This document provides a summary of the chapters included in the 14th edition of the Steel Construction Manual published by the American Institute of Steel Construction. The manual covers topics related to the design of structural steel buildings and bridges including dimensions and properties of sections, design of flexural, compression, tension and combined force members, and design of connections including bolted, welded and bearing type connections. It also includes specifications, codes and supplementary reference materials.

![x

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

SCOPE

The specification requirements and other design recommendations and considerations sum-

marized in this Manual apply in general to the design and construction of steel buildings and

other structures.

The design of seismic force resisting systems also must meet the requirements in the

AISC Seismic Provisions for Structural Steel Buildings, except in the following cases for

which use of the AISC Seismic Provisions is not required:

• Buildings and other structures in seismic design category (SDC) A

• Buildings and other structures in SDC B or C with R = 3 systems [steel systems not

specifically detailed for seismic resistance per ASCE/SEI 7 Table 12.2-1 (ASCE, 2010)]

• Nonbuilding structures similar to buildings with R = 11

/2 braced-frame systems or

R = 1 moment-frame systems; see ASCE/SEI 7 Table 15.4-1

• Nonbuilding structures not similar to buildings (see ASCE/SEI 7 Table 15.4-2), which

are designed to meet the requirements in other standards entirely

Conversely, use of the AISC Seismic Provisions is required in the following cases:

• Buildings and other structures in SDC B or C when one of the exemptions for steel

seismic force resisting systems above does not apply

• Buildings and other structures in SDC B or C that use composite seismic force resist-

ing systems (those containing composite steel-and-concrete members and those

composed of steel members in combination with reinforced concrete members)

• Buildings in SDC D, E or F

• Nonbuilding structures in SDC D, E or F when the exemption above does not apply

The AISC Seismic Design Manual provides guidance on the use of the AISC Seismic

Provisions.

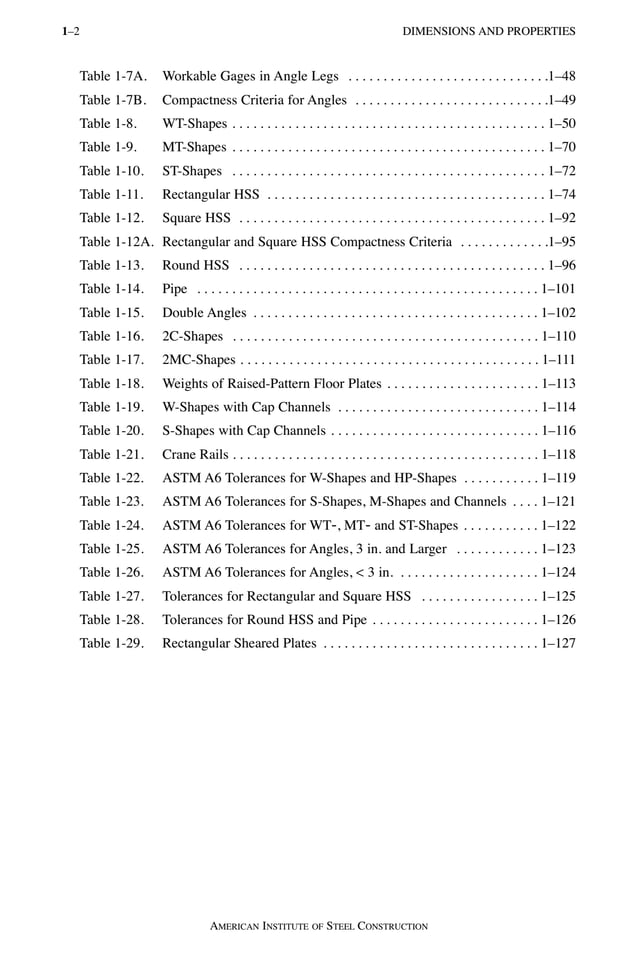

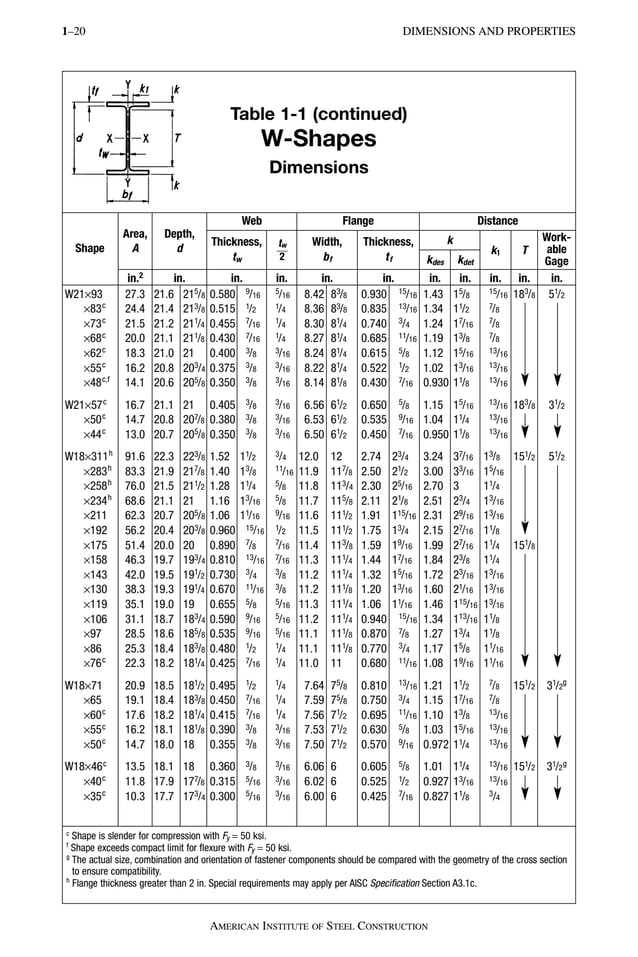

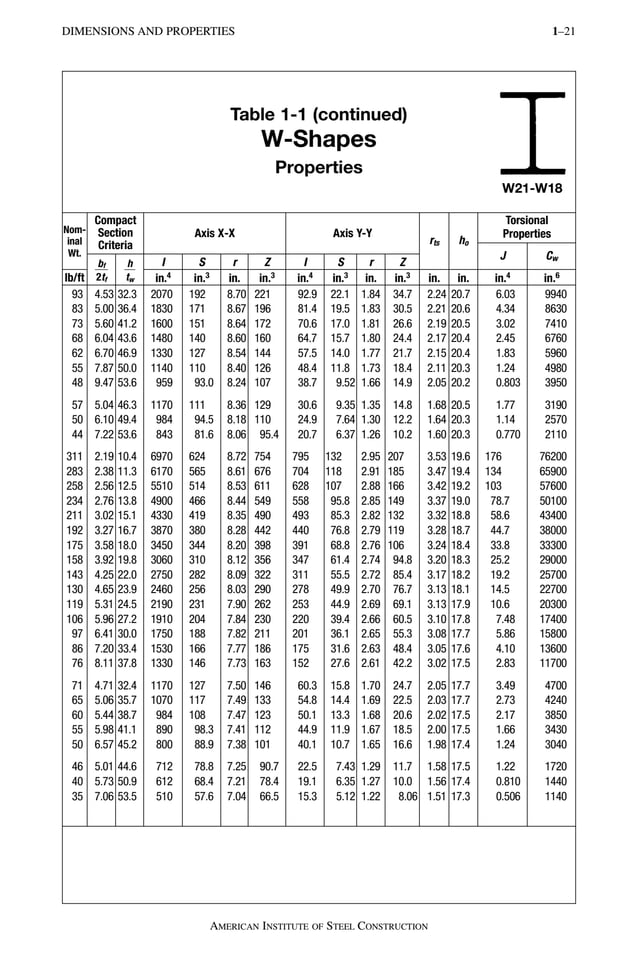

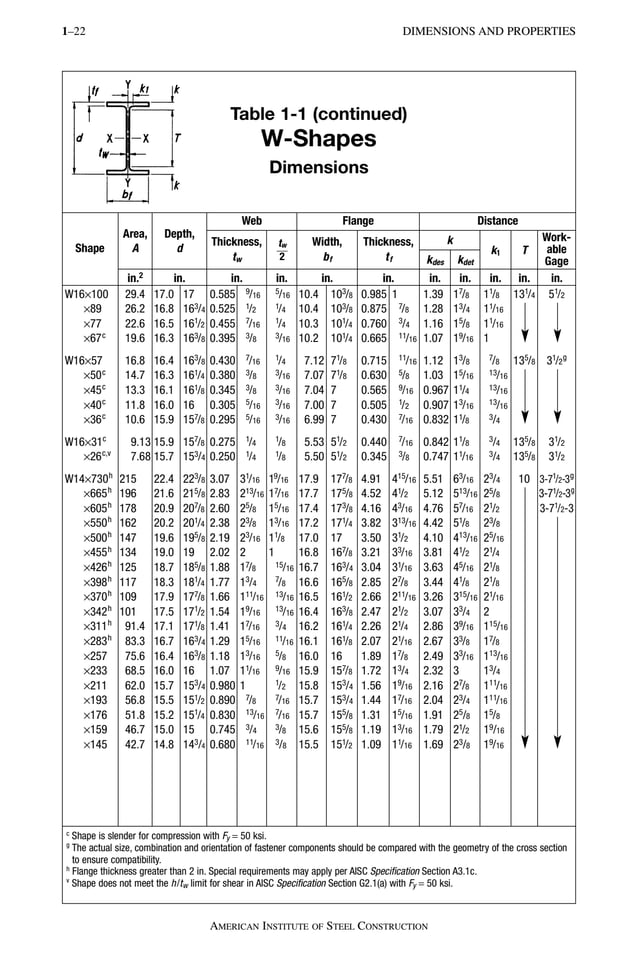

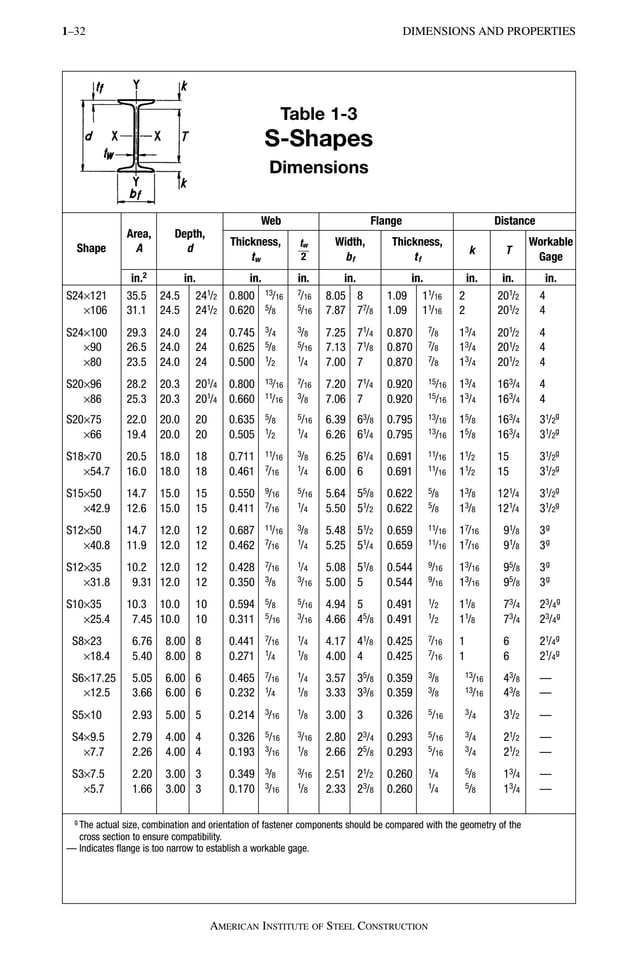

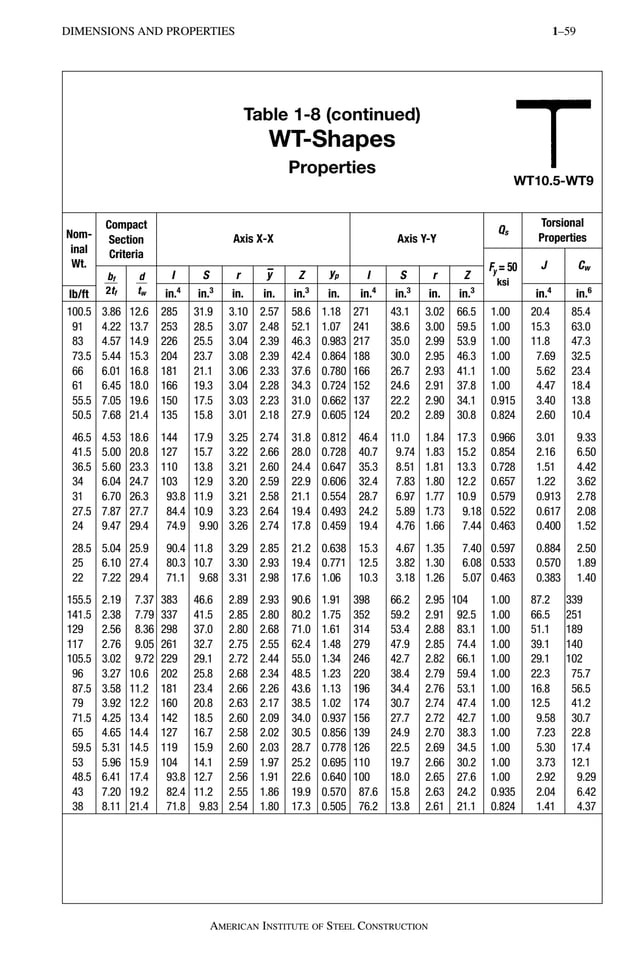

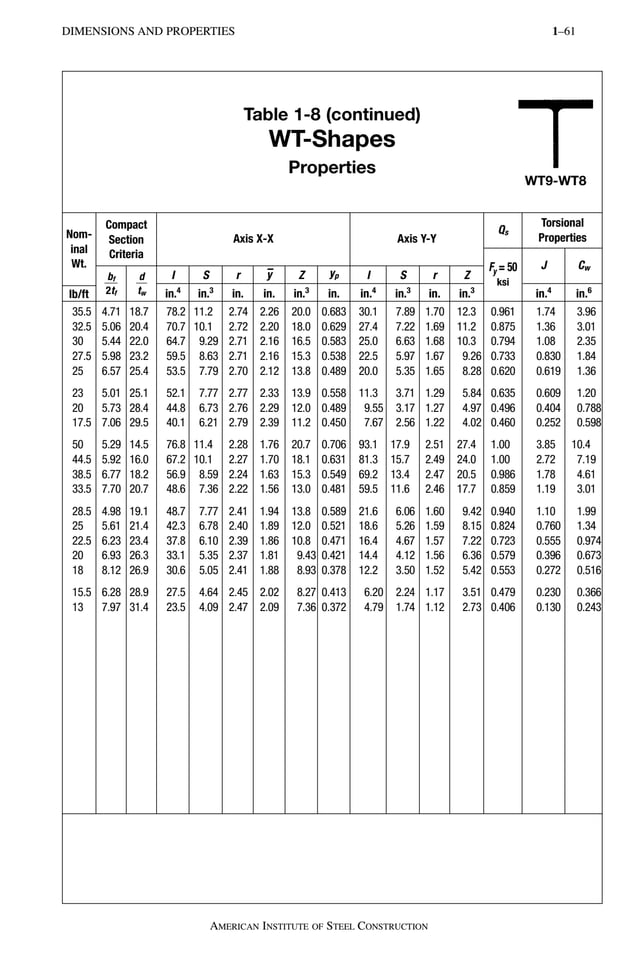

The Manual consists of seventeen parts addressing various topics related to steel build-

ing design and construction. Part 1 provides the dimensions and properties for structural

products commonly used. For proper material specifications for these products, as well as

general specification requirements and other design considerations, see Part 2. For the

design of members, see Parts 3 through 6. For the design of connections, see Parts 7 through

15. For AISC Specifications and Codes, see Part 16. For other miscellaneous information,

see Part 17.

REFERENCE

ASCE (2010), Minimum Design Loads for Buildings and Other Structures, ASCE/SEI 7-10,

American Society of Civil Engineers, Reston, VA.

AISC_Prelims:14th Ed. 1/20/11 7:23 AM Page x](https://image.slidesharecdn.com/steelconstructionmanualfourteenthedi-240120180500-549893fc/85/Steel_construction_manual_fourteenth_edi-pdf-11-638.jpg)

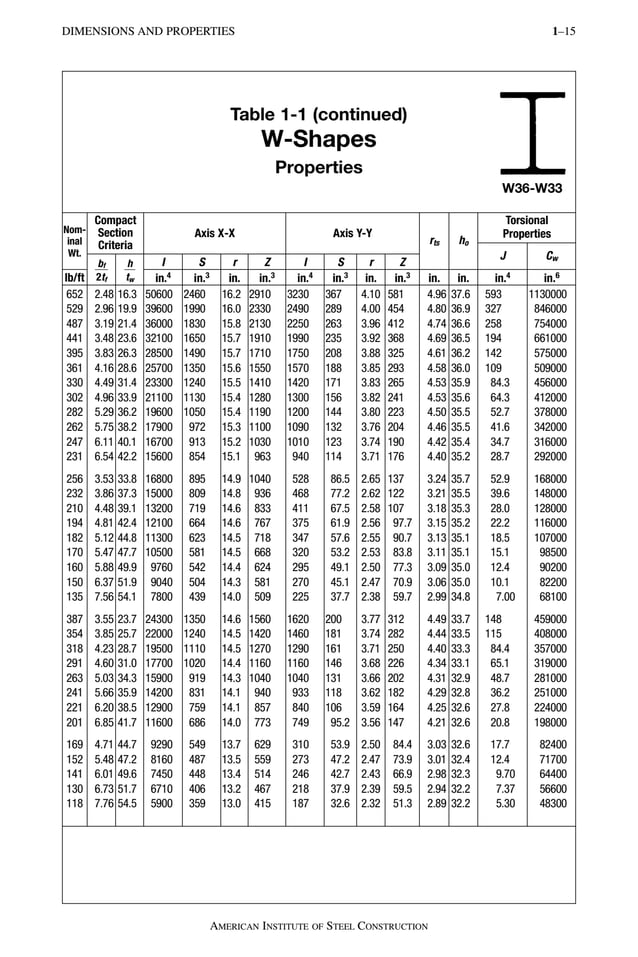

![Permissible Cross-Sectional Variations

Over Under Over Under

To 12, incl. 1/8

1/8

1/4

3/16

1/4

3/16

1/4

Over 12 1/8

1/8

1/4

3/16

5/16

3/16

1/4

Permissible Variations in Length

Variations from Specified Length for Lengths Given, in.

Nominal Depthb

, in. 30 ft and Under Over 30 ft

Over Under Over Under

Beams 24 in. and under 3

/8

3

/8

3/8 plus 1/16 for each additional 3

/8

5 ft or fraction thereof

Beams over 24 in. 1

/2

1

/2

1/2 plus 1/16 for each additional 5 ft or 1

/2

All columns fraction thereof

Mill Straightness Tolerancesc

Sizes Length

Permissible Variation in Straightness, in.

Camber Sweep

Flange width equal to

or greater than 6 in.

All

Flange width less

than 6 in.

All

Certain sections with a

flange width approx. 45 ft and under

equal to depth &

specified on order Over 45 ft

as columnsd

Other Permissible Rolling Variations

Area and Weight −2.5 to +3.0% from the theoretical cross-sectional area or the specified nominal weighte

Ends Out of Square 1/64 in., per in. of depth, or of flange width if it is greater than the depth

a Variation of 5/16 in. max. for sections over 426 lb/ft.

b For shapes specified in the order for use as bearing piles, the permitted variations are plus 5 in. and minus 0 in.

c The tolerances herein are taken from ASTM A6 and apply to the straightness of members received from the rolling mill, measured

as illustrated in Figure 1-1.

d Applies only to W8×31and heavier, W10×49 and heavier, W12×65 and heavier, W14×90 and heavier, HP8×36, HP10×57, HP12×74

and heavier, and HP14×102 and heavier. If other sections are specified on the order as columns, the tolerance will be subject to

negotiation with the manufacturer.

e For shapes with a nominal weight ≥ 100 lb/ft, the permitted variation is ±2.5% from the theoretical or specified amount.

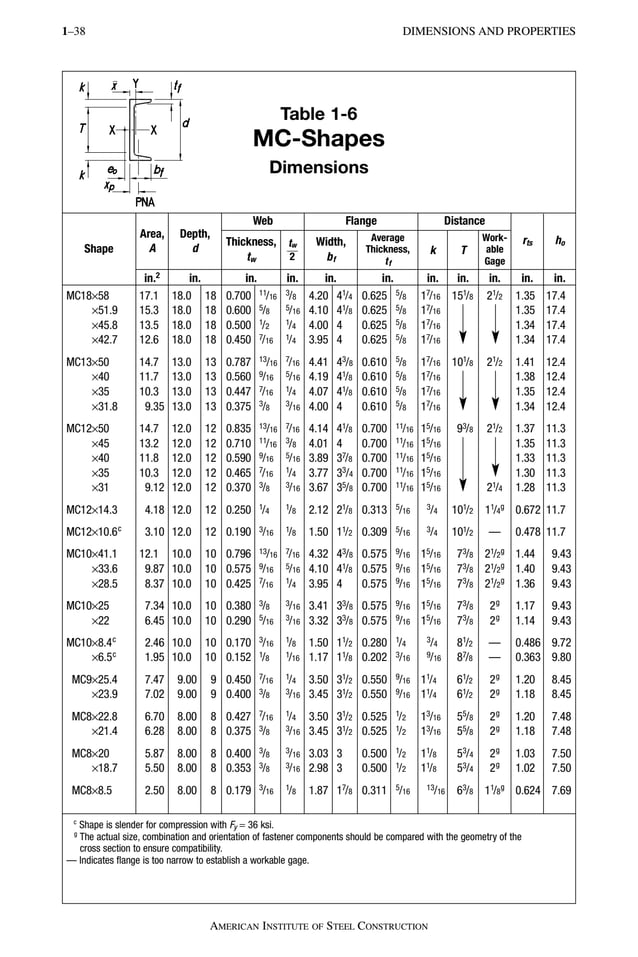

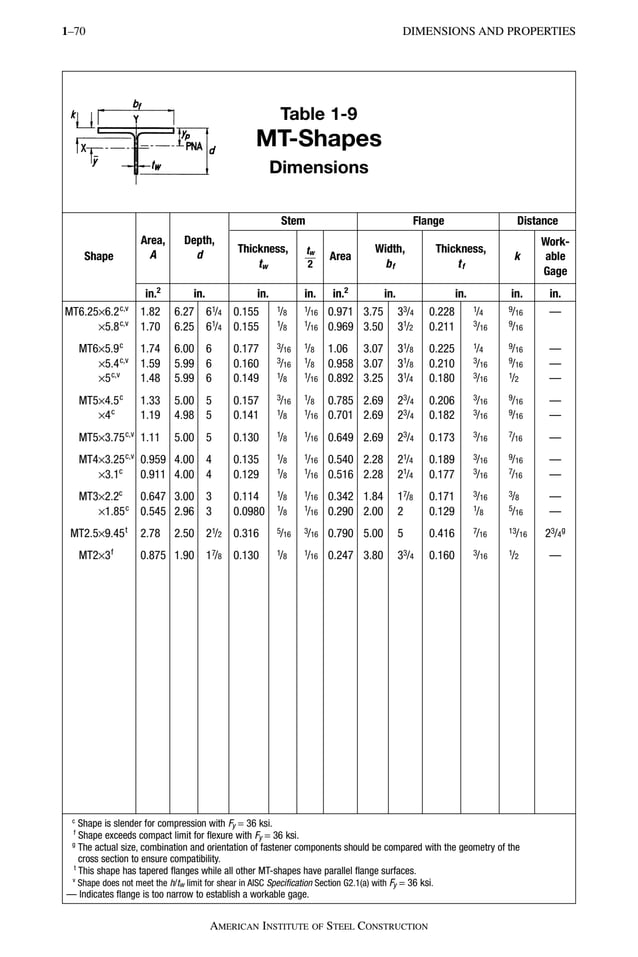

DIMENSIONS AND PROPERTIES 1–119

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

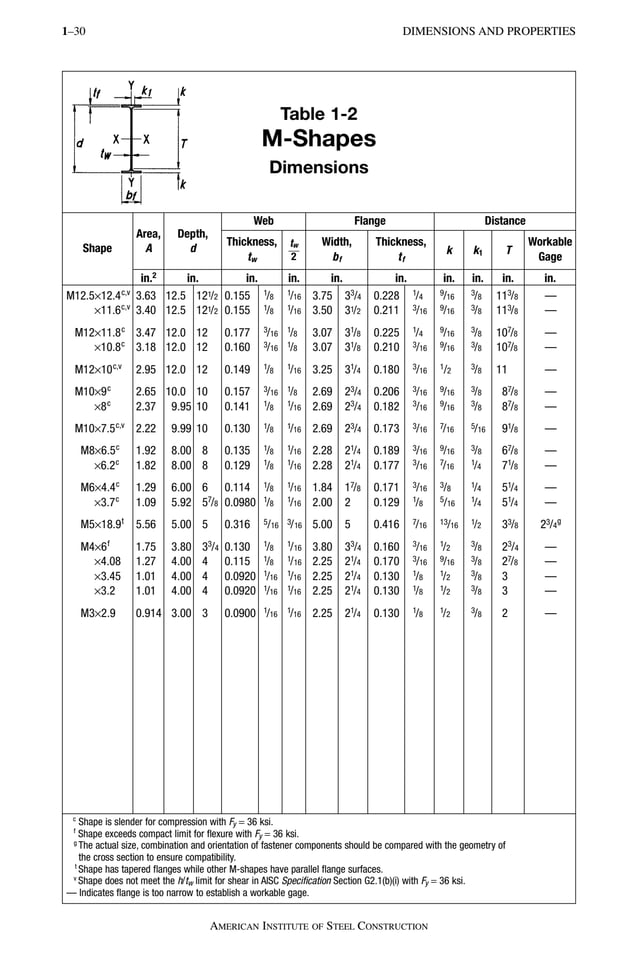

Table 1-22

ASTM A6 Tolerances for W-Shapes

and HP-Shapes

Nominal

Depth, in.

A

Depth at Web Centerline, in.

B

Flange Width, in.

T + T′

Flanges Out

of Square,

Max. in.

Ea

Web Off

Center, in.

C, Max.

Depth at any

Cross-Section

over Theoretical

Depth, in.

3/8 in. +

[1/8 in. ×

]

1/8 in. × with 3/8 in. max.

1/8 in. ×

(total length, ft)

10

(total length, ft)

10

(total length, ft – 45)

10

1/8 in. ×

(total length, ft)

10

1/8 in. ×

(total length, ft)

5

AISC_PART 01B:14th Ed._ 1/20/11 7:34 AM Page 119](https://image.slidesharecdn.com/steelconstructionmanualfourteenthedi-240120180500-549893fc/85/Steel_construction_manual_fourteenth_edi-pdf-130-638.jpg)

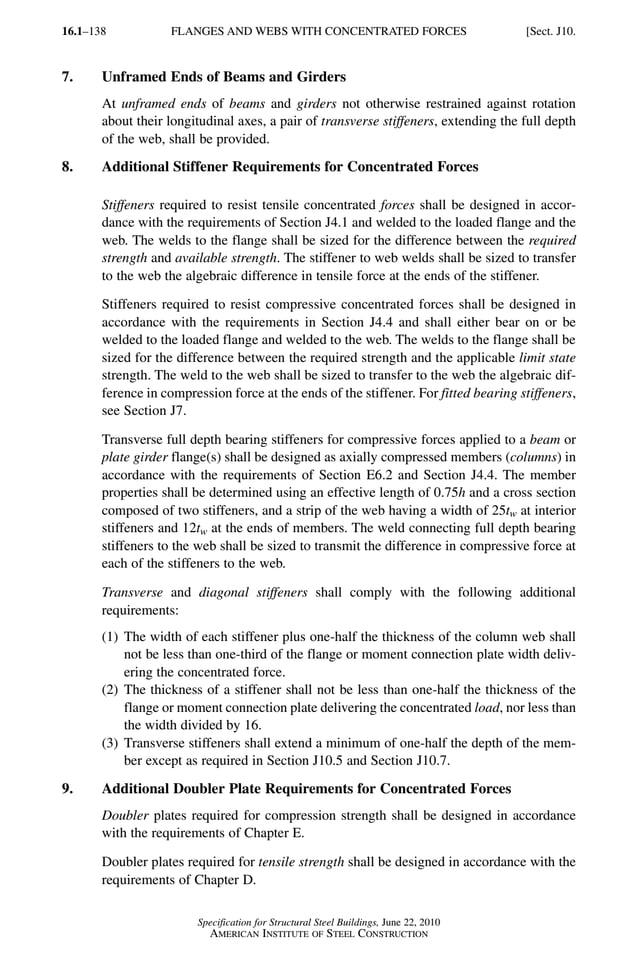

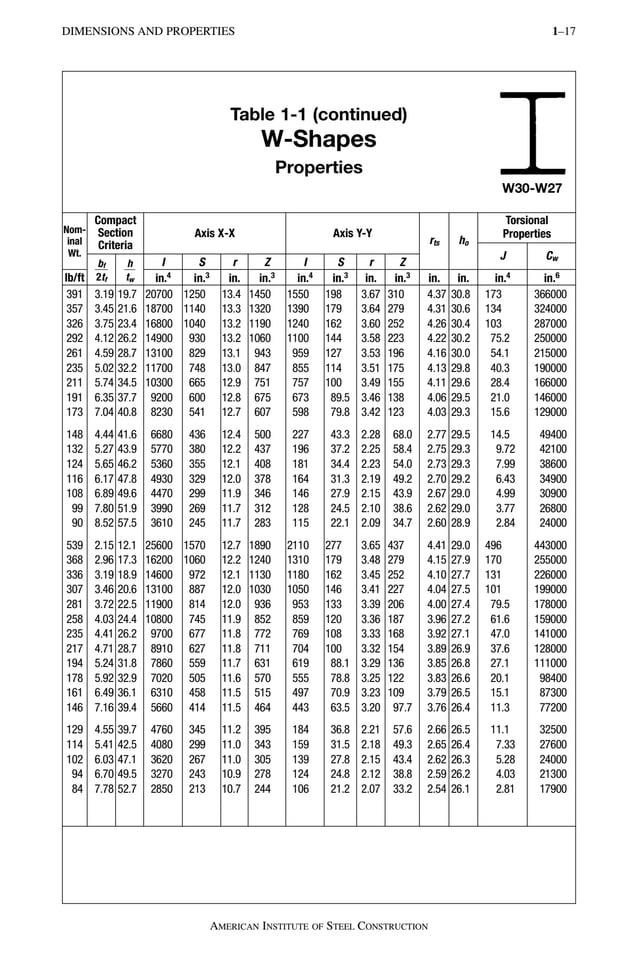

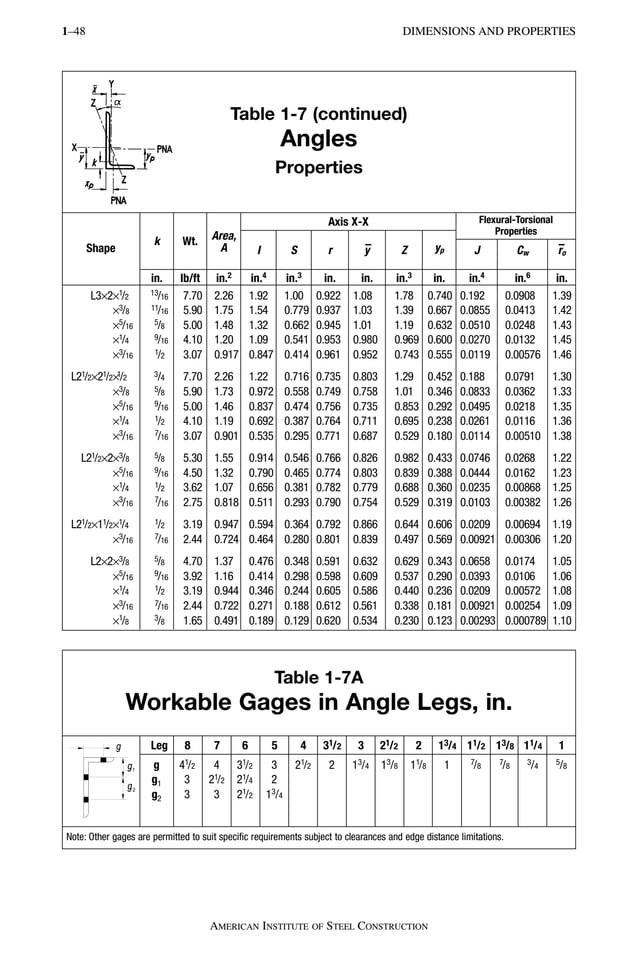

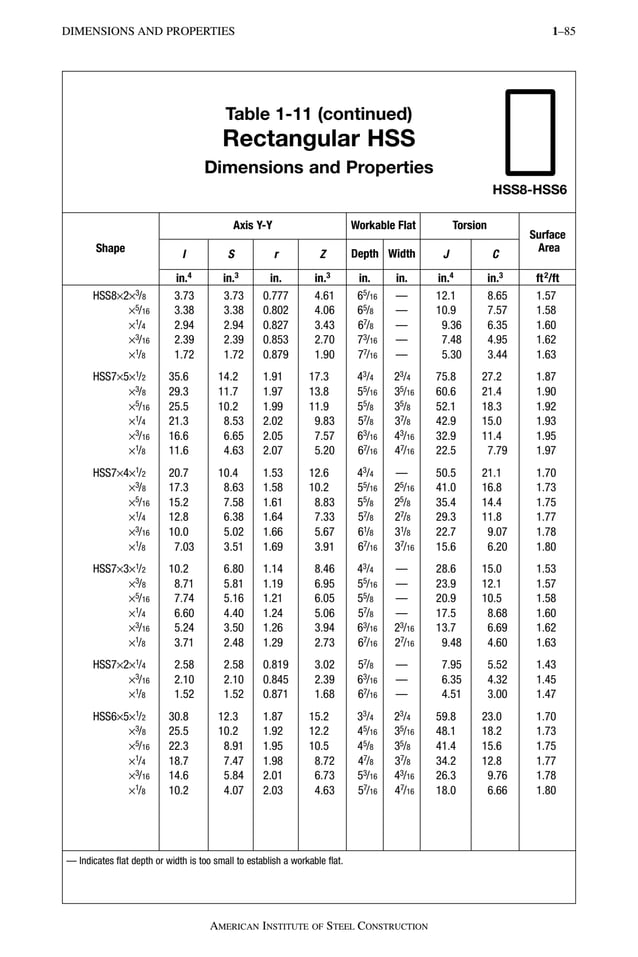

![DESIGN TABLE DISCUSSION 3–9

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

DESIGN TABLE DISCUSSION

Flexural Design Tables

Table 3-1. Values of Cb for Simply Supported Beams

Values of the LTB modification factor, Cb, are given for various loading conditions on sim-

ple-span beams in Table 3-1.

W-Shape Selection Tables

Table 3-2. W-Shapes—Selection by Zx

W-shapes are sorted in descending order by strong-axis flexural strength and then grouped

in ascending order by weight with the lightest W-shape in each range in bold. Strong-axis

available strengths in flexure and shear are given for W-shapes with Fy = 50 ksi (ASTM

A992). Cb is taken as unity.

For compact W-shapes, when Lb ≤ Lp, the strong-axis available flexural strength, φbMpx

or Mpx/Ωb, can be determined using the tabulated strength values. When Lp < Lb ≤ Lr,

linearly interpolate between the available strength at Lp and the available strength at Lr

as follows:

Fig. 3-2. Loading constants for use in determining simple beam deflections.

LRFD ASD

φbMn = Cb [φbMpx ⫺ φbBF(Lb − Lp)]

≤ φbMpx (3-4a)

M

C

M BF

L L

M

n

b

px

b

b p

px

= – ( )

b b

b

Ω Ω Ω

Ω

–

⎡

⎣

⎢

⎤

⎦

⎥

≤

(3-4b)

AISC_Part 3A:14th Ed. 2/24/11 8:39 AM Page 9](https://image.slidesharecdn.com/steelconstructionmanualfourteenthedi-240120180500-549893fc/85/Steel_construction_manual_fourteenth_edi-pdf-200-638.jpg)