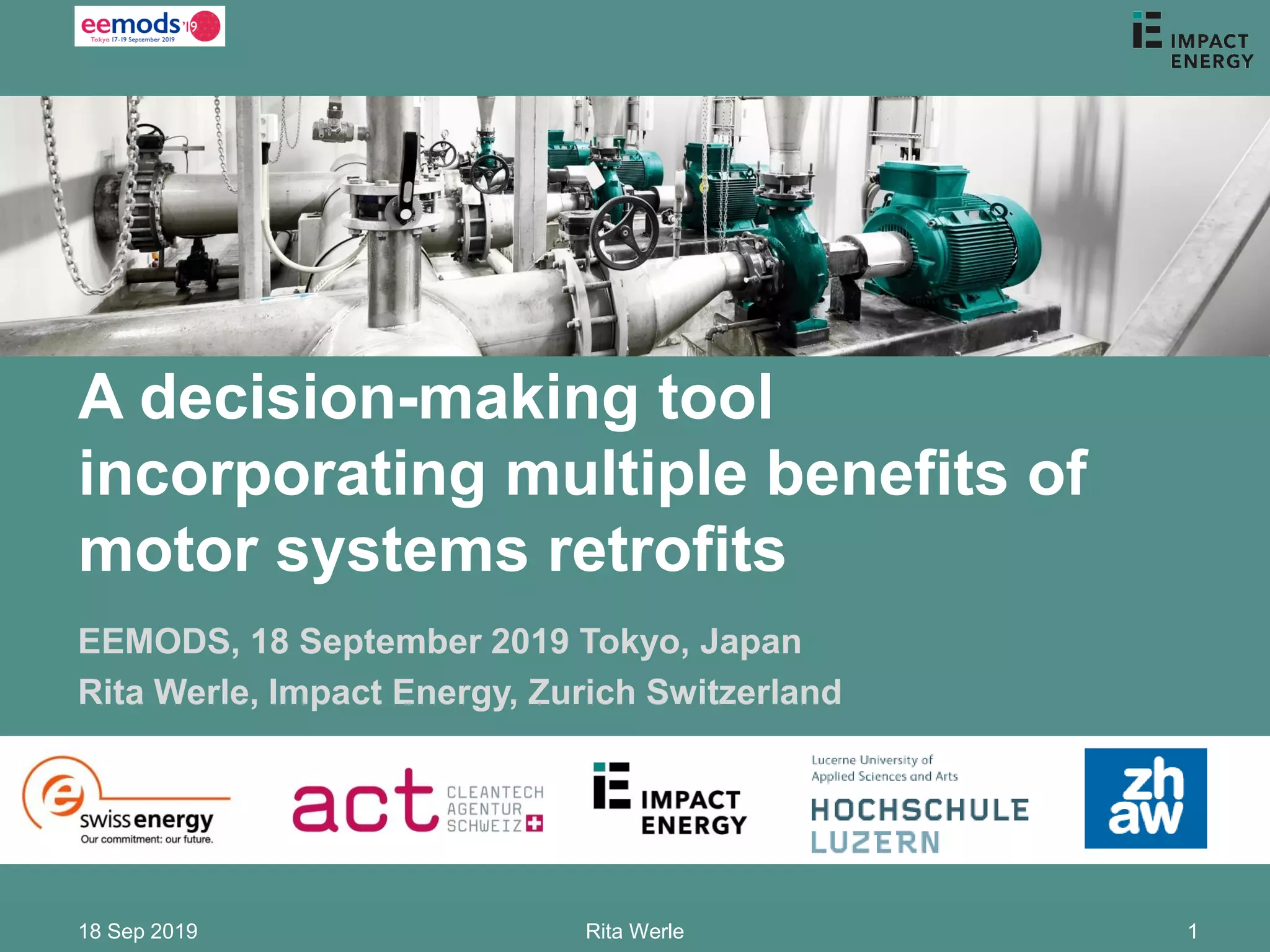

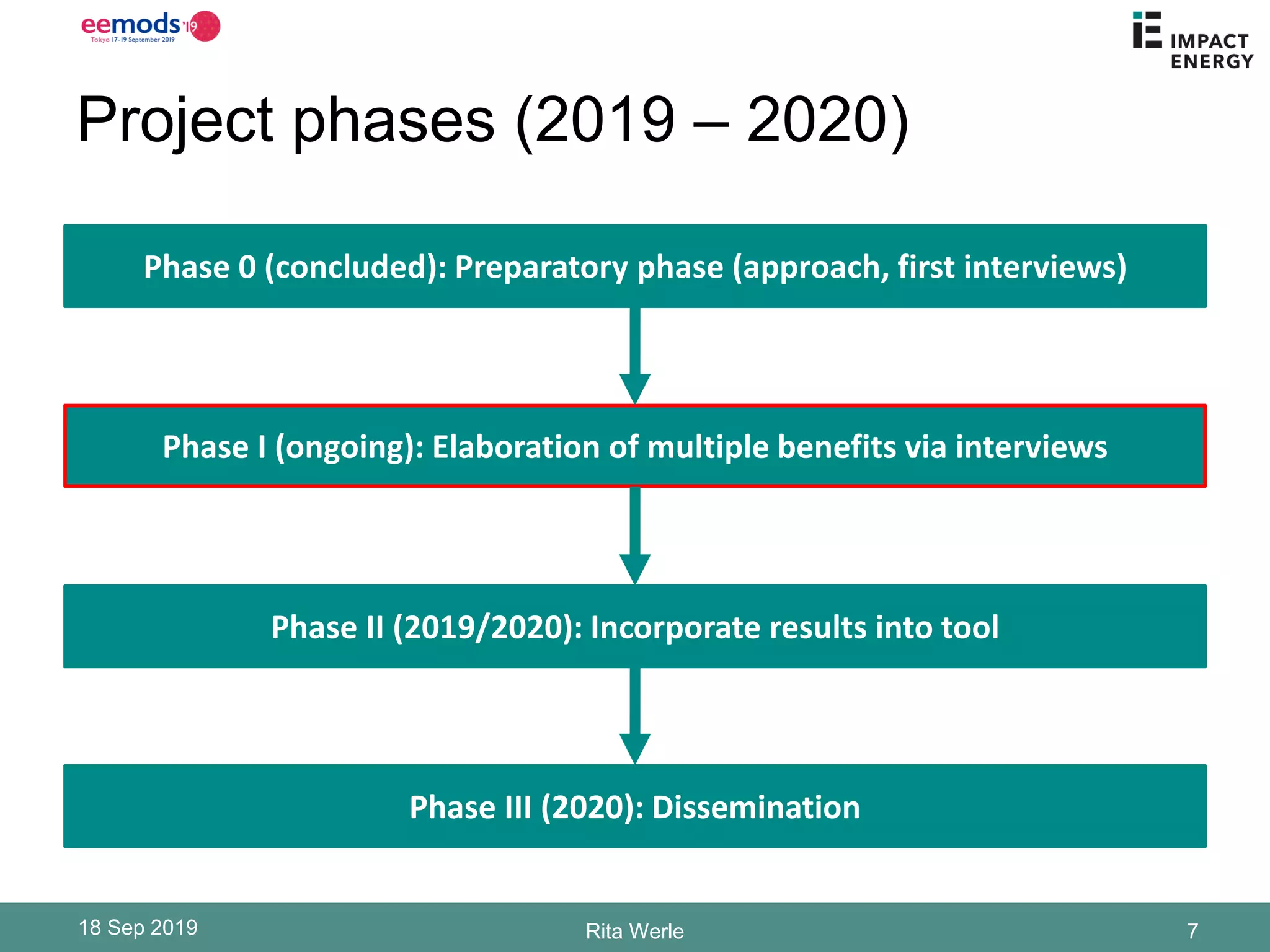

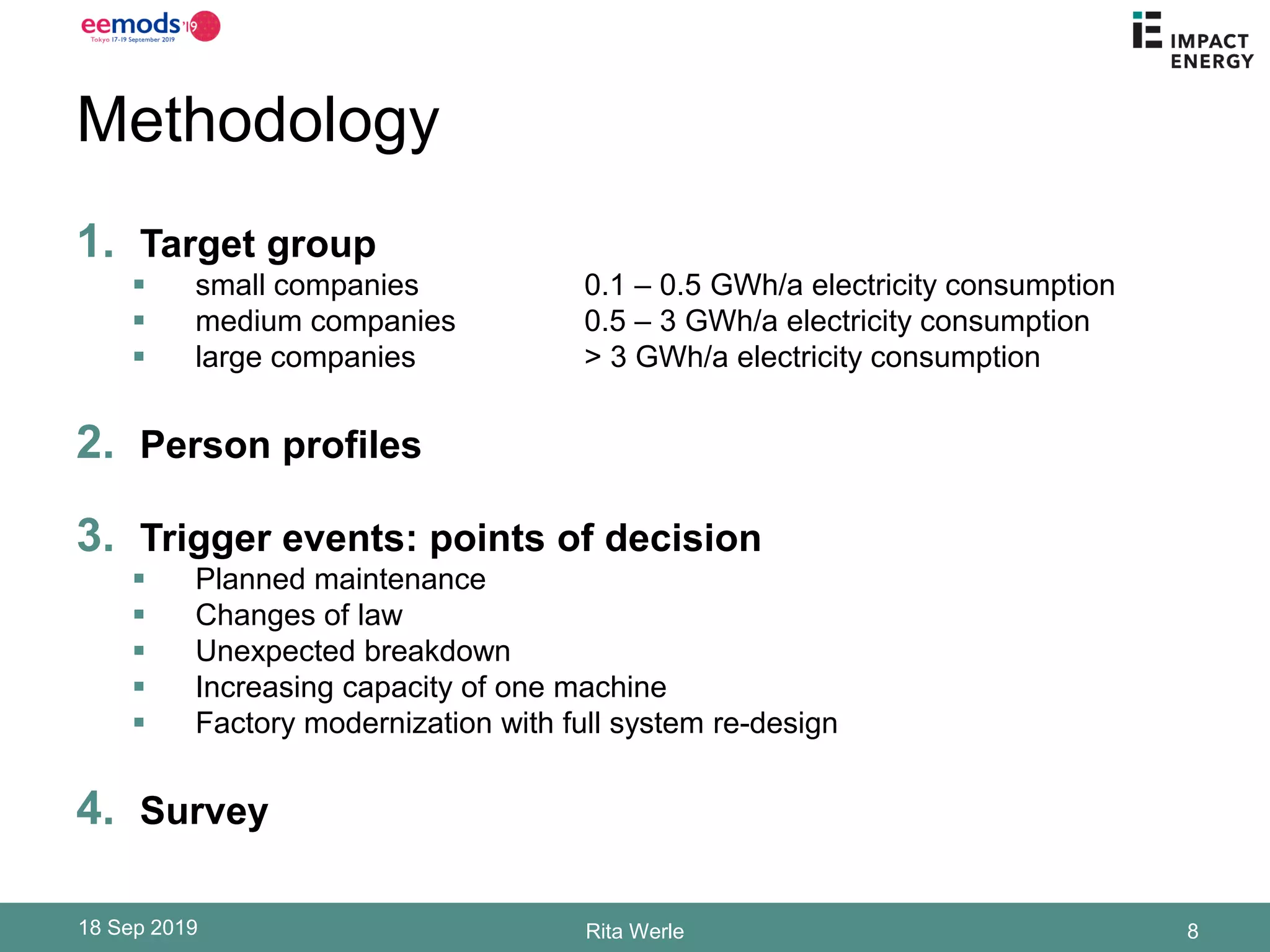

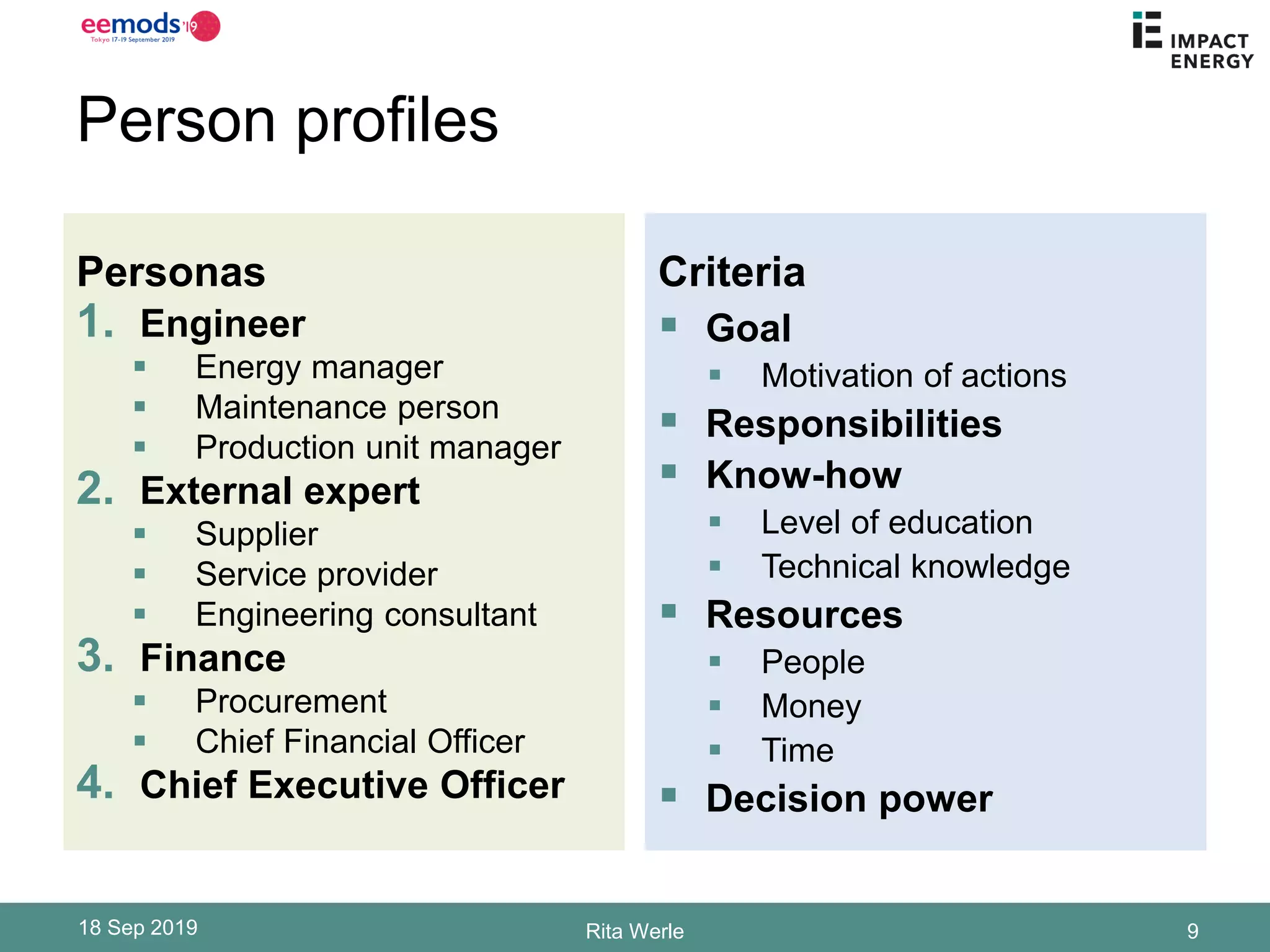

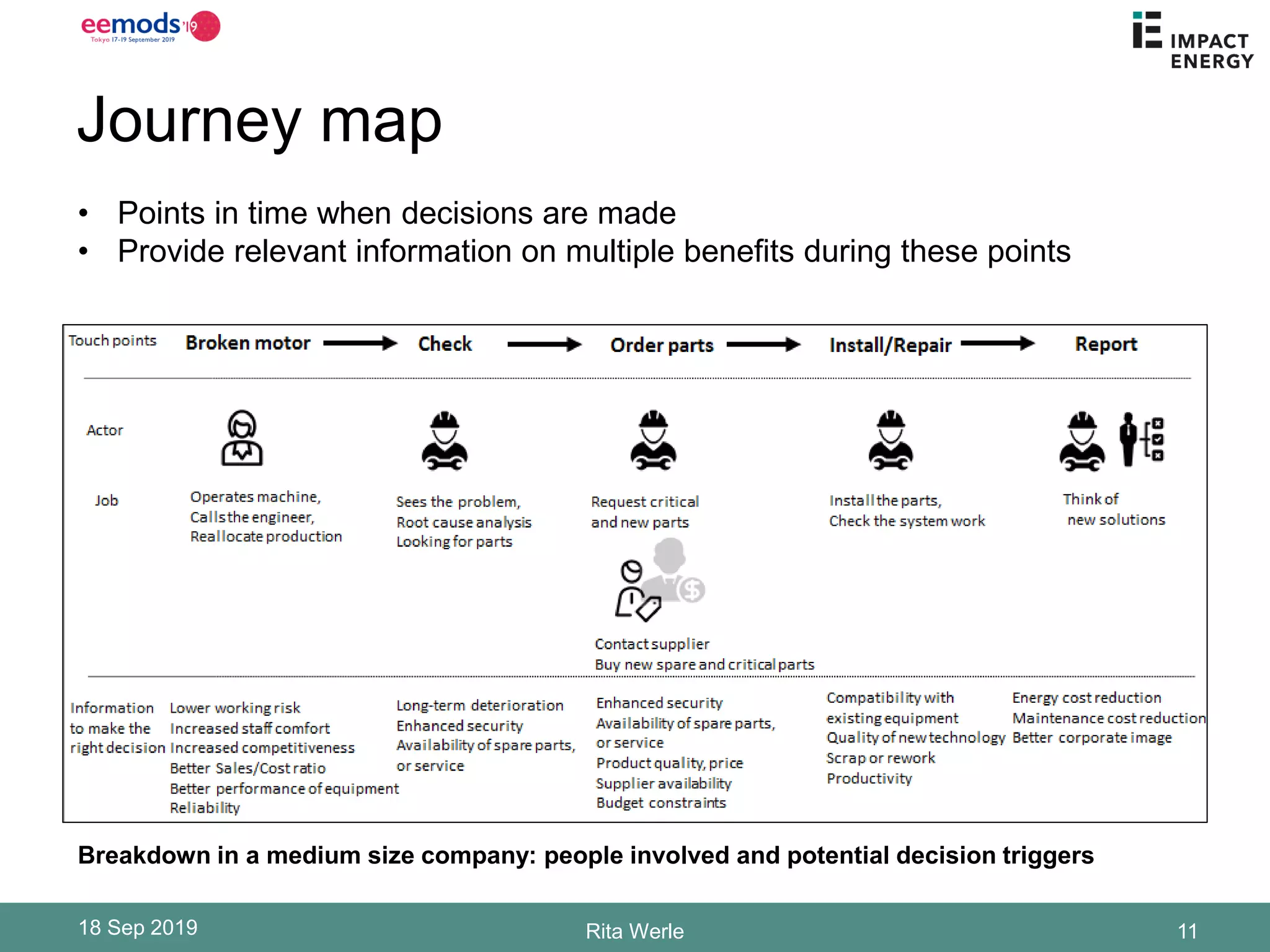

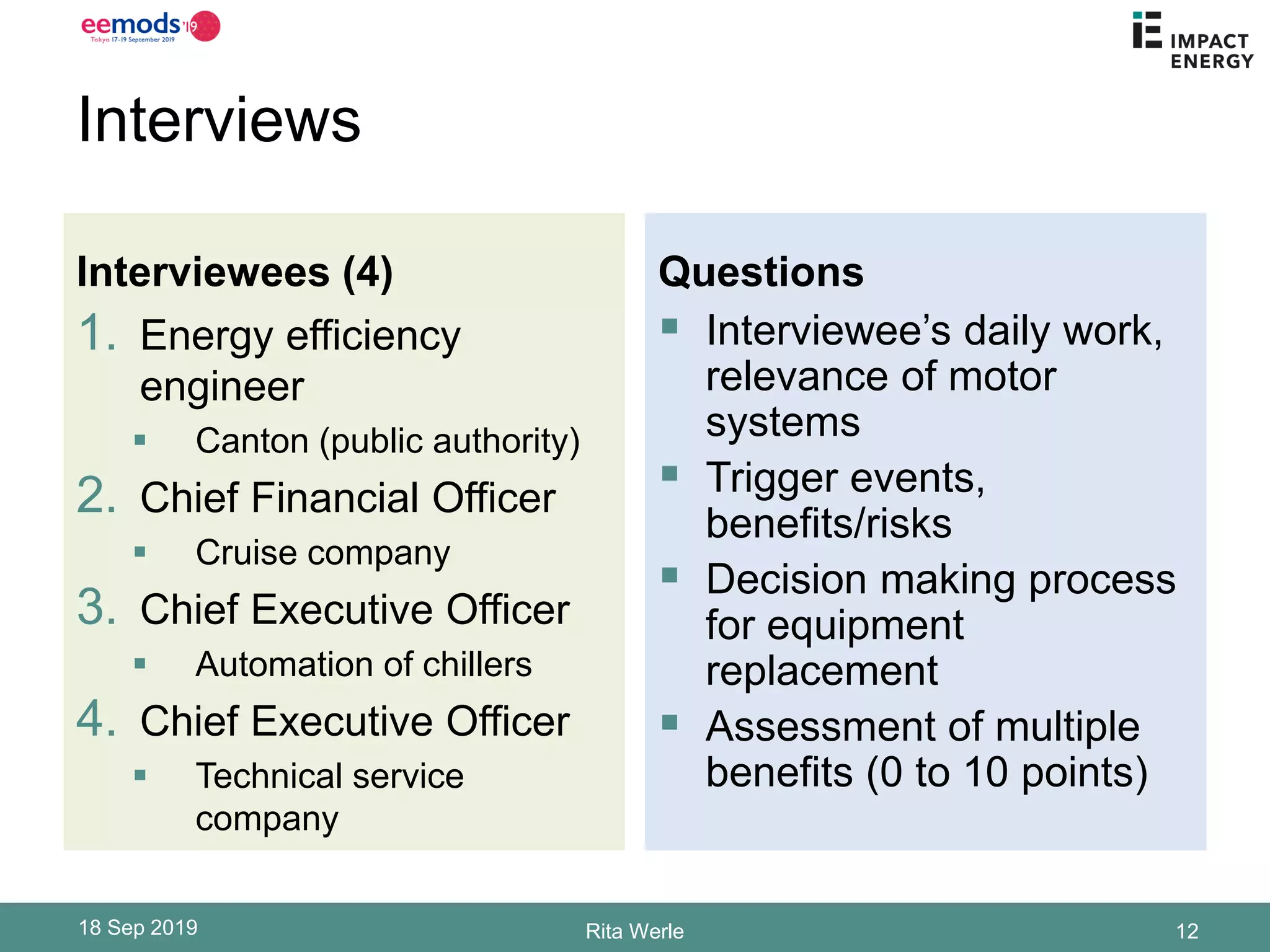

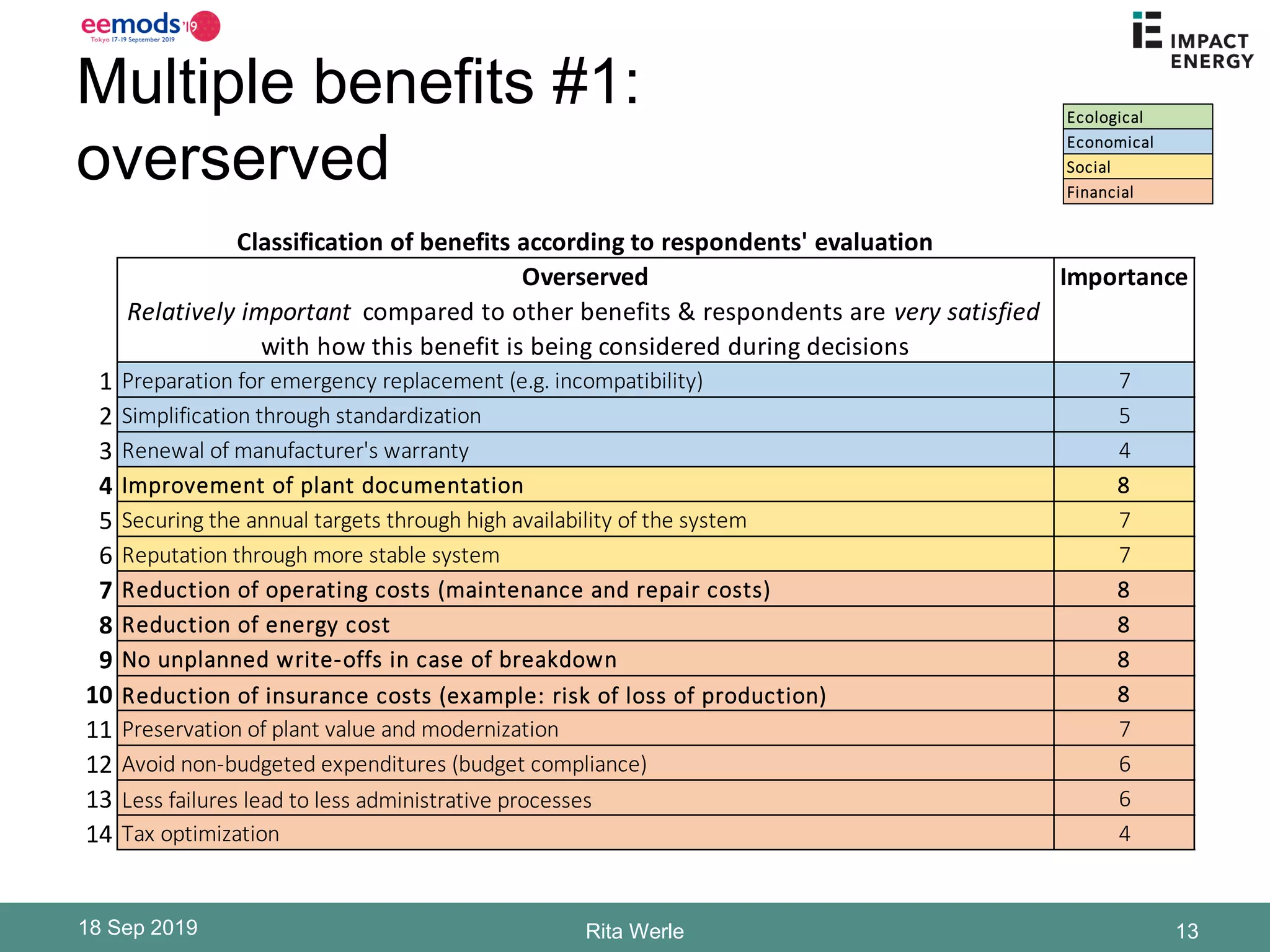

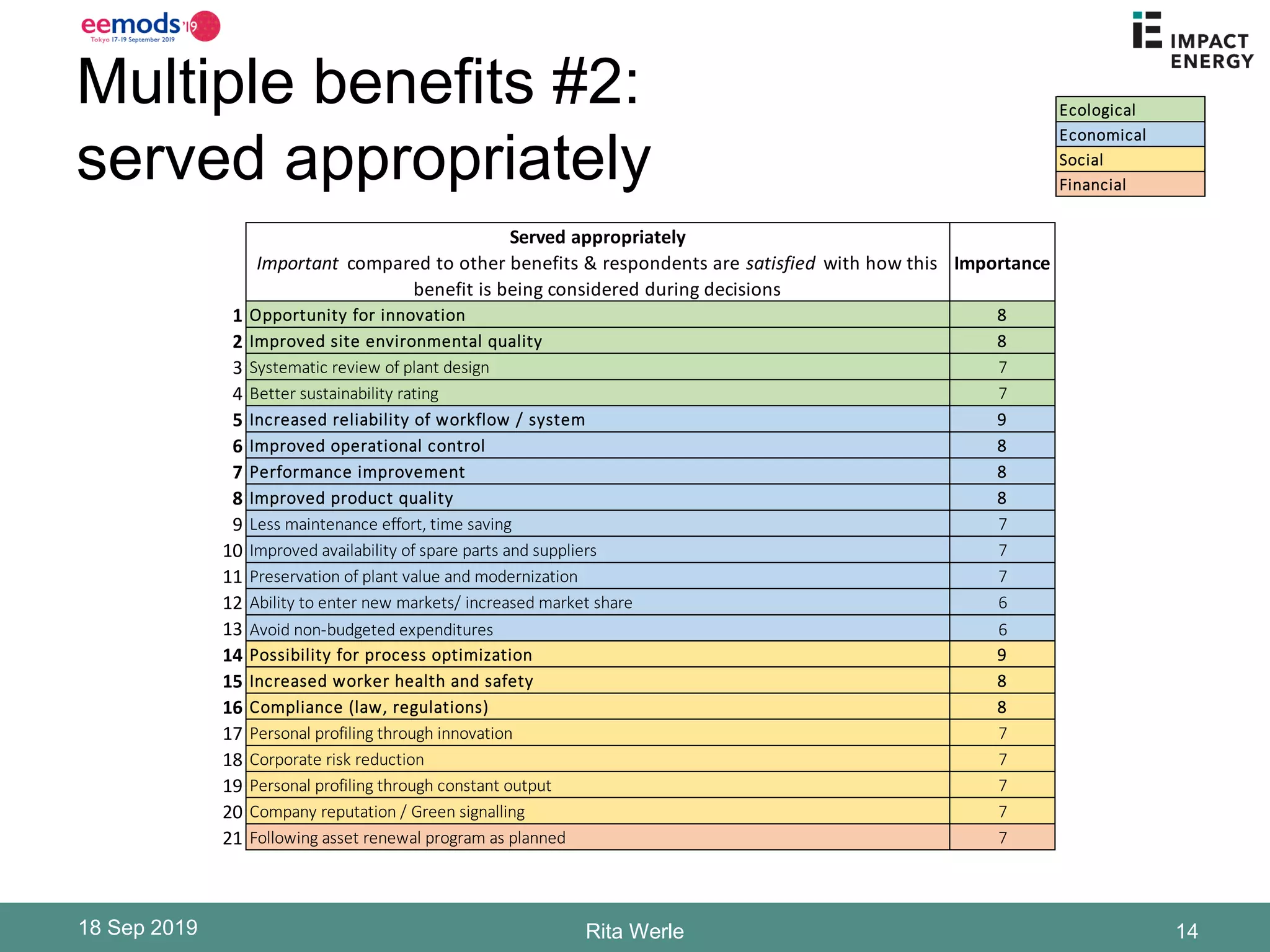

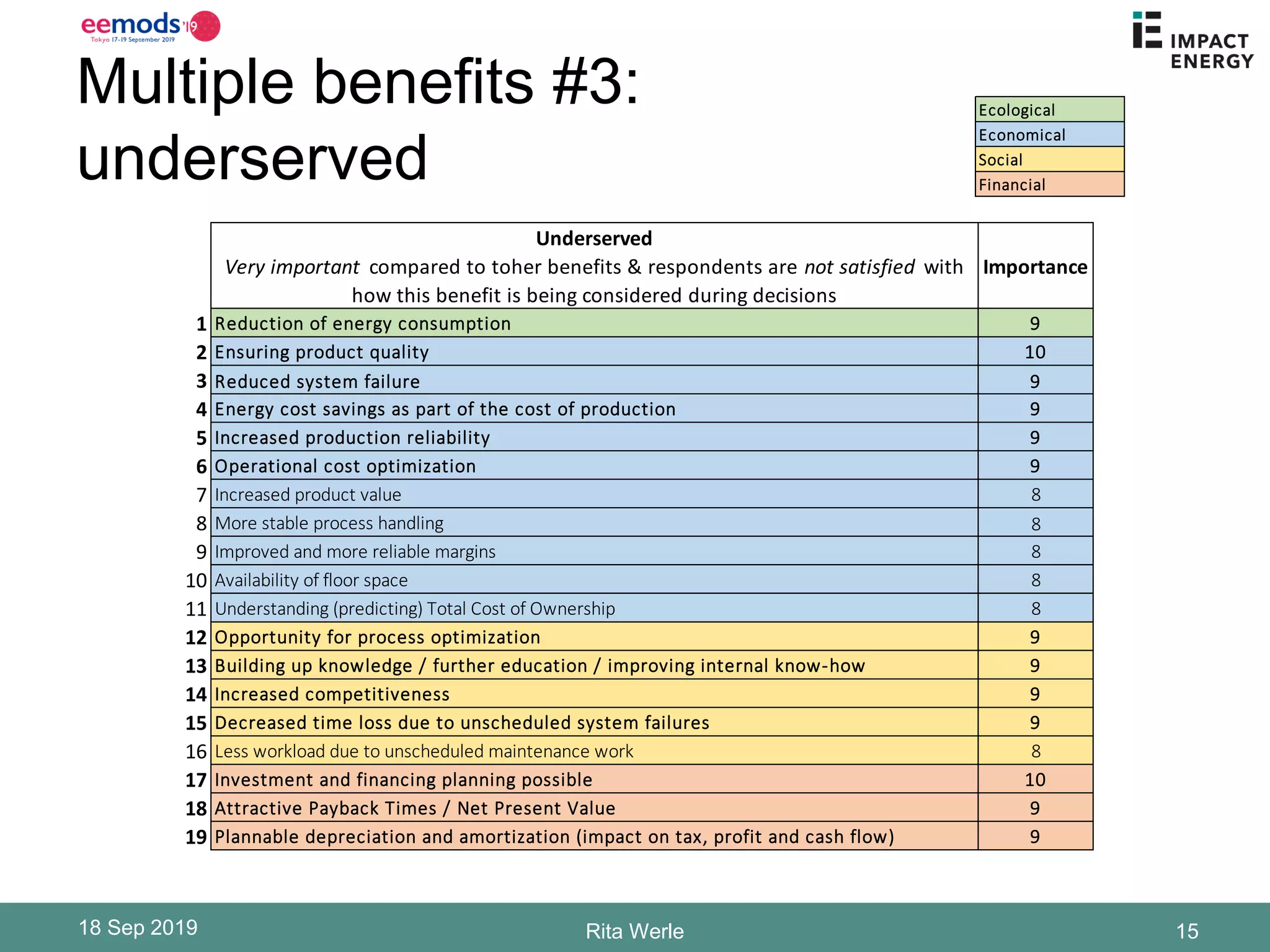

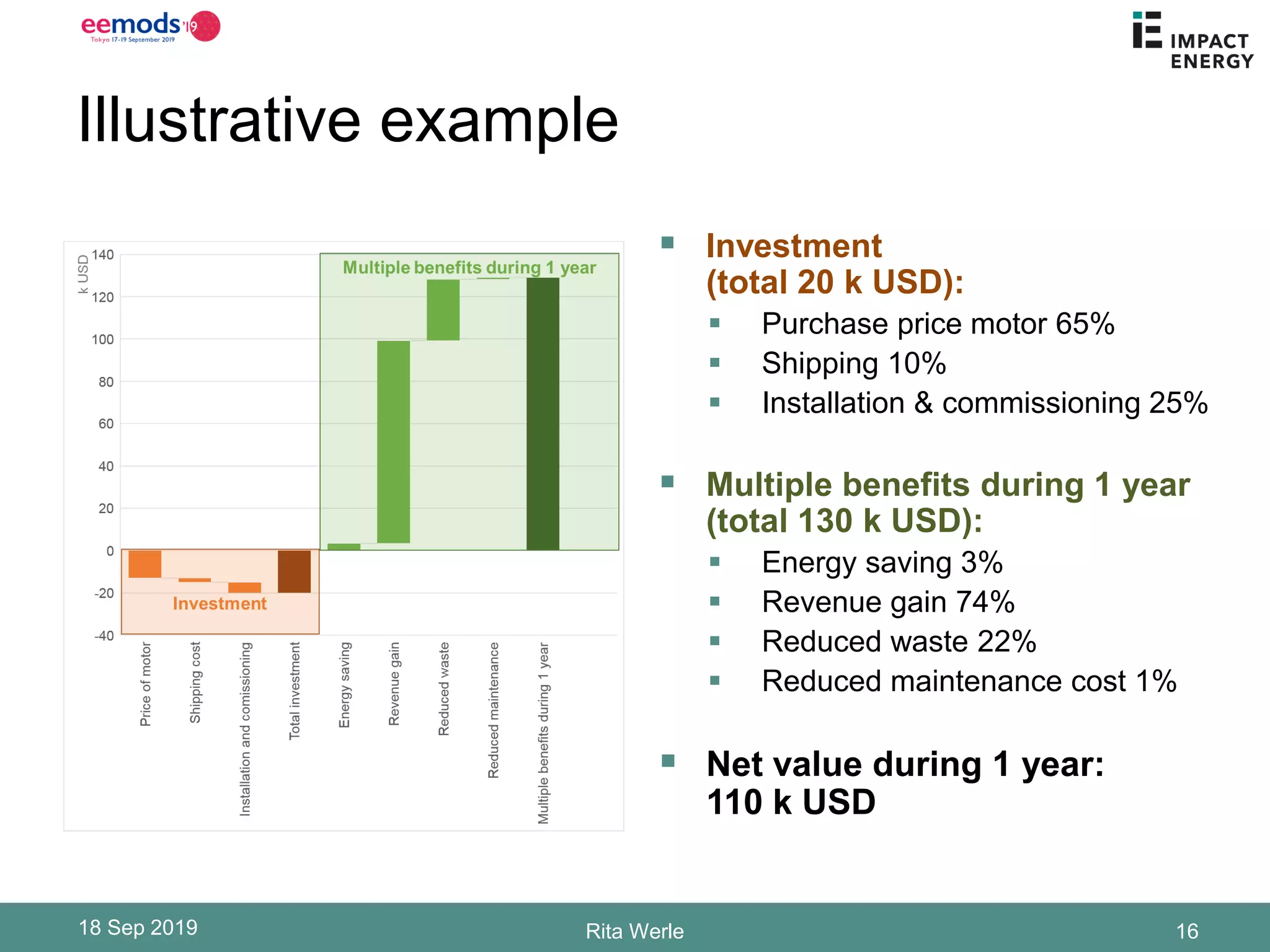

The document discusses a decision-making tool for companies focused on retrofitting electric motor systems, highlighting the multiple benefits such as cost reduction, improved efficiency, and environmental impact. It outlines the project's background, methodology, phases, and results, revealing insights from interviews about the importance of various benefits in decision-making. The aim is to create a web-based tool that supports small to large companies in evaluating energy efficiency improvements and their broader impacts.