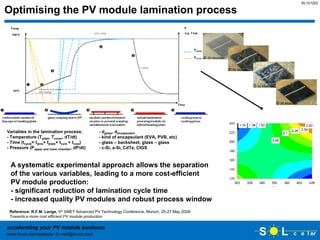

Solceler provides three main services to help lower the cost per watt of photovoltaic module production: 1) support and development assistance through improving existing production processes, ramp-up assistance, and contract manufacturing; 2) development and implementation of quality measurement tools; and 3) photovoltaic training and education. Solceler is confident it can successfully lower costs through its experience implementing production knowledge gained from systematic experimentation.