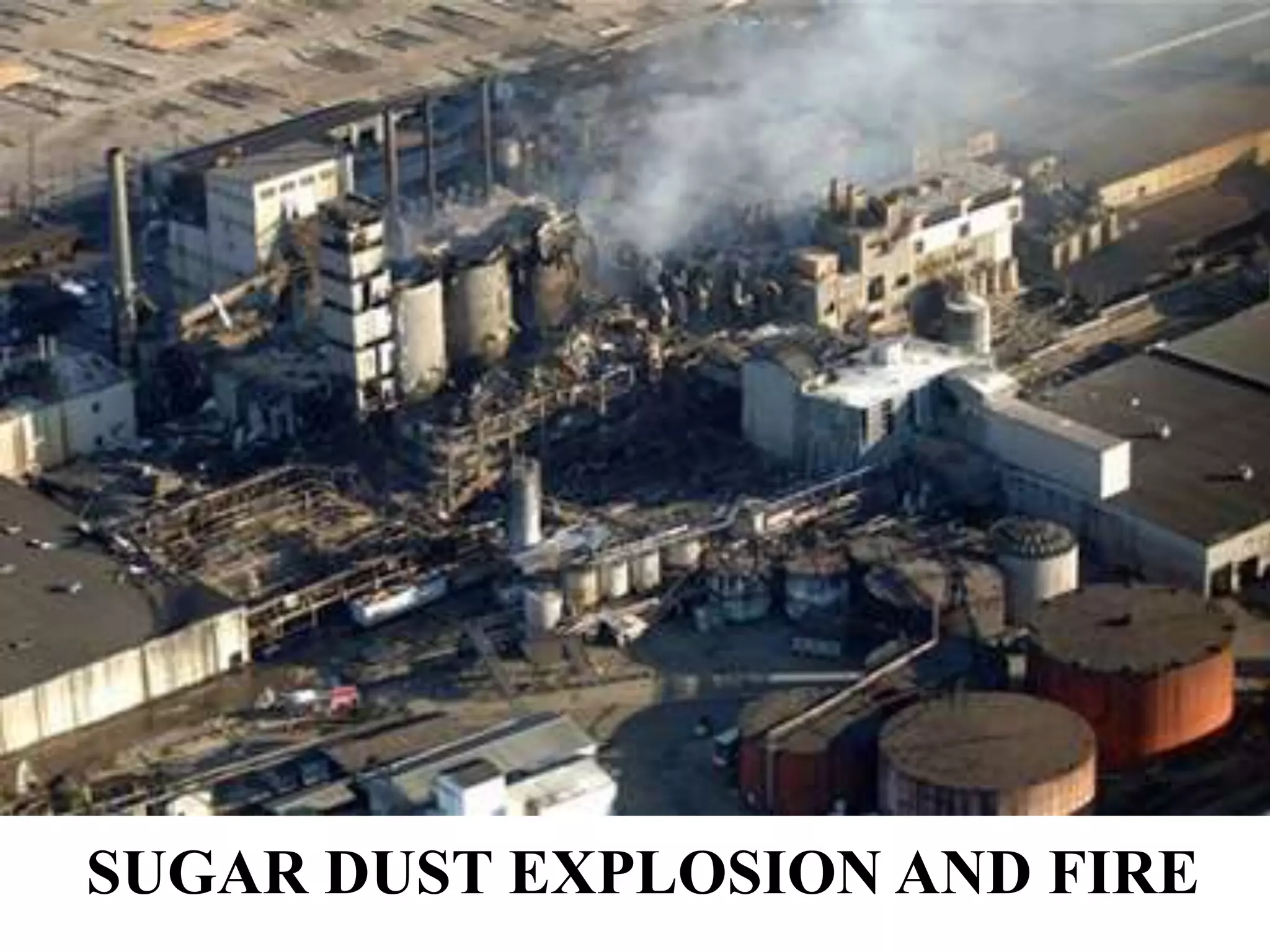

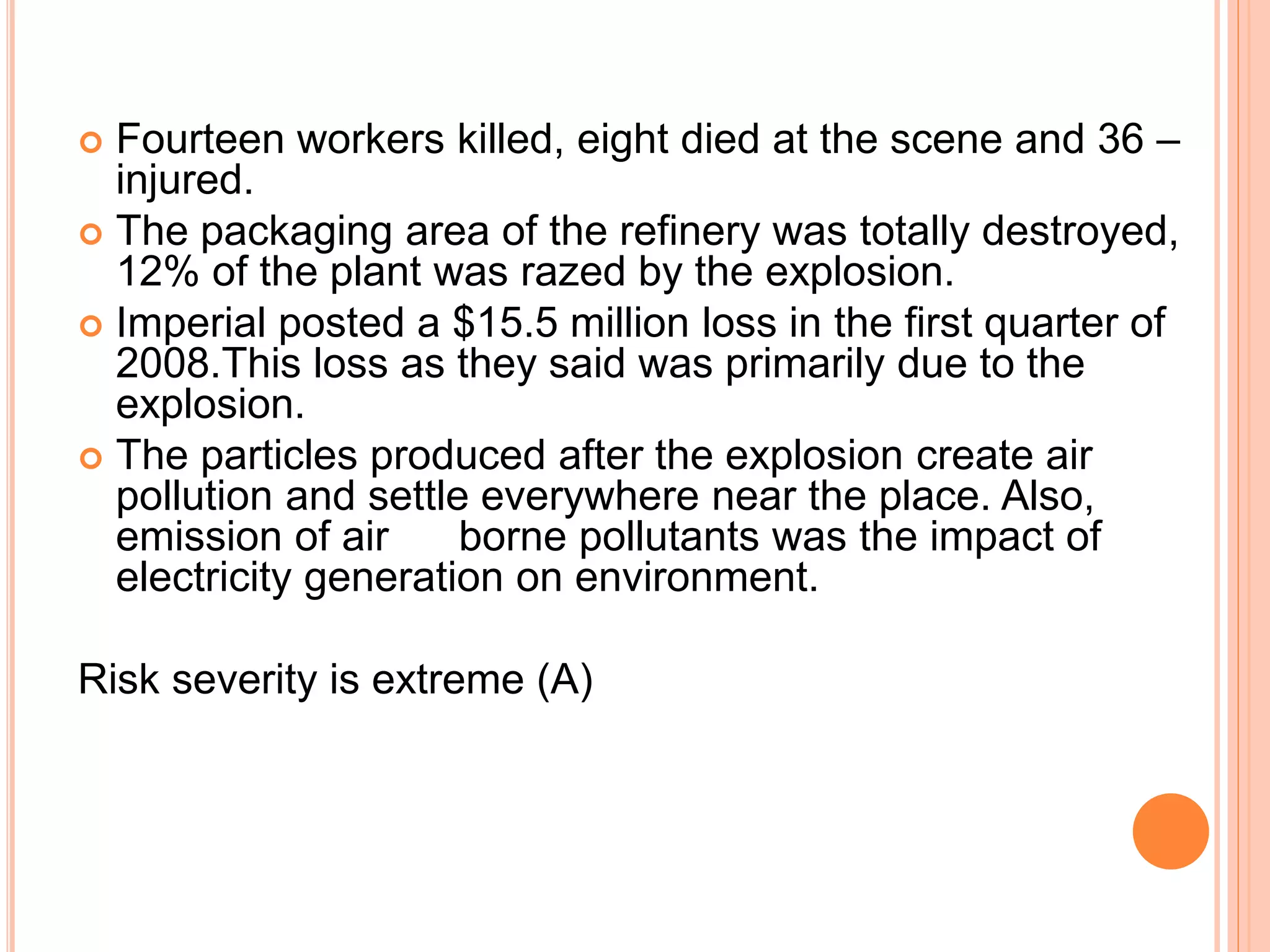

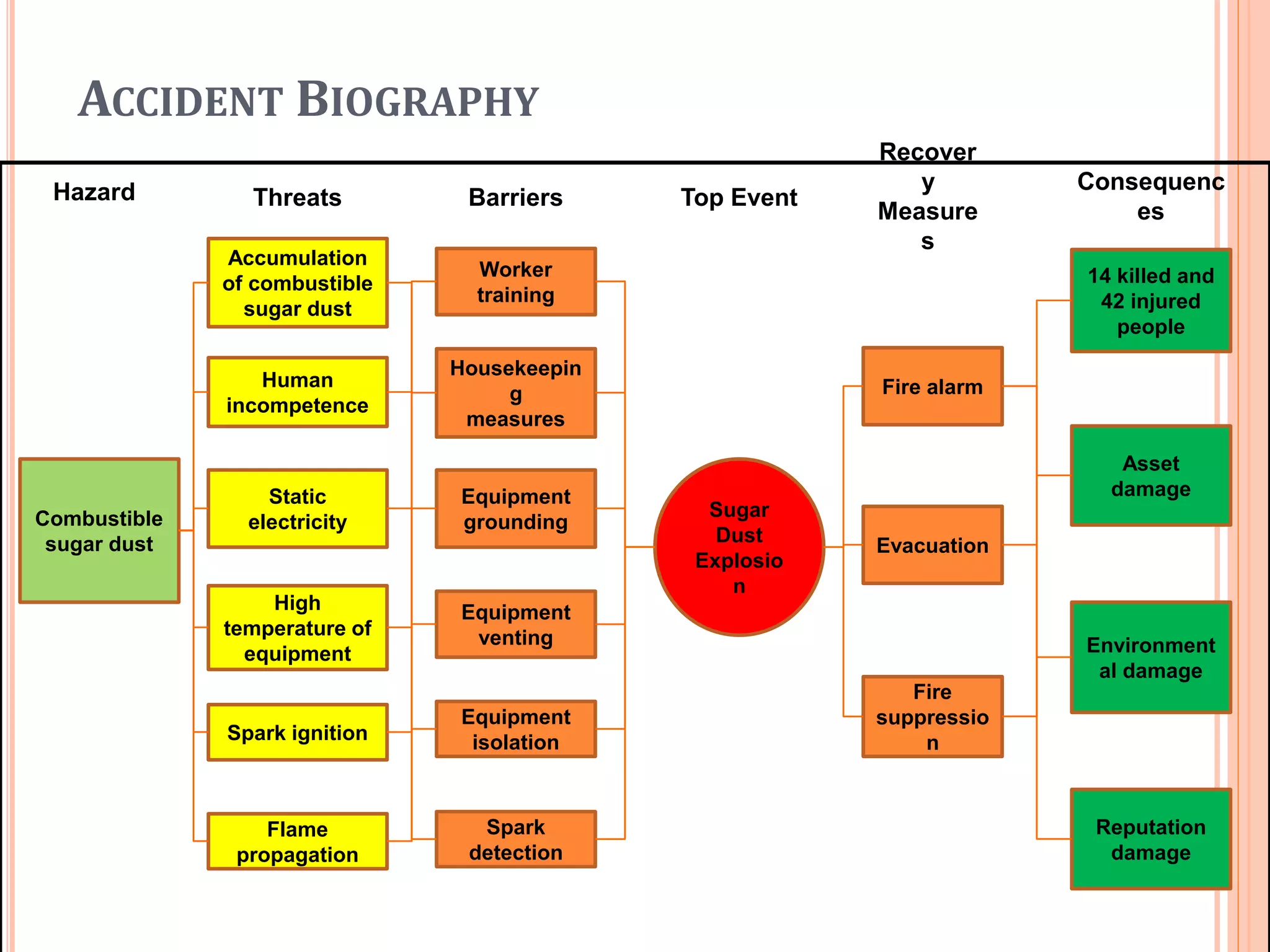

1) A sugar dust explosion and fire occurred at an Imperial Sugar refinery in Georgia in 2008, killing 14 workers and injuring 36. The packaging area of the refinery was destroyed.

2) The root causes were inadequate equipment, poor housekeeping allowing dust to accumulate, an overheated bearing igniting dust in the air, and an inadequate emergency response plan.

3) Consequences included $15.5 million in losses for Imperial Sugar, 124 safety violations found, an $8.7 million fine from OSHA, and 44 lawsuits from victims' families. The refinery was shut down for 18 months during cleanup and reconstruction.

![Reference list

Bauerlein V., 2010. Imperial Sugar to Pay Fines in Deadly Georgia Explosion

Case. [Online] Wall Street Journal. Retrieved March 22, 2014 from

http://goo.gl/I9kzxg

Csb.gov, 2009. Imperial Sugar Company Dust Explosion and Fire –

Investigations | the U.S. Chemical Safety Board [online]. Retrieved March 20,

2014 from

http://www.csb.gov/assets/1/19/imperial_sugar_report_final_updated.pdf

Dewan S., 2009. Report Cites Lack of Precautions in 2008 Sugar Plant Fire.

[Online] The New York Times. Retrieved March 24, 2014 http://goo.gl/bEcgoU

Skutch J., 2010. Appellate court rejects pre-trial appeal in Imperial Sugar case

[Online]. SavannahNow. Retrieved March 23, 2014 from http://goo.gl/K95Xww

Sugar Company Ignored Explosion Hazards, Investigation Concludes, 2009.

Retrieved March 20, 2014 from http://www.foreffectivegov.org/node/10428

Seward C., 2013. No criminal charges for Imperial Sugar in deadly blast.

[Online] The Atlanta Journal-Constitution. Retrieved March 25, 2014 from

http://goo.gl/Vphh36

http://www.youtube.com/watch?v=Jg7mLSG-Yws](https://image.slidesharecdn.com/2008imperialsugarrefineryexplosionpr-220912130941-fa7ceacc/75/2008_Imperial-Sugar_Refinery_Explosion_Pr-pptx-34-2048.jpg)