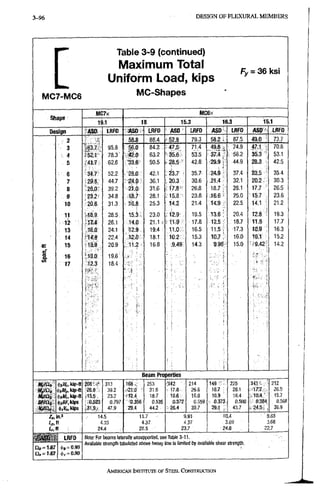

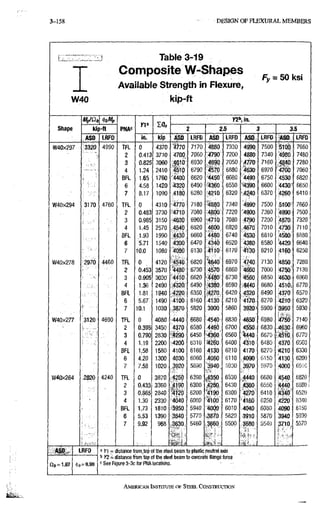

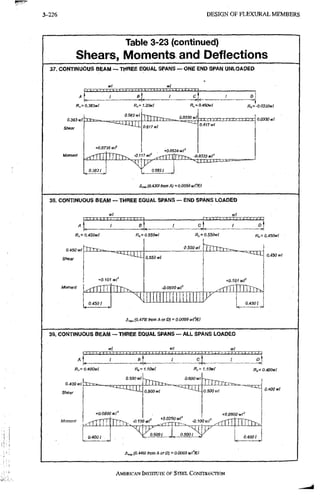

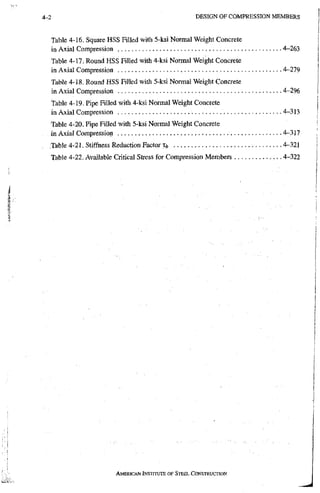

![4-4 D E S I G N O F C O M P R E S S I O N M E M B E R S

loads. Guidance on the proper determination of the value of K is given in AISC

Specification Commentary to Appendix Section 7.2.

As indicated in the User Note in AISC Specification Section E2, compression member

slendemess, KL/r, should preferably be limited to a maximum of 200. Note that this recom-

mendation does not apply to members that are primarily tension members, but subject to

incidental compression under other load conibinations.

Additional information is available in the SSRC Guide to Stability Design Criteria for

Metal Structures (Ziemian, 2010).

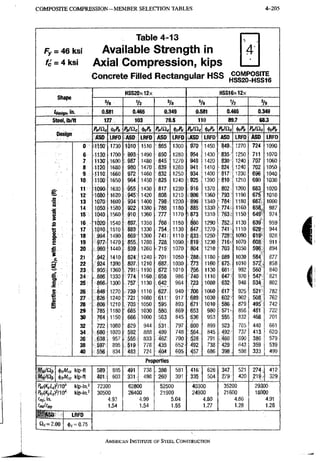

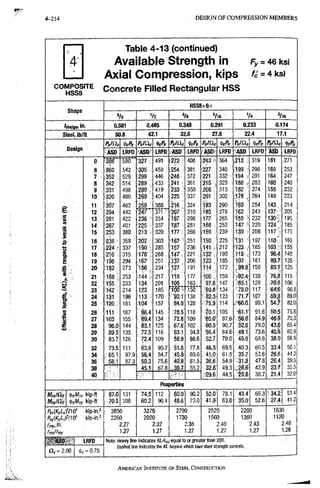

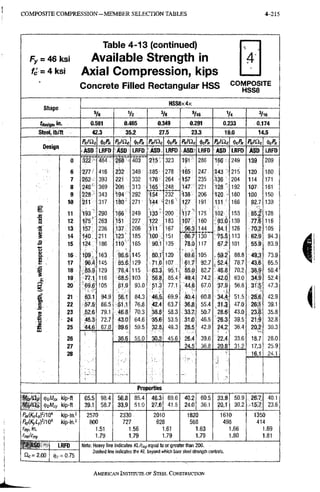

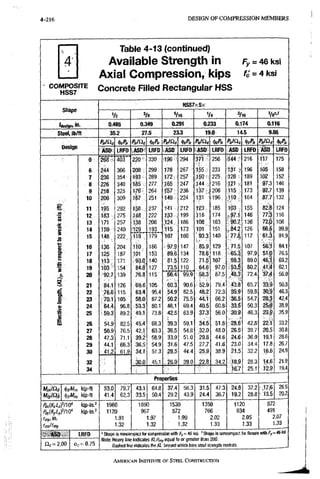

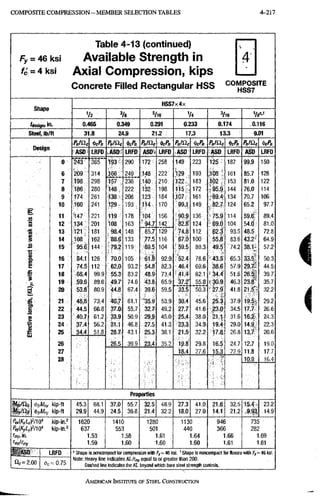

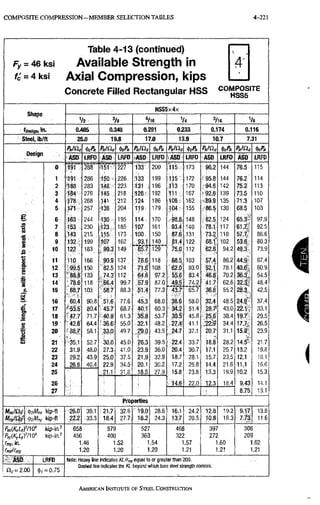

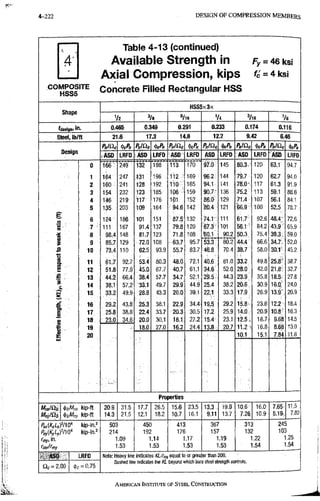

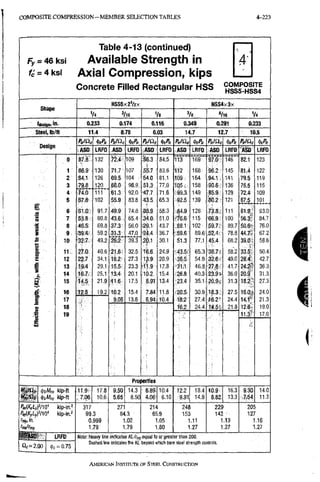

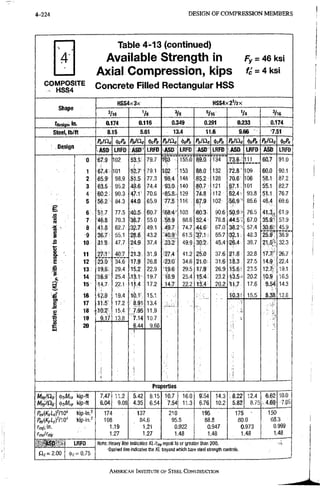

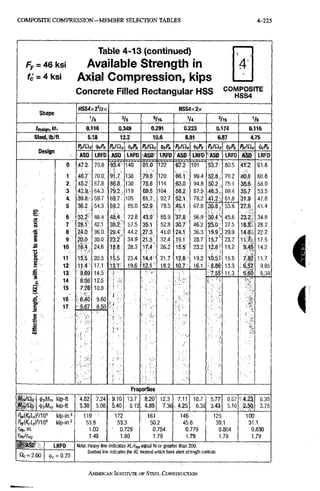

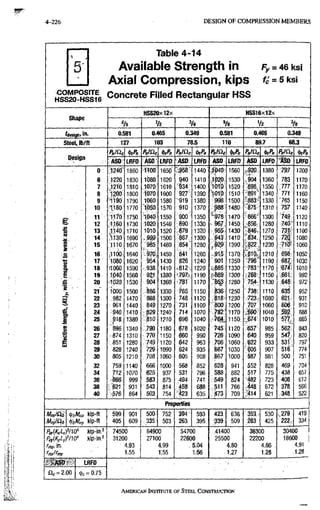

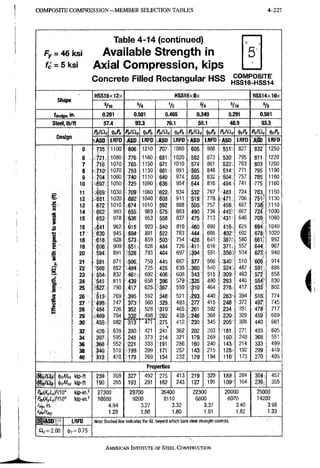

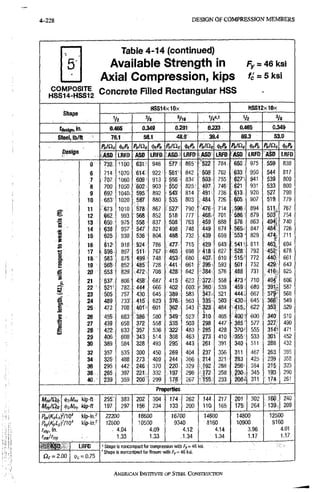

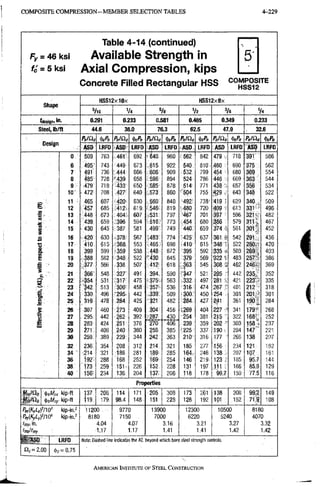

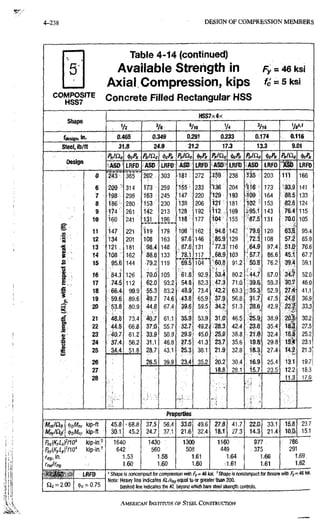

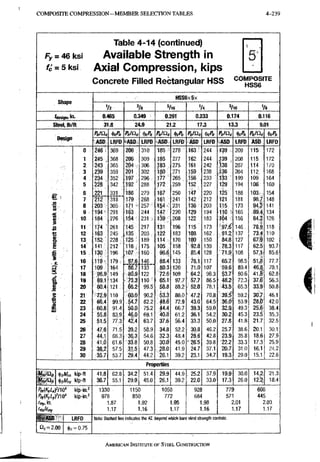

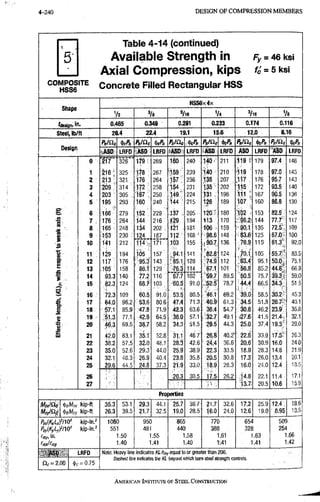

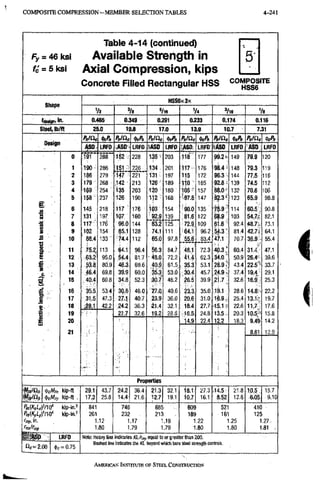

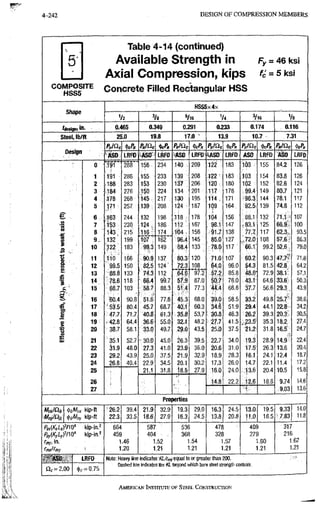

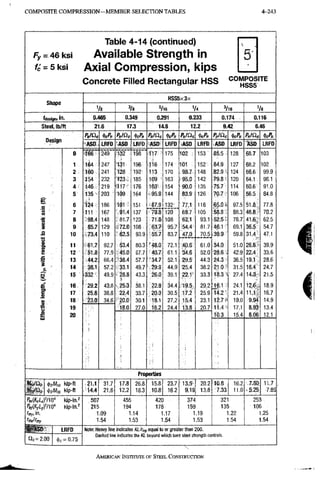

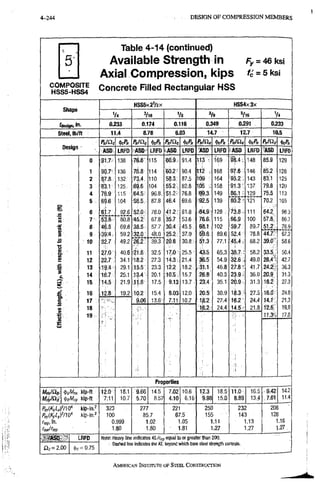

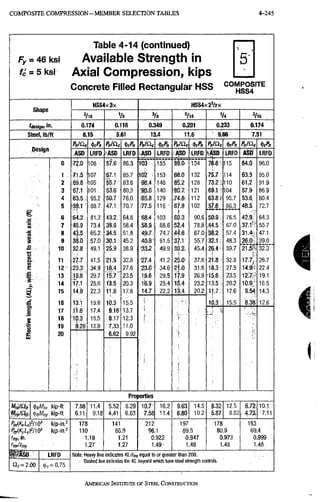

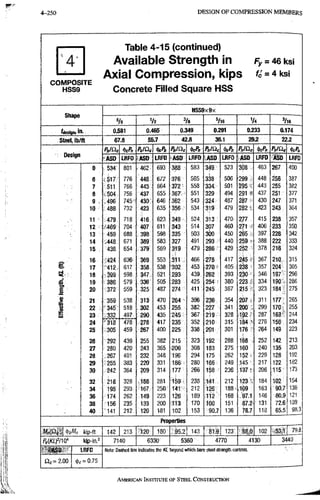

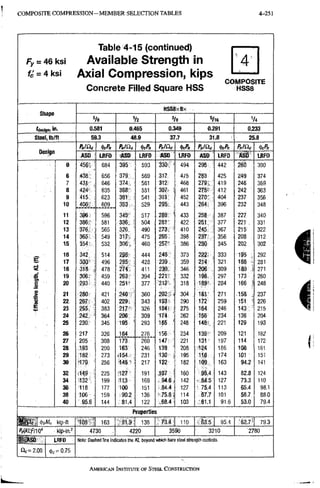

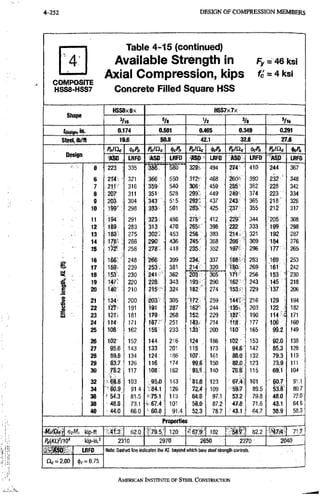

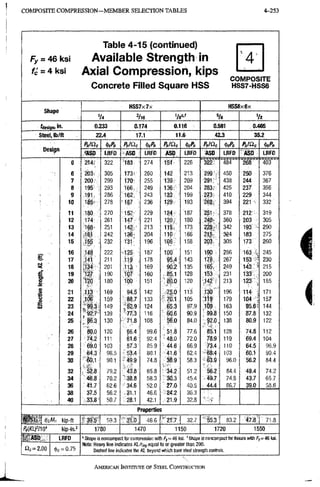

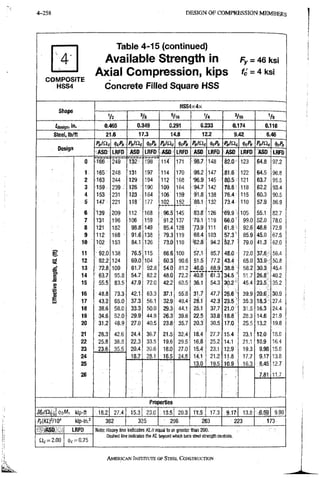

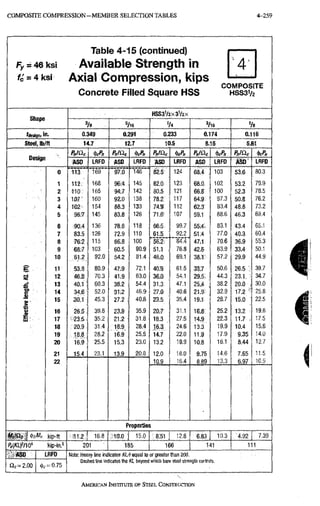

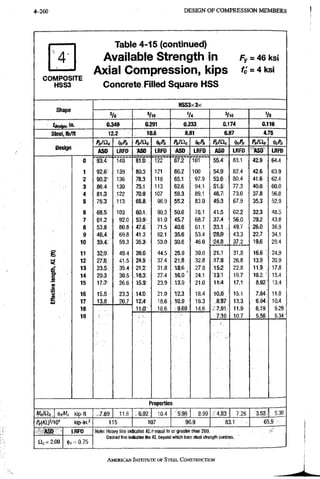

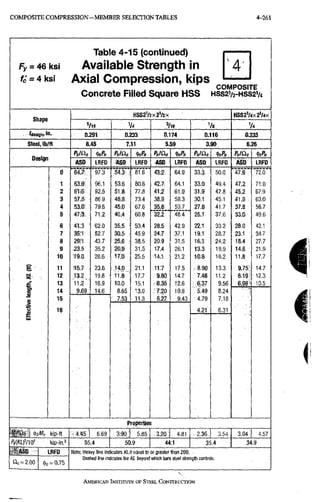

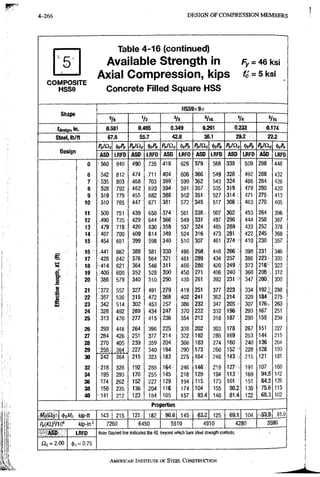

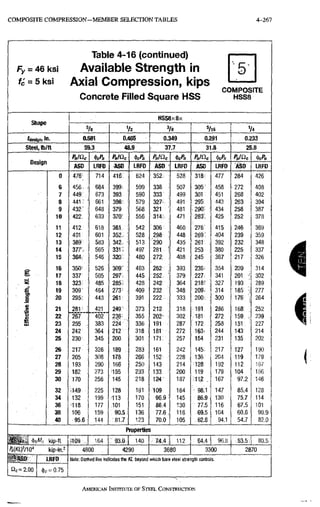

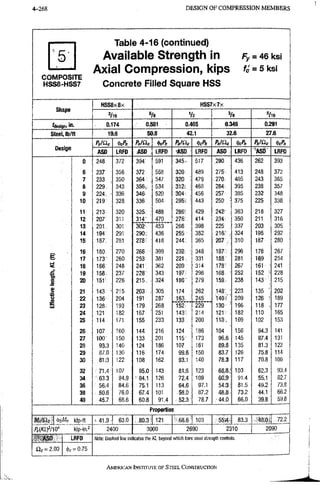

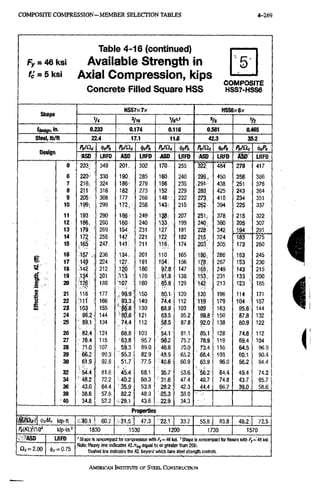

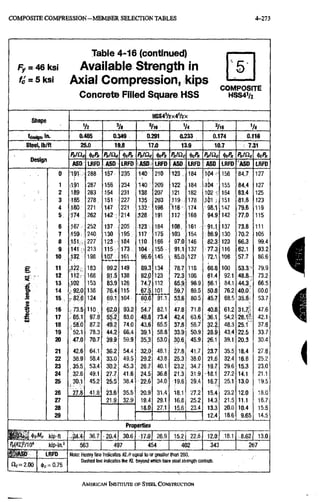

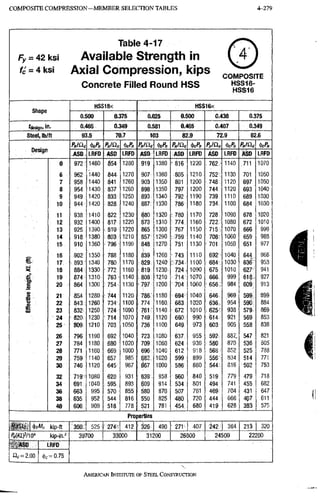

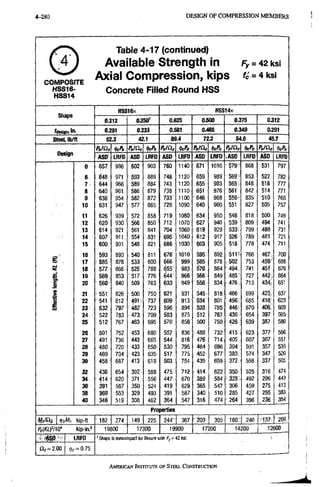

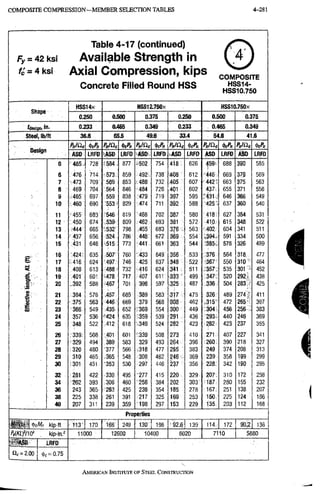

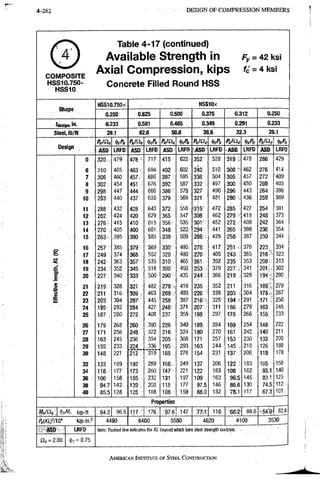

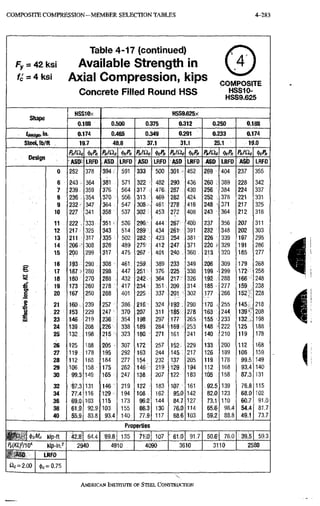

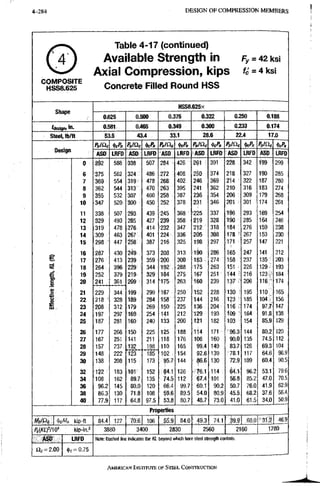

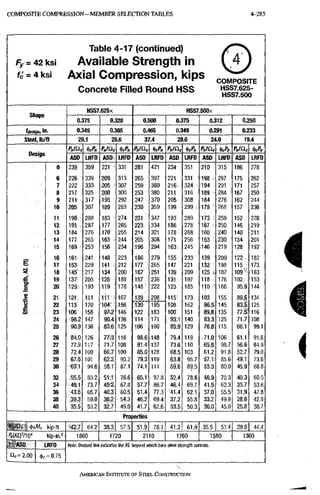

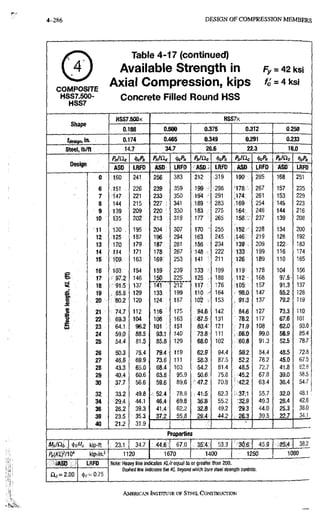

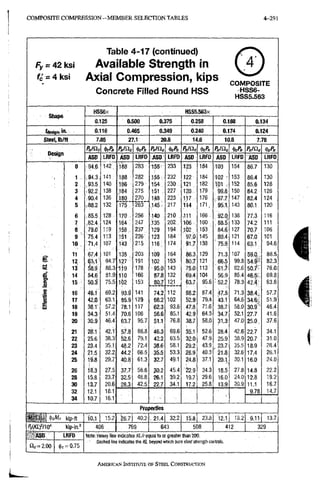

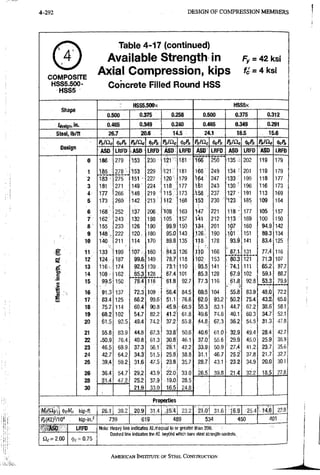

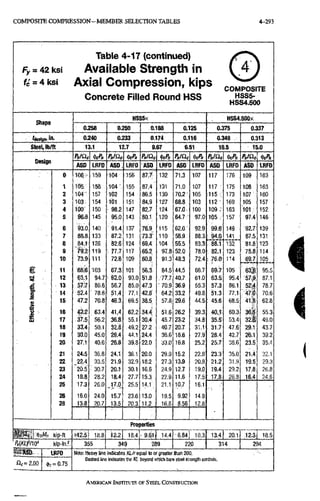

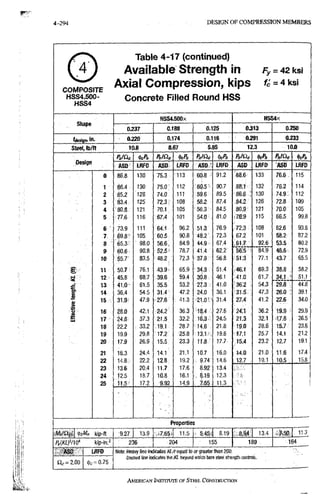

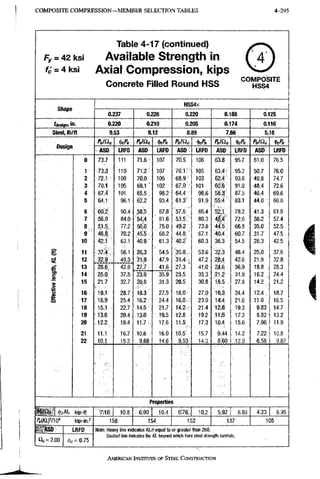

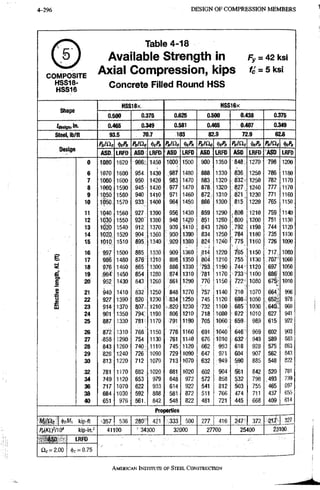

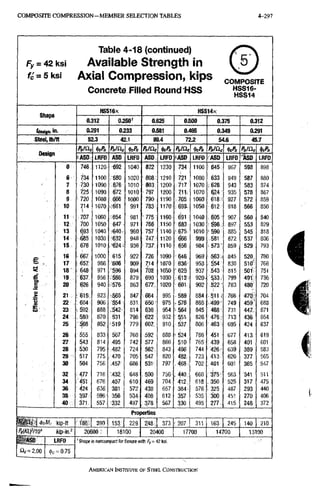

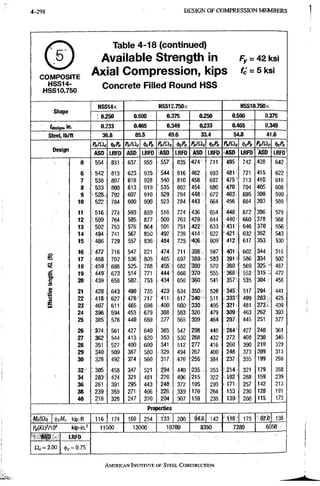

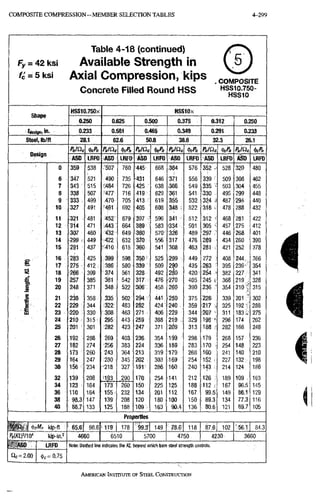

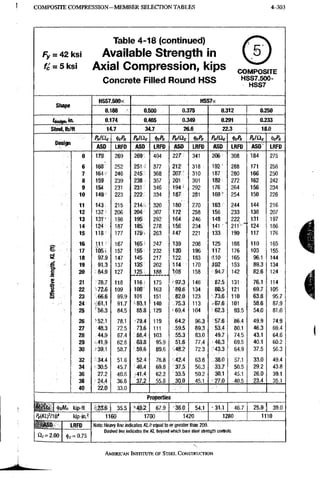

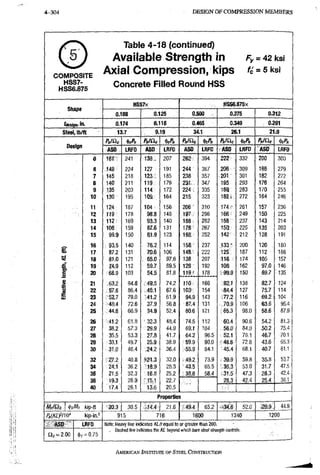

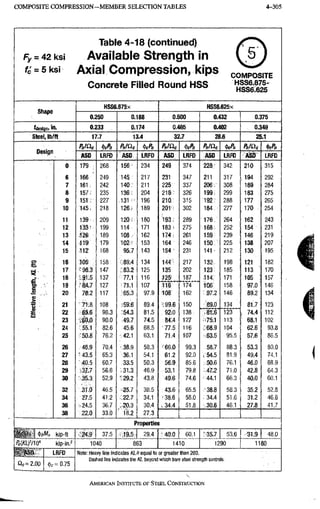

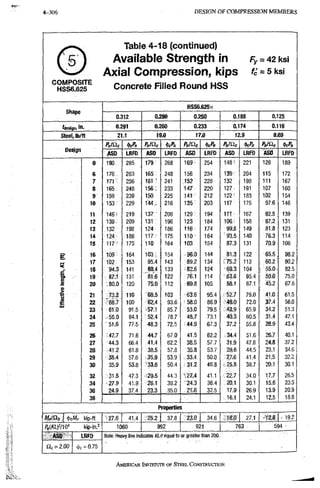

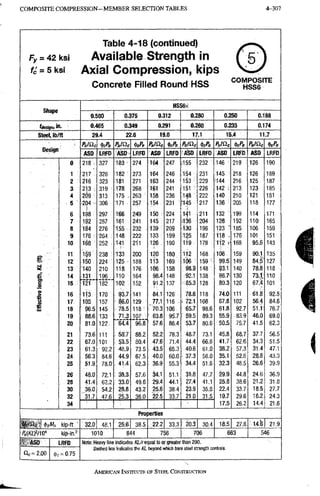

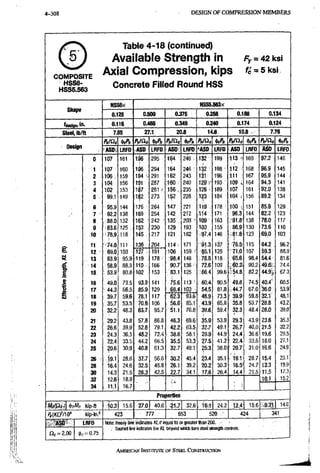

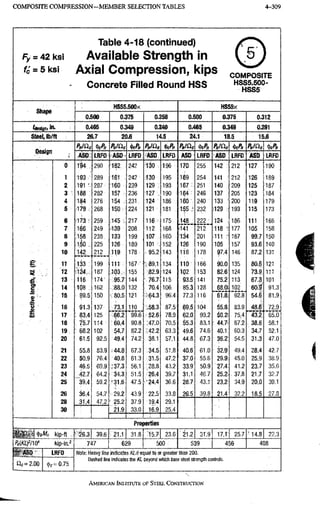

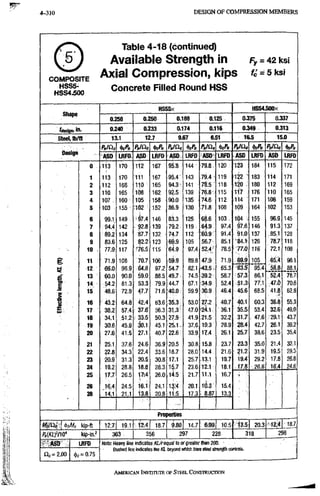

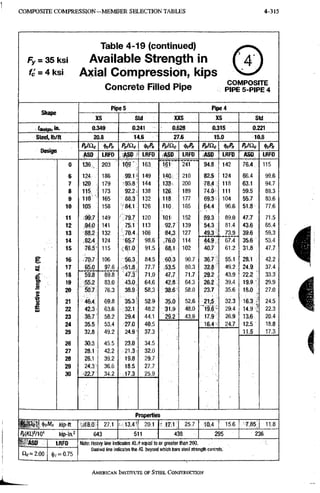

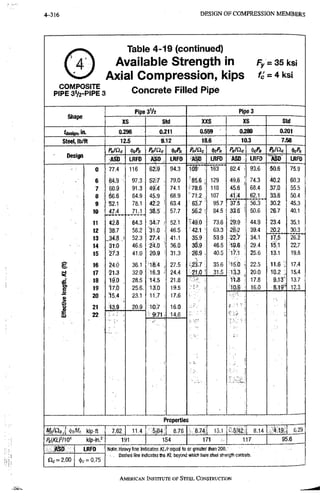

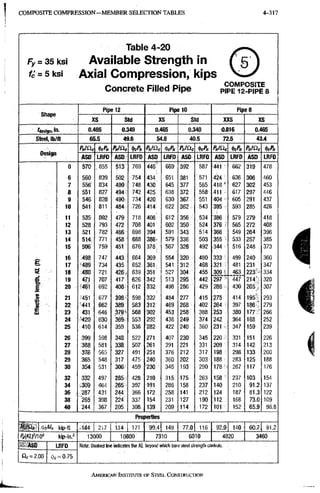

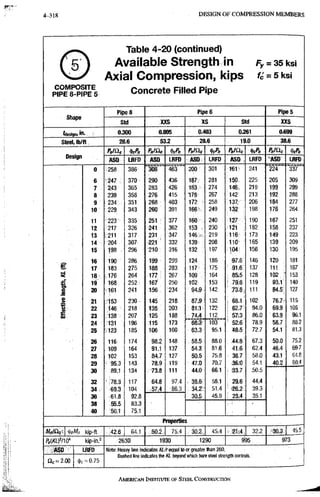

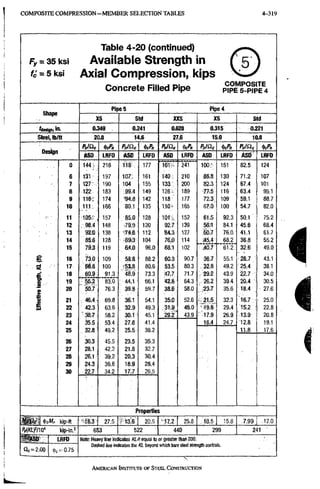

COMPOSITE COMPRESSION MEMBERS

For the design of encased composite and filled composite compression members, see AISC

Specification Section 12. See also AISC Design Guide 6, Load and Resistance Factor

Design ofW-Shapes Encased in Concrete (Griffis, 1992). For further information on com-

posite design and construction, see also Viest et al. (1997).

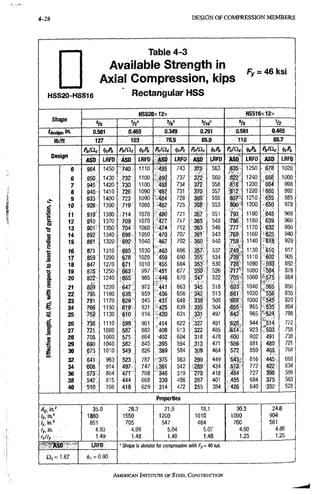

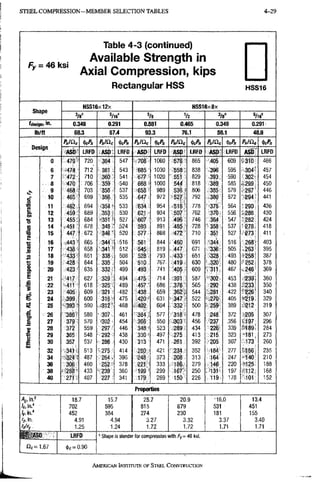

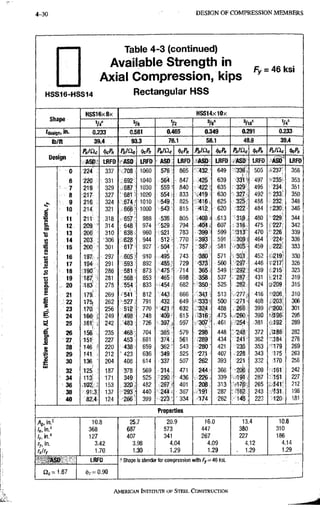

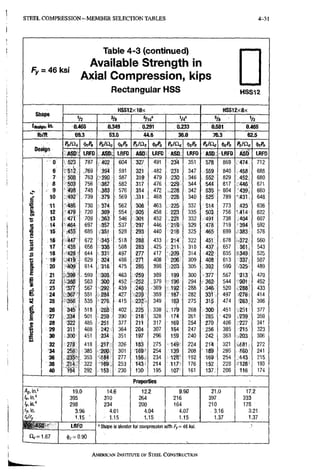

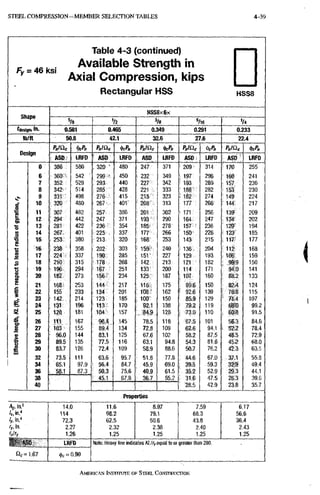

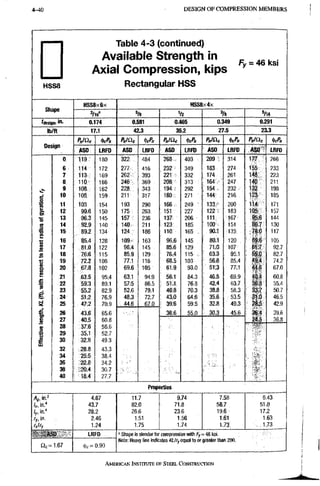

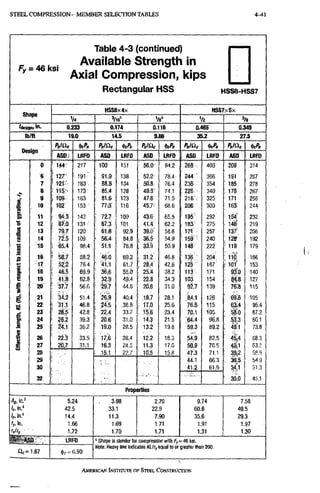

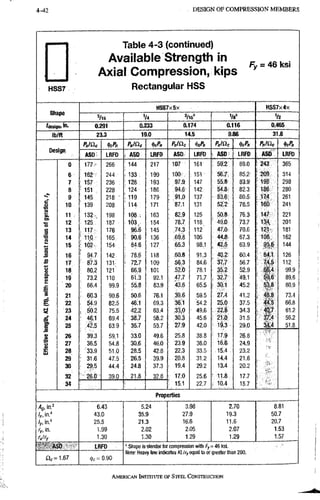

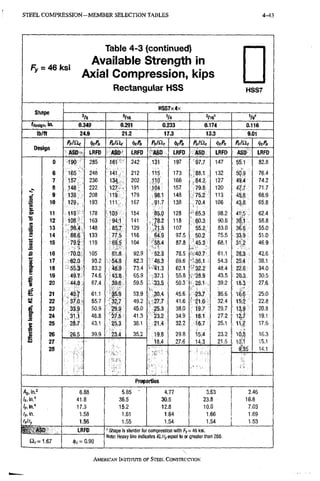

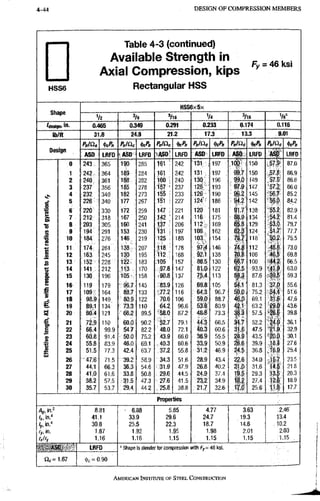

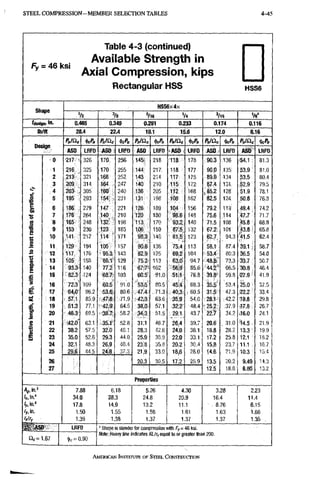

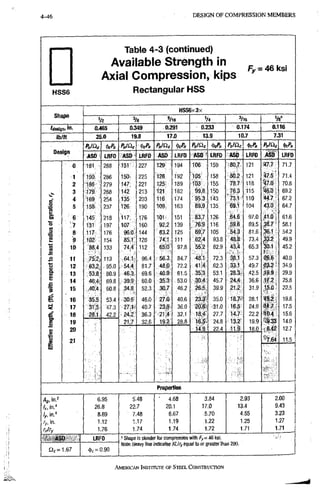

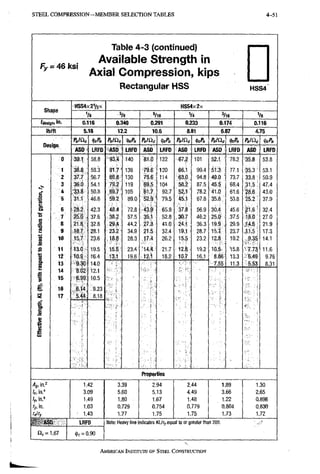

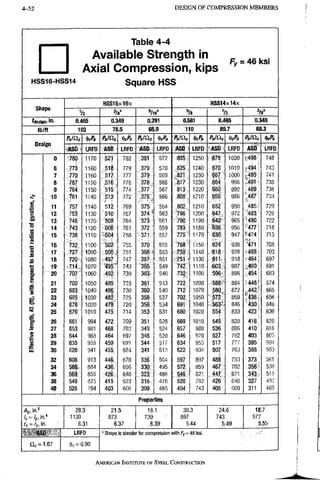

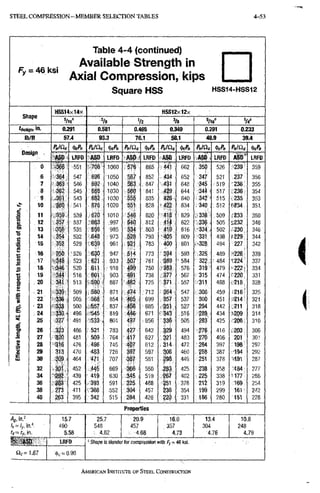

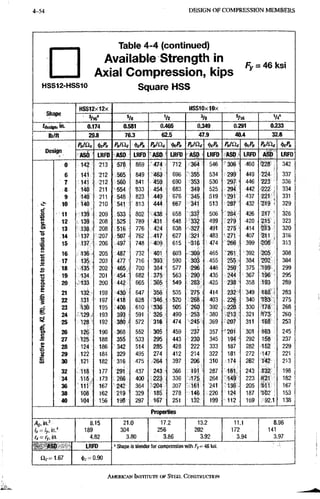

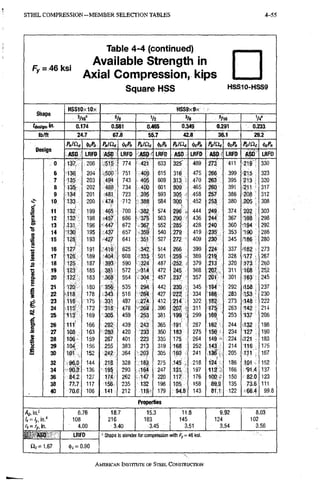

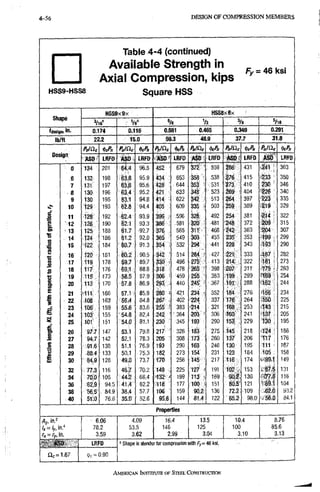

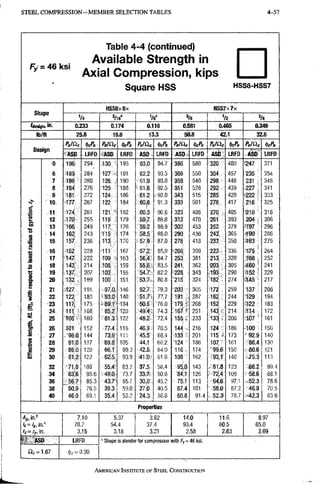

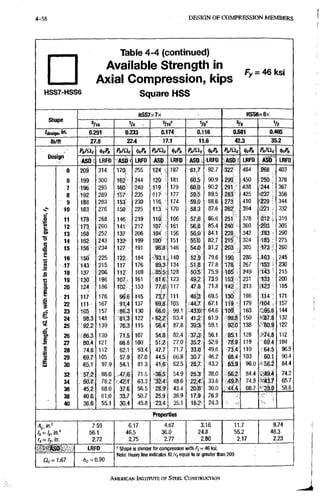

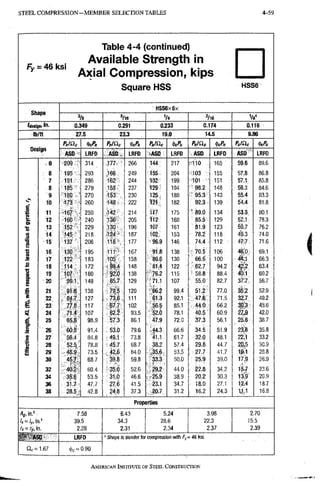

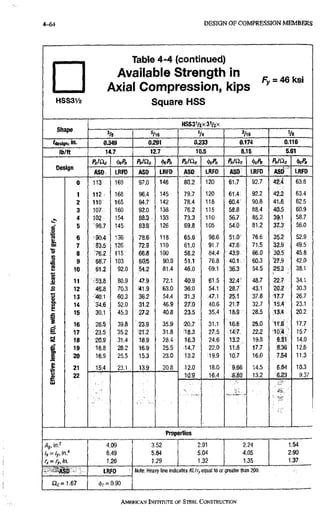

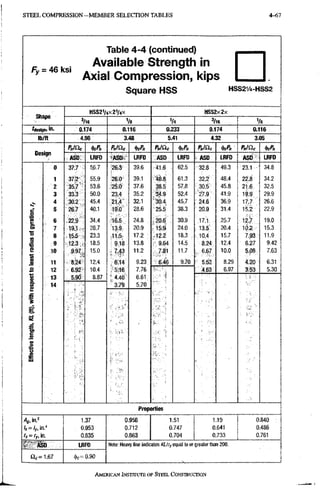

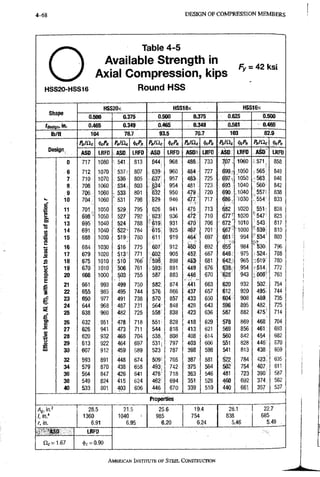

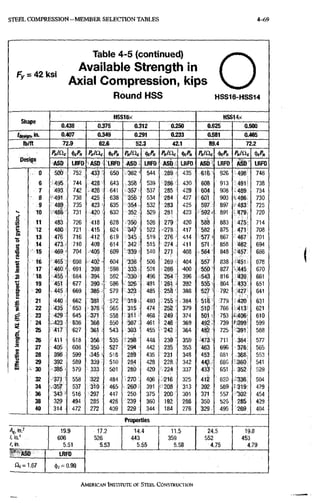

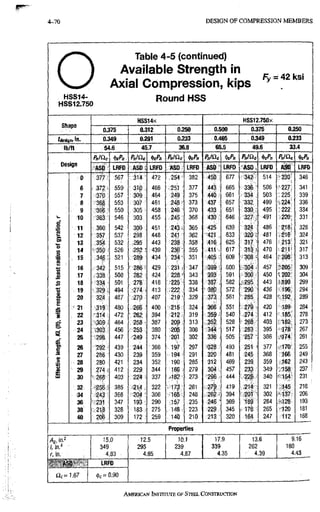

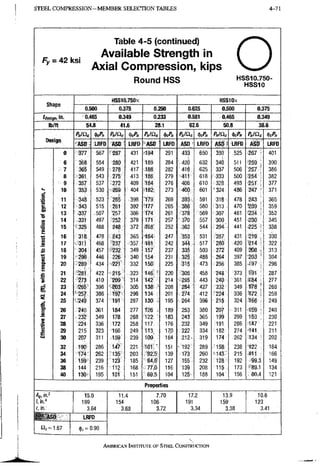

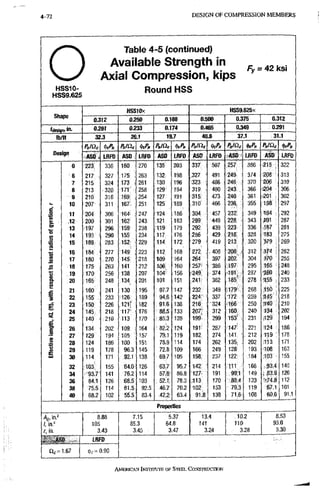

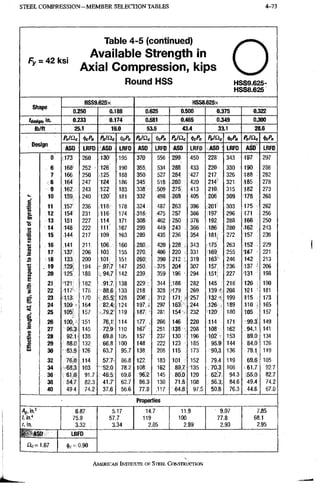

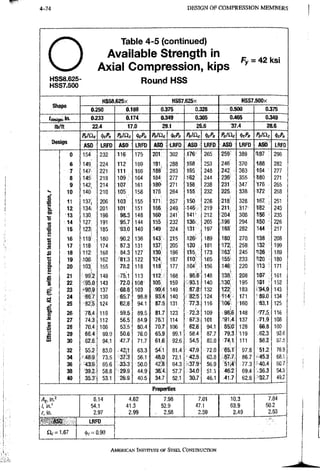

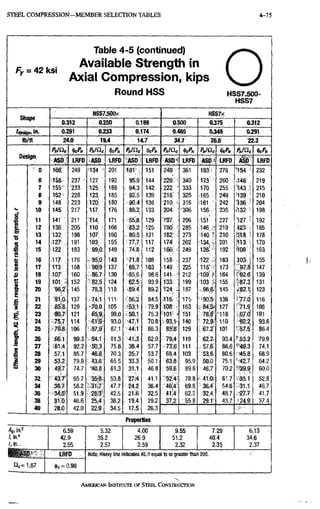

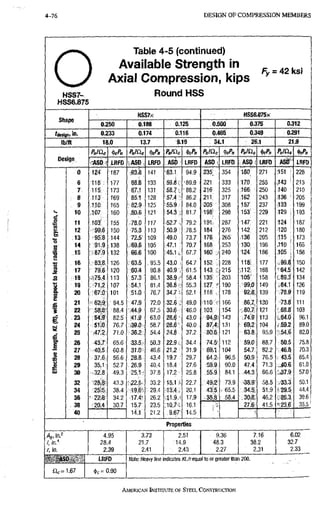

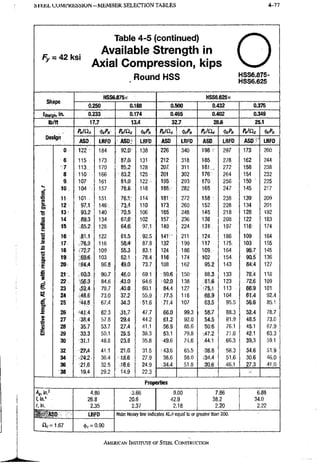

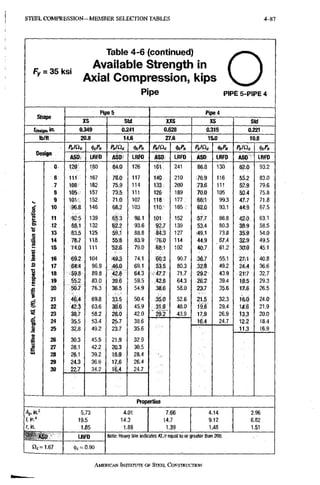

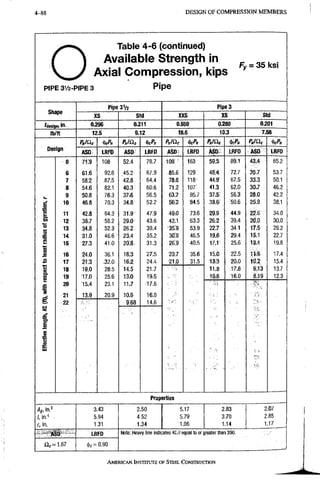

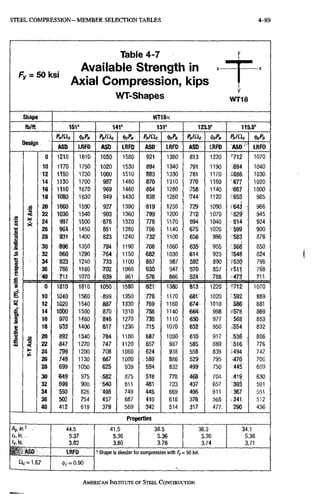

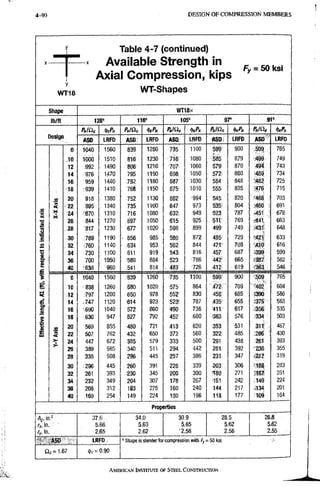

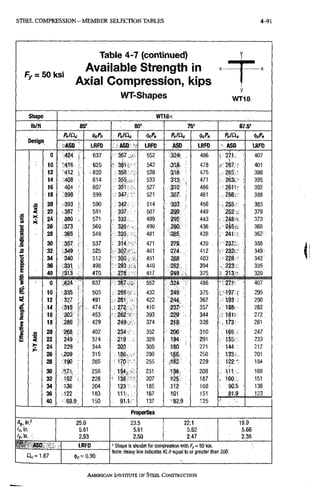

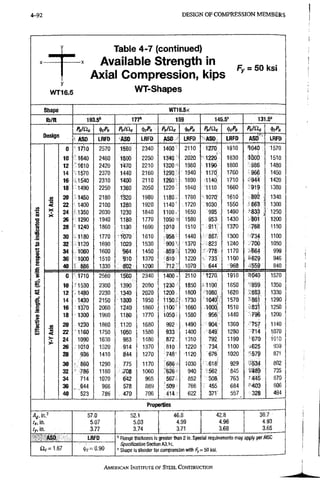

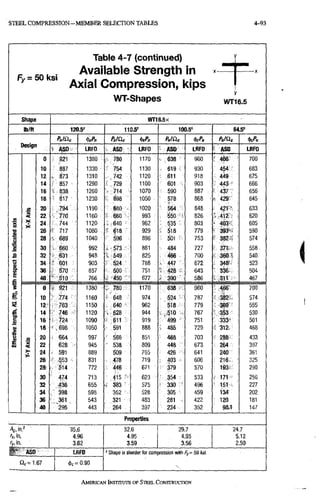

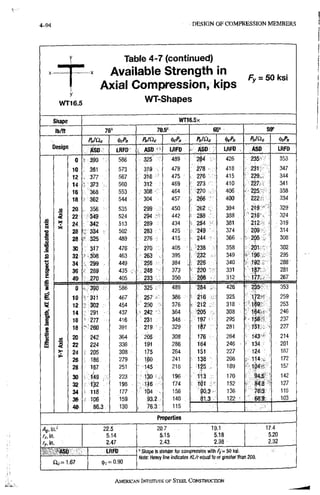

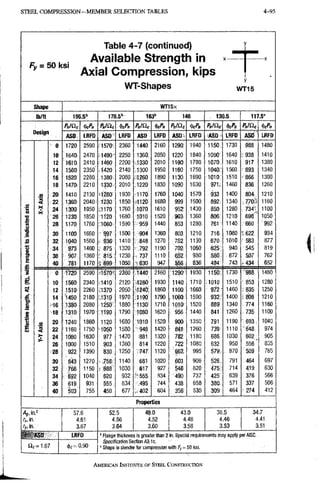

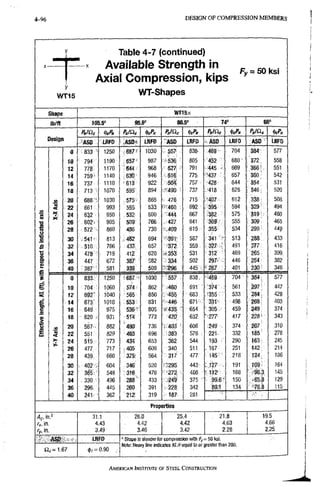

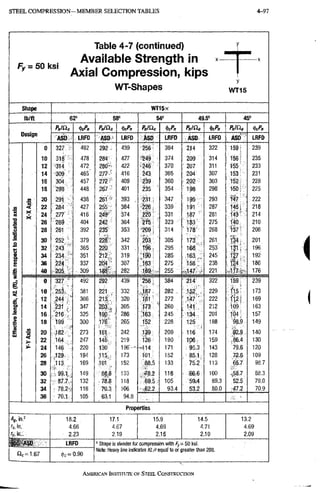

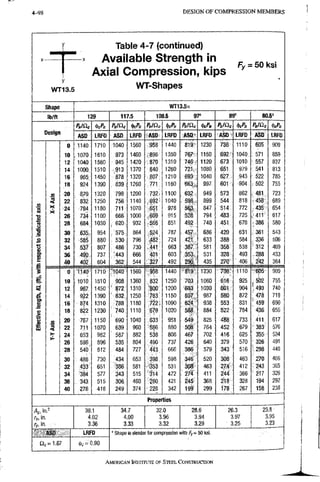

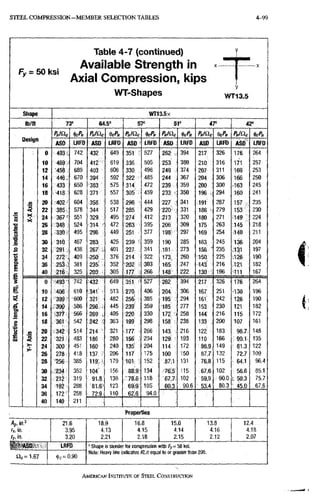

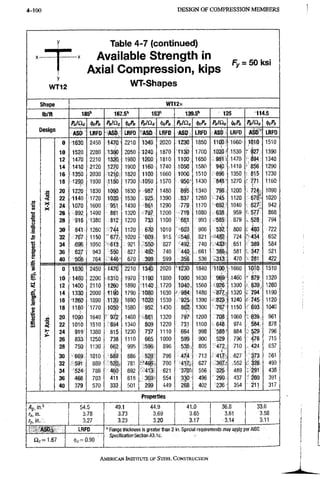

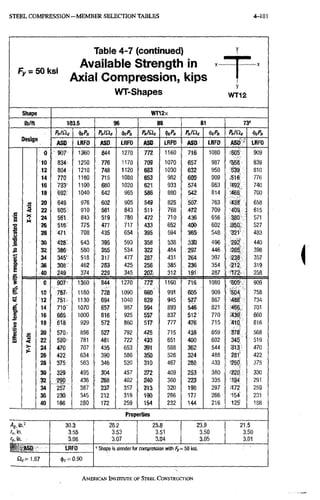

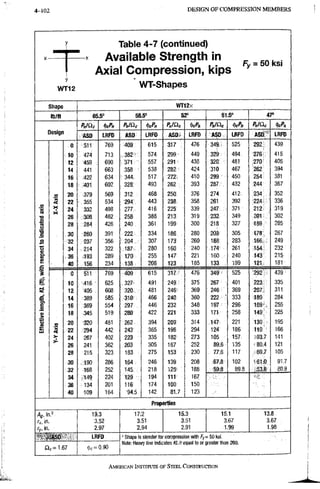

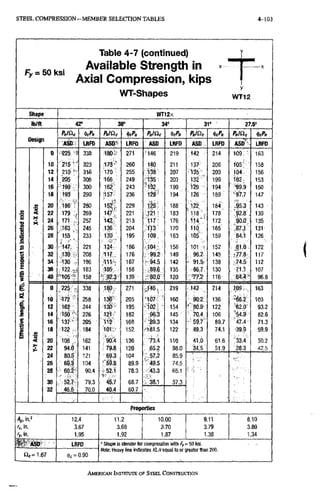

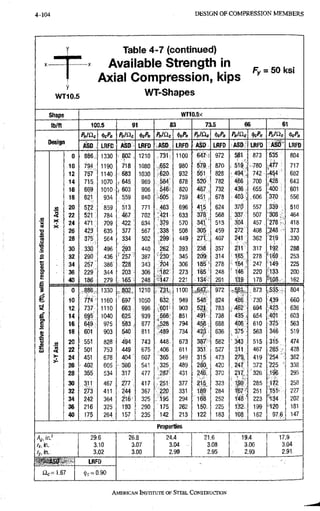

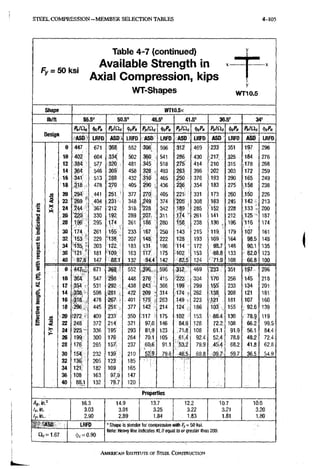

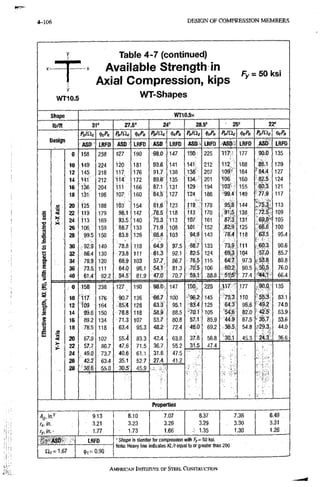

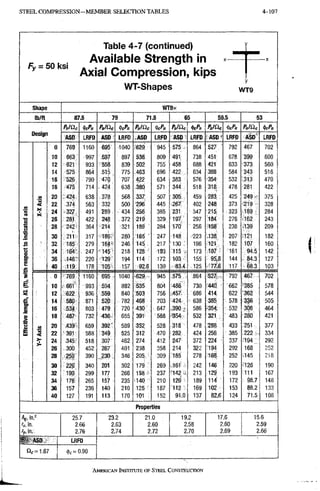

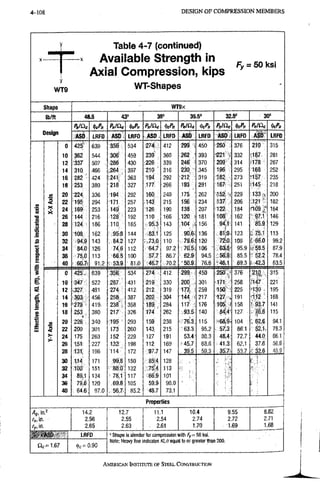

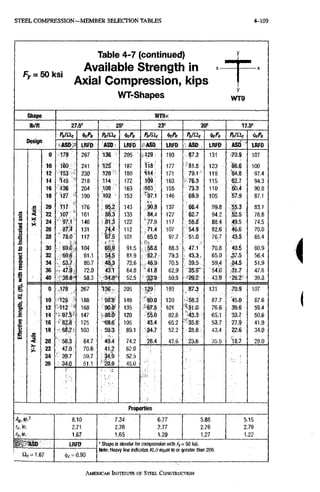

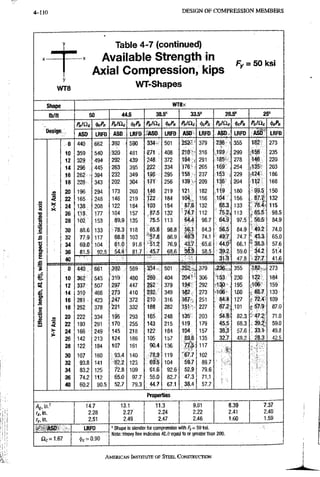

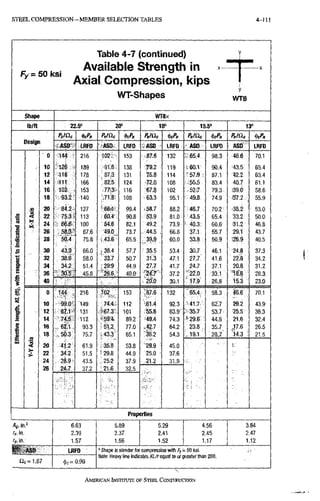

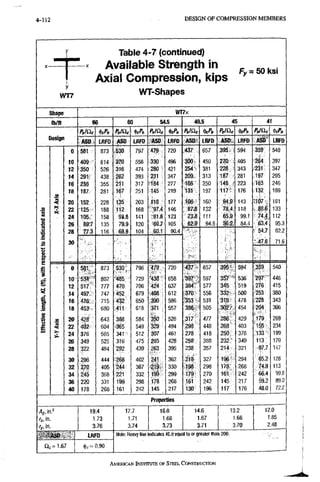

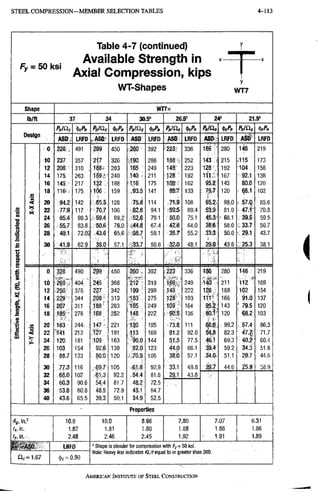

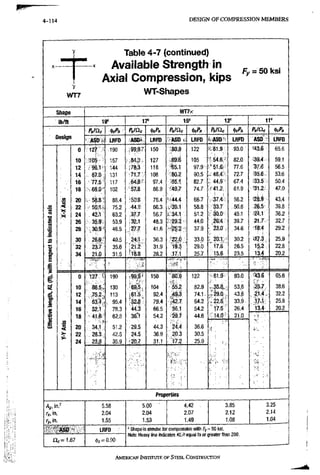

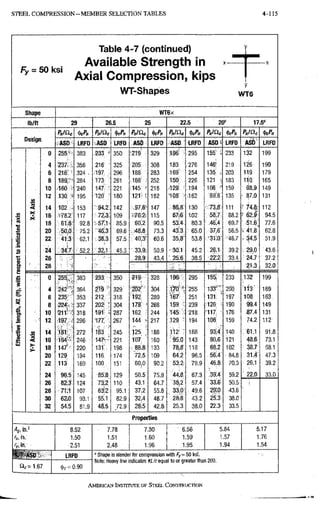

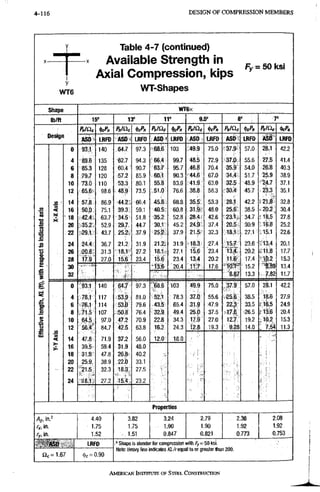

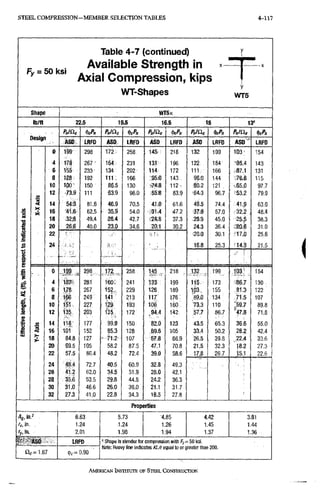

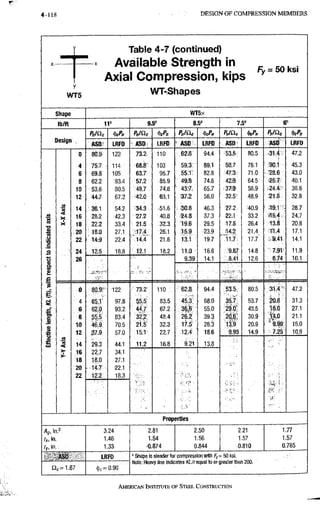

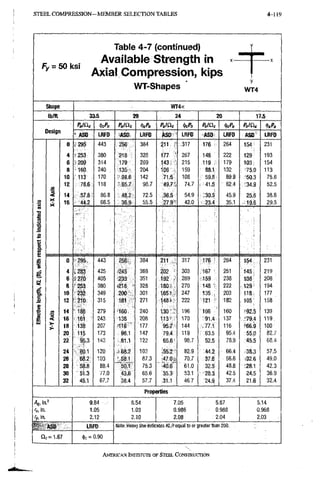

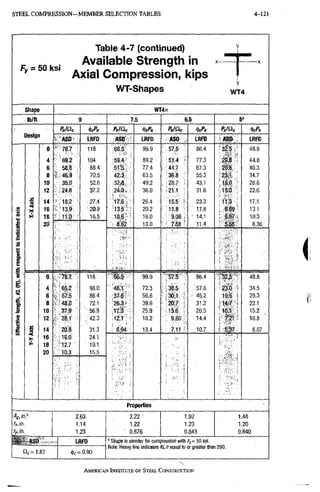

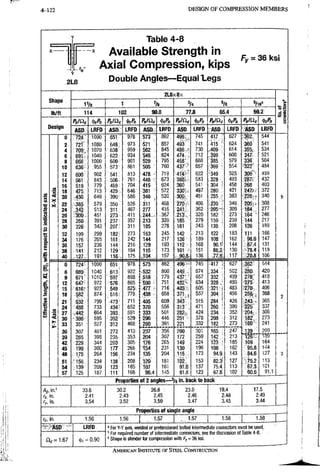

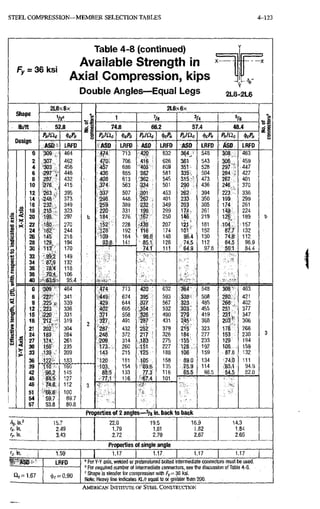

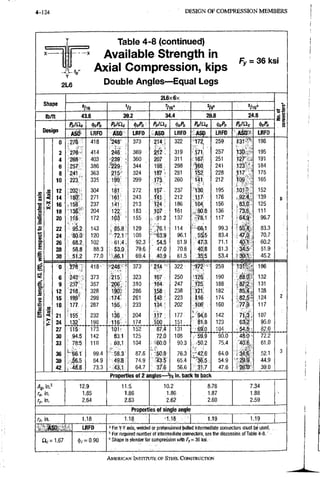

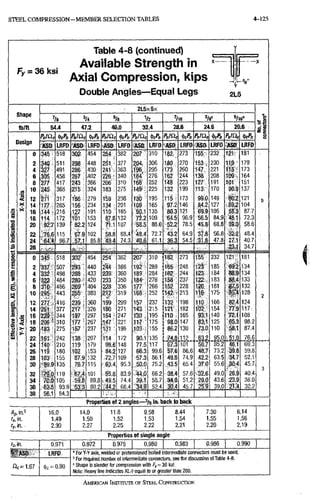

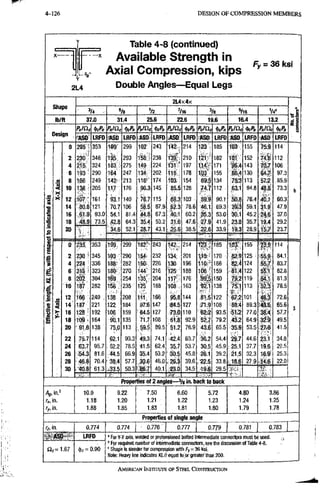

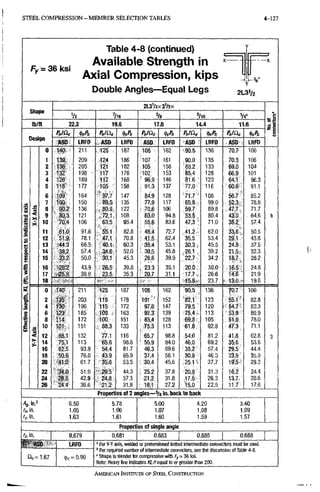

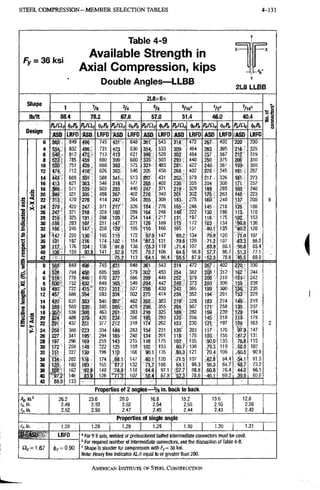

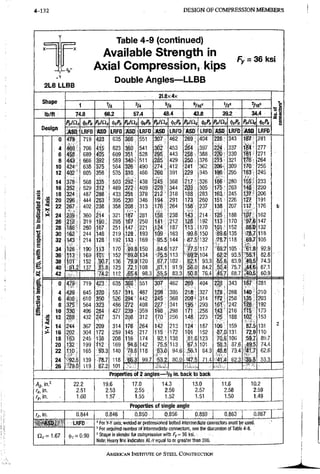

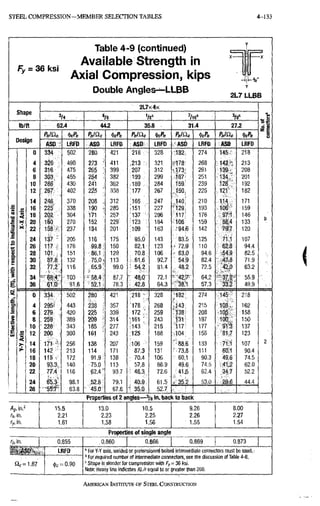

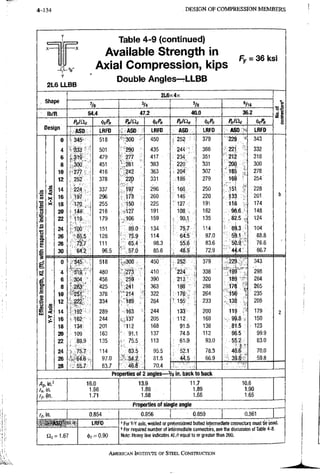

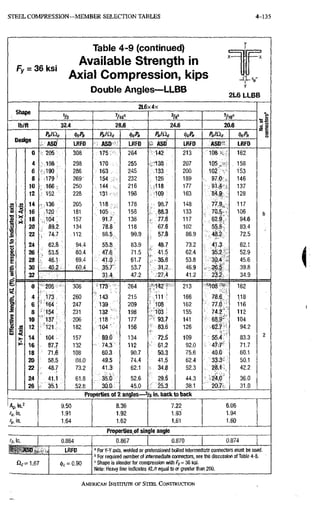

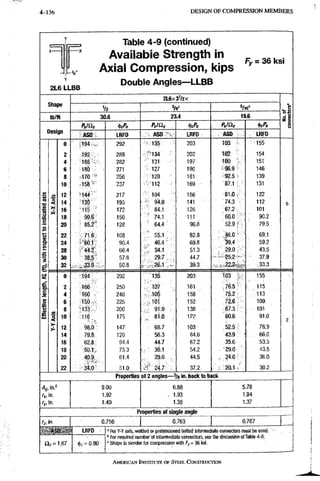

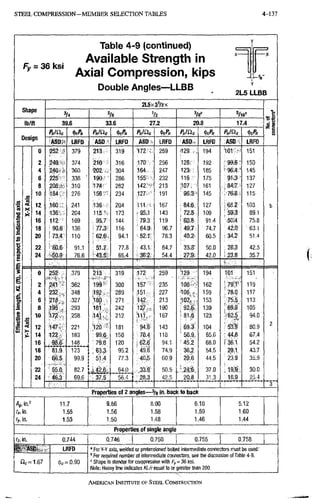

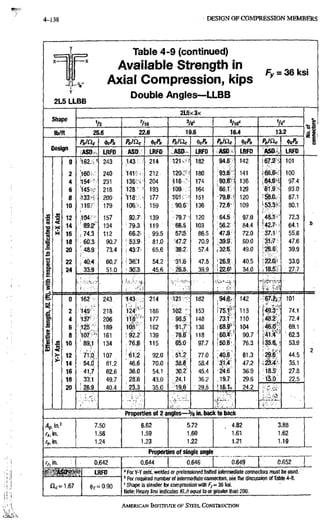

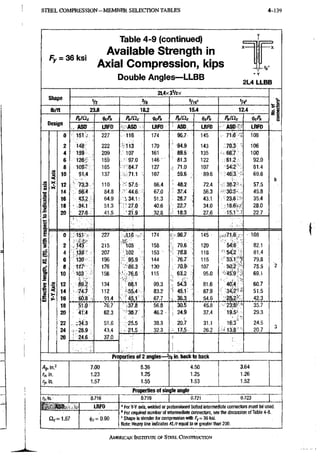

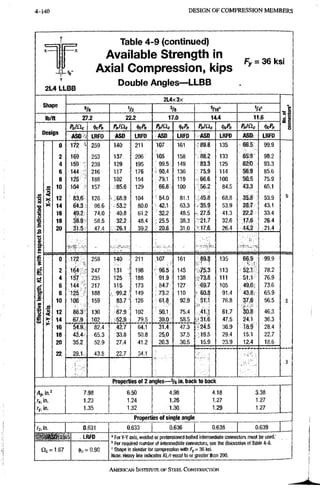

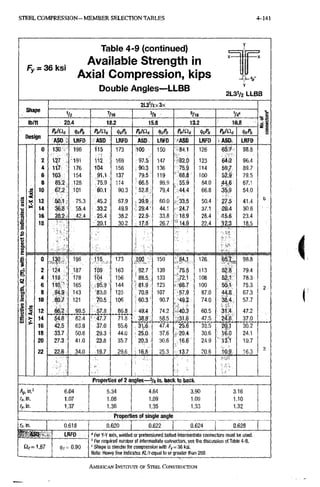

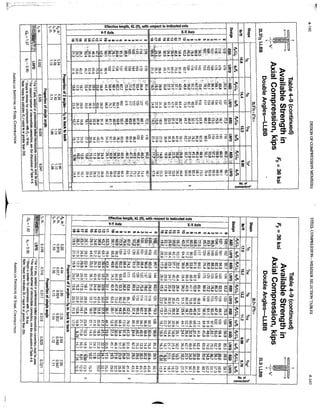

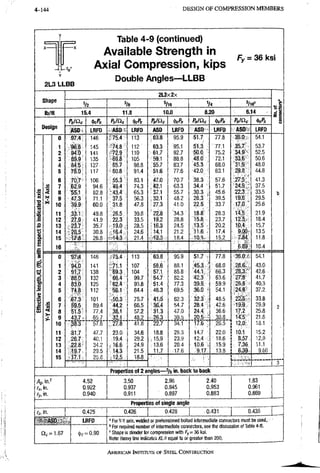

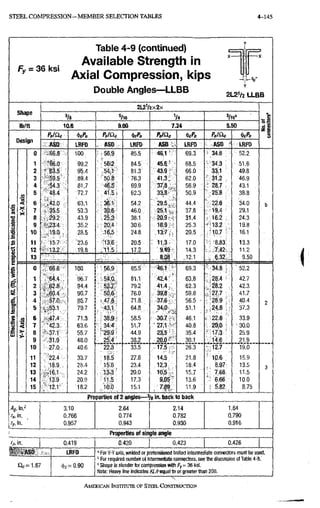

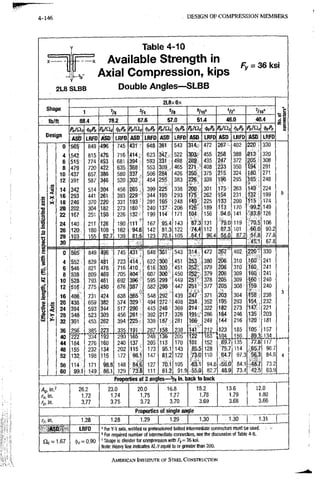

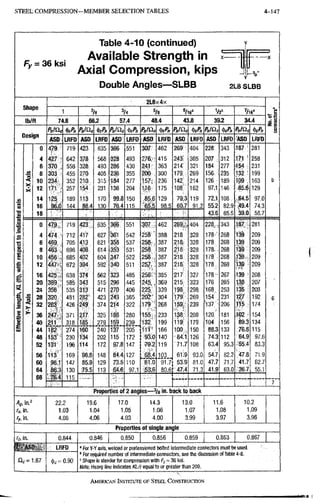

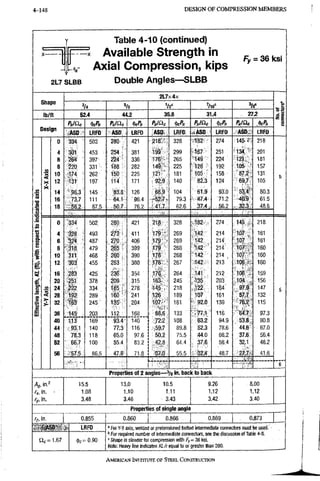

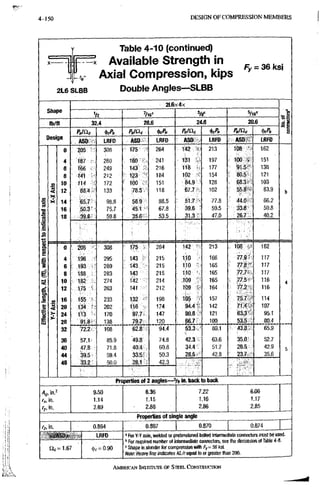

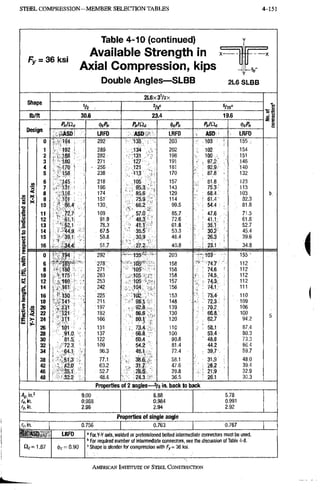

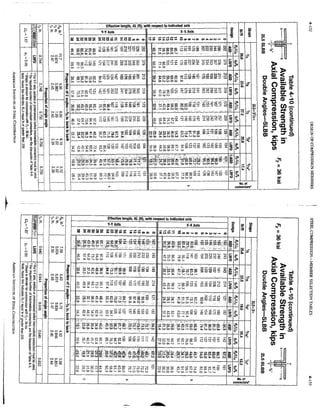

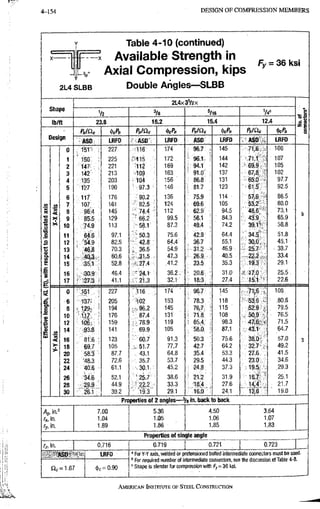

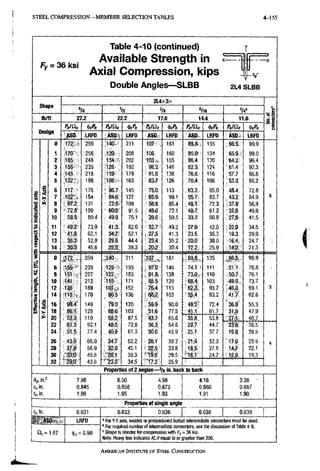

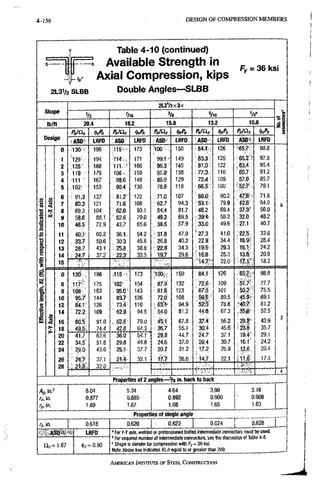

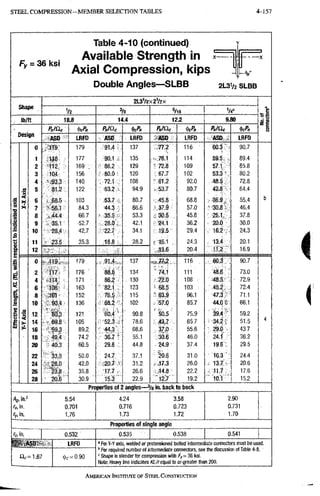

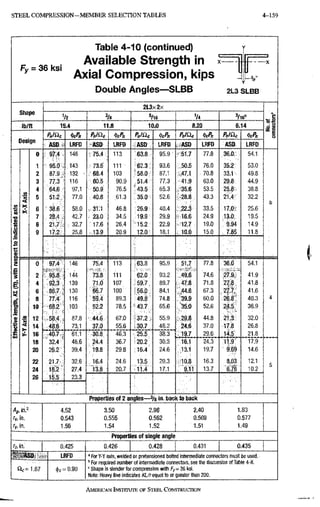

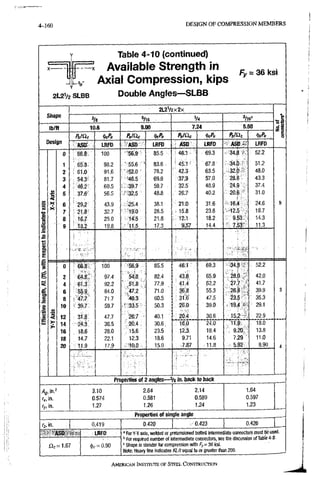

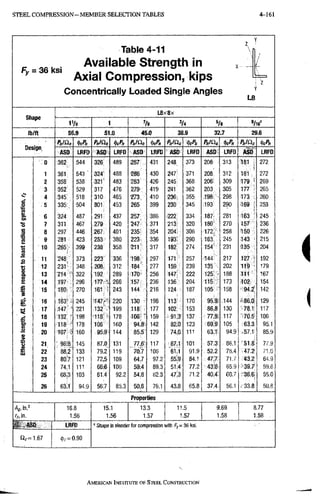

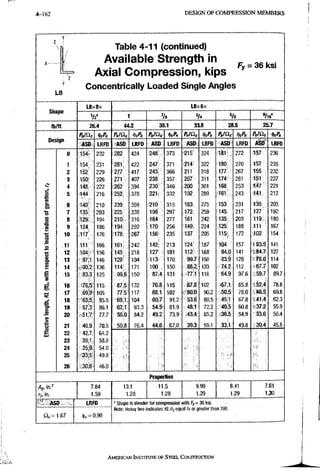

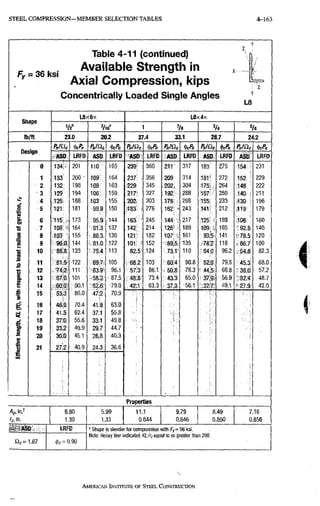

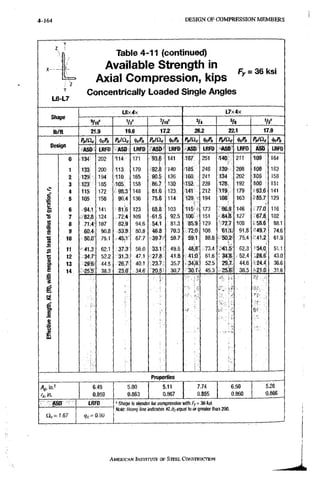

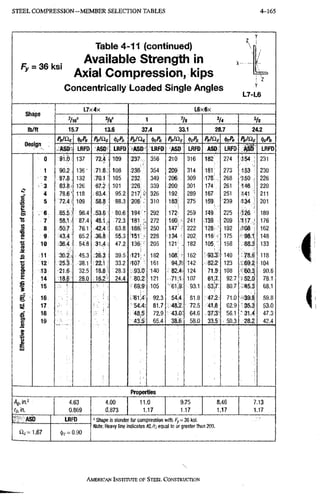

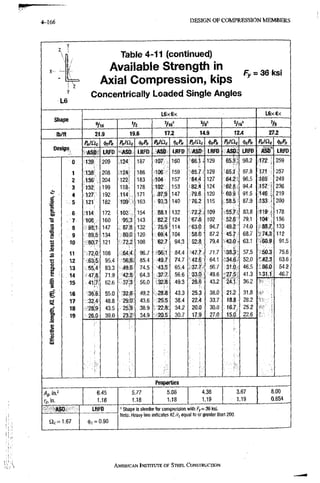

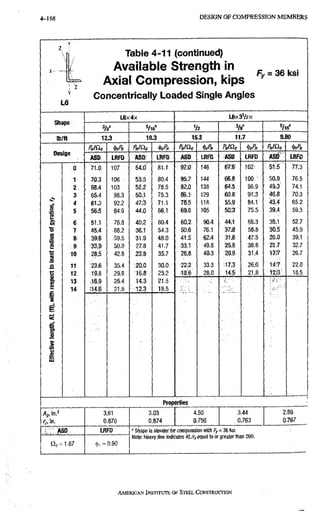

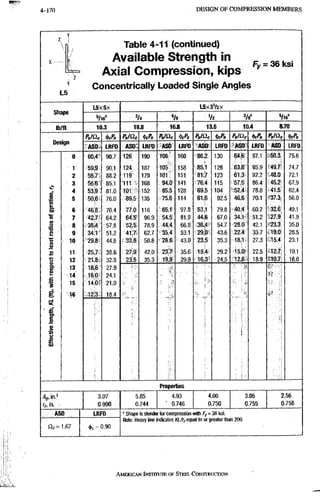

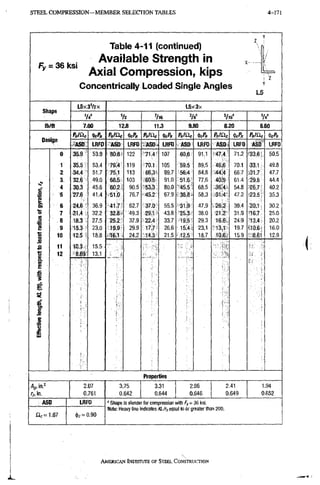

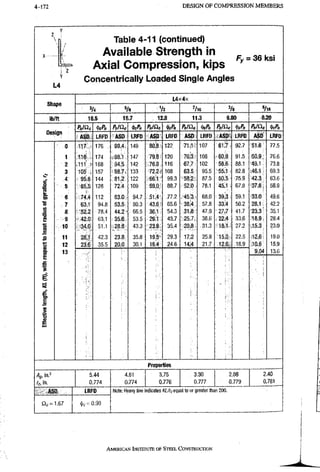

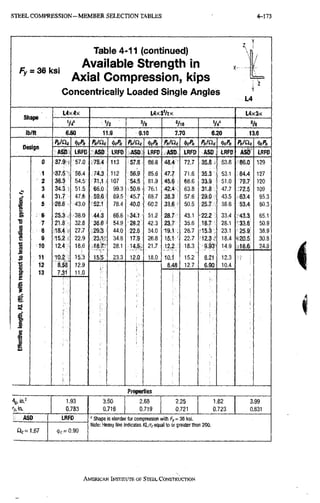

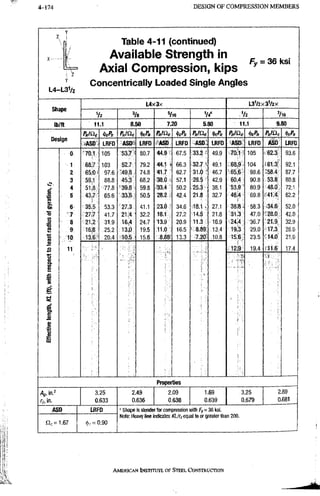

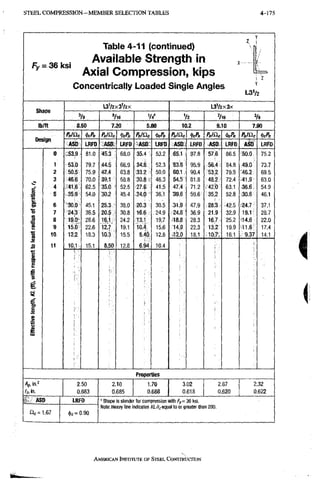

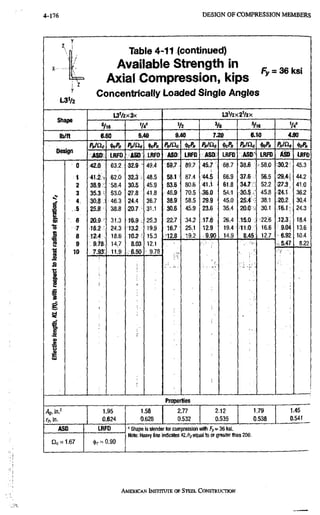

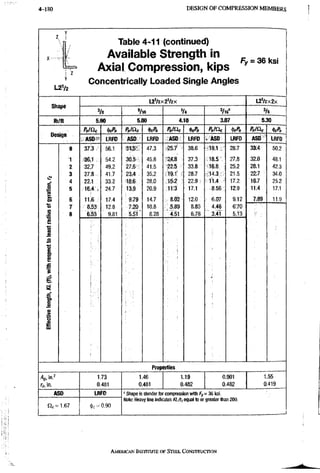

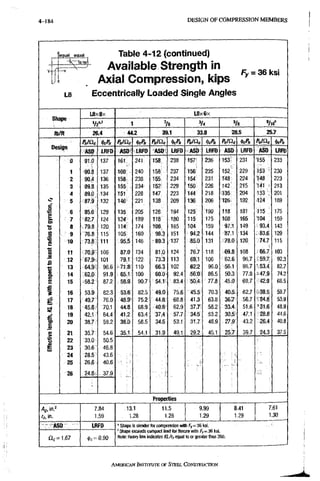

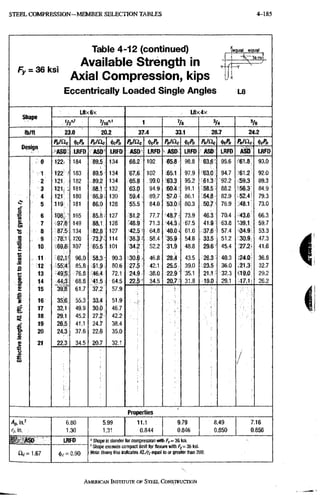

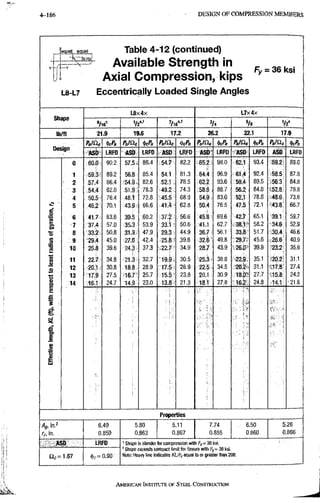

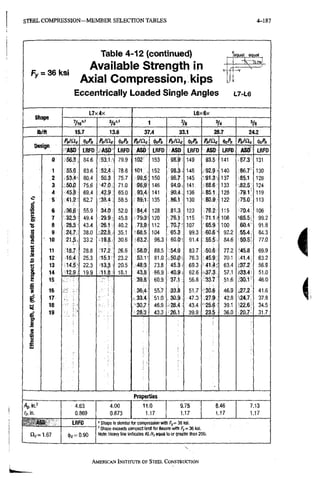

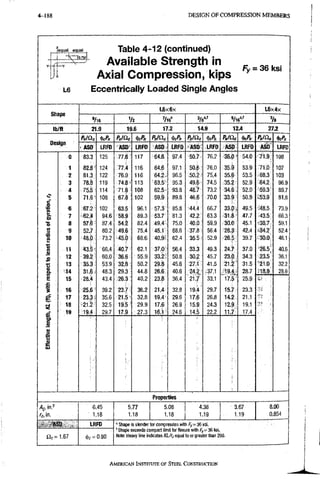

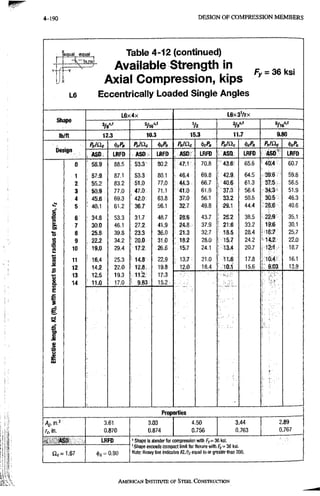

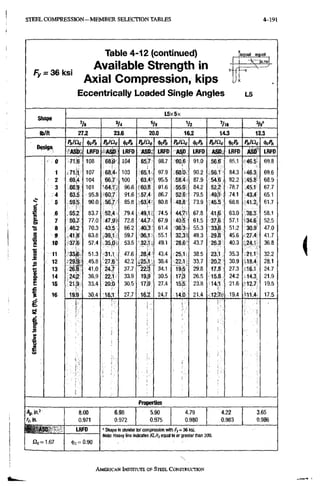

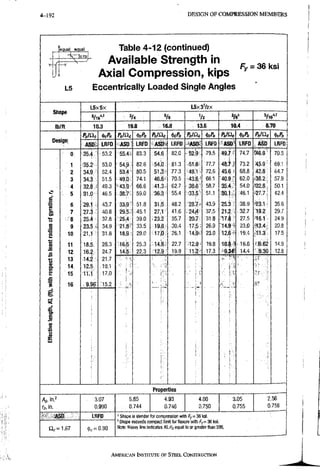

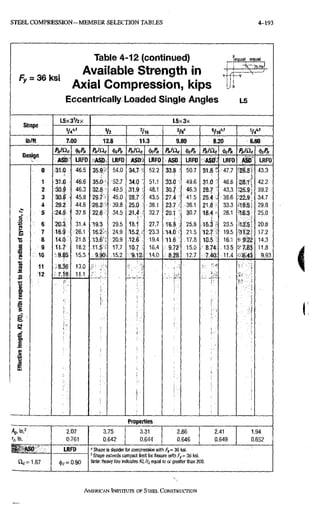

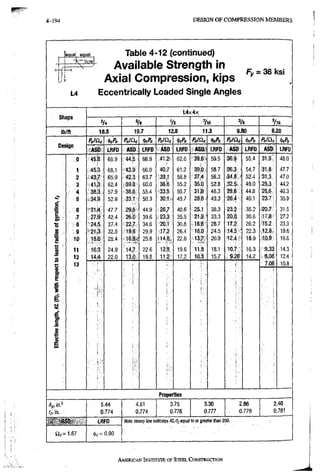

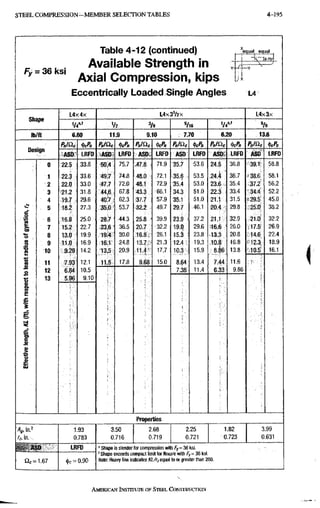

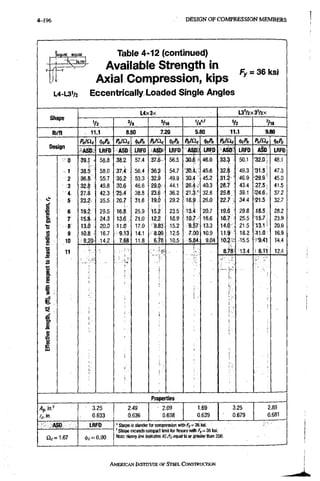

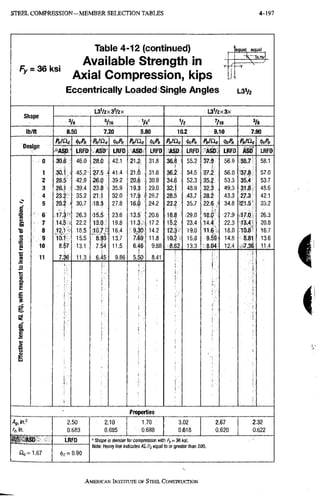

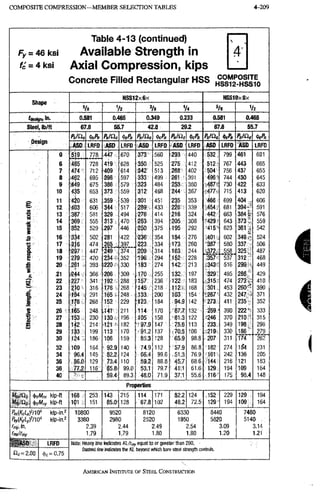

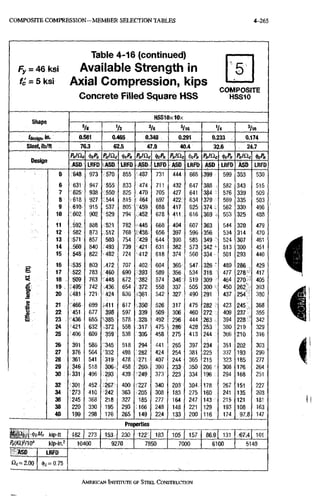

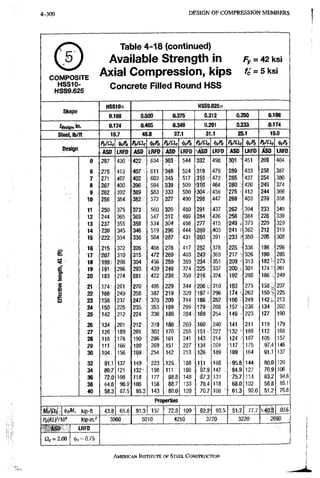

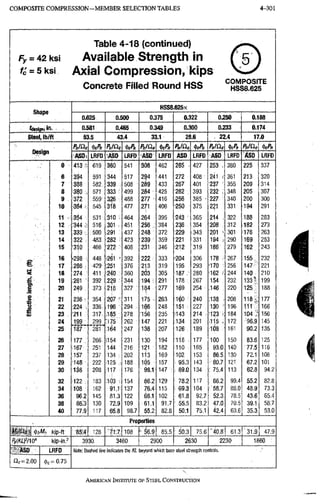

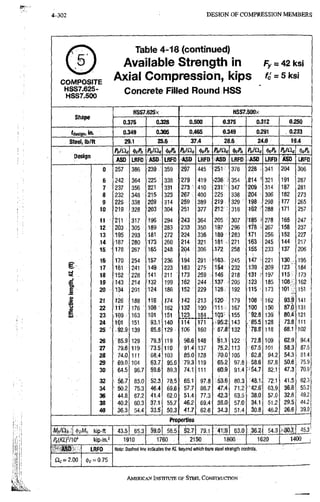

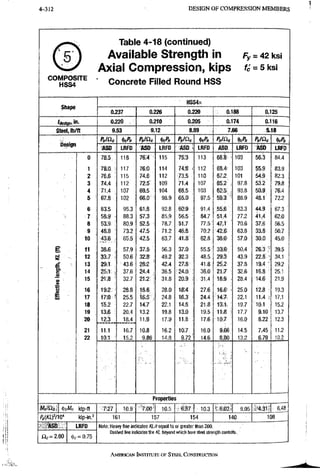

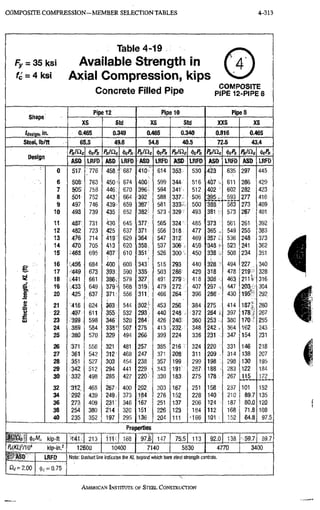

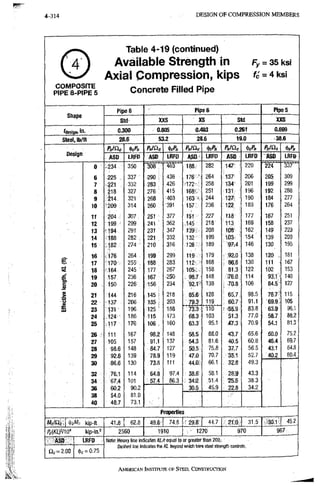

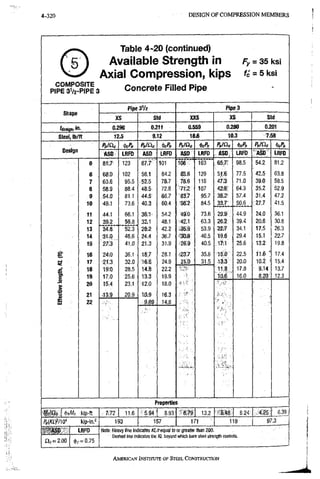

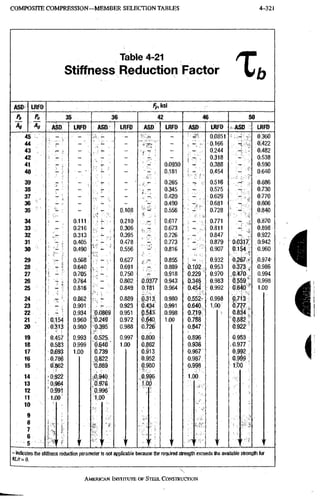

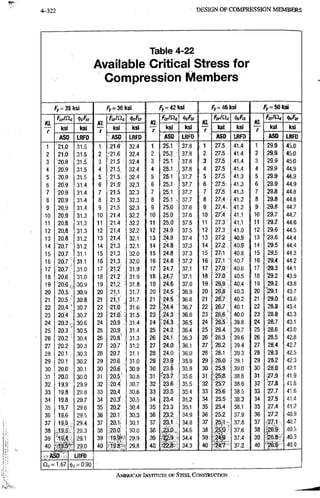

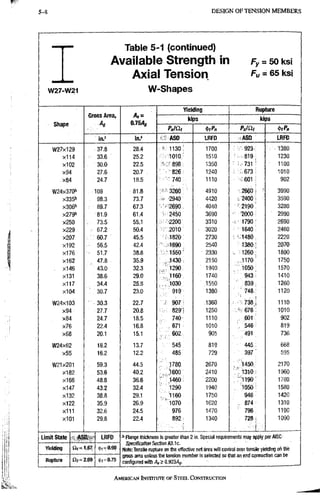

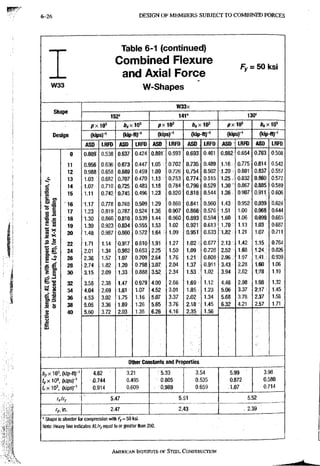

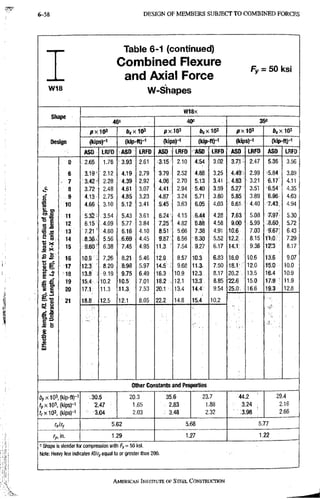

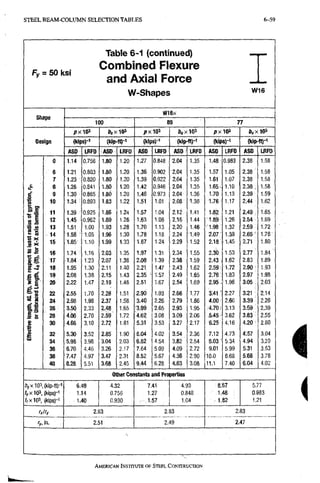

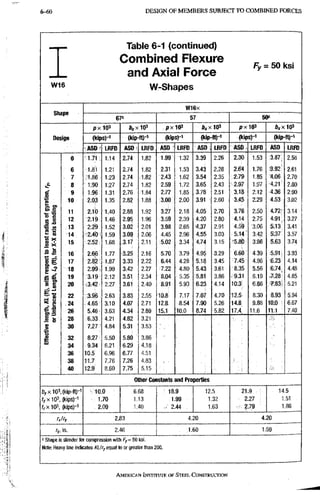

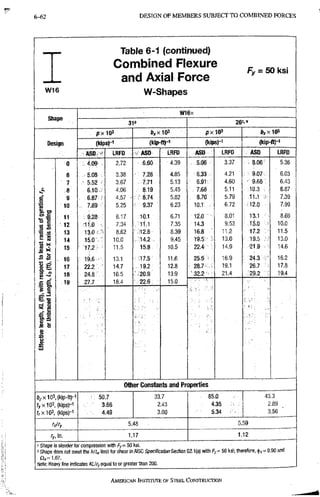

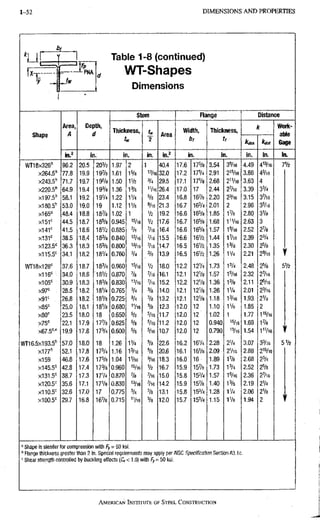

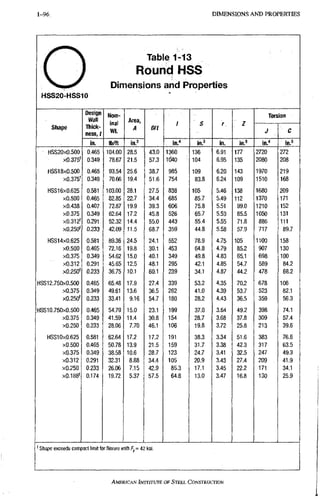

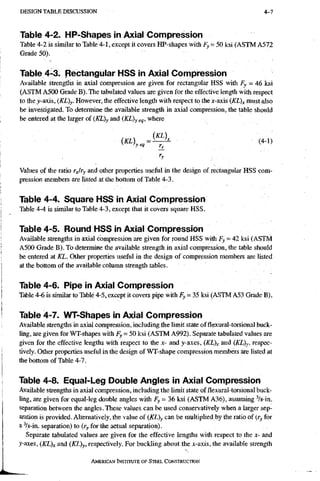

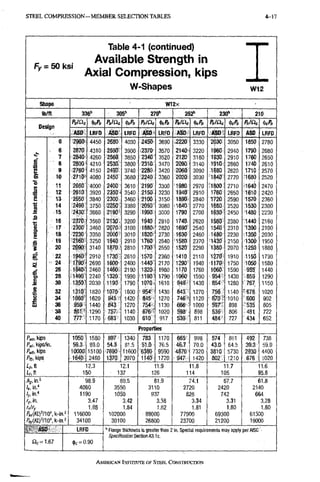

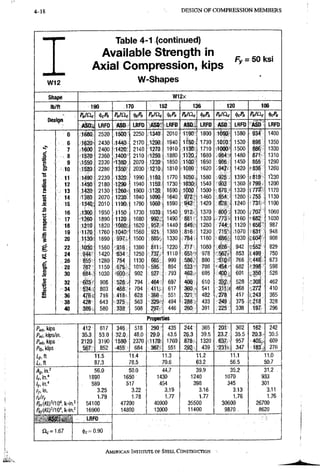

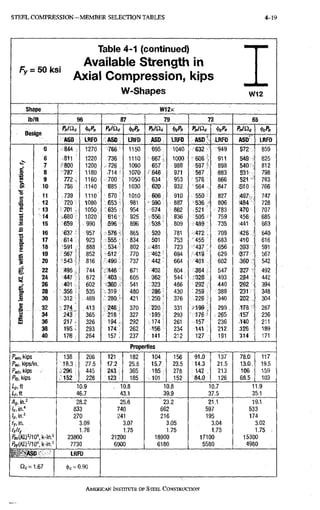

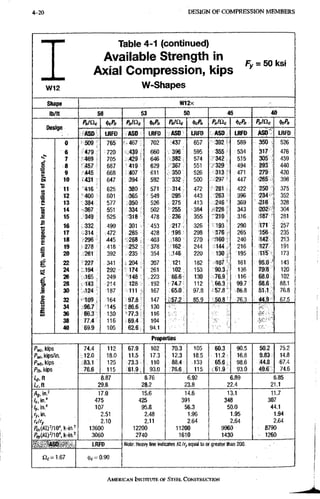

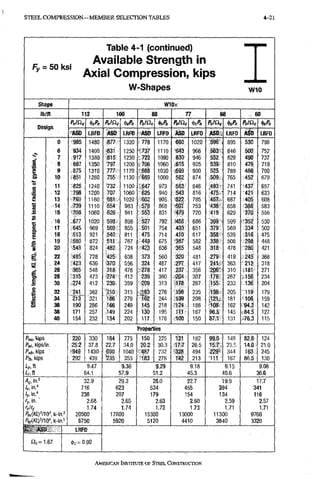

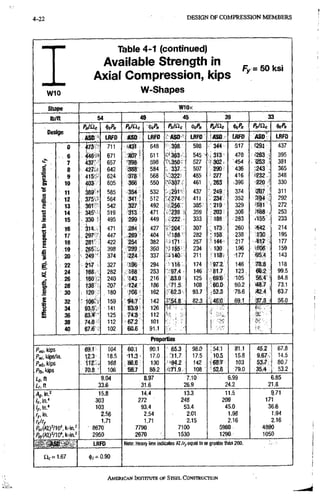

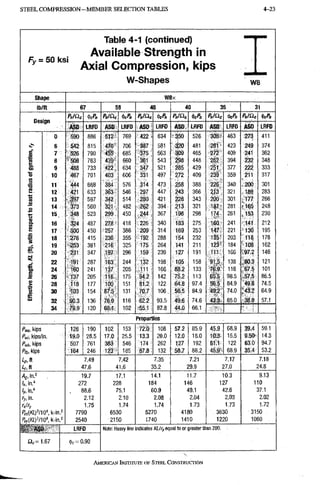

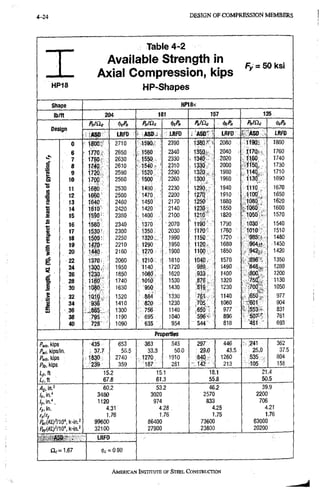

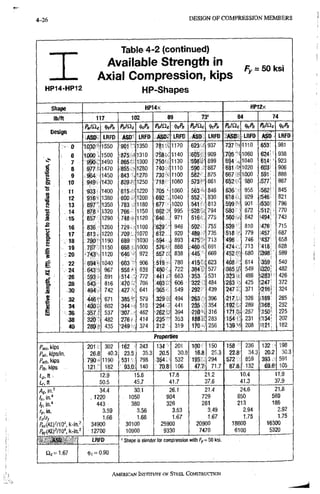

DESIGN TABLE DISCUSSION

Steel Compression—Member Selection Tables

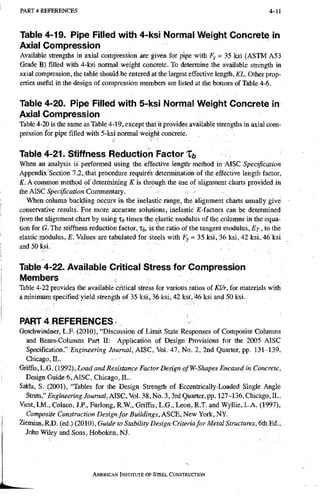

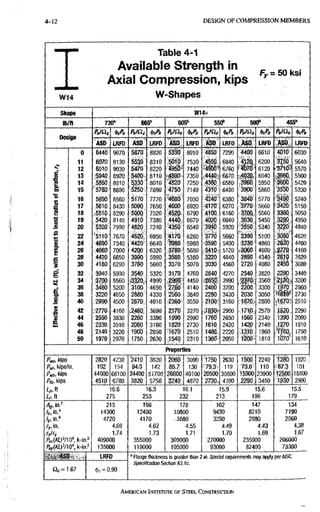

Table 4-1. W-Shapes in Axial Compression

Available strengths in axial compression are given for W-shapes with Fy - 50 ksi (ASTM

A992), The tabulated values are given for the effective length with respect to the y-axis

iKL)y. However, the effective l e n ^ with respect to the ;c-axis (KL)x must also be investi-

gated. To determine the available strength in axial compression, the table should be entered

at the larger of (KL)y and (KQy eq, where

( ^ ' U - ^ (4-.)

Values of tlie ratio rjry and other properties useful in the design of W-shape compres.sion

members are listed at the bottom of Table 4-1.

Variables Pwo, Pwi^ Pwb and Pf], shown in Table 4-1 can be used to determine the strength

of W-shapes without stiffeners to resist concentrated forces applied normal to the face(s) of

the flange(s). In these tables it is assumed that the concentrated forces act far enough away

from the member ends that end effects are not considered (end effects are addressed in

Chapter 9). When Pr S (])/?„ or /?„/£!, column web stiffeners are not required. Figures 4-1,

4-2 and 4-3 illustrate the limit states and the applicable variables for each.

Web Local Yielding: The variables P^o and P^i can be used in the calculation of the avail-

able web local yielding strength for the colunm as follows:

LRFD ASD

RJQ. = P„o + P j b (4-2b)

AMERICAN INSTITUTE OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-420-320.jpg?cb=1684244800)

![4-14 . D E S I G N O F C O M P R E S S I O N M E M B E R S

Table 4-1 (continued)

Available Strength in p -' (in kci

Axial Compression, kips

t y - • ^W IVOI

W 1 4

W-Shapes

Shape W14x

lb/ft 257 233 211 193 176 159

mo (fcPn Pn/Qc ^cPii Pn/iic P^ICic iS>cPn PnlQc ^cPn P^'Oc M

Design

ASDl LRFD ASO.- LRFD ASO LRFD ASD LRFD ASD LRFD ASO LRFO

, 0 2260 3400 2050'. 3080 1860 2790 1700 2560 1550 2330. 1400 2100

6 2210 ,S,S30 201 a 3010 1810. -2730 1660 •2500 15tff 2280 1370 2050

, 7 ??nn 3300 1990 2990 1800.. 2700 1650 2480 •1500 2260. 1350 2030

I 8 2180 3270 1970 2960 1780;' 2680 1630: 2450 "1490 2240 •1340 2010

I : 9 ?i.'in 3?40 1950 2930 1760' 2650 1610 2430 1470 •2210 1330 1990

oi 10 2130 3200 1930 2900 1740 2620 1^90 2400 1450' 2180 1310 1970

•s 11 ?inn- 31fi0 i 9 o a 2860 1720 ,2580 1570 2360 1430- 2150 1290 1.940

s 12 2070 alio 1870 2820 1690 2550 1550 2330 1410 2120 '1270 1910

p 13 2040 .3060 1840 2770 1670 2510 1530 2290 1390" 2090 1250 1880

V 14 •20in 3010 1810 2730 1640 2460 1500- 2250 1360- 2050 1230 1850

1 . 15 1970 2960 1780 2680 1610 2420 1470 '2210 l340,; 2010 1210 1810

s

16 19.% 2900 1750 2630 1580 2370 1440' 2170 1319 1970. ,1180 1780

t3

fL 17 1890 2850 1710 2570 1540 2320 1410. -2120 1280 1930 1160 1740

s 18 1850 2790 1670 2520 1510 2270 1^80 2080 126a 1890. 1130 1700

c

19 1810 2720 1640 2460 1480 2220 1350 2030 1230 1840 •1100 1660

1 ' 20 •1770 2660 1600, 2400 ,1440 2160 1320." 1980 1200 1800 ,1070 1620

g 22 .1680 2520 1510 2280 1360 2050 12505- 1870 1130 1700 1020 1530

24 1590 2380 1430 2150 1290 1930 •lira. 1770 1070 1600 .957 1440

«

26 •149Q' 2240 1340 2020 1210 1820 1100 1660 998- 1500 ,896 1350

JS

28 140Q 2100 1260, 1890 1130 1700 1 0 ® 1550 931 1400- 835 1250

J 30 1300 1950 '1170 1750 105a 1570 954 1430 863" •1300 •773 1160

.1 32 1200 1810 1080- 1620 968" 1460 881. 1320 796= 1200 ; 7 1 3 1070

34 1110 1670 •994^ 1490 890' 1340 810.5 1220 730 - 1100 653 982

U

J 36 1020 1530 911 > 1370 815 1220 740 1110 667 1000 596 896

38 928 1400 830 1250 741 1110 6 7 3 . 1010 m 909 540 812

40 841" 1260 751 1130 670- 1010 6 0 5 : 914 546; 821 487 733

Properties

Pwa, kips . 490 735 414^^ 621 353 529 303' 454 264 396 222 333

Pm, kips/in. 39.3; 59.0 35.7 53.5 32.7 ' 49.0 44.5 27.7 41.5 248 37.3

Pm,. kios 2480 3730 2780 1430 2150 IOTO; 1610 8Z0 1310 628 944

Pfu, kips r e f e i 1000 5S4;. 832 455 684 s f e . 583 321' 483 265 398

Lp, ft 14.6 14.5 14.4 14.3 14.2 14,1

in ft 104 95.0 86.6 79.4 73.2 66.7

Ag, in.2 75.6 68.5 62.0 56.8 51.8 46.7

y

Ix. in." 3400 3010 2660 2400 2140 1900

Vin." 1290 1150 1030 ' 931 838 748

ry, in. 4.13 4.10 4.07 4.05 4.02 4.00

hlu 1.62 1.62 1.61 1.60 1.60 1.60

P e M f n o ^ : k-in.= 97300 86200 76100 68700 61300 54400

36900 32900 29500 26600 24000 21400

ASO,-;--. LRFD

1.67 (])(;= 0.90

AMERICANiNSTTrUXEOF STEEL GONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-430-320.jpg?cb=1684244800)

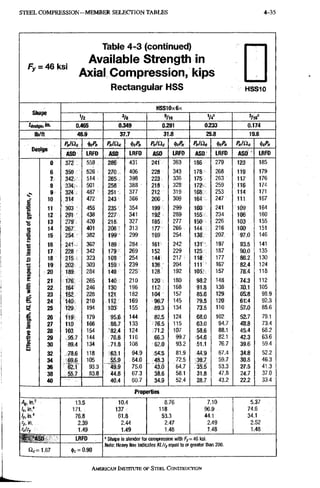

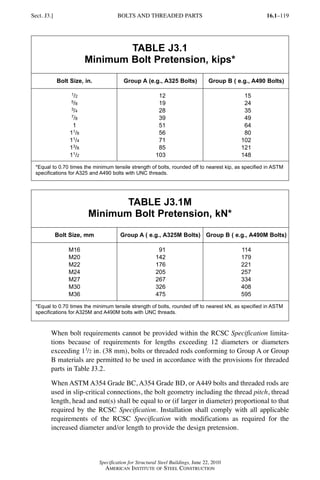

![4-16 DESIGN OF CX)MPRESSION M E M B E R S

W 1 4

Table 4-1 (continued)

Available Strength in

Axial Compression, kips

W-Shapes

Fy = 50 ksi

Shape W14x

lb/ft 82 74 68 61 53 48 43'

PnlCXc

M PnlQc PalClc p„jao ^Pn Pn/Qc^cPn

Des gn.

ASD- LRFD ASD LRFD « s o LRFD ASO LRFD ASO LRFD ASD LRFD ASD LRFD

0 719 "1080 653 981 599 900 536^ 805 -467 702 422 634 374 562

6 676 1020 614 922 562 845. 503 756 421 633 380 572 339 510

I ?

7 661 993 600 90? 550 826 492. 739 406 610 •366 551 327 491

s 8 644 968 585 879 536 805 479, 720 389 585 351 527 31'2 470

' i 9 626} 940 568 854 520 782 465 699 371 557 •334 502 297 447

10 606 910 550 827 503 756 450 676 351 528 316 475 281 422

"S

11 584 :878 531 797 485 729 433 651 -331 497 ,298 447 264 397

.3 12 562' 844 510 767 466 701" 416- 626. •310 465 279 419 247 371

E 13 538- 809 489 735 446 671 398 599 {288 433 ,259 390 229 345

m 14 514' 772 467 701 426 640 380 571 !267 401 240 360 212 318

i

s

15 489' 735 444 667 405 608 361 543 -.246 369 221 331 194 292

i

s 16 464^. 697 421 633 384 577 342 514 '225 338 202 303 177 267

a 17 438, 659 398 598 362 544 323 485 205 308 ;183 276 161 242

S 18 413 620 375 563 341 512 304 456 185 278 r166 249 145 218

19 387 582 352 529 320 480 285 428 166 250 M>49 224 130 196

S

3 20 362 545 '329 495 299 449 266 399 150 226 202 117 177

g 22 314. 472 285 428 258 388 229 345 -124, 186 •111 167 97.1 146

24 267- 402 243 365 219 330 195 293- 104 157 •93.2 140 81,6 123

j j 26 343 .207 311 187 281 166 249 88.8 133 •79.4 119 69.5 104

s

28 295 179 268 161 242 143 215. 76.6 115 68:5 103 59,9 90.1

J 30 171 • 257 .156' 234 140 211 125' 187 66.7 100 .59.7 89.7 S2'.2 78.5

1 32 150'- 226 .137 205 123 185 • 110 165 S8.6 88.1

34 133<, 200 1Z1 182 109 164 97.0 146 ;

S 36 l i 9 v 179 108 162 97.5 147 86.5 130 , H

38 107- 160 96.9 146 87.5 131 77.7 117 . 1

40 96.3 145 87.5 131 79.0 119 7 0 . r 105 • 1' ;

Properties

Pwo. kips 123 185 104 155 90.6 136 77.5 116 '77.1 116 674 101 5 6 a 85,4

Puii, kips/in. 17.0 25.5 150 22.5 13.8 20.8 12.5; 18.8 1 2 3 18.5 113 17.0 10.2, 15,3

Pwb, kips 201 302 138- 207 108 163 80J , 120 767 115 59 5 89.5 43.0, 64,7

Pfb. kips 137 206 115 173 97^0 146 irm 117 8 l 5 123 66 2 99.6 52.6; 79,0

Lp,n 8.76 8.76 8.69 8.65 6.78 6.75 6,68

/.r,ft ; 33.2 31.0 29.3 27.5 22.3 21.1 20.0

AgM? 24.0 21.8 20.0 17.9 15.6 14.1 12.6

/.•in." 881 795 722 640 541 484 428

/y, in." 148 134 121 107 57.7 51.4 45.2

r,, in. 2.48 2.48 2.46 2.45 1.92 1.91 1.89

r./ry 2.44 2.44 2.44 2.44 3,07 3.06 3,08

25200 22800 20700 18300 15500 13900 12300

4240 3840 3460 3060 1650 1470 1290

ASD

£lc=1.67

LRFD

(])<;= 0.90

' Shape is slender for compression with Fy= 50 l«i.

Note: Heavy line indicates equal to or greater than 200.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-432-320.jpg?cb=1684244800)

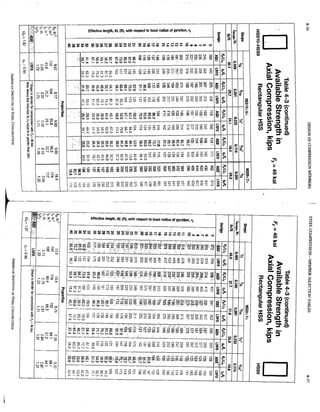

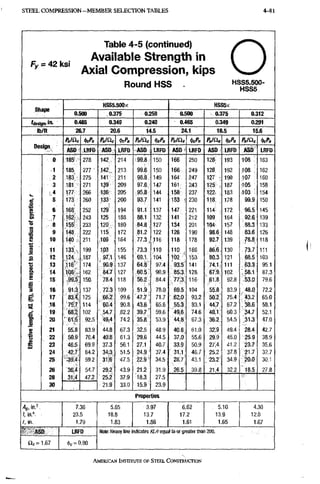

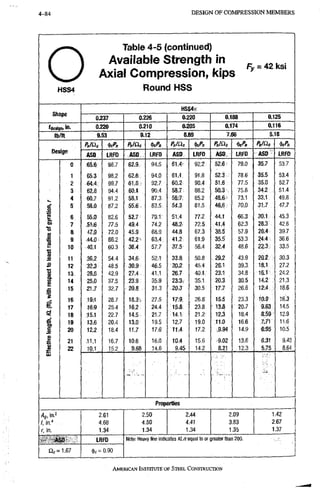

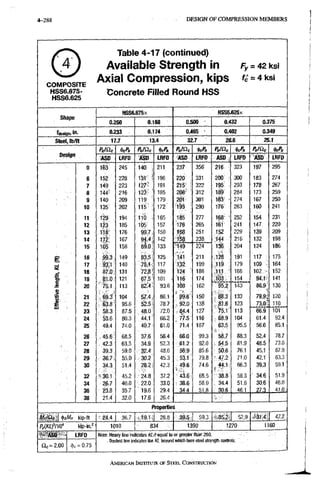

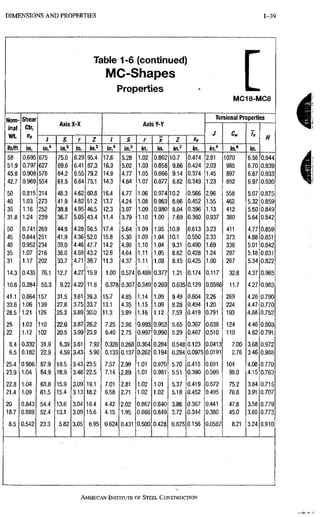

![STEEL C O M P R E S S I O N — M E M B E R SELECTION TABLES 4-25

/V = 50ksi

Table 4-2 (continued)

Available Strength in

Axial Compression, kips

HP-Shapes H P 1 6

Shape HP16X

lb/ft 183 162 141 121 101 88"'

/5,/nc P^IClc p„/ac •fcPn PnlSicAoPn Pn/Cic 'IV;'?. PnlQc APn

OGSi^n

ASD LRFD ASD LRFD •ASD' LRFD ASD LRFD A S D ' LRFD ASD LRFD

0 1610 2430 1430 2150 1250 1880 1070' 1610 895 V 1350 749, 1130

6 1570 2360 1390' 2090 1220 1830 1040. 1570 871 1310 729! 1100

•

7 1560 2340 1380 2070 1200' 1810 1030 1550 862 - 1300 722 1080

.1 8 1540 2320 13b0> 2050 1190 1790 1020 ' 1540 852 1280 714 1070

•g 9 1520 2290 1350, 2020 1180 1770 1010 - 1520 8 4 1 ' ' 1260 705 1060

•s

10 1500' 2260 1330 2000 1160 1740 995 1490 829 ' 1250 694 1040

•s

11 1480., 2230 1310 1970 1140 1720 979. 1470 816 1230 684 1030

M 12 1460 • 2190 1290 1930 1120 • 1690. 962 1450 802< - 1210 672 1010

e 13 1430 2150 1260 1900 1100 1660 944 1420 787 , 1180 •659 991

"w 14 1410 2110 1240 1860 1080 1630 926-, 1390 771 1160 646 971

J : 15 1380 2070 1210 1820 1060 1590 ^906' 1360 754 1130 632 950

s

16 1350 2020 1190 1780 1030 .1560 885 ' 1330 736 . 1110 617 928

s. 17 1320 1980 1160 1740 1010 1520 863, 1300 7 1 8 ' ' 1080 602 905

1

18 1280 • 1930 1130 1700 ^985 1480 841 1260 699 1050 S87 882

c

19 1250 • 1880 1100' 1650 958 - 1440 818 1230 679 t 1020 570' 857

"s 20 1220T. 1830 1070. 1610 931 1400 794 11.90 659 991 554 833 .

B 22 1150 - 1720 10101 1510 876 i 1320 746 1120 618 929 520 782

24 1070 1610 942, 1420 819 1230. 696. 1050 576 • 866 •485 729

*

26 1000 . 1500 877 < 1320 761 ' 1140 646 971 534 802 450 676

28 927 1390 811 , 1220 '703- 1060 596- 896 4 9 U 739 -415 623

J 30 8 M 1280 746 1120 645 .970 546- 821 450 i- 676 380' 571

.1 32 7^3 1180 682 1030 589 886 498 5 748 409 615 346 520

® 34 .713 ^ 1070 620 i 932 5i35' 804 451 678 370-' 556 313 471

u : 36 ,646 971 5sn, 843 482 725 405" 609 331' 498 281 423

38 873 503 756 433" 651 364- 547 297 447 253 380

40 787 454 682 391 587 328 ' 494 268 C 404 ,228 343

Properties

P«o,kips 435 653 363 545 300 451 241 362 189 283 155 232

P„-, kips/in. 37.7 56 5 33.3 50.0 29.2 43.8 25.0 37 5 20.8 31,3 I8.O1 270

Pwb. kips 2100- 3160 1450- 2190 974, 1460 612* 920 356-^' 535 229 345

Pa, kips 239 359 187 281 143 " 215 105 158 73.1 110 54.6 82.0

ip,ft 13.6 13.5 13.4 16,7 20.2 22,9

Lr.n 67.6 60.2 54.5 48.6 43.6 40,6

Ag, in.^ 53.9 47.7 41.7 35.8 29.9 25,8

/x.in.i 2490 2190 1870 1590 1300 1110

/y.in." 803 697 599 504 412 349

fy, in. 3.86 3,82 3.79 3.75 3,71 3.68

hlty 1.76 1,77 1.77 1.78 1,78 1.78

71300 62700 53500 45500 37200 31800

P^(KLflW. k-in; 23000 19900 .17100 14400 11800 9990

0 ^ = 1 . 6 7

LRFD ' Shape is slender for compression with 50 ksi.

(])<;= 0,90

AMERICAN INSrrrUTE OF STEEL CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-441-320.jpg?cb=1684244800)

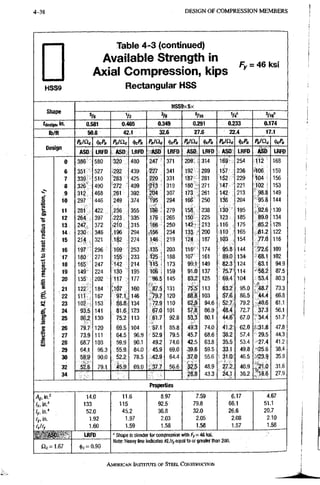

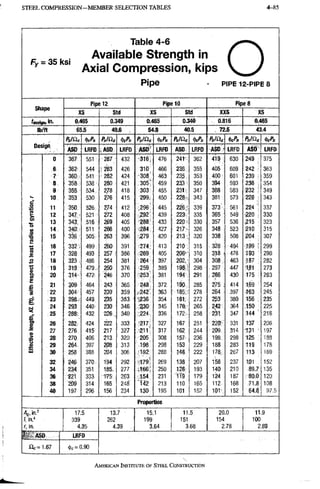

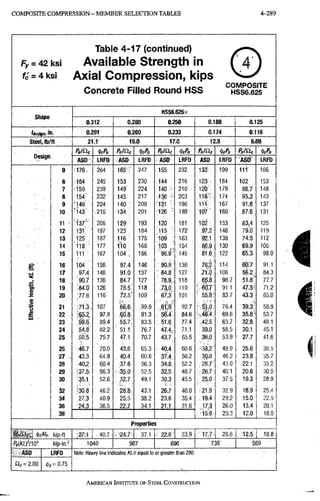

![STEEL C O M P R E S S I O N - M E M B E R SELECTION TABLES 4-27

Fy = 50 ksf

Table 4-2 (continued)

Available Strength in

Axial Compression, kips

hfl'-Shapes H P 1 2 - H P 8

Shape HP12X HPlOx HP8x

lb/ft 63 53'^ 57 42 36

PnlQc « PnlCic 'kPn P„iQc •^cPn PJQc •^cPn

ASO LRFD ASD LRFD ASD LRFD ASD LRFO ASO LRFD

0 551 828 460. 691 500 751 371 558 317 477

6 526 791 439 660 469 706 ' 348 523 287-, 432

7 518 778 49'2". 649 459 690 340 511 277 416

o 8 508' 763 424 637 , 447 672 331 497. 266 400

g 9 497 , 747 , 415 623 .434 652 . 321 482 254. 381

10 485. . 729 .405 608 ^'420 631 310 465 241 362

"S

11 472-"' 710 394 592 404 608 298 448 227 341

a

12 459 , 690 383, , 575 388' 584 286 . 430 213 320

s 13 445 « 668 371 557 372 559 273 411 199- 299

M 14 430 646 358 538 355 533 ^60 391 184 . 277

i

15 4'I4 622 ' M 5 , 519 ,^37 506 "247 371 170 256

i

16 398 598 332. ' 499 319 480 233 351 156 235

s. 17 574 318 478 ,301 453 220 330 143 214

w 18 365 . 549 304 ' 457 283 426 206 310 129 194

IH

£ 19 348 524 290 436 265 399 193 290 l i 7 175

Si

S 20 332;,, 498 ,276' 415 248 373 , i § o 270 10'§ 158

t 22 293 ,' ' 448 m 373 214 322 154 232 86.9 131

24 399 ' 221;

m •

332 182 273 131 196 73,0 110

26 234 351

' 221;

m •

292 .15.5 233 167 62.2 93,5

28 2p3 305 . 169 254 133 , 201 95.9 144 53.7 80,7

M 30 177 J • 266 147 221 .rfi6 175 83.5 126 , 46.7 70.3

g 32 156 234 1?9 ,194 102 154 . 73.4 110 41.1 61.8

» 34 f38 , 207 172 .90,5 136 ;65.0, 97.7

E 36 123 " 185 102 153 •80,7 121 58.0 87.2

38 110 166 91.6, 138 72.5 109 52.1 78.2

40 99.6 150 82.7 124 • 65,4 98.3- 47.0 70.6

Properties

Pm,m 107 161 .81.9 123 118 177 78.2 117 83.8 126

Pw, kips/in. 17.2 25.8 14.5 21.8 18.8 28.3 13.8 20.8 14.8 223

P«4,kips 243 365 147. 221 397 597 158 237 241 363

/•fekips 49,6 74.6 35.4 53.2 59.7 89.8 33.0 49.6 37.1 55.7

Lp,n 14.4 16.6 8.65 12.3 6.90

Lr.n 34.0 31.1 34,8 28.3 27.3

Ag, in} 18.4 15.5 16.7 12.4 10,6

hM 472 393 294 210 119

If.in.' 153 127 101 71,7 40,3

ry, in. 2.88 2,86 2.45 2.41 1.95

rjry 1.76 1,76 1.71 1.71 1.72

Pexm'IIO', k-in.= 13500 11200 8410 6010 3410

4380 3630 2890 2050 1150

ASO

0 ^ = 1 . 6 7

LRFD

(])<; = 0.90

«Shape is slender for compression wltli = 50 ksi.

Note: Heavy lliie Indicates KUr, equal to or greater than 200.

AMERICAN INSTITUTE OF STEEI. CONSTRUCTION](https://image.slidesharecdn.com/aiscsteelconstructionmanual14thed-230516132907-98eab4dc/85/AISC-steel-manual-443-320.jpg?cb=1684244800)