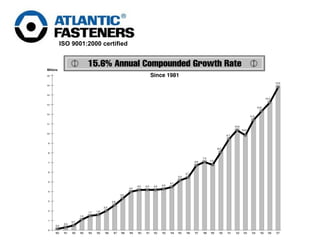

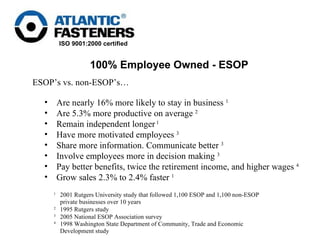

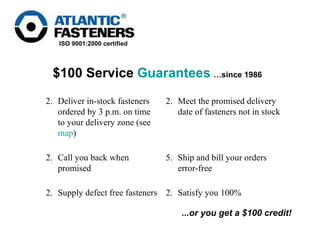

- The document discusses VMI, a 100% employee-owned industrial supply company that provides vendor-managed inventory services for fasteners and other products.

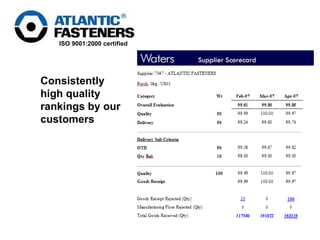

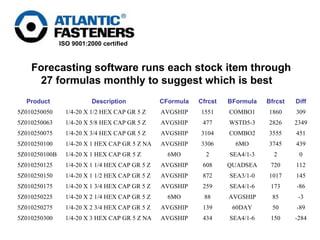

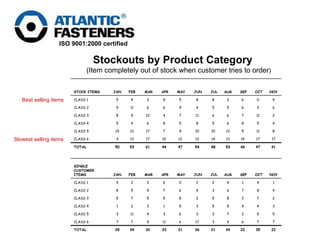

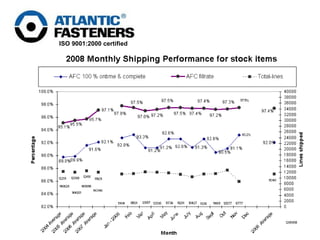

- It highlights VMI's quality capabilities including an in-house inspection lab, forecasting software to reduce stockouts, and high customer quality ratings.

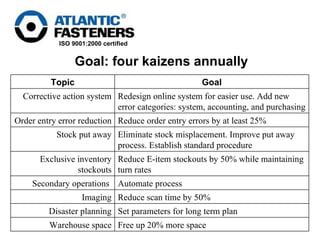

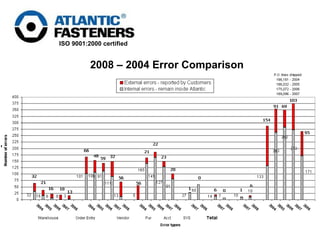

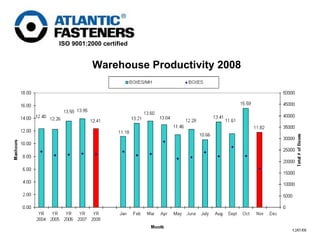

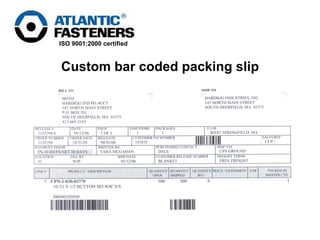

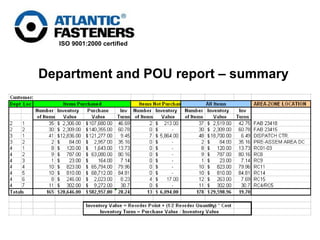

- VMI aims for continuous improvement through annual kaizen events and has goals to reduce errors, increase warehouse productivity, and enhance their online systems and services.