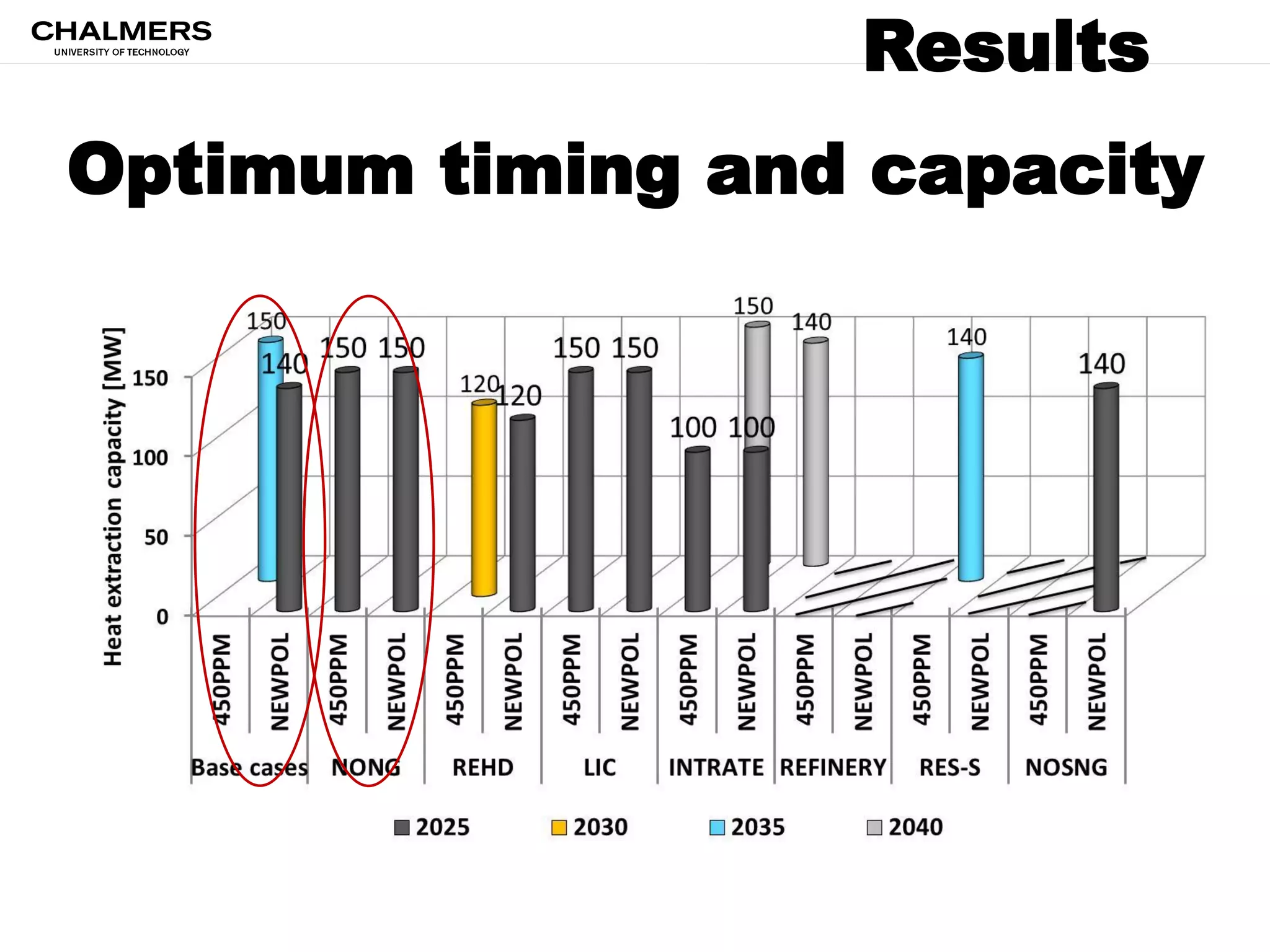

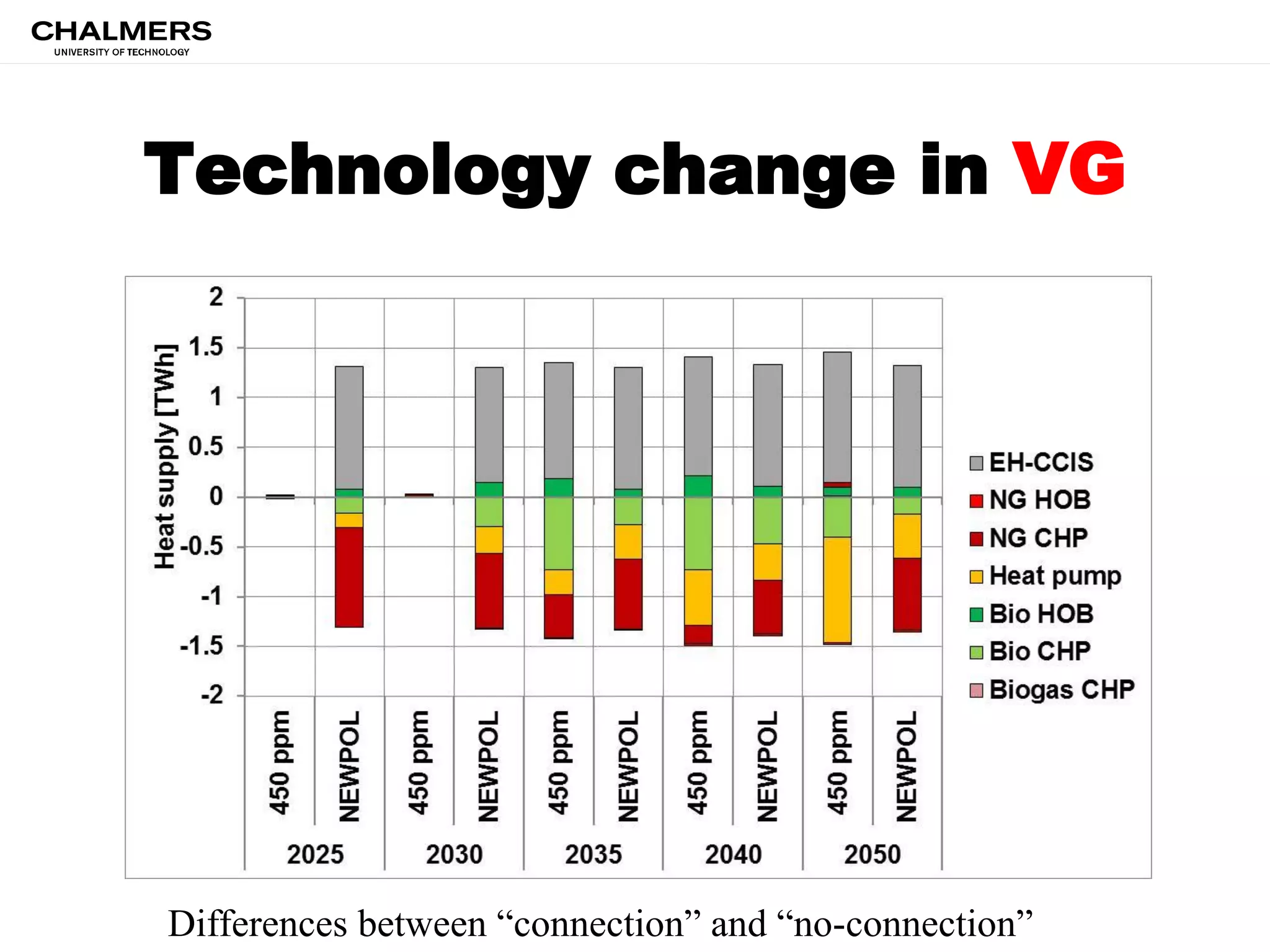

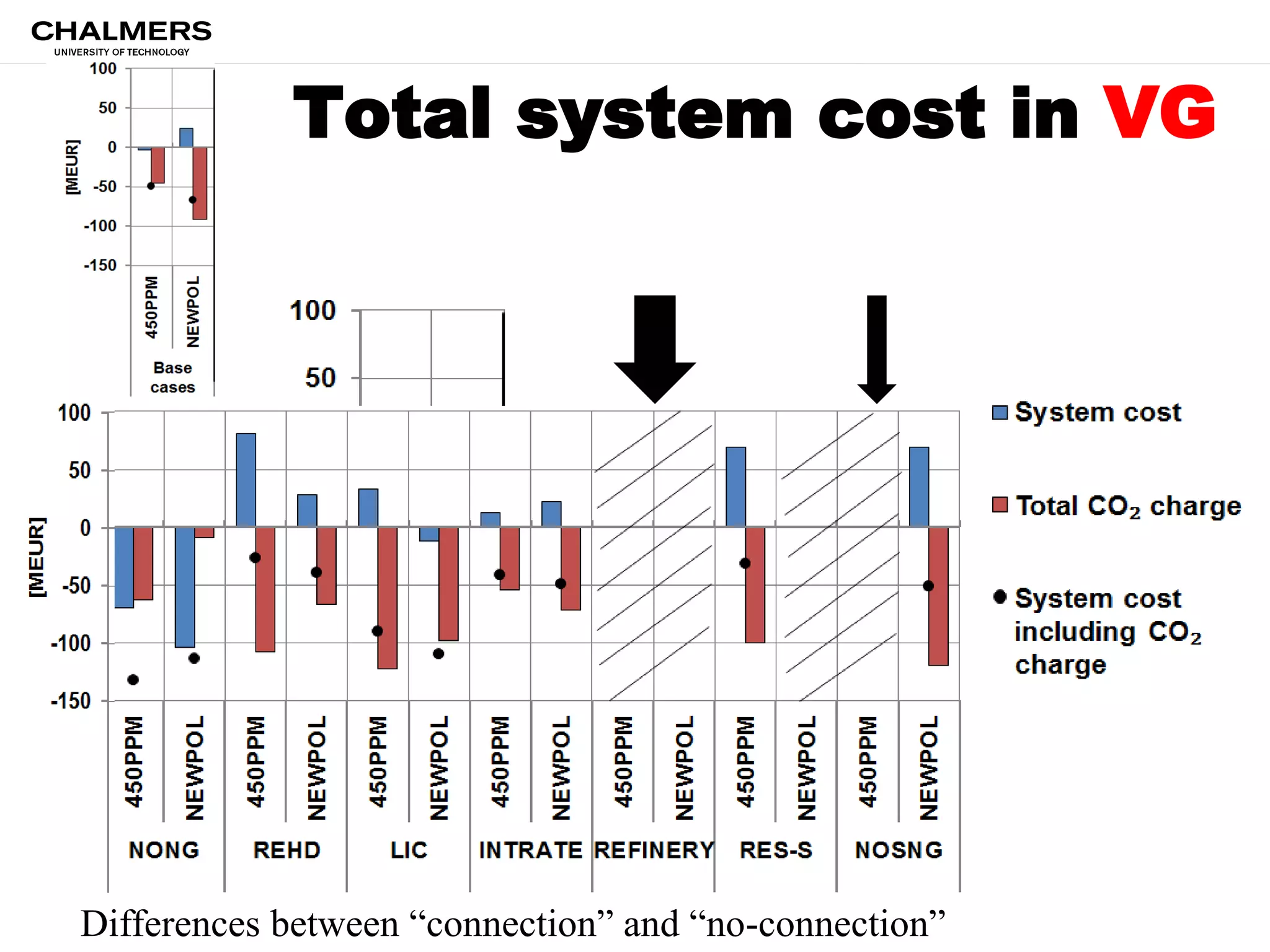

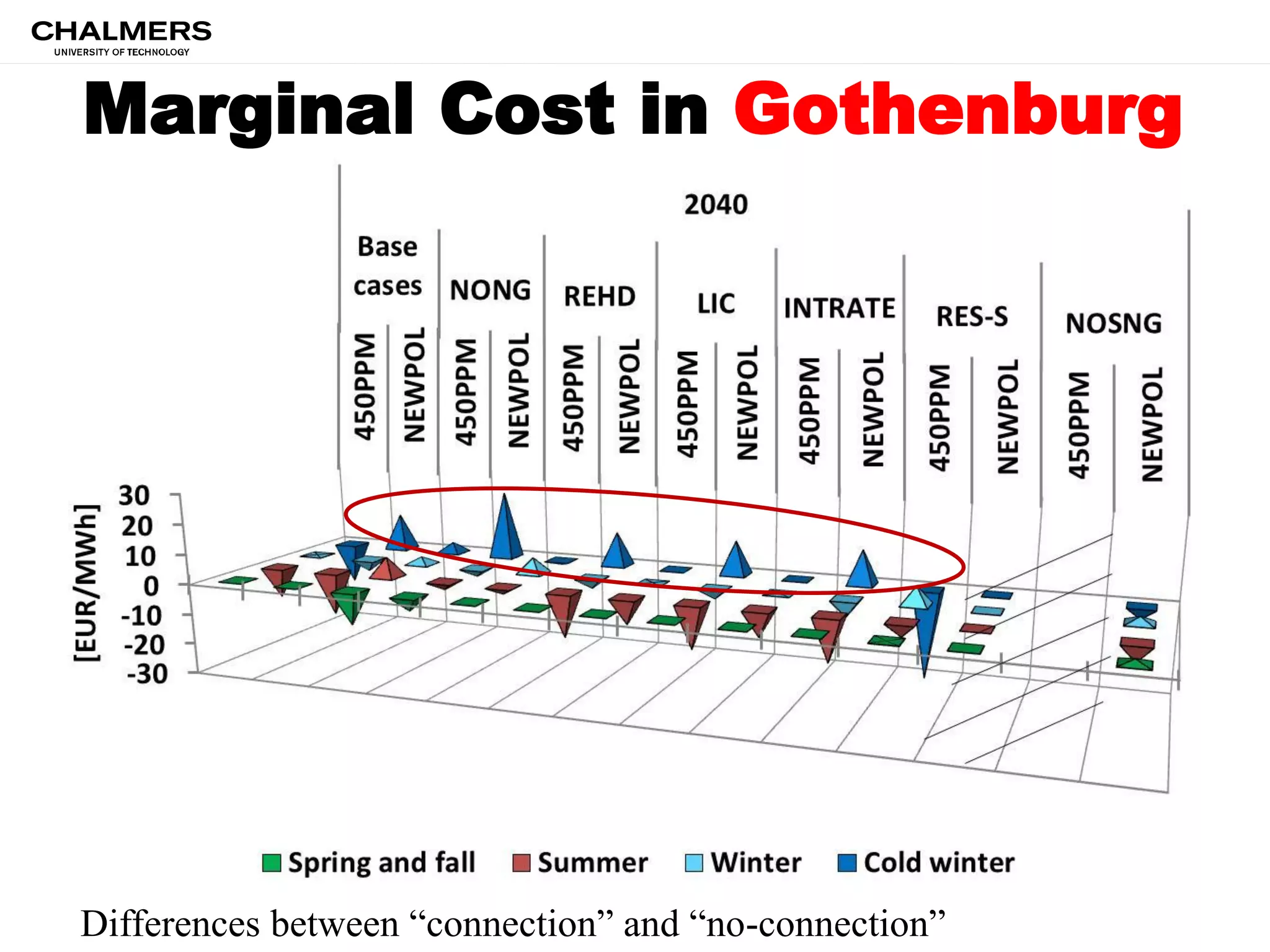

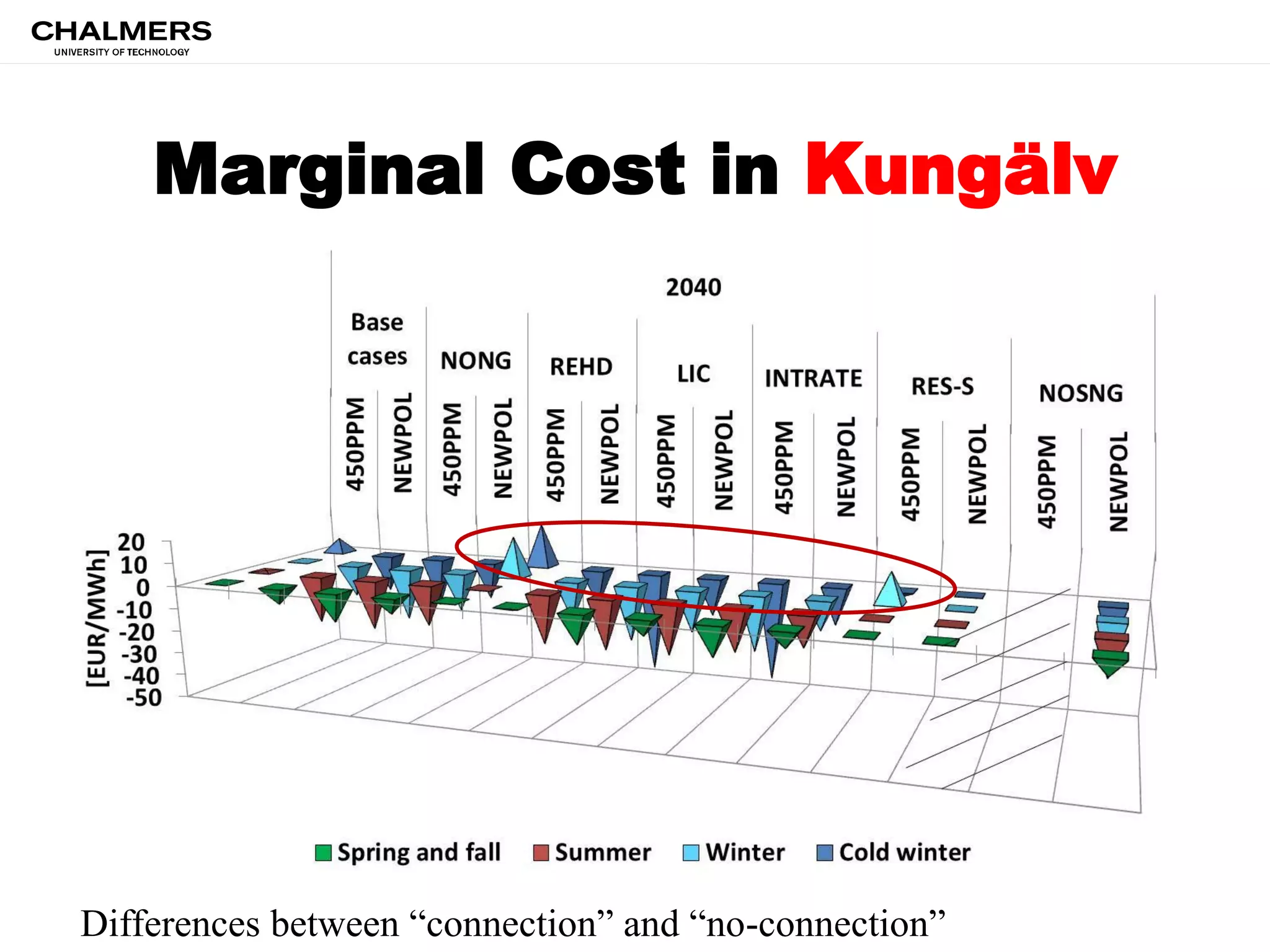

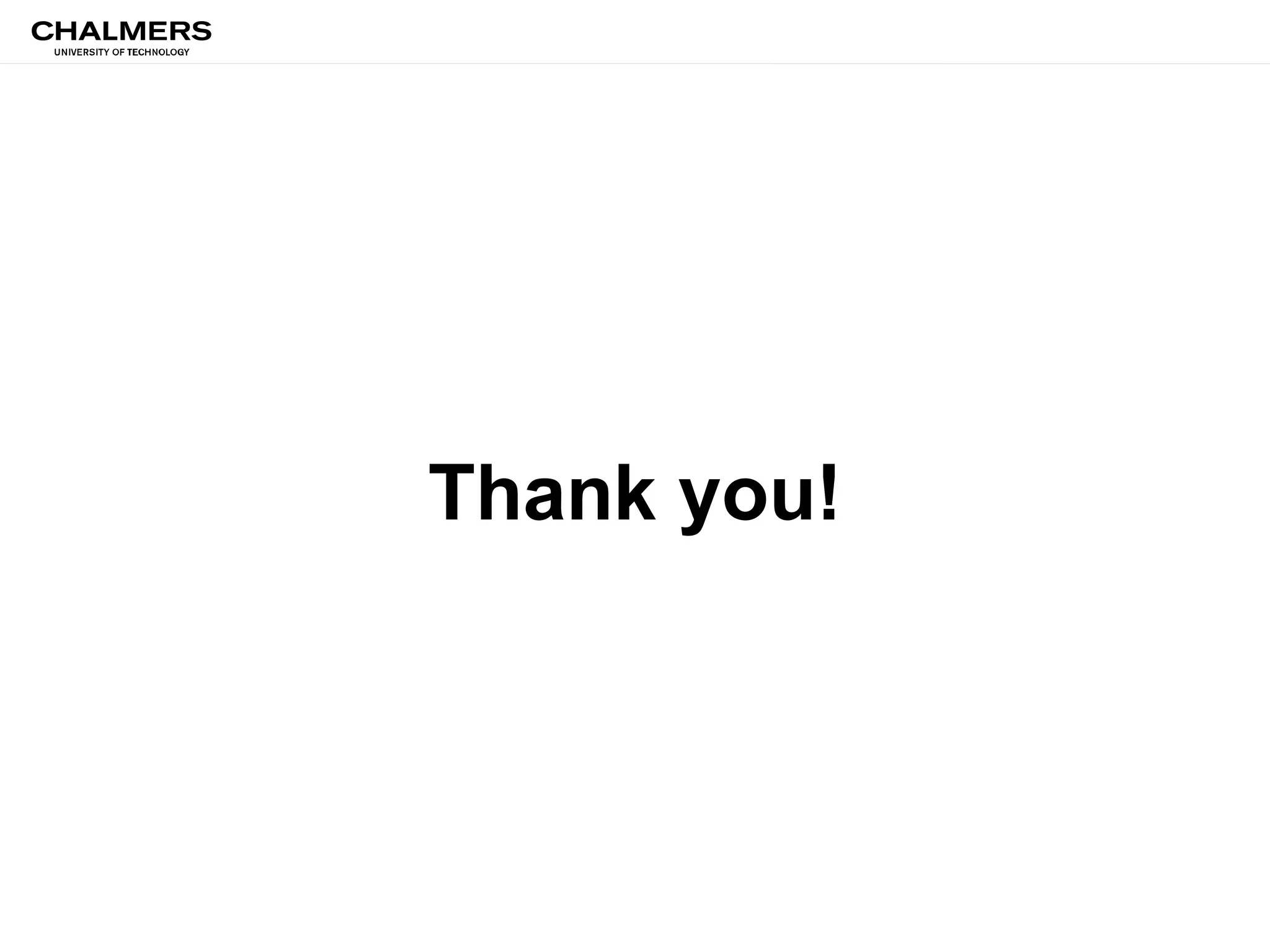

This document summarizes a study assessing the economic impacts of utilizing excess heat from industries through regional heat networks. The study uses energy system modeling to analyze scenarios with and without a large heat network connecting chemical industries to district heating systems in Gothenburg and Kungälv, Sweden. The results show that investing in the heat network reduces the total and marginal costs of district heating supply in most cases. However, the investment is only cost-effective if other excess heat sources are not more localized or biomass is not abundantly and cheaply available in the region.

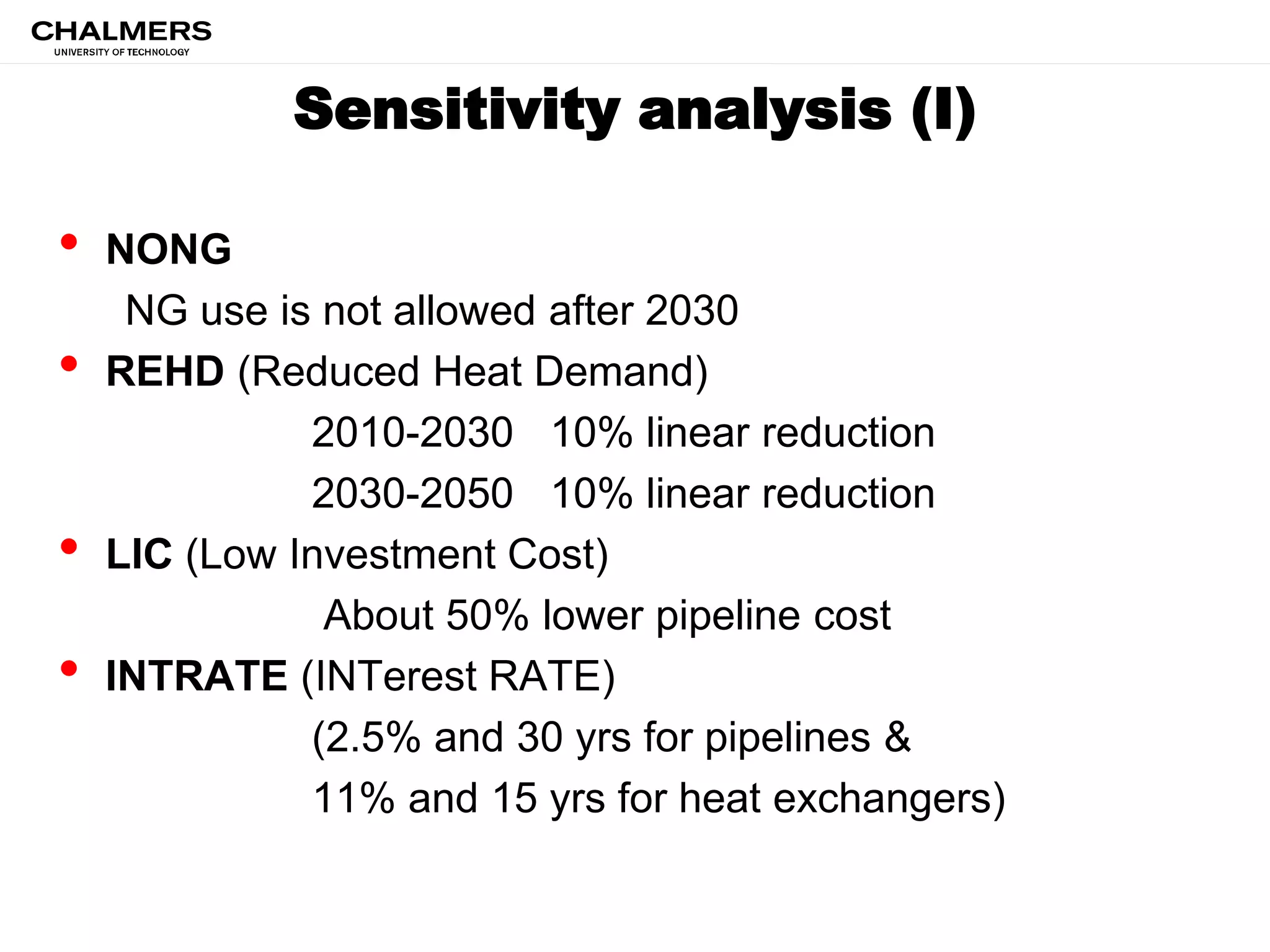

![Swedish DH systems

Source: Statistics Sweden & Swedish Energy Agency

0

10

20

30

40

50

60

70

1970

1975

1980

1985

1990

1995

2000

2005

2010

Fueluse[TWh]

Excess heat

Heat pumps

Electric boilers

Biofuels, Municipal solid

waste, peat

Energy coal including coke

oven and blast furnace gas

Natural gas including LPG

Oil

0

10

20

30

40

50

1980 1985 1990 1995 2000 2005 2010

Fuelsupply[TWh]

Peat

Tall oil pitch

Forest residues

Municipal solid waste

(MSW)

0

10

20

30

40

50

60

70

1970

1975

1980

1985

1990

1995

2000

2005

2010

Fueluse[TWh]

Industrial EH

Heat pumps

Electric boilers

Biofuels, Municipal solid

waste, peat

Energy coal including coke

oven and blast furnace gas

Natural gas including LPG

Oil](https://image.slidesharecdn.com/7presentationincopenhagen-20141117as-150530090824-lva1-app6892/75/Economic-impact-of-large-scale-utilisation-of-excess-heat-assessment-through-regional-modelling-3-2048.jpg)

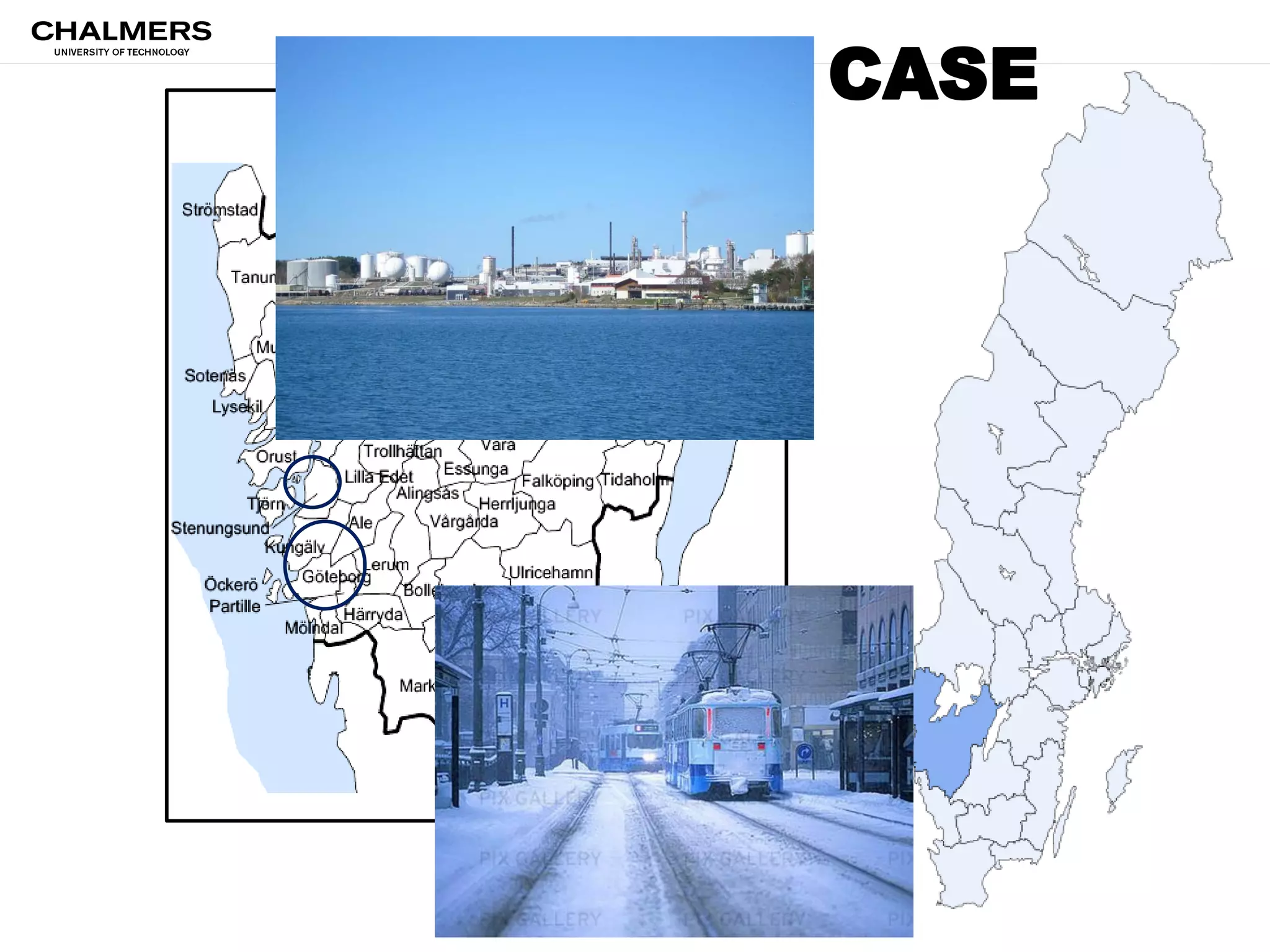

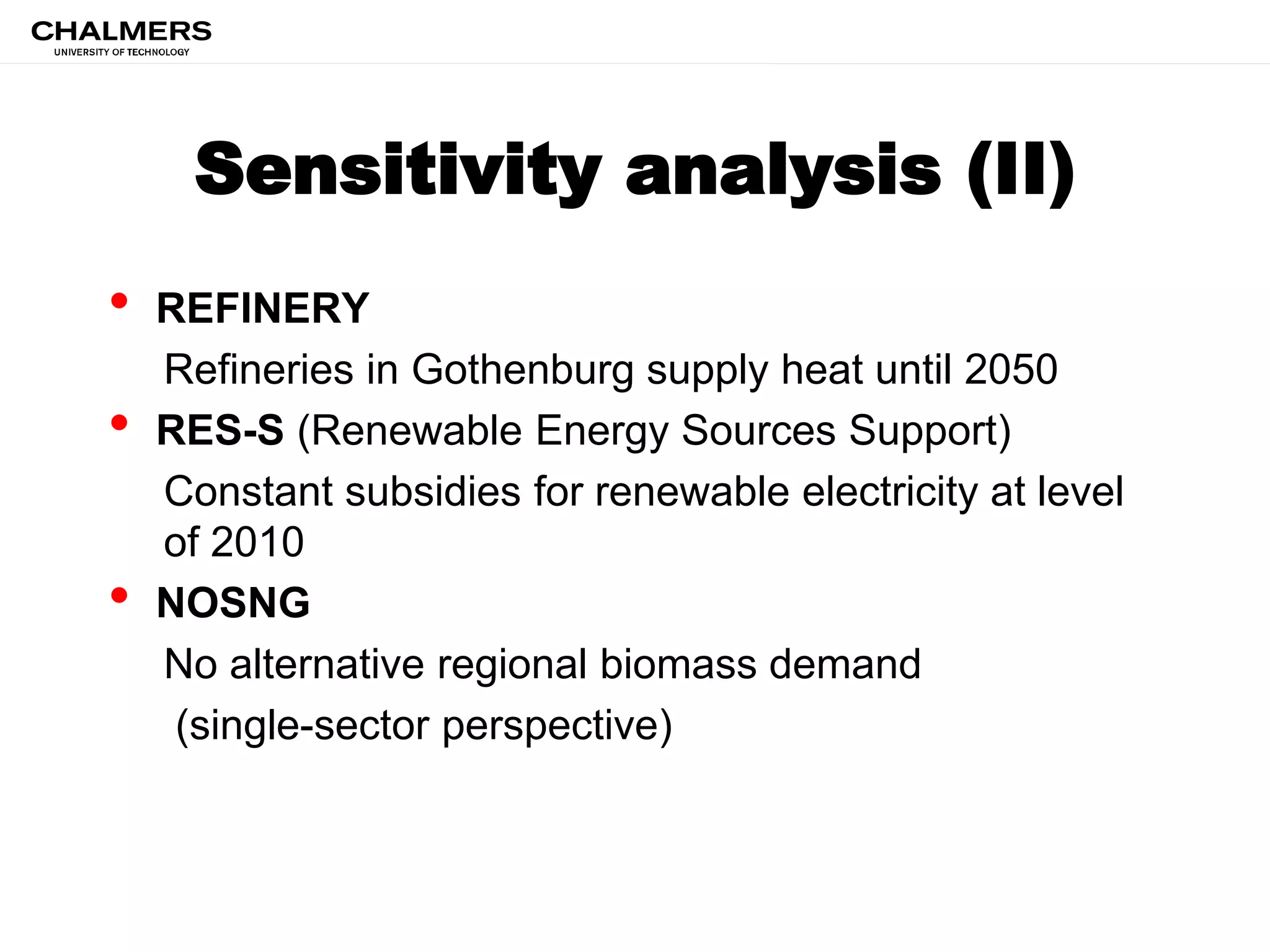

![SKG pipeline

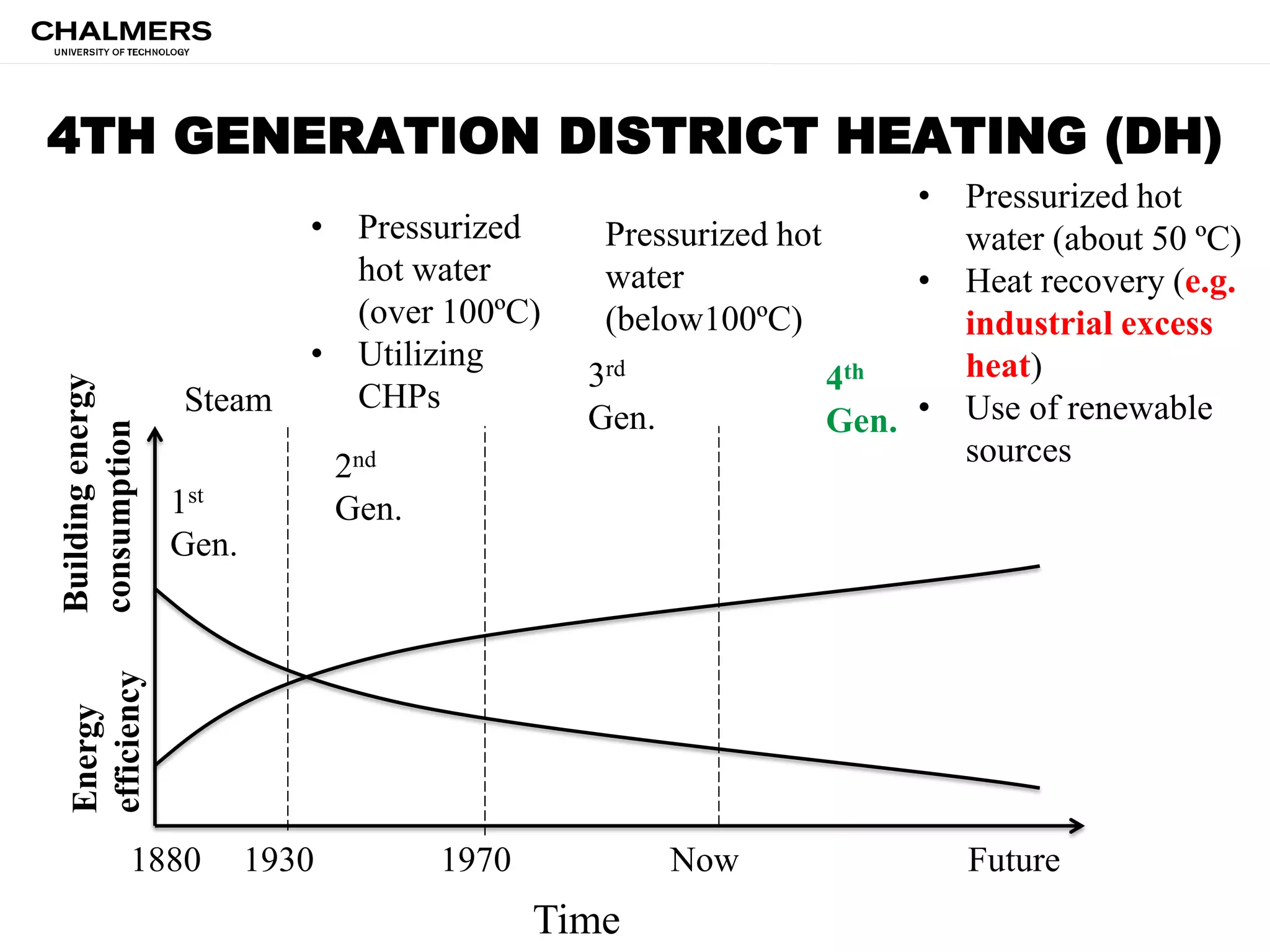

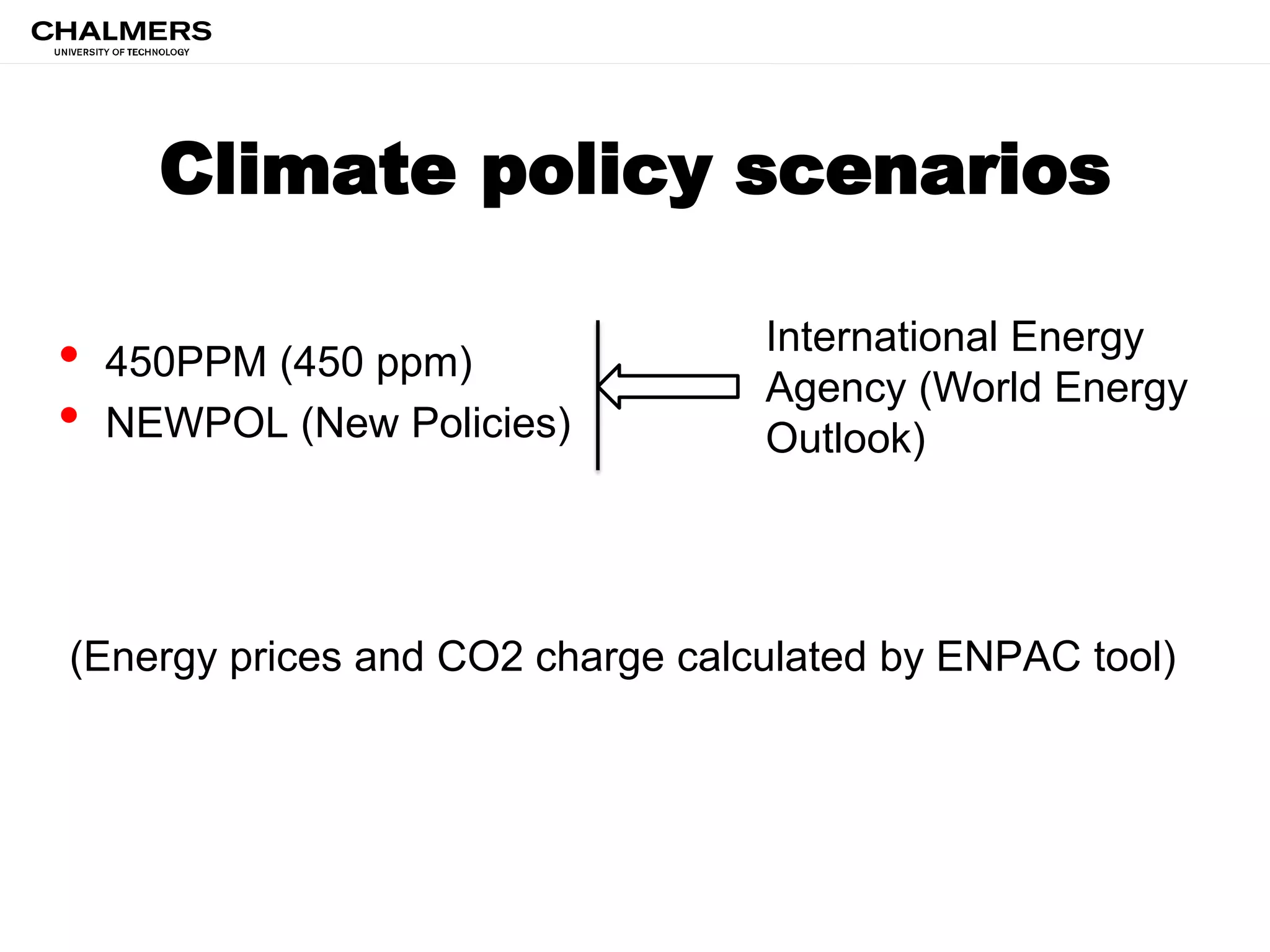

Cap≤ 50 MW 1800/ 0.25 Cap≤ 50 MW 1100/ 0.25

50˂Cap≤ 100 MW 2200/ 0.12 50˂Cap≤ 100 MW 1200/0.12

100˂Cap≤ 150 MW 2600/ 0.08 100˂Cap≤ 150 MW 1300/ 0.08

Length km

SK pipeline

Investment/ Variable

O&M Cost

[EUR/m]/

[EUR/MWh

heat]

Cap≤ 50 MW 1800/ 0.16 Cap≤ 50 MW 1100/ 0.16

Length km

EH-CCIS extraction

Cap ≤ 20 MW 4.4 Cap ≤ 20 MW 4.4

20˂Cap ≤ 40 MW 6.7 20˂Cap ≤ 40 MW 6.7

40˂Cap ≤ 60 MW 12.8 40˂Cap ≤ 60 MW 12.8

60˂Cap ≤ 80 MW 20.6 60˂Cap ≤ 80 MW 20.6

80˂Cap ≤ 100 MW 26.7 80˂Cap ≤ 100 MW 26.7

100˂Cap ≤ 120 MW 37.8 100˂Cap ≤ 120 MW 37.8

120˂Cap ≤ 140 MW 51.1 120˂Cap ≤ 140 MW 51.1

140˂Cap ≤ 150 MW 61.1 140˂Cap ≤ 150 MW 61.1

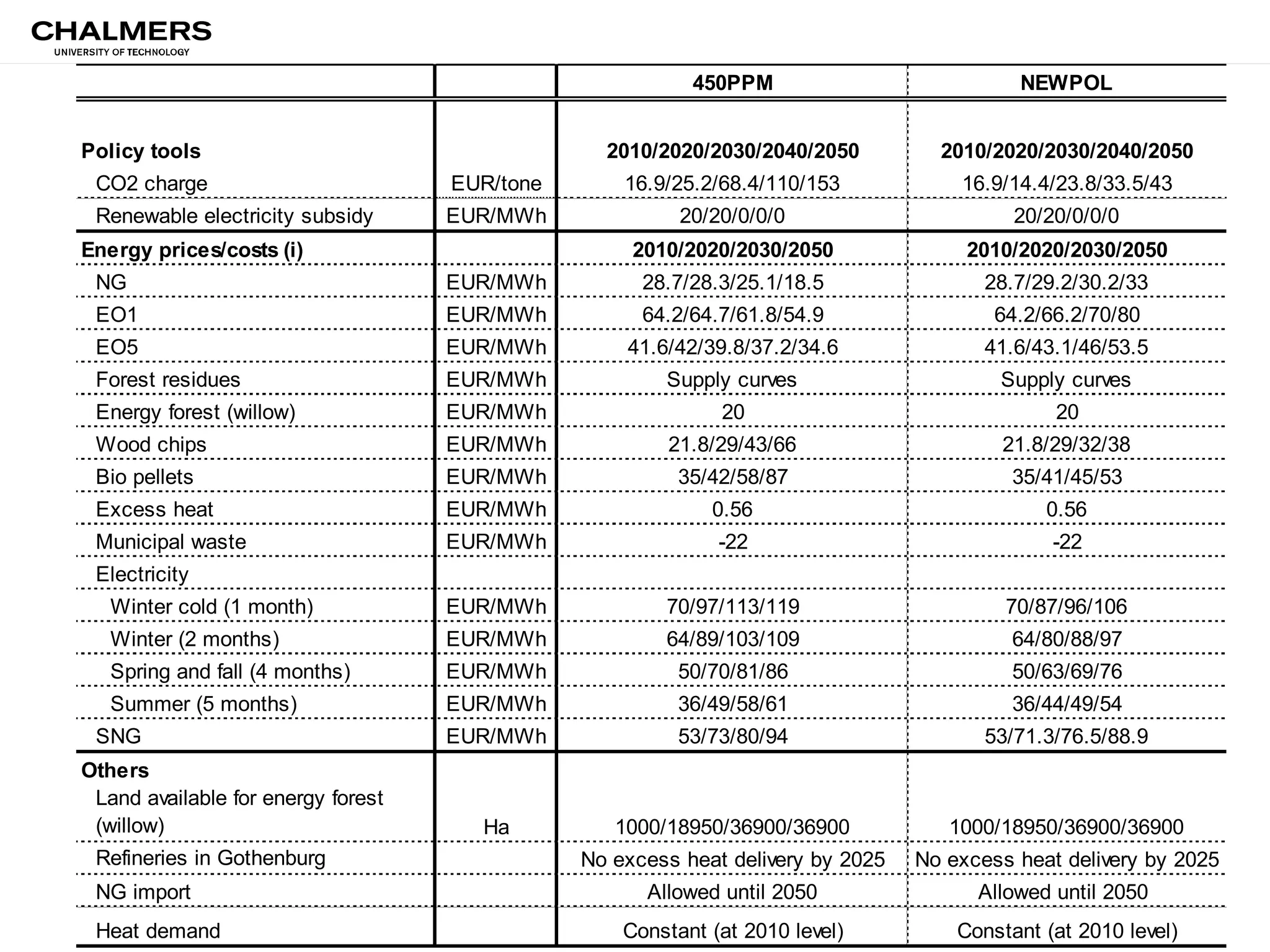

450PPM and NEWPOL LIC

55

Investment/ Variable

O&M Cost

[EUR/m]/

[EUR/MWh

heat]

55

Investment cost

(80/50 hot water)

MEUR

35 35](https://image.slidesharecdn.com/7presentationincopenhagen-20141117as-150530090824-lva1-app6892/75/Economic-impact-of-large-scale-utilisation-of-excess-heat-assessment-through-regional-modelling-27-2048.jpg)

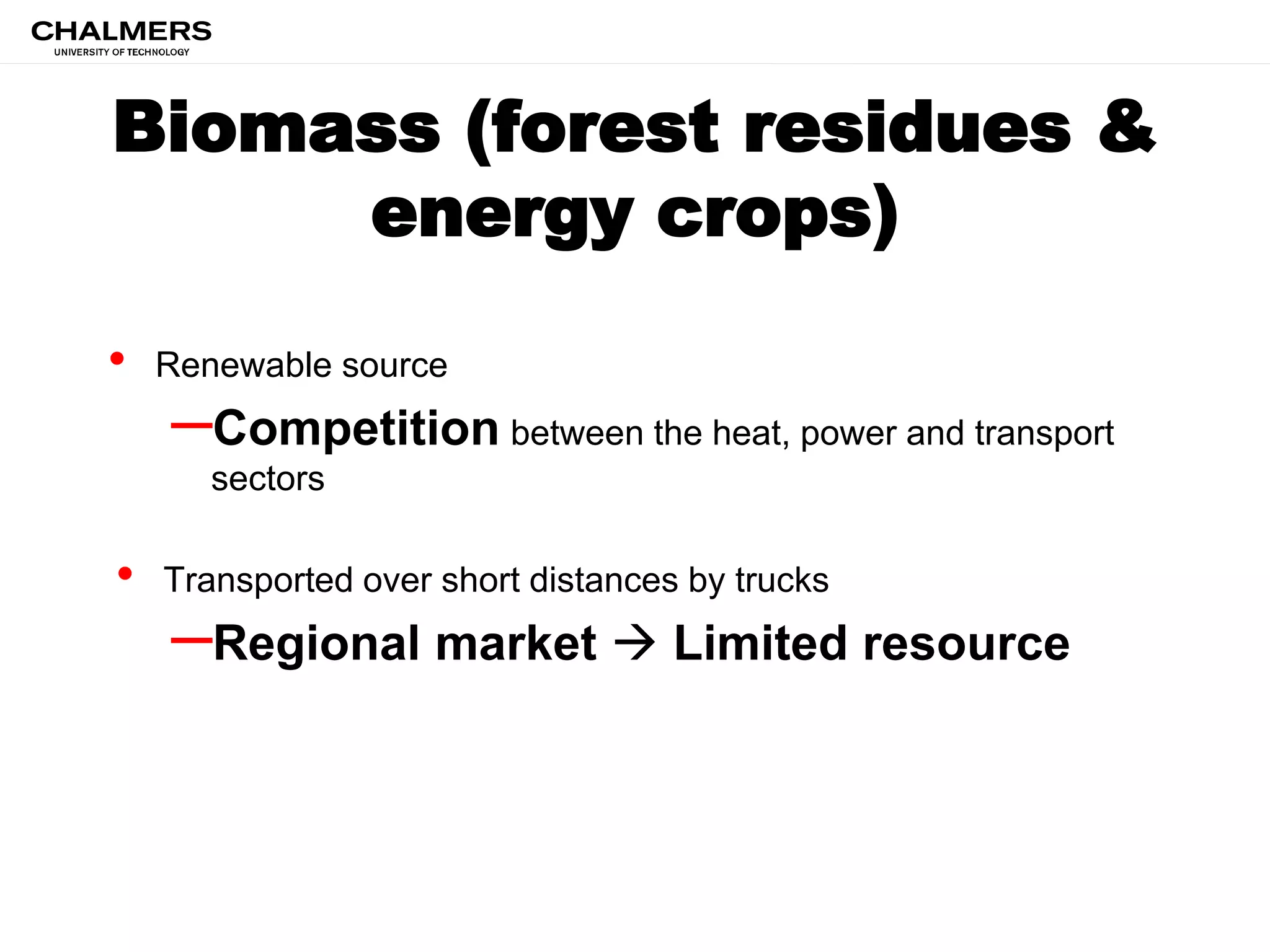

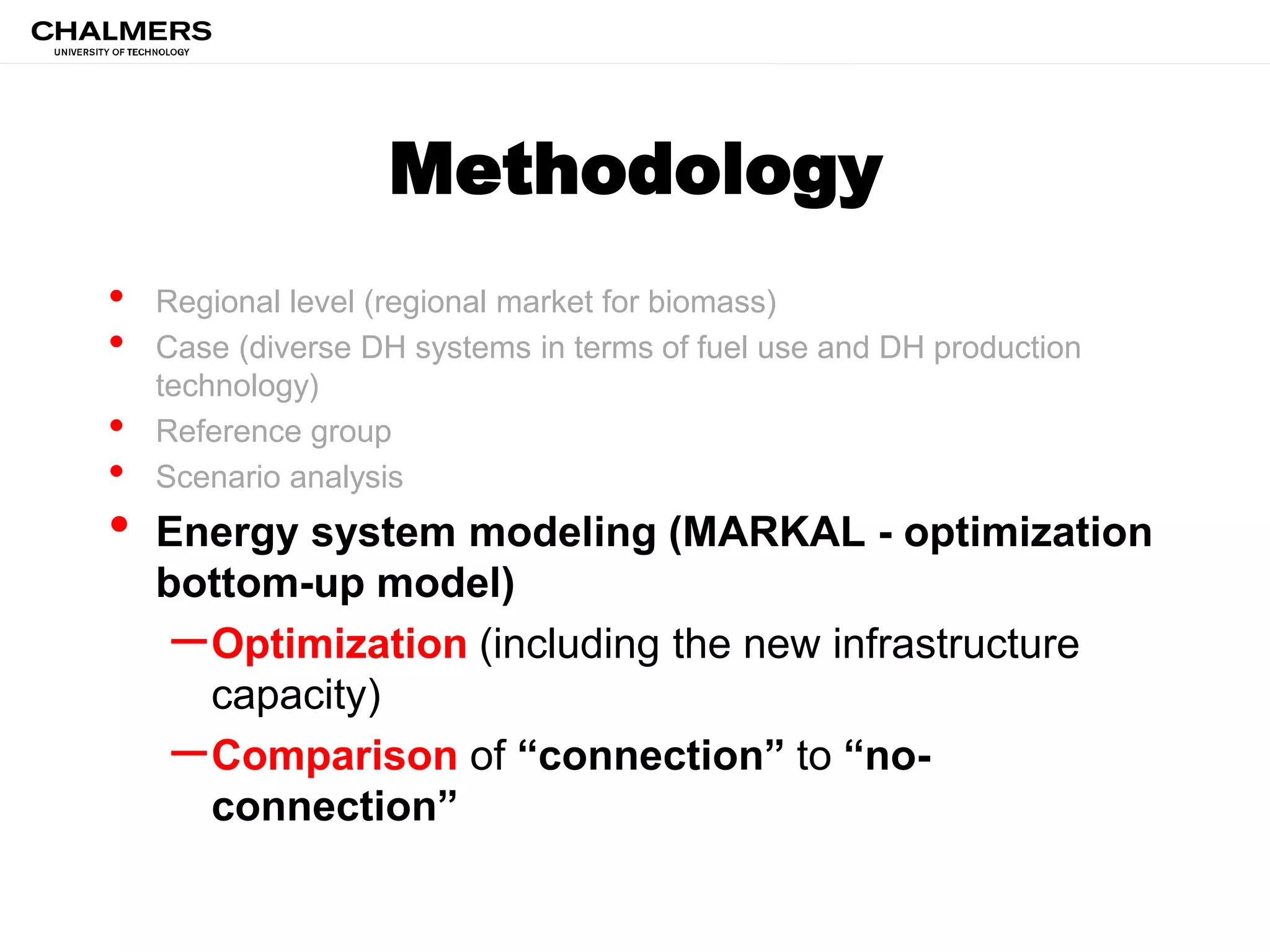

![DH technologies

Gas CC CHP 45-49 90 0.8-1.2 1 2.5

Gas Engine CHP 38 86 0.75 4.3

Biomass ST CHP 25-34 110 2.3-7.2 1.5 2.7

Waste ST CHP 22 91 5.9-8.2 3 -12

Gas HOB 0.05-1.0 2.5 0.7

Biomass HOB 0.34-0.56 1.5 2.0

Oil HOB 0.09-0.17 2.5 0.7

Waste HOB 1.0-1.1 3 -16

Heat pump 0.70 0.5 0.7

[MEUR/year] [EUR/MWh fuel]

Bio-refinery plants

SNG (iii) 2 3

[EUR/MWh fuel]

Heat plants

Fixed O&M cost Variable O&M cost

Electricity [%] Total [%] [kEUR/kW electricity] [% of inv. cost/year] [EUR/MWh fuel]

Heat [%] [kEUR/kW heat]

Specific investment

cost (ii)

Combined heat and power plants

91

SNG [%]

70

300 (COP)

[% of inv. cost/year]

90

Technology Conversion efficiency (i)

110

90](https://image.slidesharecdn.com/7presentationincopenhagen-20141117as-150530090824-lva1-app6892/75/Economic-impact-of-large-scale-utilisation-of-excess-heat-assessment-through-regional-modelling-28-2048.jpg)