This document contains questions and topics related to process planning and cost estimation for a mechanical engineering course. It covers the following key areas in 5 units:

1. Work study, method study, work measurement, and ergonomics

2. Process planning, computer-aided process planning (CAPP), and documentation

3. Introduction to cost estimation, types of estimates, and estimation methods

4. Elements of cost, types of cost, direct and indirect costs, and overhead expenses

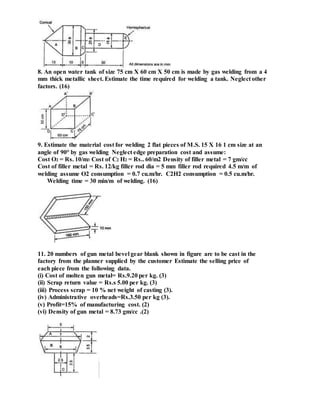

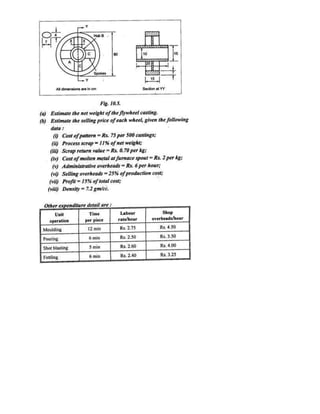

5. Production cost estimation techniques for various manufacturing processes like forging, welding, casting etc.