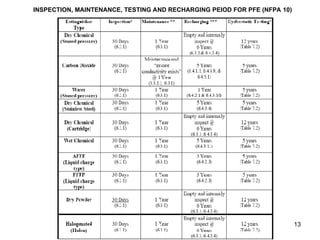

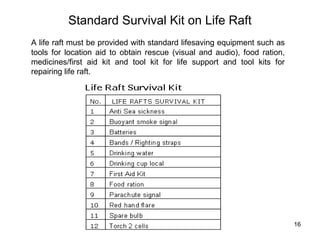

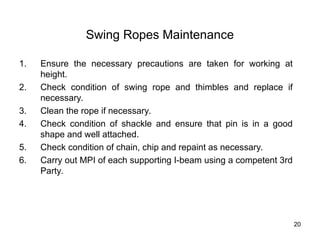

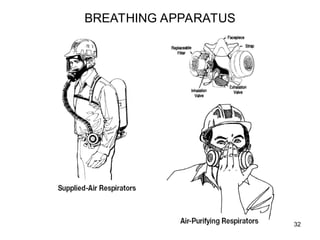

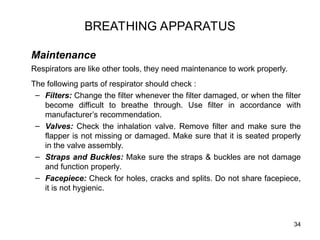

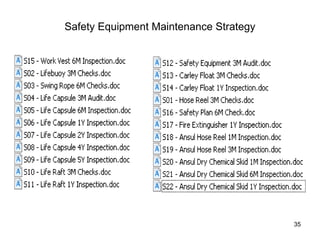

The document outlines the maintenance strategies for various safety and lifesaving equipment, emphasizing the importance of good condition and readiness for use. Key equipment covered includes large dry chemical fire extinguishers, portable fire extinguishers, life rafts, lifebuoys, and lifeboats, detailing maintenance schedules, inspection procedures, and operational requirements. It also addresses maintenance for firewater systems, hose reels, and breathing apparatus to ensure reliability and effectiveness in emergencies.