The document discusses the role of machine learning (ML) in accelerating the design of electrocatalysts by utilizing historical data to identify quantitative structure-activity relationships. It highlights the significance of descriptors—geometrical, electronic, and activity-based—in improving prediction accuracy and model effectiveness in electrocatalysis research. Despite substantial advancements, challenges remain in creating universal selection tactics for descriptors that effectively bridge the gap between material structures and their catalytic activities.

![www.afm-journal.de

© 2022 Wiley-VCH GmbH

2110748 (1 of 25)

development, it is still far from meeting

the increased demand.[3]

The emergence of artificial intelligence

(AI) has fundamentally changed the situ-

ation, which has significantly accelerated

the discovery process, owing to greatly

improved algorithms and developments in

data science.[4]

Machine learning (ML), a

simple and practical AI framework based

on computer and statistical science, is

used to develop algorithms to learn from

historic data without being explicitly pro-

grammed to obtain specific results.[5] It

can investigate relationships that are hard

to clearly and definitely model mathemati-

cally, providing insights for new scientific

advancements related to highly complex

with many uncertain twisted together

factors.[6]

There are usually three factors that

govern the learning and prediction pro-

cess of an ML: algorithms, data/database,

and descriptors.[4] The algorithms involve

data extraction, data filing, and propaga-

tion from mathematical derivation.[5,7] The

data can be derived not only from experiments but also from

theoretical calculations.[4] A number of databases based on

experiments[8] and calculations[9] have already been established.

The descriptors depend to a large extent on the predicted mate-

rial or properties. Based on the algorithm, databases, and

descriptors, the ML applications have been successfully imple-

mented to support various energy materials with analysis tools

(e.g., Python-based SciKit-Learn[10] and TensorFlow[11]) in com-

bination with workflow management tools (e.g., ASE[12]

and

Atomate[13]

). However, the prediction accuracy depends highly

on the descriptors, as descriptors have a certain uniqueness

for various materials and properties as long as the algorithm is

selected correctly and the data set is complete.[14]

For catalysis,

the descriptors contain the essence from the physicochemical

nature. Based on effective descriptors, ML can uncover the

relationship bridging structure and its activity, selectivity, and

stability.[5,15]

Thus, suitable descriptors must be established to understand

the structure–activity relationship. Although many efforts have

been made to accelerate the rational design of homogeneous

catalysts,[7b,16]

heterogeneous catalysts,[7b,16b,17]

and electroca-

talysis,[3,18]

the development of ML-assisted real catalysts is still

in its infancy. Despite these considerable research efforts, the

lack of universal selection tactics for descriptors bridging the

gap between activity and structures impedes the application

Review

Toward Excellence of Electrocatalyst Design by Emerging

Descriptor-Oriented Machine Learning

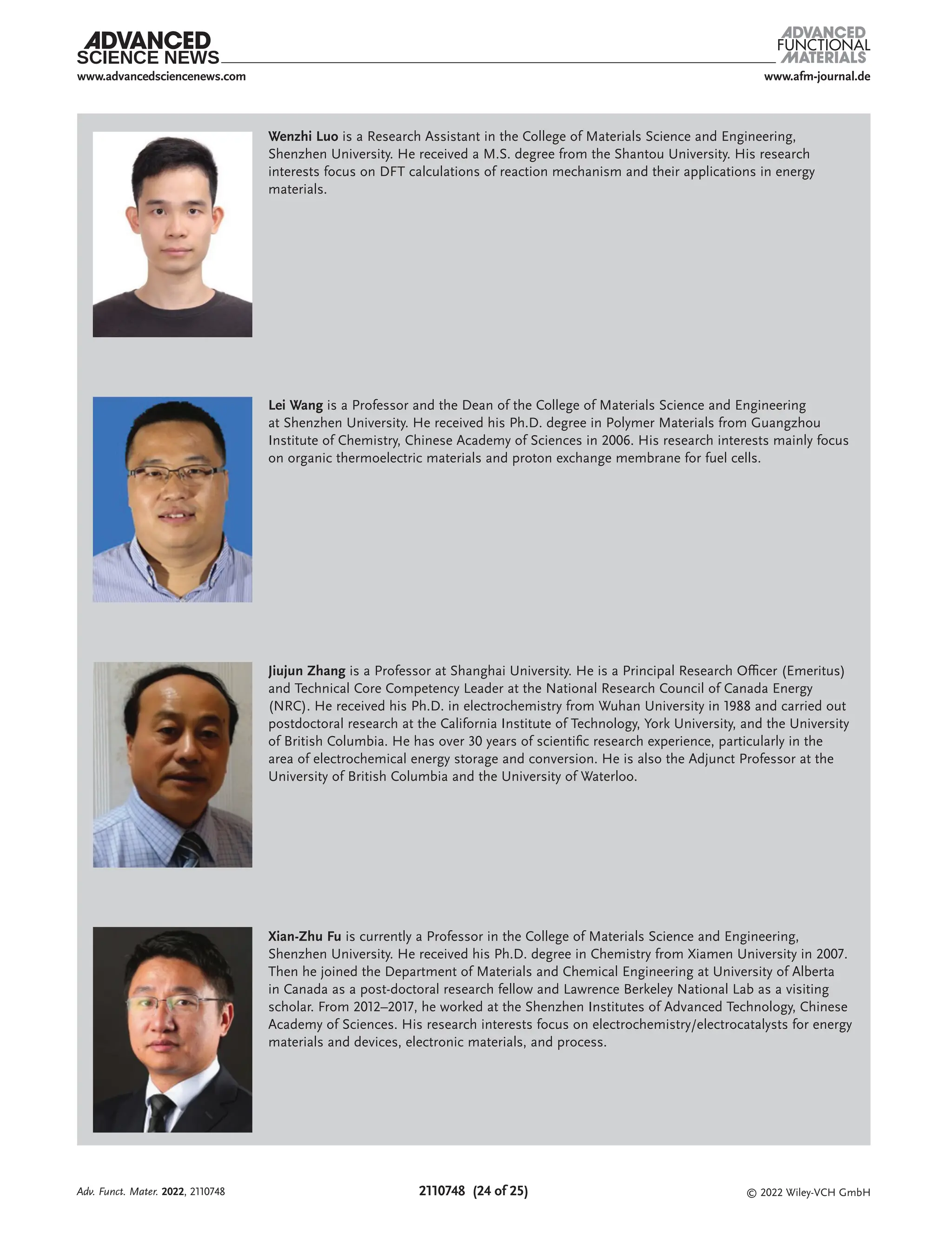

Jianwen Liu, Wenzhi Luo, Lei Wang, Jiujun Zhang, Xian-Zhu Fu,* and Jing-Li Luo*

Machine learning (ML) is emerging as a powerful tool for identifying quanti-

tative structure–activity relationships to accelerate electrocatalyst design by

learning from historic data without explicit programming. The algorithms,

data/database, and descriptors are usually the decisive factors for ML and

the descriptors play a pivotal role for electrocatalysis as they contain the

essence of catalysis from the physicochemical nature. Despite the consider-

able research efforts regarding electrocatalyst design with ML, the lack of

universal selection tactics for descriptors bridging the gap between structures

and activity impedes its wider application. A timely summary of the appli-

cation of ML in electrocatalyst design helps to deepen the understanding

of the nature of descriptors and improve the application scope and design

efficiency. This review summarizes the geometrical, electronic, and activity

descriptors used as input for ML training and predicting to reveal the general

rules for their application in the design of electrocatalysts. In response to the

challenges of hydrogen evolution reaction, oxygen evolution reaction, oxygen

reduction reaction, CO2 reduction reaction, and nitrogen reduction reaction,

the ML application in these areas is tracked for the progress and prospective

changes. Additionally, the potential application of the automated design and

discovery are discussed for the other well-known electrocatalytic processes.

DOI: 10.1002/adfm.202110748

1. Introduction

With the increasing demand for energy owing to the rapid

development of global economies, the discovery of high-per-

formance, stable, and sustainable materials for energy appli-

cations has become imperative.[1] The conventional energy

materials discovery method is usually based on trial-and-error

processes and takes 15 to 25 years (or longer) to achieve desired

applications.[2]

Although modern technology has accelerated the

J. Liu, W. Luo, L. Wang, X.-Z. Fu, J.-L. Luo

Shenzhen Key Laboratory of Polymer Science and Technology

Guangdong Research Center for Interfacial Engineering of Functional

Materials

College of Materials Science and Engineering

Shenzhen University

Shenzhen 518060, China

E-mail: xz.fu@szu.edu.cn; jingli.luo@ualberta.ca

J. Zhang

Institute for Sustainable Energy

College of Sciences

Shanghai University

Shanghai 200444, China

The ORCID identification number(s) for the author(s) of this article

can be found under https://doi.org/10.1002/adfm.202110748.

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-1-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (2 of 25) © 2022 Wiley-VCH GmbH

potential of ML. Understanding the selection rules for descrip-

tors is a prerequisite to its beneficial utilization. Timely review

of the application of ML in electrocatalyst design helps deepen

the understanding of the nature of descriptors and improve the

application scope and design efficiency.

This review summarizes the ML application in the field of

electrocatalysis from the selection tactics of descriptors for elec-

trocatalyst design and the improvement that machine learning

can make for the challenges of hydrogen evolution reaction

(HER), oxygen evolution reaction (OER), oxygen reduction

reaction (ORR), CO2 reduction reaction (CO2RR), and nitrogen

reduction reaction (NRR) (see Figure 1). To shed light on the

descriptor selection tactics, the geometrical, electronic, and

activity descriptors for the quantitative representation of elec-

trocatalysis are discussed in detail. Additionally, the progress

of machine learning in meeting the challenges of HER, OER,

ORR, NRR, CO2RR, etc., is reviewed, including the challenges

of reducing the loading of precious metals, improving catalytic

activity, and breaking the linear relationship of adsorption inter-

mediates. Afterward, the limits, problems, delays, etc., of ML in

electrocatalysis research are discussed. Finally, the challenges

and perspectives in the ML application for electrocatalysts

design are given for the potential energy storage and conver-

sion application, such as, hydrogen, methanol, ethanol oxida-

tion reactions, as well as, sulphur oxidation reactions for Li-S

batteries.

2. Descriptors for Electrocatalysis

For ML applications, descriptors are the key for developing

models that can handle in-depth domain knowledge about

physical material properties.[19]

Such properties can adequately

characterize the underlying physics and unique structures of

matter. A good descriptor is simple, easy to obtain, and low

dimensional.[20] To better understand the functions of these

descriptors, extensive prior research has been completed

on descriptors. For instance, Hong et al. systematically eval-

uate the descriptors for OER.[21] Andersen et al. systematically

studied 31 descriptors based on their OER reactions.[22] Liu and

co-workers used 38 descriptors for OER performance prediction

based on perovskite oxides using the surface center environ-

ment feature model.[23] These studies showed the importance

of descriptors, but they were not universally applicable to elec-

trocatalysis. To highlight the most-used descriptors, we summa-

rized those used for HER, OER, ORR, CO2RR, and NRR from

the recently published research articles. (see Table 1) Tradition-

ally, three types of feature descriptors are used with ML applica-

tions: geometrical, electronic, and activity-based.

As the properties are derived from the geometrical structures

of systems, they are usually referred to as structural descrip-

tors, including atomic radius/covalent radius, atomic number

(i.e., mass number), group number, molar volume, lattice con-

stants, rotational angle, bond length, coordination number,

active sites, and surface properties (i.e., defects/microstructure/

facet). Research has shown that some of the geometrical

descriptors are good indicators for the reactivity. For instance,

the coordination number has been shown as an excellent indi-

cator for structural properties of a catalyst that influences cata-

lytic performance,[24] which can predict the optimal active sites

for Pt (111).[24b] Jiang et al. have also showed that an adjusted

coordination number can act as a general descriptor to bridge

the structure and reactivity for the oxygen sites over transition-

metal oxides.[25]

In addition, if the properties are derived from electron den-

sity,[26] they are referred to as electronic descriptors. These

descriptors are usually obtained from electronic structure cal-

culations, which are time-consuming owing to the first princi-

ples/ab initio calculations required. It involves d bands/orbitals,

band gaps, s electrons, charge/charge difference, valence elec-

trons, etc. For transition metals, the main reactivity lies on the

d-bands/orbitals, whose properties include center, filling, width,

skewness, kurtosis, and density of states at the Fermi level, and

they play an essential role in electrocatalysis.[22,23] Hence, these

properties have been extensively used as descriptors.[27] The sur-

face valence band photoemission spectra provided experimental

evidences that the d-band center is indeed an active descriptor

for CO2RR[28]

and NRR.[29]

However, the d-band center endures

inaccuracy for early transition metals and strongly correlated

metals.[30]

Alternatively, Shao–Horn and co-workers illustrated

that the ORR activity for oxide catalysts basically related to the

filling of σ* orbital (eg) and the degree of B-site transition metal

covalency.[31]

In addition, the O p-band center with respect to

the Fermi level was found an active descriptors for (Ln0.5Ba0.5)

CoO3-δ double perovskites.[32]

Valence electron is another impor-

tant descriptor for reactivity alongside d-band/orbital related

properties since it directly participates the formation and

breakage of chemical bond. Koper et al. found that the number

of the outer electrons is a good descriptors for the adsorption

processes on transition metals and their oxides as the trends

of adsorption energies were well correlated with the number of

outer electrons.[33]

Another type descriptor is used to describe the ability to

accept or lose electrons/protons/groups to show the activity,

Figure 1. Overview of the descriptor-oriented ML electrocatalyst design.

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-2-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (3 of 25) © 2022 Wiley-VCH GmbH

that is, activity descriptors. They include adsorption energy,

electronegativity, electron affinity, ionization potential/energy,

pKa, and so on, as shown in Table 1. Adsorption energy shows

the adsorption ability of a group on the surface of electrocata-

lyst. It could be employed as a descriptor to predict properties

for electrocatalysis (e.g., onset potentials, turnover frequencies,

and product selectivity),[34]

although it is usually a target prop-

erty for the ML predictions.[35]

These predicted properties are

usually based on scaling relations between binding

energies

of reaction intermediates, Brønsted–Evans–Polanyi rela-

tions between reaction energies and kinetic barriers. Electron

affinity is the difference of system energies without an electron

and that of the anion, whereas the ionization potential is the

minimum energy needed for an electron to detach from the

molecule. For ML applications, these two descriptors are

usually used simultaneously.

In addition, other descriptors also exist and usually are

used for specific systems. For example, Yin and co-workers

Table 1. Descriptors and their applications in ML for electrocatalysis.

Descriptors HER OER ORR CO2RR NRR

Atomic radius/covalent radius [36] [37] [38] [39] [40]

Atomic number/mass number [36a,41] [37b,37c] [1,41a] [40]

Group number [38c] [40a]

Molar volume [42] [42]

Lattice constants [36a,43]

Rotational angle [44] [44]

Bond length/bond information [36a,43–45] [38d]

Coordination number [41a,41c] [46] [24b,46,47] [1,41a,46,48] [40b,46]

Active sites [41b]

Surface properties (defects/microstructure/facet) [49] [49,50]

d bands/orbitals:

1) Centre [36,43] [37c,51] [51] [52] [53]

2) Hibert transformation [26]

3) Electrons [36b,41b,54] [37b,42,51] [42,47b,51,54] [39]

4) Orbitals information [36a]

5) eg occupation [37c,54] [54]

6) Width [37c] [52]

7) Skewness [37c] [52]

8) Kurtosis [37c] [52]

9) Pseudopotential radius [42] [42]

Band gap [44] [44]

s electrons [42] [42]

Charge/charge difference [55]

Valence electrons [41c,56] [37a,46] [38d,46] [46,48a] [46]

Adsorption energy [41a] [47b,57] [1,39,41a] [53]

Formation enthalpy [54] [58] [54] [39]

Charge-transfer energy [59] [60]

Electronegativity [36,41a,41b,56,61] [37,42,46,51,54,61a] [38a,38c,38d,42,46,47b,51,54,61a] [1,39,41a,46,48,52] [40,46]

Electron affinity (EA) [41b] [37b] [38a,38d,47b] [39,48b] [40a]

Ionization potential (IP)/energy [36b,41b] [37b] [38c,38d,47b] [39,48b] [40a]

pKa [54] [54]

Chemical potential [62]

Strain [42] [42]

Tolerance factor [63]

Octahedral factor [63]

Fukui function [64]

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-3-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (4 of 25) © 2022 Wiley-VCH GmbH

developed the octahedral (µ) and tolerance (t) factors ratio as

a simple descriptor to accelerate the discovery of new perov

skite catalysts with superior OER activity since the tolerance

and octahedral factor have well known geometrical/structural

interpretations for perovskite.[63] Gusarov et al. developed an

unused sort of ML-enhanced descriptor based on the Fukui

function, which provided information about the local

system’s response to perturbations and was used as a descriptor

to describe the chemical properties of surfaces.[64] In addition,

Shao-Horn et al. summarized that the electrochemical redox

potential can act as an efficient descriptor for OER and ORR.[65]

3. Machine Learning Application for

Electrocatalyst Design Based on Calculations

The application for the electrocatalyst design involves mainly

oxidation and reduction reactions. In this section, we review

these redox reactions for electrocatalysis applications based on

the calculations independent of experiments. These involve

HER, OER, ORR, CO2RR, and NRR.

3.1. Machine Learning for Hydrogen Evolution Reaction

Application

The production of hydrogen has attracted extensive attention

for providing pollution-free energy with high energy density.[66]

To this end, HER has emerged with paramount significance

for hydrogen energy conversion and storage. HER is a classic

two-electron transfer reaction with only one intermediate H*,

where * denotes the adsorption. This principle is applied in the

following sections. A two-electron transfer reaction might occur

via either the Volmer–Tafel or the Volmer–Heyrovsky mecha-

nism (see Table 2).

These mechanisms are the basis for ML-auxiliary electrocata-

lyst design, and have been reviewed by many researchers.[3,66,67]

Because all mechanisms involve the adsorption of hydrogen,

the optimization of the adsorption of hydrogen is the main

target for catalyst design according to the Sabatier principle.

Pt-based precious-metal electrocatalysts dominate HER appli-

cations,[68] although some non-precious metals composites are

effective.[67c] To make electrocatalysts more cost-effective, it is

desirable to minimize the dosage of Pt or to use non-precious

metals. The construction of precious-metal alloys and stable

non-precious-metal electrocatalysts are new strategies for ML

HER applications.

Table 2. Mechanisms for HER in acidic and alkaline environments.

Mechanisms Reactions

Volmer-Tafel Volmer step: H+

+ e−

+ * → H*

Tafel step: 2H* → H2 + *

Volmer-Heyrovsky Volmer step: H+

+ e−

+ * → H*

Heyrovsky step: H* + H+

+ e−

→ H2 + *

Figure 2. a) Illustration for the random sampling for a bimetallic alloy (100) surface. b) Algorithmic architecture of the BPNN model employed for the

random sampling of bimetallic alloys. Reproduced with permission.[36a] Copyright 2020, Royal Society of Chemistry.

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-4-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (5 of 25) © 2022 Wiley-VCH GmbH

Based on conditional combinations of ML regression algo-

rithm, density functional theory (DFT) data and descriptors, Yang

and co-workers explored the catalytic activity of bimetallic alloy

(100) surfaces by alloying strong (Pd and Pt) and weak-binding

(Ag, Au, and Cu) transition metals as shown in Figure 2.[36a] They

varied the contents for MxNy (x + y = 1) for screening the high-

performance electrocatalyst, as shown in Figure 2a. The results

indicated that PdxAg1-x and PdxAu1-x possessed the foremost

promising HER activity in acidic environment, owing to the pro-

foundly active fourfold ensembles. Combining the geometrical,

electronic and activity descriptors such as the electronegativity,

d-orbital atomic radius, lattice constant, and atomic number as

descriptors (Figure 2b), additional ML analyses based on three-

layer artificial neural networks (ANNs) using a back-propagation

neural-network algorithm predicted that the Pt4/Ir0.75Pt0.25 (100)

would show the most active electrocatalyst for HER among the

≈900 predicted bimetallic alloy structures.

Ulissi and co-workers created a workflow from the ideas ini-

tiated by active ML- and surrogate-based optimizations, which

used a less-consuming surrogate model to supplant a com-

putational cost model to optimize the objective function.[41a]

With this method, a surrogate model was first created from a

given dataset and used to select data based on the geometrical

and activity descriptors, that is, atomic number, coordina-

tion number, electronegativity, and adsorption energy. Then,

the selected data were added to the original dataset to create

an updated one. The surrogate model continuously improved

through this repetition. Using this workflow, the researchers

screened 50% of the d-block elements and 33% of the p-block

elements, and 258 surfaces across 102 alloys were identified for

experimental validation. The distinguishing proof of surfaces

with near-optimal ΔEH values are shown in Figure 3. The work-

flow could be effortlessly transplanted to other reaction systems

if the perfect thermodynamic descriptors are known.

Figure 3. Near-optimal ΔEH values for HER. a) Identified near-optimal surfaces number and violin plots versus time. b) The normalized distribution

for the DFT calculated ΔEH of all the surfaces. c) Surface for DFT and ML calculated ΔEH at low coverage. d) Surface for ML calculated ΔEH only at low

coverage. Reproduced with permission.[41a] Copyright 2020, Springer Nature.

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-5-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (6 of 25) © 2022 Wiley-VCH GmbH

Non-metal electrocatalysts are alternatives to Pt. Hence, a

recent ML HER application focused on 2D materials,[41b,41c,43,44,69]

especially those supporting single-atom catalysts (SACs) such

as, graphdiyne (GDY),[41b] metal–nitrogen–carbon (M–N–C),[36b]

MXene,[43] MoS2,[41c] and transition-metal dichalcogenide

(TMD).[44]

Huang and co-workers applied DFT calculations to ML to

systematically investigate the HER process catalyzed by GDY-

based atomic catalysts covering all transition and lanthanide

metals with adsorption energies, adsorption trends, electronic

structures, reaction pathways, and active sites.[41b] Six descrip-

tors were employed for the input data of ML, including two

geometrical descriptors (mass numbers and active sites), one

electronic descriptor (d/f electrons) and three activity descrip-

tors (electronegativity, electron affinity, and ionization poten-

tial). The ML bag-tree approach was employed based on data

separation and converse prediction fuzzy models to estimate

HER performance, followed by DFT calculations. The methods

gave nearly the same results, indicating their highly accurate

ML prediction capability.

Because recent studies have illustrated that 2D M–N–C-

based SACs exhibit superior performance for HER,[70] Jiang and

co-workers reported a new tuning approach by altering the size

and dimensionality of the M–N–C carbon substrate whereas

keeping up the same coordination environment.[36b] Taking the

geometrical descriptors (covalent and Zunger d-orbital radii),

electronic descriptors (d band center, d electrons number and

states) and activity descriptors (formation energy, electron-

egativity, ionization potential) into consideration, they set up

ML models and screened the 3–5d transition-metal SACs in

N-doped graphene and nano-graphene of several sizes of HER

using a DFT, predicting that nano-graphene involving V, Rh,

and Ir would have significantly improved HER activity. Wang

and co-workers used four ML models alongside DFT to accel-

erate the HER catalysts screening in 299 MXene materials.[43] It

was found that the random-forest algorithm gave high accuracy

based on simple elemental descriptors. Additionally, they evalu-

ated correlationship between the descriptors (d-band center,

Bader charge transfer, bond length, the lattice parameter) and

the adsorption energy ΔGH. It was found that simply descriptors

cannot establish a good relationship with ΔGH. The integration

of multiple descriptors is necessary for a more accurate predic-

tion of ML. In addition, Liu et al. also studied the electronic and

composition attribution to the catalytic activity based on TMDs

and established an equation for ΔGH prediction of TMDs based

on activity descriptor electronegativity and electronic descriptor

valence electrons.[56]

Moreover, Goddard III and co-workers pro-

posed that the optimization of descriptors would dramatically

improve catalytic performance.[44]

They applied the least abso-

lute shrinkage and selection operator process, incorporating

unconventional descriptors such as, rotational angle, layer dis-

tances, and bandgaps ratio of component materials with DFT to

predict novel structures. It predicted that MoTe2/WTe2 would be

high performance electrocatalyst with overpotentials of 0.03 V

and 0.17 for HER and OER, respectively.

Collectively, previous works on the design of alloy and simple

2D materials suggest that ML models are highly competitive

in accelerating electrocatalyst design for HER, exhibiting a

decent prediction precision. The geometrical, electronic, and

activity-based descriptors are deeply involved for the ML HER

applications. The combination of these descriptors is critical for

the efficient ML applications. The integration of geometrical

and electronic descriptors with activity descriptors improves

the ML prediction significantly. Notably, the electronegativity is

found essential for the ML prediction of electrocatalytic activity

as electronegativity is the ability of an atom to attract an elec-

tron pair shared with another atom to form a chemical bond,

which is an indicator of intrinsic activity properties. To this end,

the selection tactics of descriptors is one of the most critical fac-

tors for the electrocatalyst design based on ML.

3.2. Machine Learning for Oxygen Evolution Reaction

Application

OER is another half reaction for water splitting. However, owing

to the sluggish kinetics of four-electron transfer reactions, OER

is a bottleneck for electricity-driven water splitting.[71] Hence,

the mechanisms for OER in acidic and alkaline environment

have been intensively reviewed as shown in Table 3,[72] indi-

cating that one of the main challenge for electrocatalyst design

lies with the strong correlations of adsorption energies for

intermediates *OH, *O, and *OOH.[73] Breaking the correlation

relationship to achieve superior performance is the main goal

of OER electrocatalyst design. Recently, ML-based electrocata-

lyst design has focused on modelling the precious-metal oxide

IrO2,[50,58,74] and non-precious metal oxides, for example, spinel

oxides,[37a] perovskite,[23,37c,63] quaternary metal oxides,[75] and

2D materials.[37b,44,51,54] In this section, some examples are given

for these materials application.

3.2.1. Iridium Oxide

Nowadays, iridium oxide is one of state-of-the-art electrocata-

lysts for OER and IrO2 is usually used as the benchmark for

OER.[72a] Understanding the oxygen chemistry of these mate-

rials is essential for OER performance enhancement, but it is

complicated. Bligaard and co-workers studied the relationship

between IrO2/IrO3 polymorphs and OER functionality by cou-

pling active ML with subsequent analysis.[58] For each IrO2/

IrO3 polymorph, surfaces were established by cutting along the

Miller indices with the sharpest diffraction peaks associated

Table 3. Reaction mechanisms for OER in acidic and alkaline

environments.

Environment Mechanisms

Acidic * + H2O (l) → *OH + H+ + e−

*OH → *O + H+

+ e−

*O + H2O (l) → *OOH + H+

+ e−

*OOH → * + O2 + H+

+ e−

Alkaline * + OH−

→ *OH + e−

*OH + OH− → *O + H2O + e−

*O + OH− → *OOH + e−

*OOH + OH−

→ * + O2 (g) + H2O(l) + e−

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-6-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (7 of 25) © 2022 Wiley-VCH GmbH

with planes having higher atom density (see Figure 4a). The

results showed that surface stability analysis was pivotal for pre-

cise determination of the activity, revealing that octahedral coor-

dination were preferable for about all low-energy structures.

Additionally, Pourbaix Ir-H2O investigation showed that α-IrO3

was remarkably stable under acidic environment superior to

that of IrO2. The activity plot for the OER against the descriptor,

ΔGO−ΔGOH (Figure 4b), displayed two thermodynamic limiting

potential volcanos and kinetic OER volcanos, which was in good

agreement with the strong binding portion and exhibit a sim-

ilar optimum value. The α-IrO3 (100), (110), and (211) showed

the highest performance for the surface structures with high

oxygen coverage (Figure 4c). Around 0.4 VRHE overpotentials

have been observed for these surfaces, outperforming R-IrO2

with ≈0.2 VRHE improvement. It confirmed the onset poten-

tials shift experimentally. The main reason for the OER activity

enhancement was the higher oxidation state (Ir6+

) of IrO3 with

three 5d-electrons compared with the low oxidation state (Ir4+

)

of IrO2 with five 5d-electrons. Therefore, oxygen-saturated IrO3

bound OER intermediates more weakly, leading to positive

shifts of ΔGO–ΔGOH. To this end, the descriptor ΔGO–ΔGOH

involved in this work can be regarded as a composite descriptor,

including both activity descriptor (adsorption energy) and elec-

tronic descriptors (d electrons) to account for the electrocata-

lytic activity. With this approach, 956 different type AB2 and AB

structures were identified among 38 000 existing materials in

the databases. 196 IrO2 polymorphs were found thermodynami-

cally stable, and 75 IrO3 polymorphs were found synthesizable.

Finally, α-IrO3 was reported as the most stable.

Ulissi et al. proposed an automated method to help under-

stand oxygen chemistry while predicting OER overpotentials

for universal oxide surfaces making use of the descriptor ΔGO-

ΔGOH in combination of surface information.[50]

It was found

that low-index surfaces of IrO2 were more active and the IrO2

Figure 4. a) Pourbaix diagrams for R-IrO2, α-IrO3, R-IrO3, and β-IrO3. b) OER activity volcano for IrOx using ΔGO−ΔGOH as the descriptor. c) Models

for selected OER surfaces with monolayer O* coverage. Reproduced with permission.[58]

Copyright 2020, American Chemical Society.

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-7-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (8 of 25) © 2022 Wiley-VCH GmbH

and IrO3 were identified with the most promising active sites,

which were superior to rutile (110) by 0.2 V in theoretical over-

potential. Moreover, they provided catalyst design strategies for

improving the activity of Ir-based catalysts and an ML model

that could predict surface coverages and site activity based on

the DFT calculations. Reuter and co-workers also identified

IrO2 surface complexions through ML.[74] Using simulated

annealing, they trained a Gaussian approximation potential

using DFT data to construct a global geometry optimization for

low-index rutile IrO2 facets. The (101) and (111) (1 × 1) termina-

tions were surprisingly identified by ab initio thermodynamics

that compete with (110) in reducing environments, which

was confirmed by single-crystal analysis experimentally. The

unexpected surface structures identified for such well-studied

system indicates the powerful predictive quality of ML.

3.2.2. 2D Materials

2D van der Waals heterostructure materials were proven to

be excellent water-splitting electrocatalysts to produce H2 and

O2.[66] Therefore, these kinds of materials have received con-

siderable attention. The usage of 2D materials for OER could

significantly lower precious-metal loading while facilitating

the activity. Based on DFT calculations of graphene-supported

SACs, Chen and co-workers built ML models to portray the

latent pattern of easily available physical properties and limiting

potentials, employing these models to forecast the electrocata-

lytic performance of other graphene-supported SACs involving

metal-NxCy active sites. Integrating the electronic descriptor

(d electron number) and activity descriptors(oxide formation

enthalpy, electronegativity, and pKa), they recomputed the best

catalysts prescribed by the ML demonstrate toward the OER

using DFT, confirming the high reliability of their ML dem-

onstrations. Further, the Ir incorporated graphene with 2 and

3 pyridine-N atoms dopant OER catalyst (Ir-N3-C1 and Ir-N2-C2)

were identified to outperform RuO2 and IrO2.[54] Li and co-

workers used atomic mass, atomic radius, d-electron, electron-

egativity, electron affinity, and ionization energy as descriptors

to predict the overpotential for OER of single-atom catalysis.[37b]

Owing to the maximum atomic efficiency,[76] it can predict the

overpotential precisely and quickly for OER catalyzed by SACs

and found the prediction was similar to these from DFT calcu-

lations but 130 000-fold reduction of time.[37b]

3.2.3. Spinel Oxide

Along with IrO2 enhancements, the usage of other oxides as

alternatives has been notable, among which spinel oxide (AB2O4)

is representative. Xu and co-workers showed that the activity of

AB2O4 toward OER was inherently overwhelmed by the competi-

tion between tetrahedral (A2+

cation), and octahedral (B3+

cation)

covalency (see Figure 5).[37a]

Owing to the crystal field effect,

the d-orbitals of the tetrahedral cations were split into three t2-

orbitals and two e-orbitals whereas the d-orbitals of octahedral

cations were split into three t2g-orbitals and two eg-orbitals due

to symmetry difference. These types of bonds formed MTO

and MOO due to the orbital overlapping between the metal

d-orbitals and oxygen p-orbitals. Because the tetrahedral (A2+

cation) and octahedral (B3+

cation) cations were alternately con-

nected, each oxygen atom was shared by these cations via the

p-orbitals overlapping, leading to covalency competition. This

subsequently resulted in non-equivalent bonds for MTO and

MOO with one stronger, forming asymmetrical backbone with

structure of MT−O−MO. In the case of bias applied for the OER

application, the surface reconstruction of spinel oxides might

happen, and weaker bond might break. Once the weaker bond

broke, the MTOMO was separated into two parts, MO and

M. The coordination of the cations in MO remained full, so

it hardly contributed to the performance enhancement. However,

the coordination of the bared M was changed with unpaired

valence electrons, which could serve as active sites to start OER

cycles. To this end, the breakage of either MTO or MOO

from MTOMO could generate exposed cation sites to acti-

vate the OER cycles. Thus, the weaker metal–oxygen covalency

of MTOMO backbone determined the exposure of cation sites

and therefore its activity. Driven by this discovery, more than

300 spinel oxides were calculated to train an ML model to screen

spinel oxides, and [Mn]T[Al0.5Mn1.5]OO4 was forecast to be a

highly active OER catalyst, which was confirmed experimentally.

3.2.4. Perovskite

Perovskite is another active non-precious metal oxide electrocat-

alyst for OER. It possesses a regular ABO3-type structure. The

ABO3-type structure is flexible with various component options

for A and B, which leads to a combinatorically large number

that can be estimated based on combinatorics.[31a] Xin and co-

workers developed an adaptive ML method to search ABO3-

type perovskites for high-performance OER activity with a set of

multi-fidelity features and probabilistic models.[37c] The set fea-

tures included composition and electronic structures, whereas

the probabilistic models were trained by Gaussian processes with

ab initio calculation data for predicting *O and *OH adsorption

energies and other activity descriptors. A univariate analysis of the

discrepancy of probability density functions (pdf) was performed

to discover the physical factors determining the OER activity

using the Kullback–Leibler (KL) divergence, an indicator to dis-

tinguish informative descriptors. Figure 6a,b show that small KL

divergence values were obtained for the descriptors A-site elec-

tronegativity and tolerance factor as the pdf distributions were

mostly overlapped for the OER activity samples. In comparison,

the high divergence values were obtained for the descriptors

dx y

2 2

− orbital center and dz2 orbital filling due to the mismatched

pdf distribution (Figure 6c,d). Additionally, Figure 6e highlighted

all highest constructive descriptors, showing that the eg orbitals

dz2 , dx y

2 2

− fillings with high KL divergence values were strongly

correlated to the OER activity of perovskite. The further univar-

iate analysis demonstrated that the electronic descriptors as phys-

ically instinctive highlights were invaluable to understanding the

fundamental physical laws that determine the OER activity at the

molecular level. The finds agreed with the experimental observa-

tion that the occupancy of eg orbital for the metal B site mainly

determines the OER activity. The main reason lay in the fact that

the eg orbital dz2 interacted with the p-orbitals of oxygen interme-

diates with overlapping at active sites. By evaluating the potential

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-8-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (9 of 25) © 2022 Wiley-VCH GmbH

perovskites with theoretical overpotentials <0.5 V, the ML models

rapidly screened ≈4000 double perovskites and selected the stable

structures with potential high-performance OER activity.

Yin and co-workers used symbolic regression to design

new oxide perovskite electrocatalysts with improved OER

activities.[63]

As the larger tolerance and octahedra factor lead

to structure distortions and instability of oxygen in the perov-

skite, the ratio of octahedral and tolerance factors (µ/t) was

used to accelerate the discovery of a number of new perovskite

electrocatalysts having improved OER activity. Based on the

descriptor, a few new perovskites having potentially high OER

activity were synthesized, among which four new ones (i.e.,

Cs0.4La0.6Mn0.25Co0.75O3, Cs0.3La0.7NiO3, SrNi0.75Co0.25O3, and

Sr0.25Ba0.75NiO3) showed excellent intrinsic OER activities.

3.2.5. Quaternary Metal Oxide

Gregoire et al. accelerated the material discovery process

using updating ML sequential learning (SL) based on the

quaternary metal-oxide electrocatalysts designed for OER to

quantify superior electrocatalyst performance and accuracy.[75]

The overpotential of OER was chosen for the performance

metric. Various SL schemes were examined on four chemical

components, each containing 2121 catalysts (see Figure 7).

Their work suggested that electrocatalyst design could be

accelerated by up to a factor of 20 compared with random

acquisition methods (RCM) in particular scenarios. Further,

they showed that certain choices of SL models were not suit-

able for a given investigative goal, resulting in a significant

slowdown compared to RCM.

The evidence presented in this section suggests that the

ML application of OER was designed for the precious metal

oxide, IrO2, to better understand the reactivity origin and

optimize performance. ML applications for 2D materials

aim to lower the loading of precious metals. Moreover, non-

precious metals, such as, spinel oxides, perovskites, and

quaternary metal oxides, were used to design ML for new

OER electrocatalysts to replace precious metals. The value

of ΔGO−ΔGOH can act as excellent descriptor to exhibit the

Figure 5. OER mechanisms for spinel oxides based on the density of states and the machine learning prediction results. Reproduced with permission.[37a]

Copyright 2020, Springer Nature.

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-9-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (10 of 25) © 2022 Wiley-VCH GmbH

correlation of *OH and *O and construct the vancono curve

to locate the optimal electrocatalyst. Although some pro-

gress was made in improving the reaction activity, reducing

the loading of precious metals, and designing non-precious

metal catalysts, the correlation between the *OH, *O, and

*OOH remains one of the main obstacles to OER electro-

catalyst design.

3.3. Machine Learning for Oxygen Reduction Reaction

Application

For the energy conversion process in energy storage and con-

version equipment such as fuel cells, the ORR plays a pivotal

role in the electrocatalytic process.[77] The slow kinetics of the

cathode limits the overall performance of fuel cells.[77] Hence,

Figure 7. a) Illustration for compositions containing 1–4 cation elements. b) The 2121 OER overpotentials for the 6, 15, 20, and 15 compositions con-

taining 1–4 cations. Reproduced with permission.[75] Copyright 2020, Royal Society of Chemistry.

Figure 6. Probability distribution plots for perovskite a) A-site electronegativity as descriptor, b) tolerance factor as descriptor, c) B-ion 2 2

dx y

−

orbital

center as descriptor, d) B-ion 2

dz orbital filling as descriptor. e) Polar distribution plots for the most informatic descriptors with KL entropy index > 0.4.

Reproduced with permission.[37c] Copyright 2020, American Chemical Society.

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-10-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (11 of 25) © 2022 Wiley-VCH GmbH

accelerated electrocatalyst design is highly desired to facilitate

the kinetics of ORR for the fuel cells. Nowadays, the expensive

and efficient Pt-based materials are the most practical electro-

catalyst for ORR. However, the high price for electrocatalysts

becomes a challenge for the large-scale commercialization of

fuel cells. Thus, ML applications to find efficient ORR catalysts

are of paramount importance.

In acidic and alkaline environments, the mechanisms of

ORR have been well-reviewed,[77,78] as shown in Table 4. The

greatest challenge to ORR catalyst design lies with the unfa-

vorable scaling relationships between the binding energies of

reaction intermediates, *OH, *O, and *OOH for OER.[77] ML

has been used to discover efficient ORR catalysts to minimize

the loading of precious metals and to improve the design of

non-precious-metal electrocatalysts (e.g., 2D materials,[38a,47b,54]

high-entropy alloys (HEAs),[38b] and precious-metal core–shell

nanostructures).[47a]

3.3.1. 2D Materials

2D materials are attractive non-precious electrocatalysts because

Fe-N-C- and Co-N-C-based electrocatalysts have been found to

be active for ORR.[79] However, the Fenton effect for Fe-N-C, its

low activity and its low stability remain obstacles to their wide

application.[79] Therefore the design of stable, active 2D mate-

rial electrocatalysts for ORR-based MLs is extremely prom-

ising. Bi-atom catalysts might provide solutions by constructing

the synergy effect, as shown in Figure 8. Li and co-workers

unveiled design principles of 2D graphene-based dual-metal-

site catalysts for ORR using DFT with ML.[38a] This ML study

revealed that the ORR activity of dual-metal-site catalysts was

intrinsically determined by activity descriptors (electron affinity

and electronegativity) and the geometrical descriptor (radii of

embedded metal atoms). Huang et al. illustrated that 31 SACs

had the potential to break the scaling relations of *OH, *O,

and *OOH from 210 2D SACs by manipulating the supporting

environment of the materials. Eight descriptors were involved,

including geometrical descriptors (coordination number),

Table 4. Reactions mechanisms for ORR in acidic and alkaline

environment.

Environment Electrons transferred Reactions

Acidic 4 O2 + 4 H+

+ 4e−

→ 2 H2O

2 O2 + 2 H+

+ 2e−

→ H2O2

H2O2 + 2 H+ + 2e−→2 H2O

Alkaline 4 O2 + 2 H2O + 4e− → 4OH−

2 O2 + H2O + 2e−

→ HO2

−

+ OH−

H2O + HO2

−

+ 2e−

→ 3OH−

Figure 8. a) Illustration of the structures for dual-metal-site catalysts; b) ORR activity trends plot of dual-metal-site catalysts versus both ΔGOOH* and

ΔGOH*; c) free energy diagrams of dual-metal-site catalysts; d) simulated ORR polarization curves for 8 screened dual-metal-site catalysts versus Pt

(111). Reproduced with permission.[38a] Copyright 2020, American Chemical Society.

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-11-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (12 of 25) © 2022 Wiley-VCH GmbH

electronic descriptors (d/p electrons), and activity descrip-

tors (the oxide formation enthalpy, electronegativity, elec-

tron affinity, and first ionization energy) and some composite

descriptors such as sum of the electronegativity of neighboring

C and N atoms. The predicted electrocatalysts simultaneously

achieved high activity and selectivity toward H2O2 production,

among which seven SACs were equipped with higher activity

than PtHg4 in acidic media.[47b] Notably, multiple-variable anal-

ysis discovered that the underlying origin of the selectivity and

activity arising from the charge transfer between the active site

and OOH* intermediate, as well as, the MO band hybridi-

zation, which provides hints for the electrocatalyst design to

enhance the activity and selectively simultaneously.

3.3.2. High-Entropy Alloys

HEAs comprised various elements in solid solutions to form

well-ordered crystal structures with randomly distributed con-

stituents, offering atomic arrangement sites having extraordi-

nary catalytic properties. With such manipulations, the loading

of the precious metal could be lowered while enhancing its per-

formance. Rossmeisl and co-workers made HEA the discovery

platform for ORR based on the activity descriptor (adsorption

energy) and geometrical descriptors (composition of the local

binding site).[38b] Making use of DFT in combination of ML,

they found that the calculated and predicted values of *OH and

*O adsorption energies were in good agreement on any subset

of available binding sites. With a complete list of available

adsorption energies, this excellent expression of electrocatalytic

activity prediction was employed to optimize the composition

of HEA. As a result, the HEA was changed to a design platform

for unbiased discovery of new alloys by optimizing sites with

special electrocatalytic activity. Specifically, the results predicted

that the binary alloy IrPt significantly enhanced the perfor-

mance compared to pure Pt (111).

3.3.3. Core–Shell Nanostructure

Construction of core–shell nanostructures is another effec-

tive strategy of lowering the loading of precious metals.

Gagliardi and co-workers presented an ML framework that

introduced strain to enhance ORR activity for Pt core–shell

nano-catalysts.[47a]

Based on the geometrical descriptor general-

ized coordination number, they demonstrated that the optimal

strain depended on the nanoparticle size or the weakening of

the compressive strain. It was predicted that bimetallic Pt@Au

and Pt@Ag would have the best mass activities at 2.8 nm, as

long as active sites were exposed to weak compressive strain.

This work is mainly for precious metals, which have been

proven to have good activity for ORR. So the generalized coordi-

nation number can be used as the descriptor solely to optimize

the geometric structure. However, the usage for non-precious

metals to design efficient electrocatalyst has not been reported

yet, which requires further exploration.

Overall, there were two general strategies for electrocatalyst

design based on ML application to ORR: Searching for alter-

native electrocatalysts (non-precious metal electrocatalysts) or

lowering the loading of precious metals. The adsorption ener-

gies of *OH, *O, and *OOH are essential activity descriptors

for the electrocatalyst design. Note that it could break the corre-

lation between *OH, *O, and *OOH to produce H2O2 with both

high selectivity and activity by manipulating the supporting

environment of the 2D materials. Although some descriptors

such as coordination number can be solely used as indicator for

ML application, the combination of geometric, electronic, and

activity descriptors is usually an efficient strategy for the predic-

tion of ORR electrocatalysts.

3.4. Machine Learning for CO2 Reduction Reaction Application

Electrochemical CO2 reduction to value-added chemicals and

fuels has attracted extensive attention because it provides a

clean and effective method to alleviate energy shortages while

reducing global carbon emissions.[80] Electrochemical reduction

methods of CO2 are varied, producing 16 different products,

including C1 products (i.e., CO, HCOOH (formic acid), HCHO

(formaldehyde), CH3OH (methanol), CH4 (methane)) and

multi-carbon products (i.e., H2C2O4 (oxalic acid), CH3CH2OH

(ethanol), CH2 = CH2 (ethylene), CH3CH3 (ethane), and

CH3CH2CH2OH (n-propanol)), which have been well-sum-

marized in previous research.[81] The 2–18 electron reduction

reactions are shown in Table 5. Owing to the diversity of prod-

ucts, selectivity has become one of the most concerning issues

for electrocatalytic CO2RR.[80,81,81e] To account for this, the ML

application of electro-catalyzed CO2RR was performed[82] while

Table 5. Reactions, potentials (E0

vs SHE and pH = 7) and electron

transferred (n) for the CO2RR.

n Reactions[81a] E0

2 CO2 + 2H+ + 2e− → HCOOH −0.610 V

CO2 + 2H2O+ 2e− → HCOOH + 2OH− −1.491 V

CO2 + 2H+ + 2e− → CO + H2O −0.530 V

CO2 + H2O+ 2e− → CO + 2OH− −1.347 V

2CO2 + 2H+ + 2e− → H2C2O4 −0.913 V

2CO2 + 2e−

→ C2O4

2−

−1.003 V

4 CO2 + 4H+

+ 4e−

→ HCHO + H2O −0.480 V

CO2 + 3H2O+ 4e−

→ HCHO+4OH−

−1.311 V

CO2 + 4H+ + 4e− → C + 2H2O −0.200 V

CO2 + 2H2O + 4e−

→ C + 4OH−

−1.040 V

6 CO2 + 6H+

+ 6e−

→ CH3OH + H2O −0.380 V

CO2 + 5H2O+ 6e−

→ CH3OH + 6OH−

−1.225 V

8 CO2 + 8H+ + 8e− → CH4 + 2H2O −0.240 V

CO2 + 6H2O + 8e−

→ CH4 + 8OH−

−1.072 V

12 2CO2 + 12H+

+ 12e−

→ CH2 = CH2 + 4H2O −0.349 V

2CO2 + 8H2O + 12e− → CH2 = CH2 + 12OH− −1.117 V

2CO2 + 12H+

+ 12e−

→ CH3CH2OH + 3H2O −0.329 V

2CO2 + 9H2O + 12e− → CH3CH2OH + 12OH− −1.157 V

14 2CO2 + 14H+ + 14e− →CH3CH3 + 4H2O −0.270 V

3CO2 + 18H+ + 18e− → CH3CH2CH2OH + 5H2O −0.310 V

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-12-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (13 of 25) © 2022 Wiley-VCH GmbH

focusing on alloys,[1,41a,48a,52,64,83] 2D materials,[39,62] and a data-

driven framework.[84]

Copper is unique to CO2RR because it adsorbs CO strongly

to inhibit the production of CO and formic acid. However, it

interacts with H weakly to suppress the formation of H2.[83a]

Hence, Cu is the predominant metal electrocatalyst for CO2RR

since the adsorption CO is regarded as an ideal descriptor

for catalytic performances of CO2RR.[85]

However, the energy

efficiency and productivity achieved cannot meet the criteria

for producing ethylene at cost-competitive prices. Hence, the

construction of alloys has become predominant. Ulissi and

co-workers presented a fully automated screening strategy

that used a combination of ML and DFT calculations to pre-

dict electrocatalyst performance of CO2RR with the same geo-

metrical and activity descriptors as mentioned above.[1,41a]

As

Figure 9a,b shows, the Cu-Al alloy was found to be the most

promising electrocatalyst for the reduction of CO2 to ethylene

with a very high Faradaic efficiency of over 80% amongst 244

various Cu-containing alloys by screening 12 229 surfaces

and 228 969 adsorption sites. The Cu-Al alloy also exhibited

the most adsorption sites with near-optimal CO adsorption

values, indicating a large range of adsorption feasibility for

surface compositions and adsorption sites (Figure 9c). The t-

SNE diagram in Figure 9d reveals that the binding for Al sites

was weak, whereas, the bonding of Cu sites surrounded by Al

atoms was strong for CO. As a result, the bridge sites of Cu-Al

surrounded by Cu atoms were active. In situ X-ray absorption

measurements have confirmed that CC dimerization can be

mainly attributed to the favorable Cu coordination environment

arising from Cu and Al alloys.

Rossmeisl and co-workers presented a discovery approach

of selective and active catalysts for the CO2RR on more com-

plicated HEAs.[83a]

By combining DFT with a supervised ML,

they predicted CO and H adsorption energies of the (111) sur-

faces for disordered CoCuGaNiZn and AgAuCuPdPt HEAs,

providing an optimal strategy for suppressing H2 formation by

weakening H2 adsorption and facilitating the reduction of CO

by strengthening its adsorption. The approach led to the unbi-

ased discovery of electrocatalyst having high selectivity.

Additionally, gold nanoparticles and de-alloyed Au3Fe

core–shell nanoparticles surfaces also showed enhanced per-

formance for the formation of CO from CO2RR. Goddard III

Figure 9. a) Activity volcano for CO2RR by the ΔECO versus ΔEH. b) Selectivity volcano for CO2RR by the ΔECO versus ΔEH. c) t-SNE representation of

adsorption sites for Cu-containing alloys based on DFT calculations. d) Representative coordination sites. Reproduced with permission.[1]

Copyright

2020, Spring Nature.

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-13-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (14 of 25) © 2022 Wiley-VCH GmbH

and co-workers combined ML, multiscale simulations, and

quantum mechanics to predict the performance of surface sites

on gold nanoparticles and de-alloyed Au surfaces, identifying

the optimal active sites for CO2RR with far fewer calculations

than normal.[83b] A methodology based on α-value-mapping was

developed to discover the catalytic activity of an entire surface,

and two neural network based on ML models were developed

to accurately predict CO adsorption energy and hydro-car-

boxyl formation energy on extremely distorted and disordered

Au surfaces (see Figure 10). Applications of these models to

Au nanoparticles and de-alloyed Au surfaces resulted in the

identification of active sites and their features responsible for

enhancing CO2RR performance for disordered and irregular

surfaces. This strategy provided a powerful tool for discov-

ering the catalytic activity of an entire surface by comparing the

α-value with descriptors from experiments, computations, and

theory.

Because alloying is an effective method for enhancing the

efficiency of CO2RR, a good methodology for the universal

design is essential. To address the universal catalyst design

principle and illustrate structure–activity relationship of alloy

catalysts, Jiang et al. combined ML and descriptors (e.g., coor-

dination number, valence-electron number, electronegativity,

etc.) based on the inherent characteristics of the substrate, as

well as, adsorbents, and developed a model that allowed rapid

and large scale screening for alloys with accuracy similar to that

from DFT calculations.[48a]

The ML scheme shed light on active

center size, the alloying impact, and the coupling mechanism. It

not only helped with the understanding of the structure–activity

relationship of alloy catalysts and the reaction mechanisms of

CO2RR, but also provided a basis for catalyst design. Moreover,

Xin and co-workers presented an ML-enhanced chemisorption

model, which quickly and precisely forecast the surface reac-

tivity for metal alloys within a wide chemical space.[52]

They

showed that the trained ANNs based on electronic fingerprint

of idealized bimetallic surfaces and adsorption energies could

discover the complex nonlinear interaction relationship of the

adsorbate on multi-metallics with small error. Making use of

the proportional relationship between the adsorption ener-

gies of similar adsorbates, they illustrated that this integrated

approach significantly facilitated high-throughput catalyst

screening, while suggesting promising (100)-terminated multi-

metallic alloys with efficiency and selectivity enhancement for

CO2RR and C2 species.

In view of the discussion thus far, the ML application for

CO2RR mainly focused on improving selectivity and activity.

Cu-Al alloys were designed, and the design principles have

been examined in-depth for the formation of CO from CO2RR.

Due to the diversity of CO2RR products, the design of electro-

catalysts has also become particularly complicated. The design

of electrocatalysts for more value-added reactions required a

deeper understanding of the reaction.

3.5. Machine Learning for the Nitrogen Reduction

Reaction Application

Ammonia is a key chemical in fertilizers. However, the indus-

trially used Haber-Bosch process for NH3 production from N2

reduction is an energy-intensive chemical process that is highly

dependent on non-renewable fossil fuels.[86] It is increasingly

attractive to use renewable energy to reduce N2 to NH3 electr

ochemically.[86b,87] A major challenge for electrochemical NRR

is its low catalytic activity, selectivity and Faradaic efficiency.[88]

The main mechanisms have been addressed to understand the

nature using reversible hydrogen electrodes, standard hydrogen

electrodes, and normal hydrogen electrodes, as shown in

Table 6.[86a]

Currently, the ML application for NRR mainly

Figure 10. Active sites identification for AuNPs surfaces based on the α-values for all 11 537 surface sites. Reproduced with permission.[83b]

Copyright

2019, American Chemical Society.

Table 6. Reactions and potentials (vs RHE) for NRR.

Transferred

electrons

Reactions E0

1 N2 + H+ + e− → N2H −3.20 V (vs RHE)

2 N2 + 2 H+

+ 2e−

→ N2H2 −1.10 V (vs RHE)

4 N2 + 4 H+ + 4e− → N2H4 −0.36 V (vs RHE)

6 N2 + 6 H+ + 6e− → 3 NH3 (g) 0.55 V (vs NHE)

N2 + 6 H2O + 6e− → 2 NH3 + 6OH− (g) −0.736 V (vs SHE at pH = 14)

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-14-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (15 of 25) © 2022 Wiley-VCH GmbH

focuses on the boron (B)-doped graphene single-atom[40b]

and

L12 crystal[40a]

catalysis.

Kim and co-workers used a ANN to design efficient electro-

catalysts for the NRR using boron-doped graphene SACs, which

could significantly reduce computation time by removing non-

efficient catalysts from screening.[40b]

As shown in Figure 11,

based on the ANN architecture with 10 neurons for each hidden

layer, the adsorption and free energies of intermediates repre-

senting the geometrical structure and bonding characteristics

can be predicted using the feature-based light-gradient boosting

machine model. Among the evaluated catalysts, CrB3C1 was

predicted as the most efficient electrocatalyst for NRR with a

minimal overpotential of 0.13 V. Further research revealed

that the average d-orbital occupation (around 4–6) is essential,

which could lower the limiting potential in addition to potential

overcoming the scaling relationship of the NRR.

To achieve acceleration electrocatalyst design of NRR, Kim

et al. developed a slab-graph convolutional neural network

(SGCNN) that accurately and flexibly probed surface catalysis

reactions (Figure 12).[40a]

For such SGCNN, only the elemental

properties and connectivity information were required as input,

which made the acceleration facile realization. Based on the

DFT-calculated and self-accumulated database, SGCNN pre-

dicted the binding energies for five key adsorbates for NRR,

Figure 11. a) ANN architecture with 10 neurons for each hidden layer. b) Feature–feature correlation map. c) DFT-calculations versus machine-learning

prediction. Reproduced with permission.[40b] Copyright 2020, Royal Society of Chemistry.

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-15-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (16 of 25) © 2022 Wiley-VCH GmbH

that is, H, N2, N2H, NH, and NH2. The mean absolute error

was only 0.23 eV, indicating high accuracy for the predictions.

Four novel catalysts, that is, V3Ir, Tc3Hf, V3Ni, and Tc3Ta, were

found as potential electrocatalyst for NRR with both lower lim-

iting potentials and higher Faradaic efficiencies.

Collectively, ML applications for NRR could be used to meet

the challenge of low catalytic activity, selectivity, and Faradaic

efficiencies. Since the NRR is a complex multi-step reaction,

the activity and selectivity of its electrocatalyst still has a lot

of room for improvement. Similar to above mentioned elec-

trocatalysis, the combination of the geometric, electronic, and

activity-related descriptors is an efficient way for the ML appli-

cation for NRR.

Based on the summarization of the HER, OER, ORR,

CO2RR, and NRR, it is found that a unified selection method

has not yet been achieved due to the diversity of electrocatalytic

materials. Generally, atomic radius, atomic number, coordina-

tion number etc. geometrical descriptors, d-band center and

related properties, valence electrons, etc., electronic descrip-

tors, adsorption energy, electronegativity, electron affinity,

ionization energy, etc., activity descriptors are more common

used descriptors to date. Since a single descriptor is unable to

describe the entire electrocatalytic properties, these descriptors

are usually combined each other with comprehensive applica-

tions to achieve the excellence for the electrocatalyst design.

4. Machine Learning Application for

Electrocatalyst Design Based on Experiments

Due to the huge amount of calculations required, it is a big

challenge to predict the molecular/crystal structure based on

first principles/ab initio calculations.[89]

It is even more chal-

lenging to predict the products of a reaction based on the reac-

tants, because it requires a comprehensive understanding of

the potential energy surface of the reaction.[90]

Alternatively, A

ML approach based on the experiments can accelerate the pro-

cess.[91]

Usually, chemists typically design experiments based on

their intuition by understanding the structures/properties of

the reactants, patterns of reagent properties and composition

Figure 12. a) Elements used. b) The ordered intermetallic and core–shell binary catalyst systems. c) Illustration for key adsorbates in the NRR (upper)

and binding energy populations (ΔEads) for each adsorbate (lower). Reproduced with permission.[40a]

Copyright 2020, American Chemical Society.

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-16-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (17 of 25) © 2022 Wiley-VCH GmbH

ratios that determine the synthesis. These intuitions imply the

information of the structure and properties of the reactants and

the relationship between them. The underlying relationship

can be mapped out by data-mining techniques from successful

and failed experiments, which can be subsequently used to pre-

dict the molecular/crystal structures and reaction products.

Based on failed experiments, Norquist et al. used ML trained

reaction data to predict reaction outcomes for the crystalliza-

tion of templated vanadium selenites.[92] In order to guide

future experimental design, they built a web-based database on

their own to record both successful and failed experiments in

details. The properties of the molecules (e.g., molecular weight,

number of hydrogen-bond donors/acceptors as a function of

pH and polar surface area), tabulated values of atomic prop-

erties (ionization potential, electron affinity, electronegativity,

hardness, and atomic radius), experimental reaction conditions

(for example, temperature, reaction duration, and pH), and

mole ratios of the different reactants, etc., were systematically

recorded. A support vector machine (SVM) model was then

built using those information of reactant properties. Based on

the test-set data, the single SVM model found that the predic-

tion accuracy is 78% for describing all of the reaction types, and

79% for vanadium-selenite reactions. Moreover, their ML model

outperformed traditional human strategies, and successfully

predicted conditions for new inorganic products with 89% suc-

cess rate for hydrothermal synthesis experiments.

The flow-chart representation for the SVM model is shown

in Figure 13. For the production of amines with moderate polar-

izability (shaded in blue), it requires a sulfur-containing reac-

tant and V4+ ions for organically templated vanadium selenites,

which is either introduced as a reagent or produced in situ.

The use of V(IV)OSO4 insures the generation of V4+. In com-

parison, amines with high polarizability (shaded in red) require

oxalates for success. The reason may be due to the charge den-

sity changed by the oxalate on the inorganic secondary building

units, matching the charge density of these long, linear, and

highly charged triamines and tetraamines. In addition, amines

with low polarizability (shaded in green) have a higher pKa

value than other amines and without the requirement of pH

<3 to be in the correct protonated state. These amines generate

Figure 13. SVM-derived decision tree for ML-guided synthesis based on failed experiments. Ovals, rectangles, and triangles represent decision nodes,

reaction-outcome bins, and excised subtrees, respectively. The shading of green, blue, and red indicate the three distinct successful groups, which are

corresponding to low- (<9.32 Å3), medium- (10.29–19.51 Å3), and high-polarizability (17.64–29.85 Å3) amines, respectively. Reproduced with permis-

sion.[92] Copyright 2015, Springer Nature.

Adv. Funct. Mater. 2022, 2110748](https://image.slidesharecdn.com/advfunctmaterials-2022-liu-towardexcellenceofelectrocatalystdesignbyemergingdescriptororientedmachin-240614113519-b972e140/75/Adv-Funct-Materials-2022-Liu-Toward-Excellence-of-Electrocatalyst-Design-by-Emerging-Descriptor-Oriented-Machine-pdf-17-2048.jpg)

![www.afm-journal.de

www.advancedsciencenews.com

2110748 (18 of 25) © 2022 Wiley-VCH GmbH

enough V4+ from the V5+ precursor, but at a slower rate and

require a longer reaction time (>26 h). The usage of NaVO3

generally leads to the formation of inorganic-only polycrystal-

line products. However, use of NH4VO3 can exclude sodium

from the reaction mixture, enabling formation of the target

phase. Thus, through the SVM model, specific recommenda-

tions for compound formation are provided: i) Understanding

the production of appropriate primary building units (V4+);

ii) adjusting charge density to enable the matching between the

construction of secondary building units and the cationic com-

ponents; and iii) avoiding undesirable building units (Na+) that

result in non-templated phases. To this end, the ML approach

successfully exploited underlying pattern contained in historical

data and to elucidate the factors determining reaction products,

revealing previously unknown insights. It has universal guiding

significance for the synthesis of electrocatalyst.

Palkovits and co-workers also used several ML methods to

predict water-splitting catalysts based on published and original

data.[93] The ML models exhibited decent prediction accuracy,

confirming that even simple models were suitable for fore-

casting. Ahmed and co-workers joined high-throughput experi-

ments and ML-based regression models to guide Pt-group

metal-free electrocatalyst synthesis for ORR.[94] They developed

several ML-based regression models to predict ORR activity,

depending on selected synthesis control parameters (e.g., Fe

precursor identity, precursor content, and pyrolysis tempera-

ture). Based on the best gradient boosting regression and sup-

port-vector methods, the predicted candidates were obtained

with smaller root mean-square errors. Catalyst synthesis was

further performed. It was found that the advanced electro-

catalyst were obtained with 36% performance enhancement

compared to the original optimal ORR electrocatalyst. The suc-

cess of the combination of ML and experiment represented

a promising method for the development of high-efficiency

next-generation electrocatalysts. Additionally, Tapan and co-

workers used the decision tree analysis for CO2RR based on 471

experimental data points from 34 different publications.[95] The

results showed that the Faradaic efficiencies depend on the con-

tents of Sn, the type of catholyte, the potential applied and the

pH values. When the Sn content was higher than 15% and the

Cu content was lower than 52%, the selectivity of formic acid

was the highest for the most generalizable path. This showed

that exploratory data analysis and decision trees could provide

useful information to determine the high selectivity conditions

of CO2 electroreduction performance, to guide future research.

Furthermore, many applications for the catalyst charac-

terization such as, X-ray absorption fine structure,[96]

trans-

mission electron microscopy and scanning transmission

electron microscopy,[97]

energy-dispersive X-ray[98]

and electron

energy-loss[98a]

has been reported, which has been reviewed

previously.[7b]

Since these are not direct electrocatalyst design,

we will not repeat it here.

Collectively, the design of electrocatalysts through ML is still

in the preliminary stage based on experimental values. Neverthe-

less, it was found that the catalytic efficiency can be significantly

improved when the ML design was applied. In the future, if the

experimental values could be retrieved through a convenient

database, the ML modelling would be used before each experi-

ment. It will greatly save the time and cost of the experiment.

5. Challenges

ML and its combinatorial methods have been applied suc-

cessfully to electrocatalysts design, resulting in powerful tools

that are used to discover novel electrocatalysts while extracting

knowledge from extant datasets. Nevertheless, design chal-

lenges remain.

First, the lack of standard datasets for ML applications

limits its wider applicability. Although fast-developing big-data

mining technologies promise to extract useful information

and knowledge from large data pools,[5] data diversity limits

their scope. Currently, discovering and optimizing electrocata-

lysts are empirically driven. There is not enough relevant and