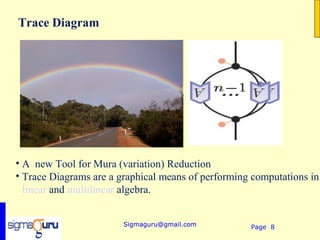

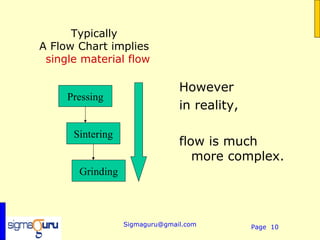

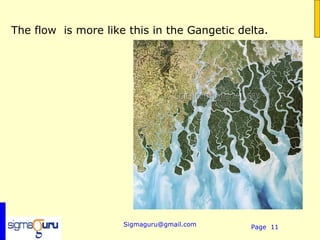

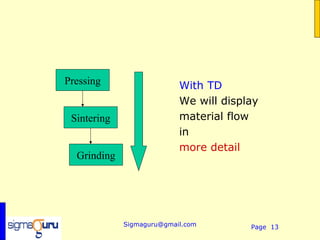

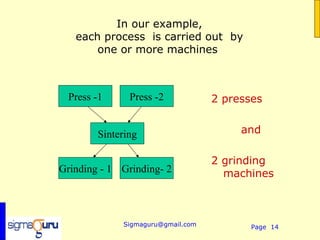

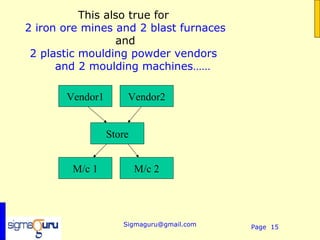

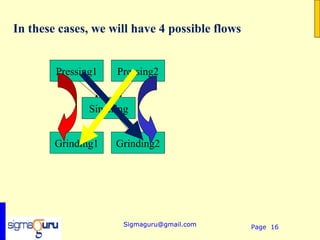

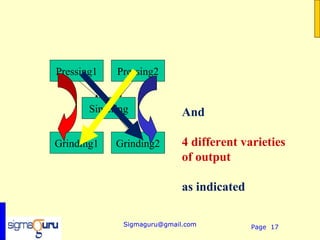

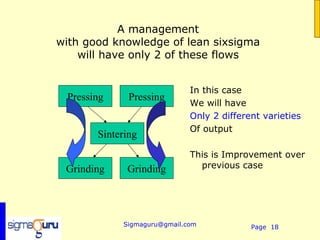

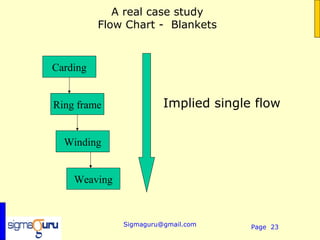

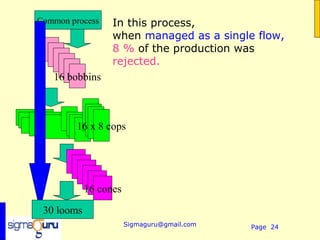

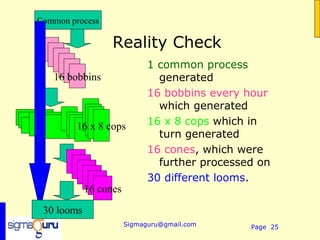

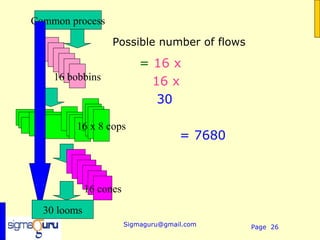

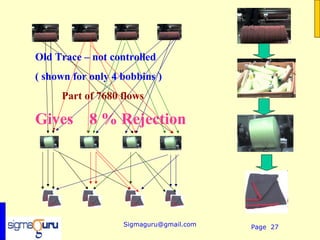

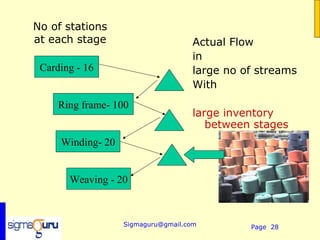

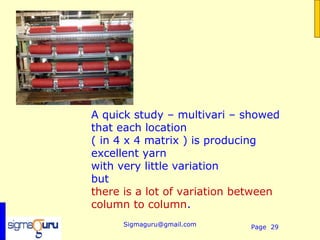

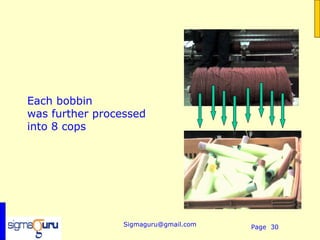

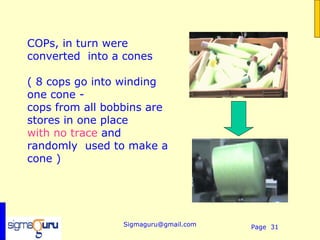

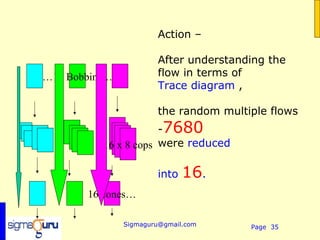

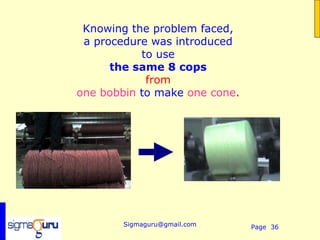

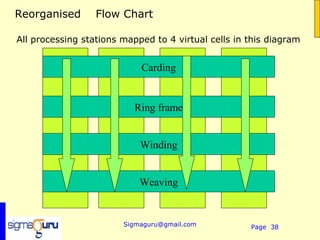

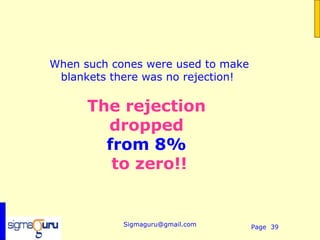

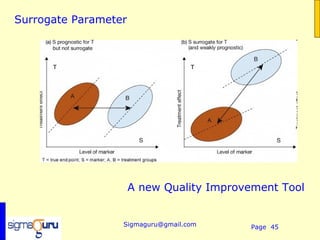

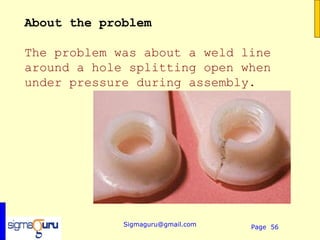

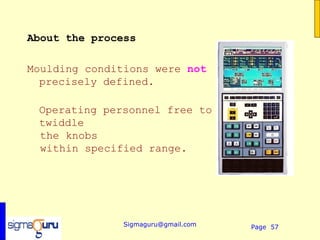

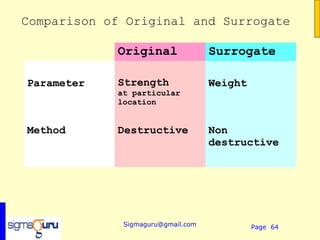

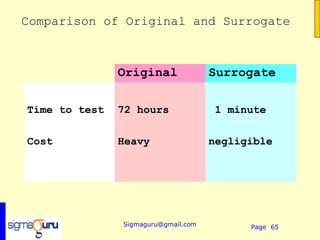

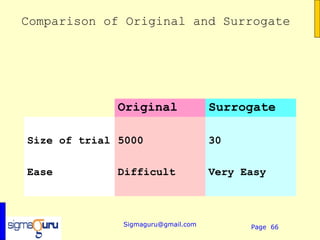

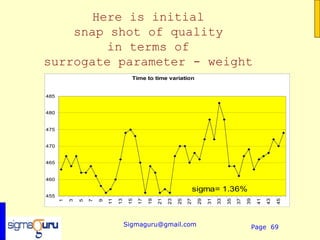

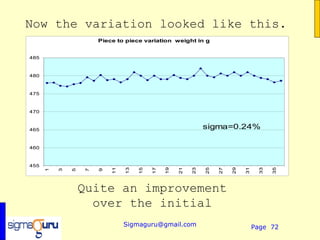

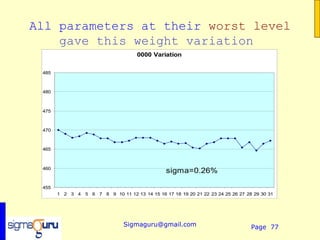

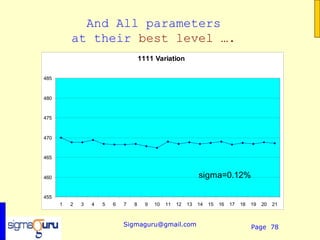

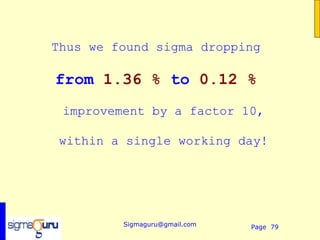

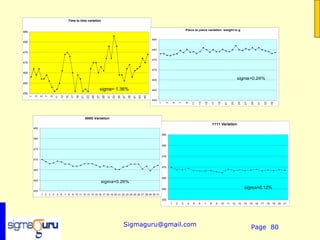

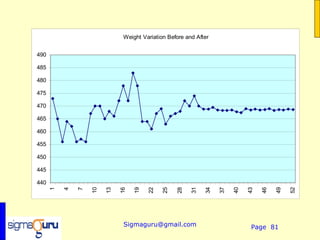

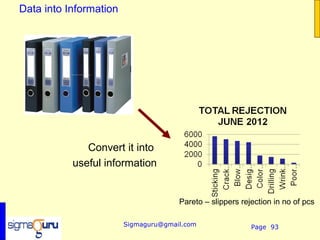

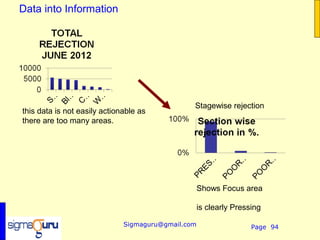

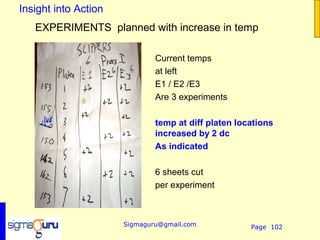

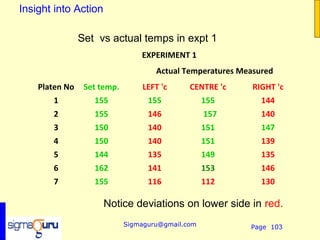

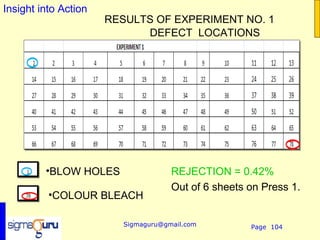

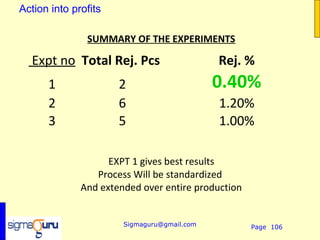

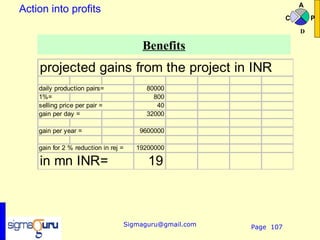

The document presents three new problem-solving tools developed by Sigmaguru: trace diagram, surrogate parameter, and DAM (data to money). Each tool is accompanied by case studies demonstrating their effectiveness in reducing product rejection rates to zero. These methods provide graphical representations and substitute parameters that help organizations identify and eliminate root causes of defects in their production processes.