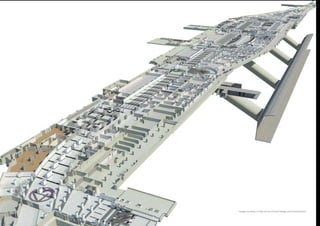

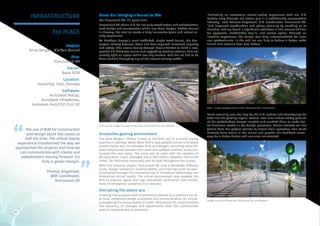

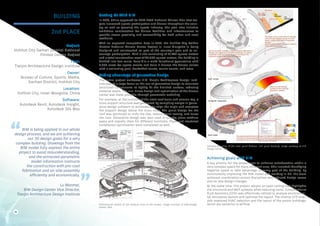

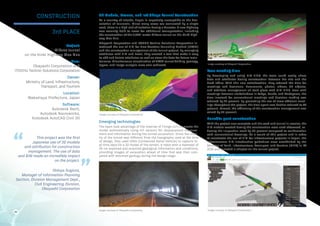

The 5th annual AEC Excellence Awards showcased 145 innovative projects emphasizing sustainable practices and advanced technologies like BIM, augmented reality, and drones. Notable winners included the Nuevo Aeropuerto Internacional de la Ciudad de Mexico, East Side Access, and Arna-Bergen Ulriken Tunnel, recognized for their exceptional design and engineering. Sponsored by leading firms, the awards aim to celebrate achievements in the architecture, engineering, and construction industry while promoting a better, more sustainable world.