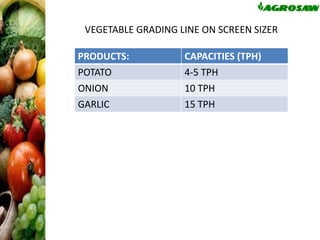

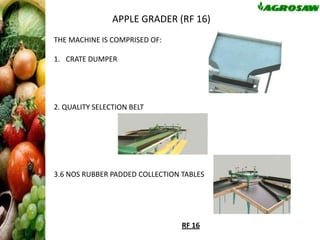

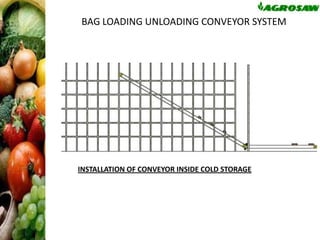

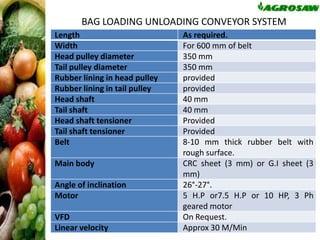

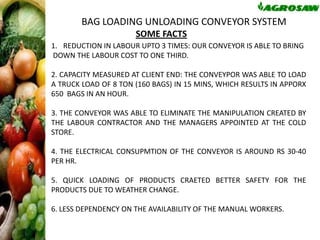

This document provides information on Agrosaw, an Indian manufacturer of cleaning, grading, sorting and handling equipment for seeds, grains, spices, pulses, oil seeds, fruits and vegetables. It was founded in 1984 and has three manufacturing plants with state-of-the-art facilities. The document outlines various machines and plants produced by Agrosaw, including round fruit sorting lines, vegetable grading lines, bagging machines, conveyor systems, and potato and apple grading equipment. It provides details on the specifications and capabilities of the different machines.