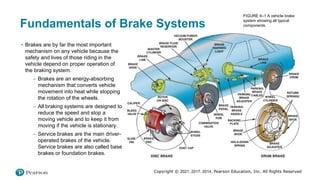

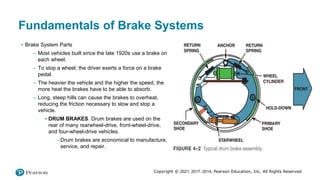

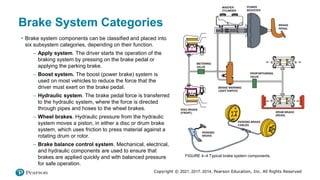

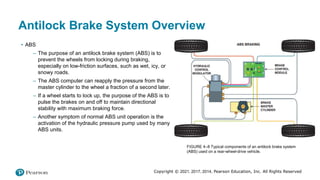

The document discusses the fundamentals of brake systems, emphasizing their critical role in vehicle safety through converting motion into heat to stop wheels. It categorizes brake system components into six subsystems, explains the function of antilock brake systems (ABS), and outlines federal safety standards for brake performance established by the U.S. Department of Transportation. Additionally, it highlights the responsibility of vehicle owners and technicians in maintaining effective braking performance post-manufacture.