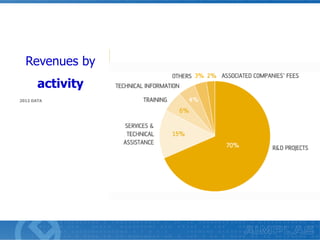

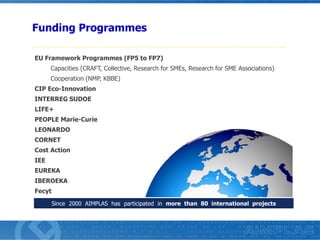

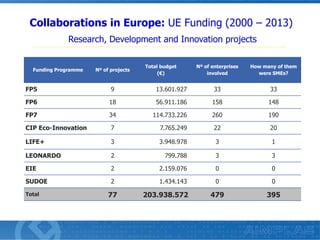

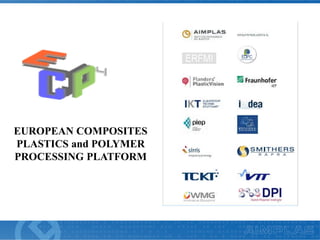

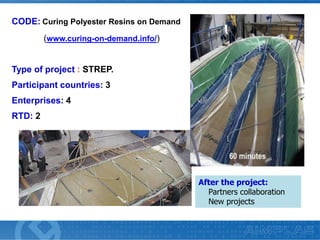

This document summarizes AIMPLAS, a Centre of Innovation and Technology that supports companies in the plastic sector. It has over 100 professionals and 8,500 square meters of facilities with advanced technologies. AIMPLAS provides R&D projects, testing, materials processing, technical assistance, and training solutions. It also discusses opportunities for international collaboration and EU funding programs. AIMPLAS has participated in over 80 projects, providing benefits like facing ambitious challenges, preparing for the future, risk sharing, and networking. Examples of successful projects involving SMEs are provided. Innovation trends are highlighted like weight reduction, improved properties, multifunctionality, and environmental improvement.