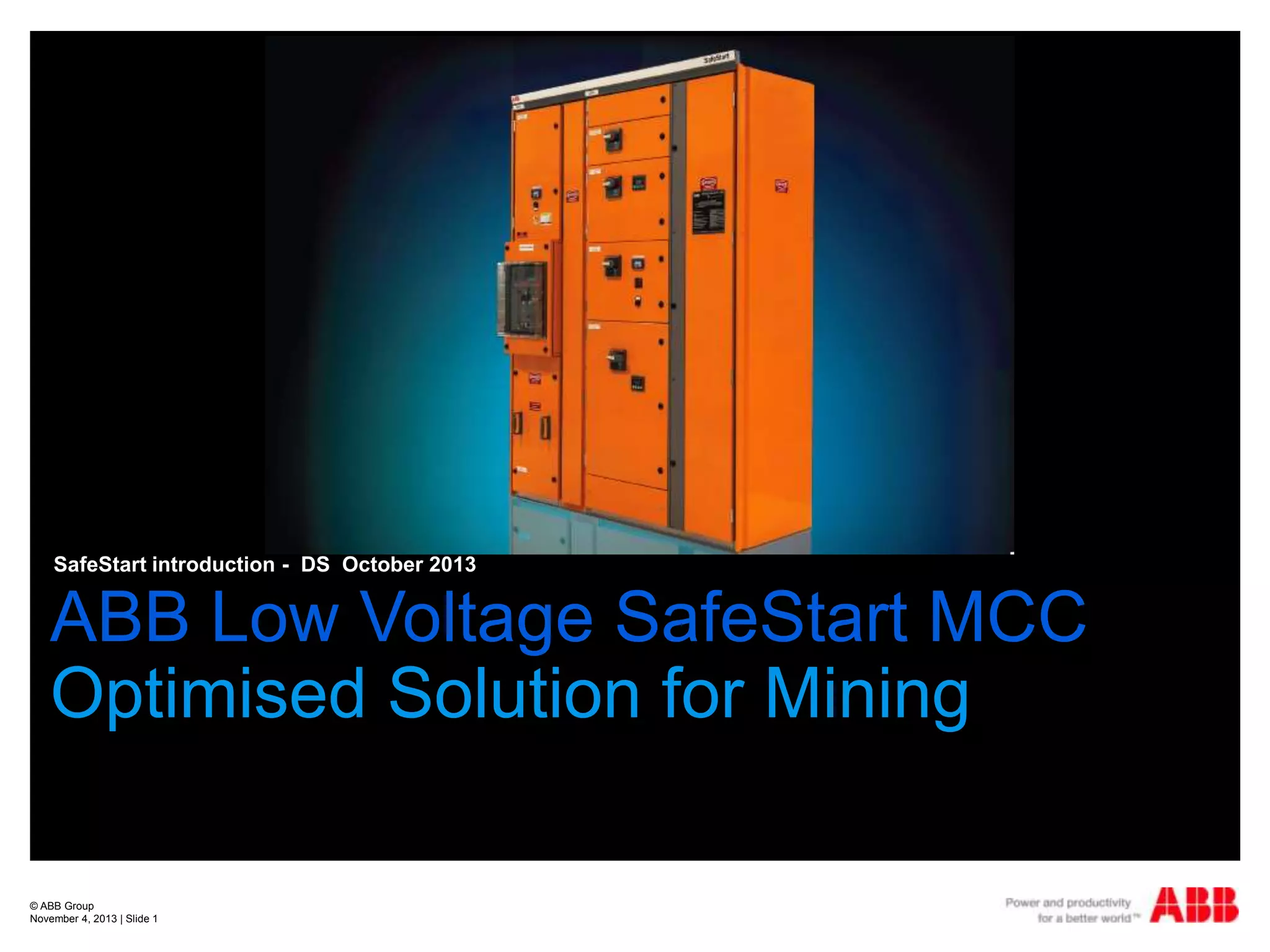

The document summarizes ABB's SafeStart Motor Control Centre (MCC), an optimized solution for motor control in mining applications. Key points:

1) SafeStart was developed in 2012 as an Australian optimized MCC solution and fully type tested to Australian standards in 2013.

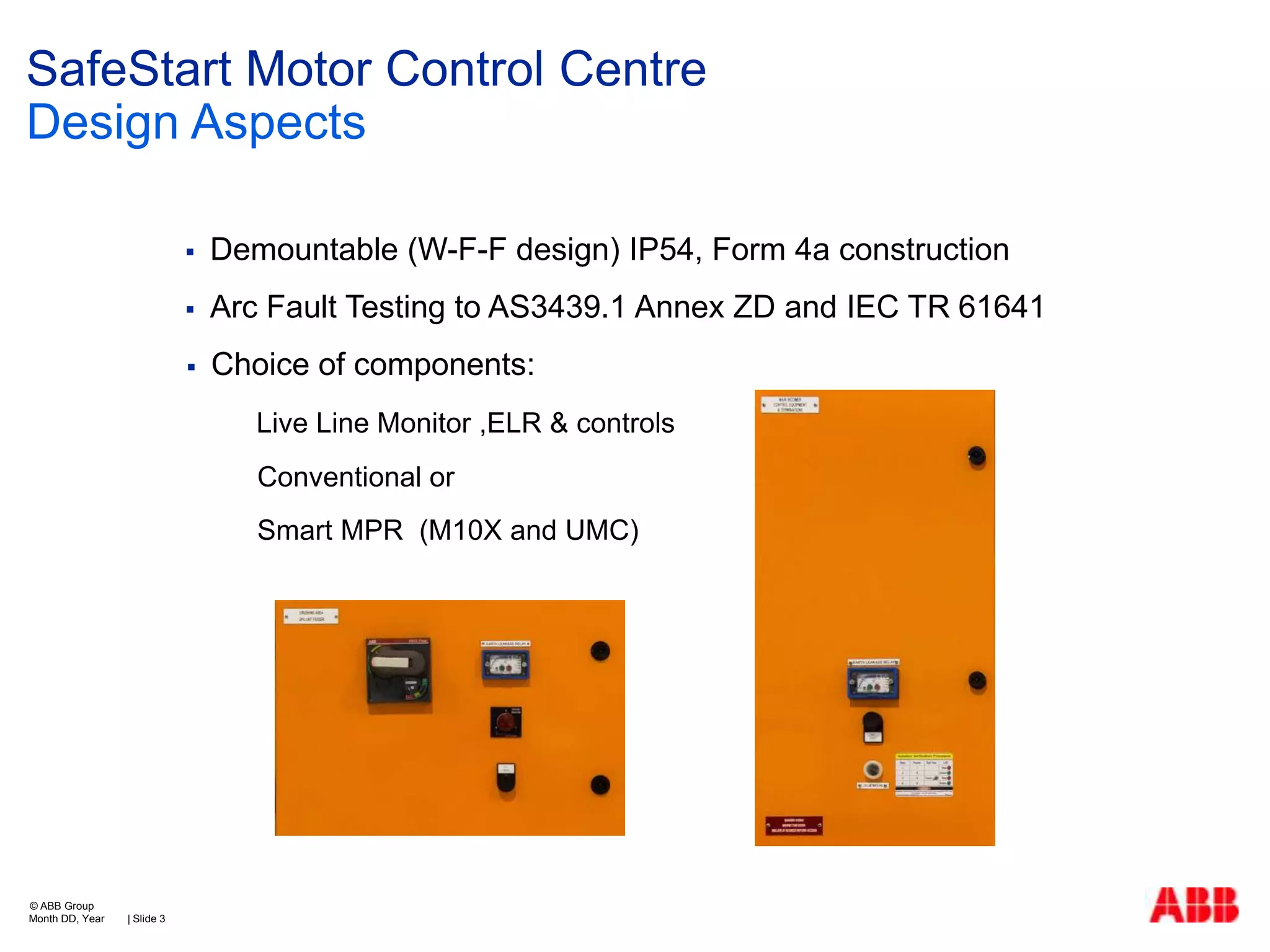

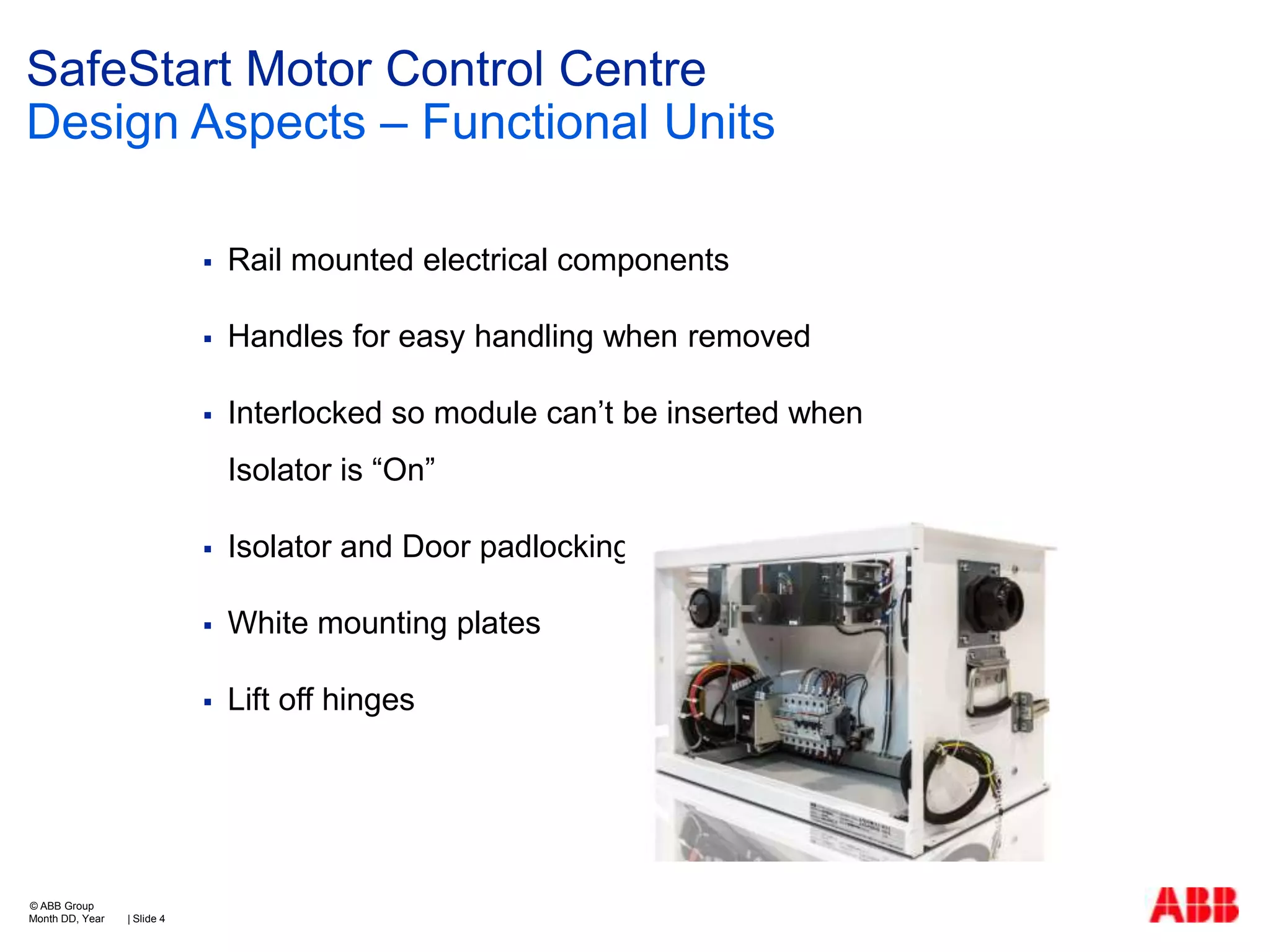

2) SafeStart uses a demountable construction, rail-mounted electrical components, and interlocked modules that cannot be inserted if the isolator is on.

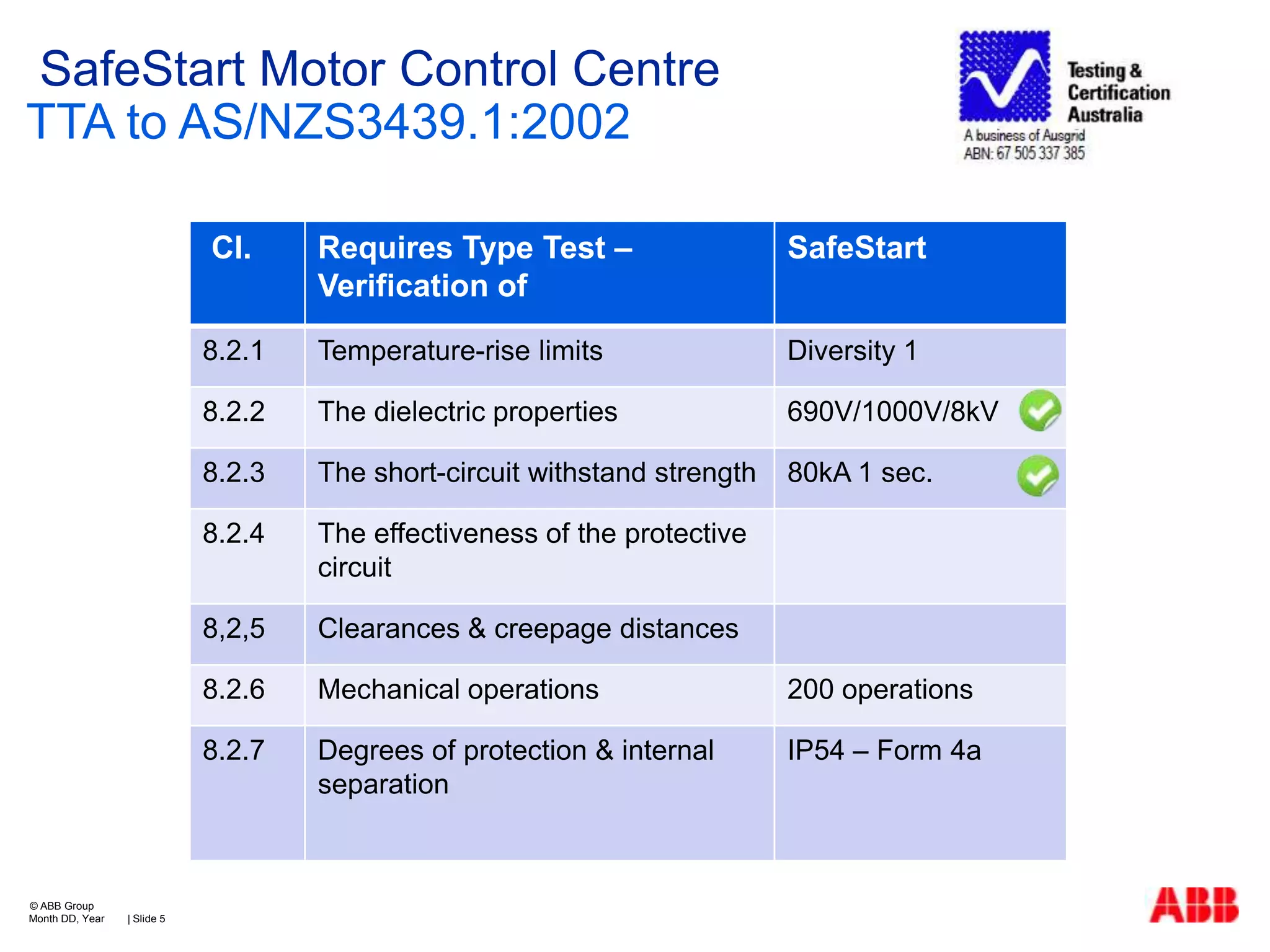

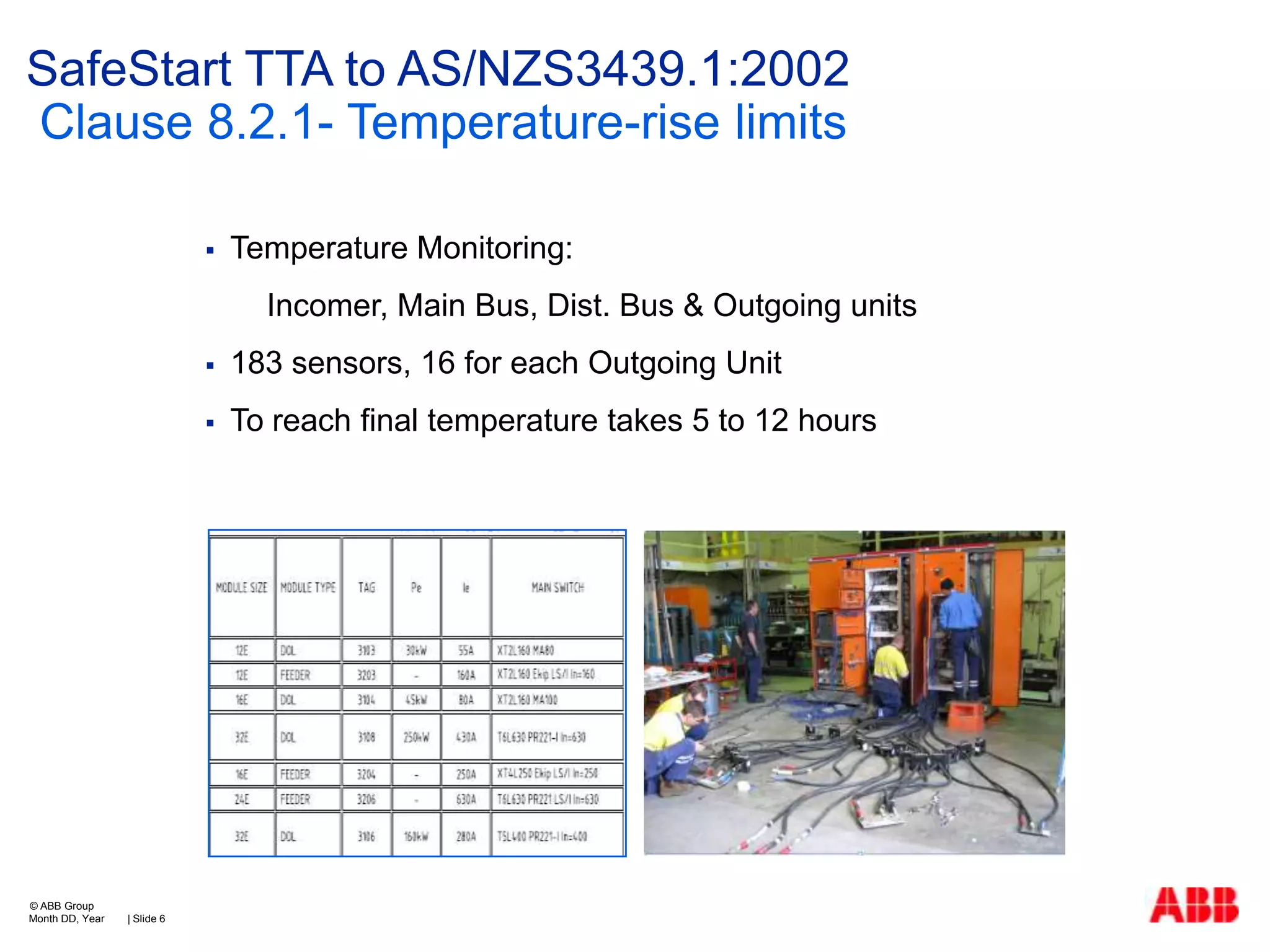

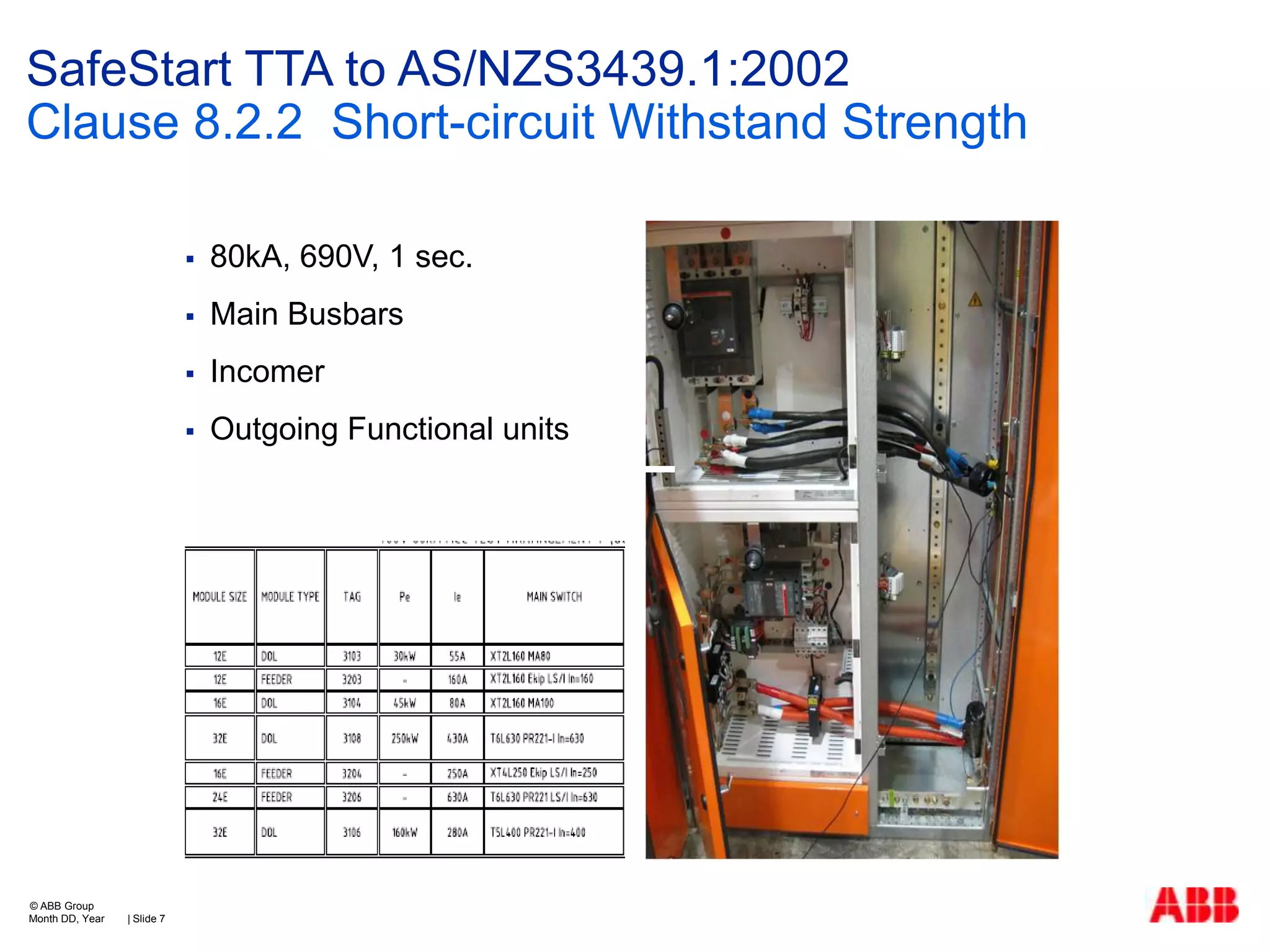

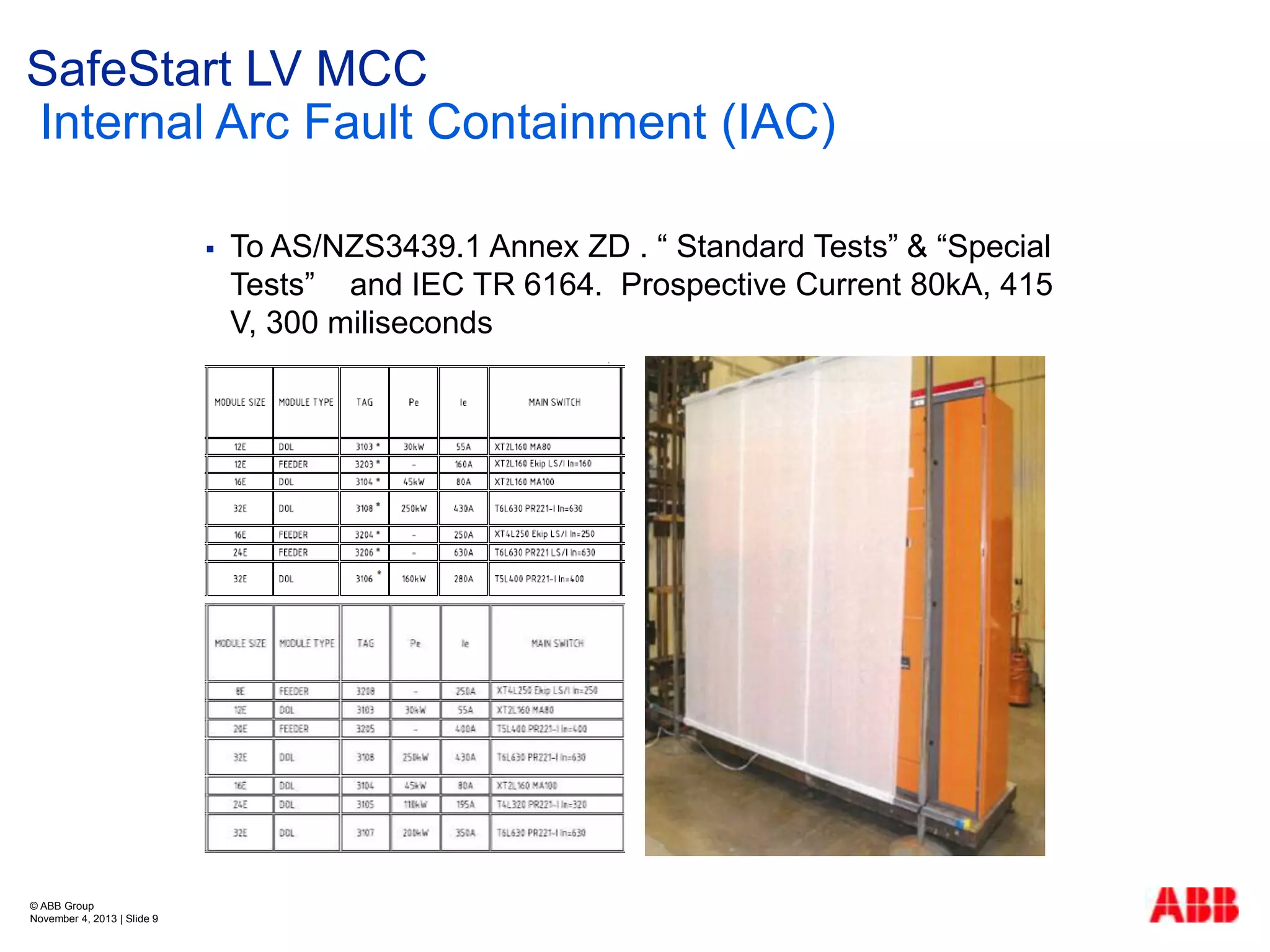

3) Extensive testing was conducted including temperature rise limits, short-circuit withstand strength, protective circuit effectiveness, and internal arc containment, meeting relevant Australian standards.