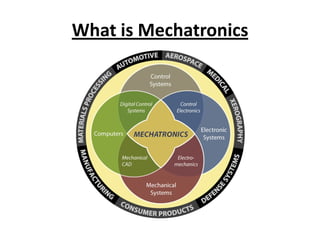

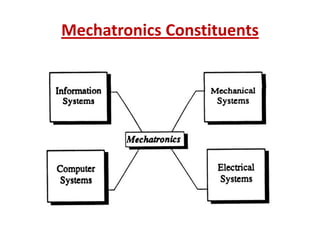

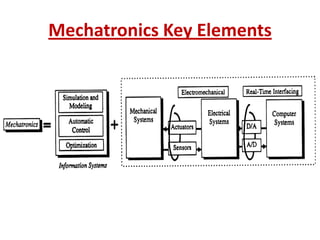

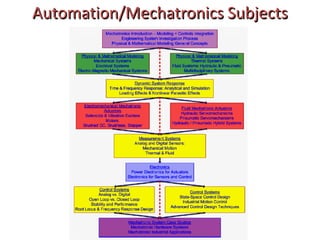

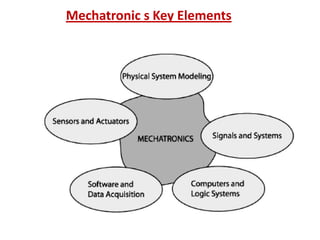

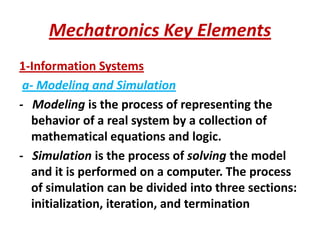

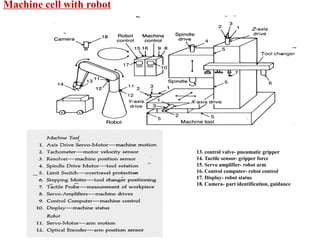

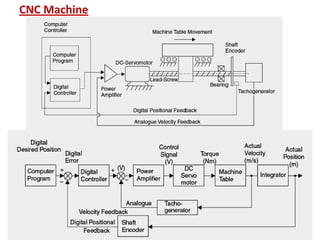

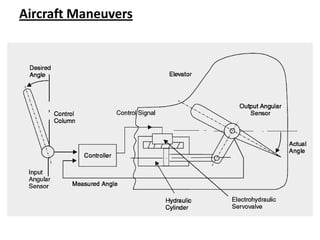

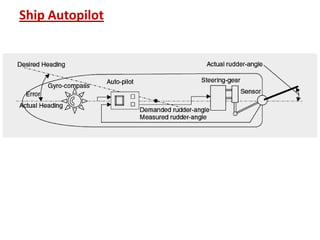

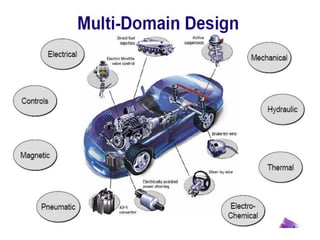

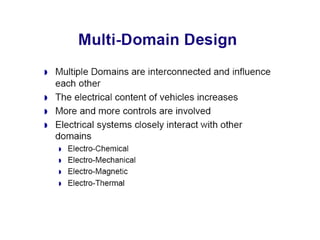

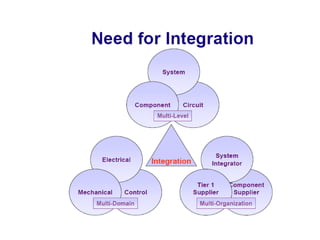

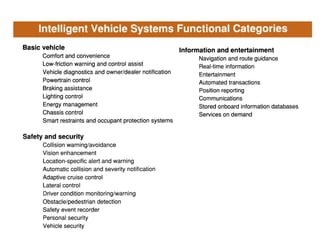

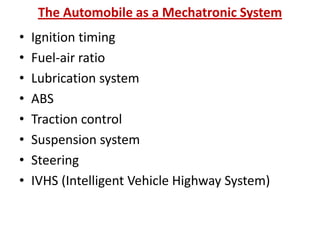

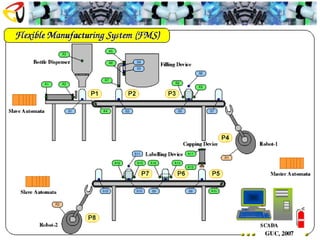

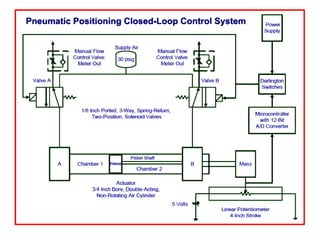

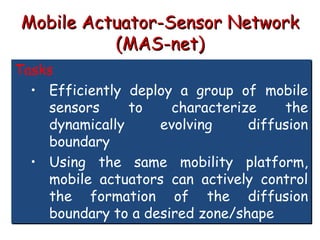

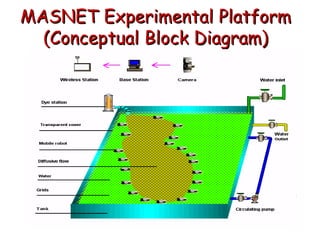

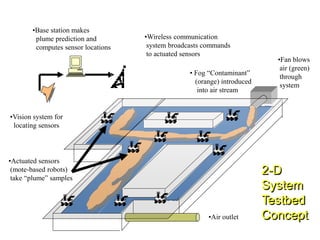

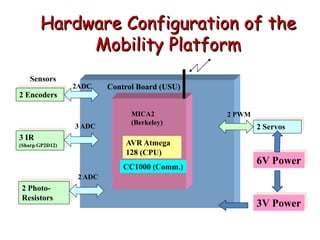

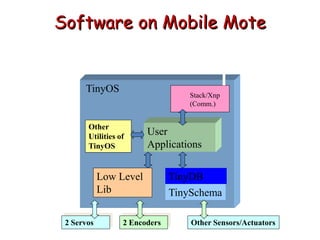

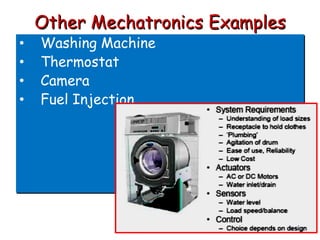

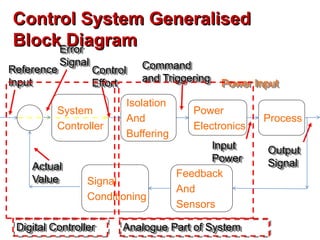

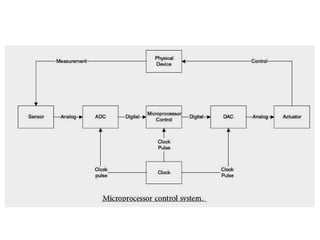

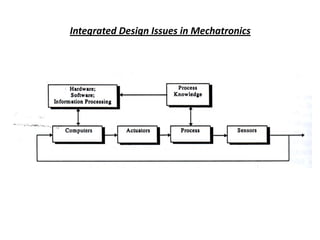

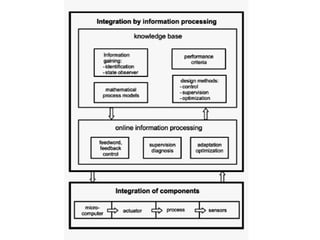

Mechatronics is a multidisciplinary design approach that integrates mechanical engineering, electrical engineering, computer science, and systems design engineering. It combines sensors and actuators with digital computers and basic control loops to create electromechanical systems. Key elements of mechatronic systems include modeling and simulation, automatic controls, optimization, electrical systems like motors and sensors, actuators, computer systems, and real-time interfacing between physical systems and computational control systems. Mechatronics is used in various applications including automobiles, aircraft, manufacturing machines, and mobile sensor networks.