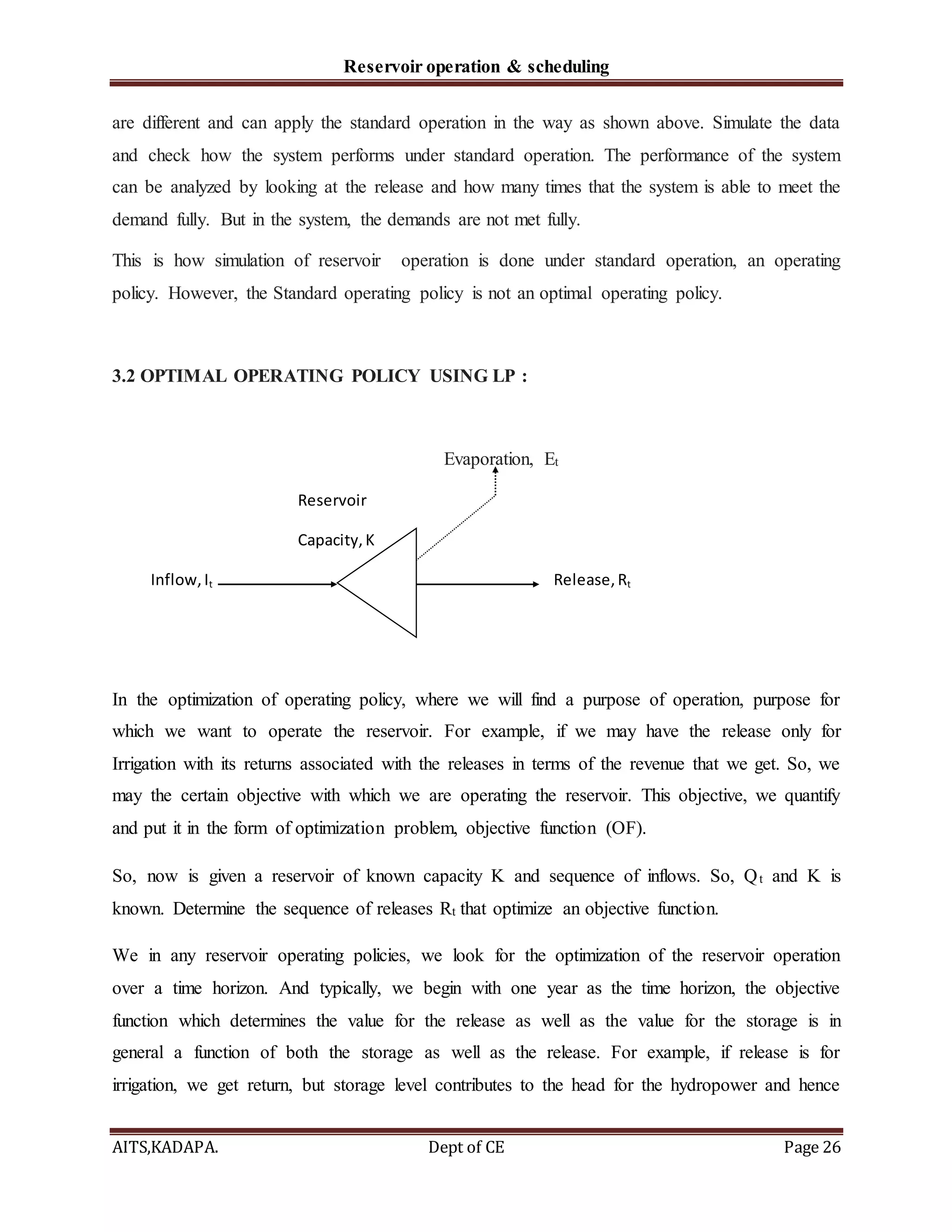

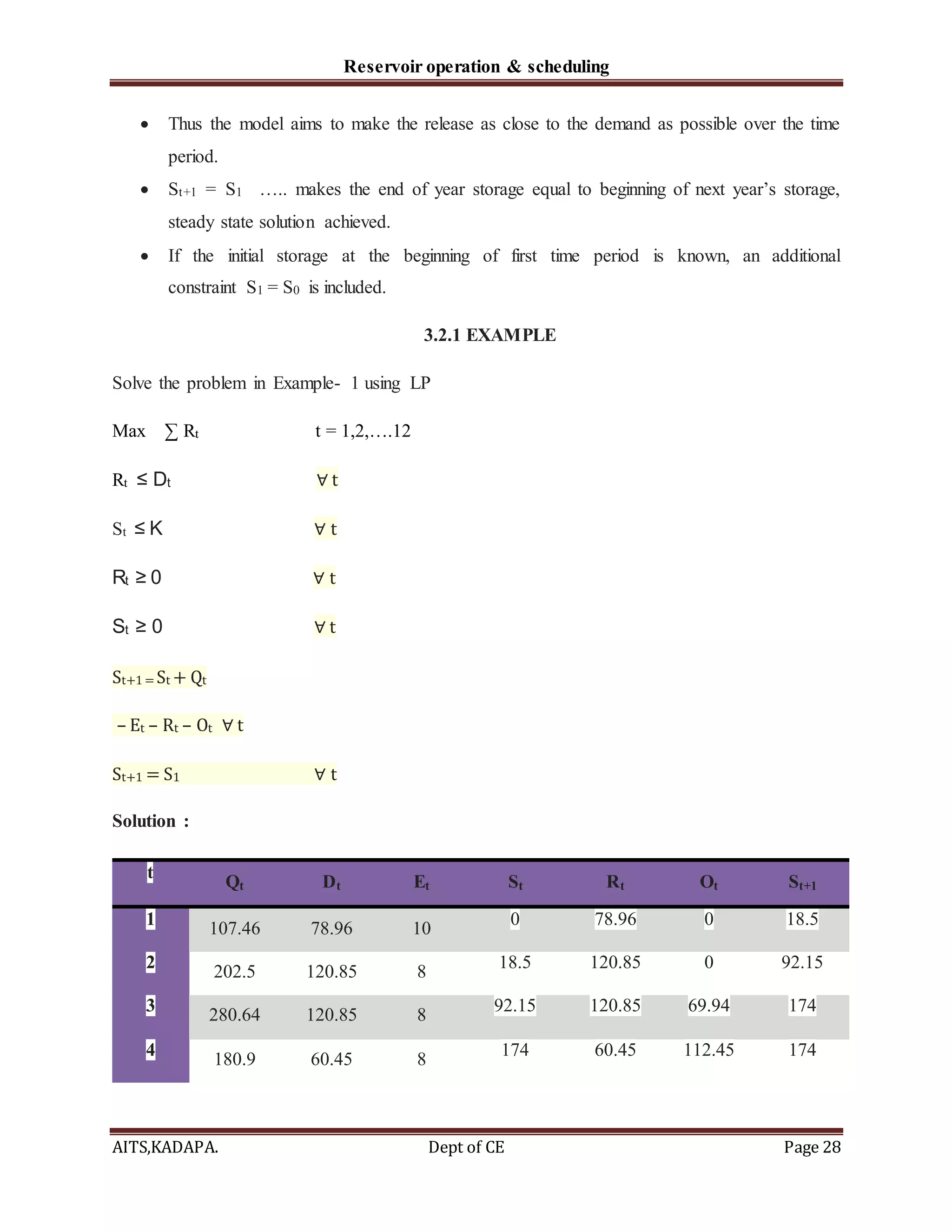

This document provides an overview of reservoir operation and scheduling. It discusses how reservoirs are used to regulate natural stream flow by storing surplus water in wet seasons and releasing it in dry seasons. This equalizes the natural stream flow and changes the temporal and spatial availability of water. Reservoirs are commonly built for conservation and flood control purposes. The operation of reservoirs involves resolving conflicts between storage needs for conservation versus empty space needs for flood control. Reservoir operation policies specify water release amounts based on the reservoir state, demands, and expected inflows. The document also discusses irrigation scheduling and literature on optimizing reservoir operation for multiple purposes.

![Reservoir operation & scheduling

AITS,KADAPA. Dept of CE Page 18

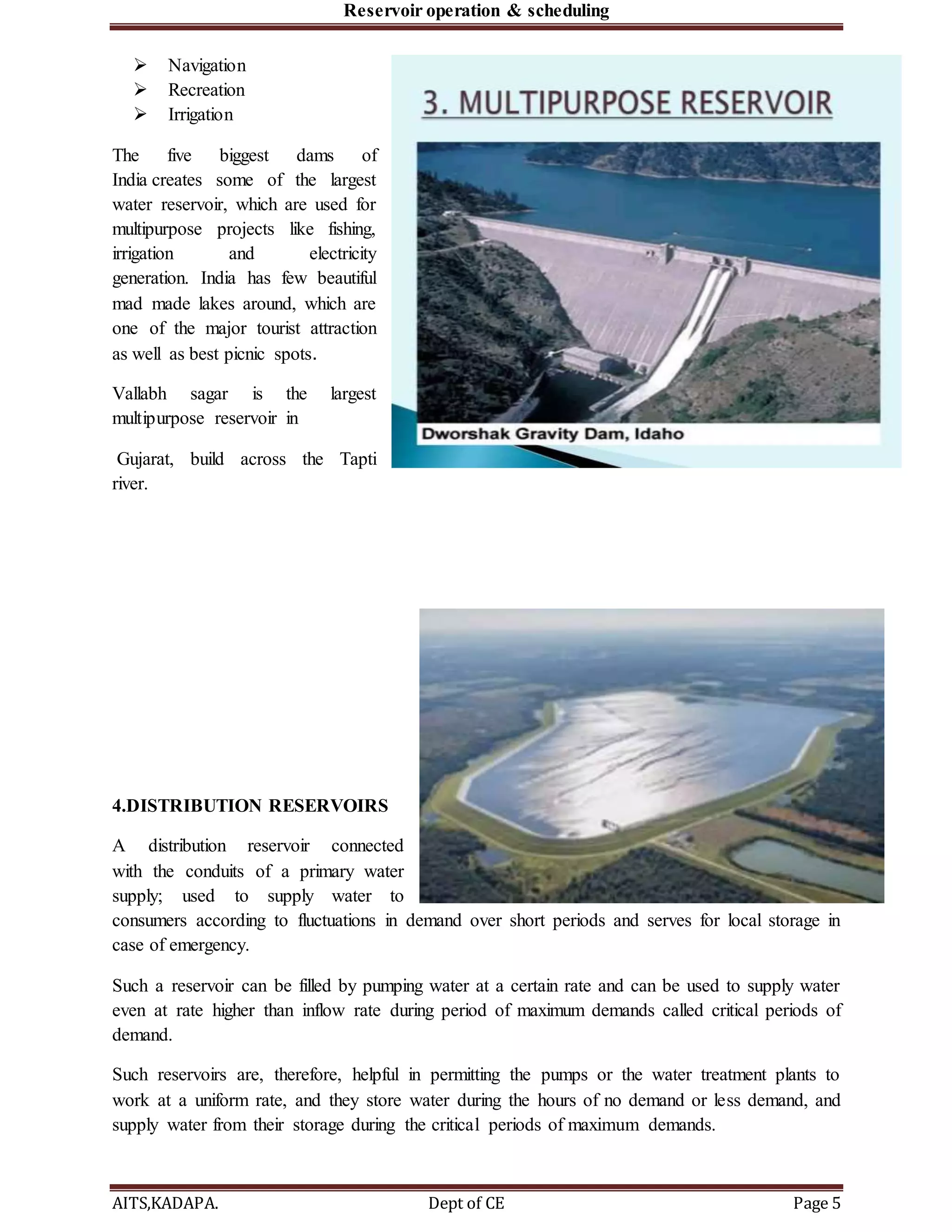

to be accorded to the status. Its reservoir spreads into parts of Chhattisgarh and Odisha states

also.

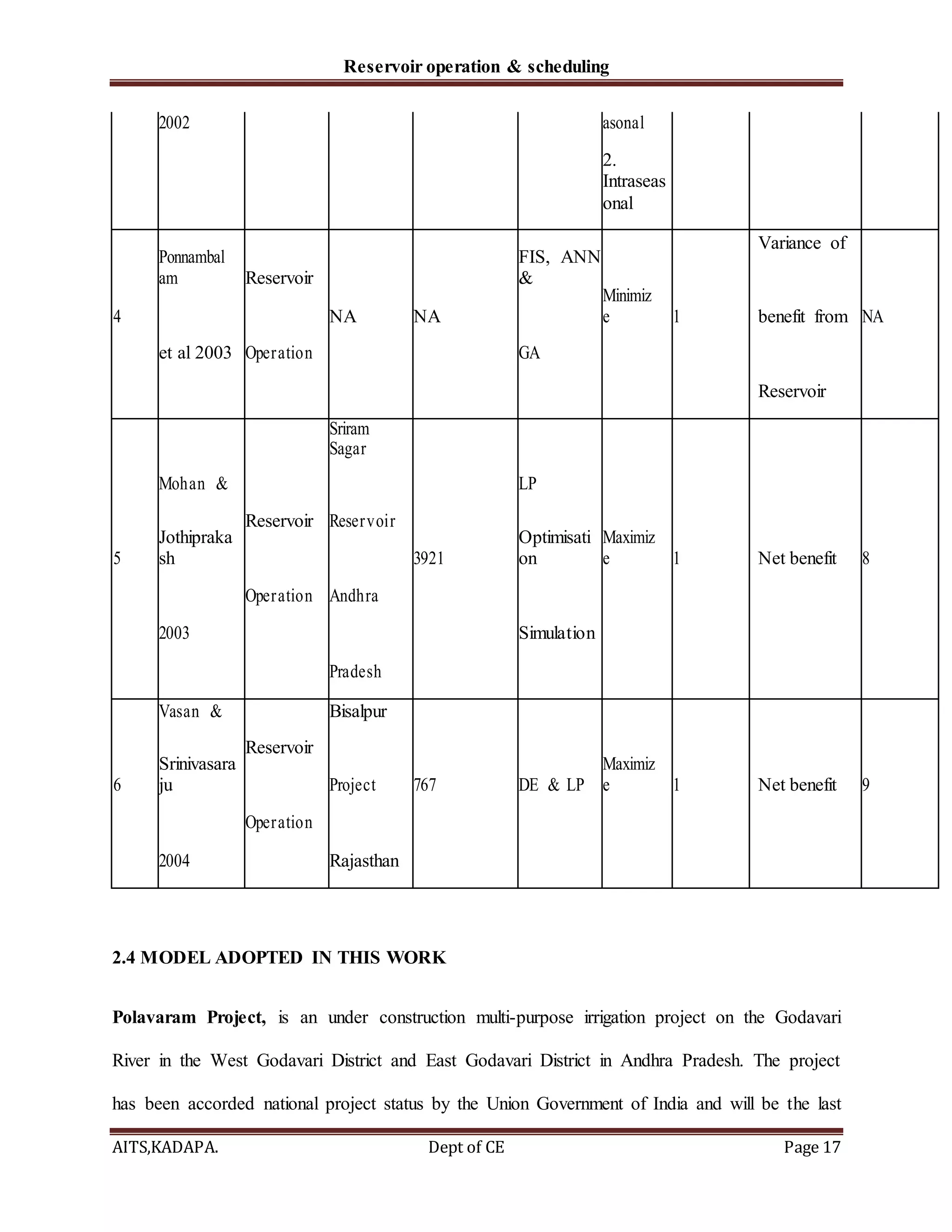

Polavaram Dam

Polavaram Right canal near Eluru

Location Polavaram, West Godavari

District, Andhra Pradesh, India

Coordinates

17°15′40″N81°39′23″ECoordinates:

17°15′40″N 81°39′23″E

Purpose Irrigation, power and transport

Status under construction

Construction began 2004

Opening date 2019.[1]

Operator(s) Andhra Pradesh Irrigation Department

Dam and spillways

Type of dam Concrete spill way (754 m), Non over

flow masonry dam (560 m) & Earth

dam (1600 m)](https://image.slidesharecdn.com/12354565681-190216052454/75/1235456568-1-18-2048.jpg)

![Reservoir operation & scheduling

AITS,KADAPA. Dept of CE Page 19

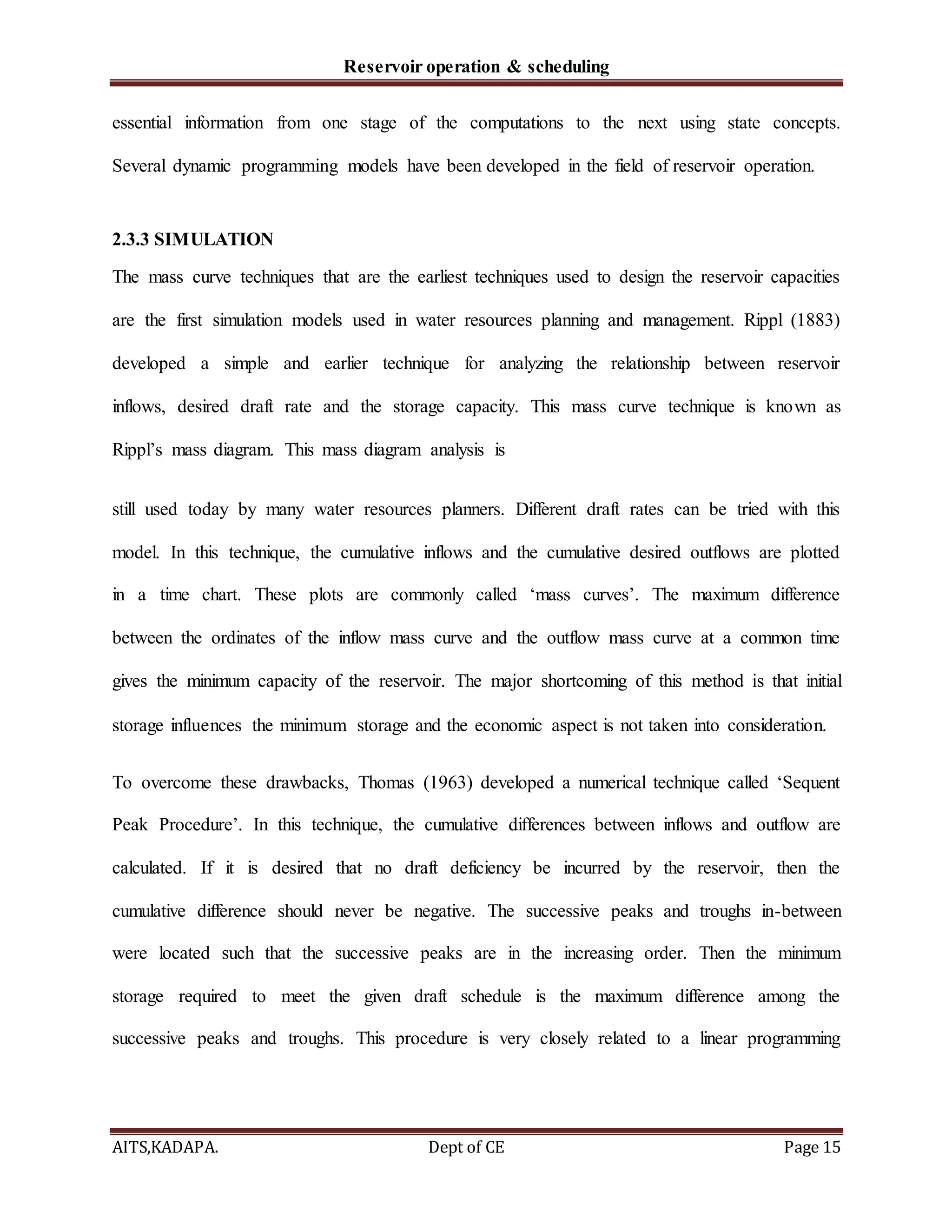

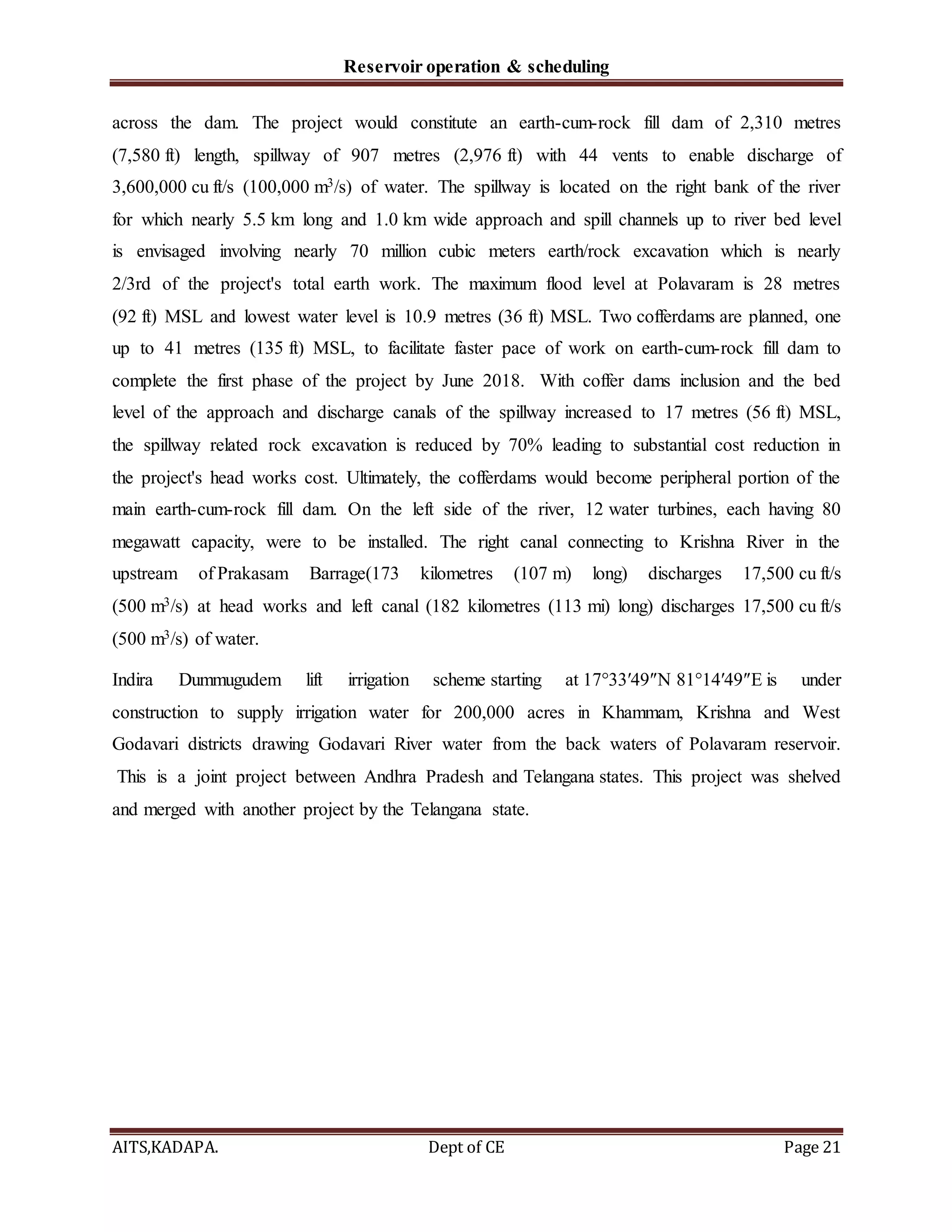

Impounds Godavari River

Height 39.28 m (129 ft) up to top of earth

dam above the lowest river bed.

Length 2,914 m (9,560 ft)

Spillway type Chute spillway

Spillway capacity 5,000,000 cusecs at 140 ft msl

Reservoir

Creates Polavaram Reservoir

Total capacity 194 tmcft at FRL 150 ft msl

Active capacity 175 tmcft (at 25.4 m msl crest level of

spillway)

Inactive capacity 19 tmcft (below 25.4 m msl)

Catchment area 307,800 km2

(118,800 sq mi)

Surface area 600 km2

(230 sq mi)

Maximum water depth 32.08 m at FRL 150 ft msl

Power Station

Operator(s) APGENCO

Turbines 12 × 80 MW Kaplan-type (left bank

side)

Installed capacity 960 MW (under construction)[2]](https://image.slidesharecdn.com/12354565681-190216052454/75/1235456568-1-19-2048.jpg)

![Reservoir operation & scheduling

AITS,KADAPA. Dept of CE Page 33

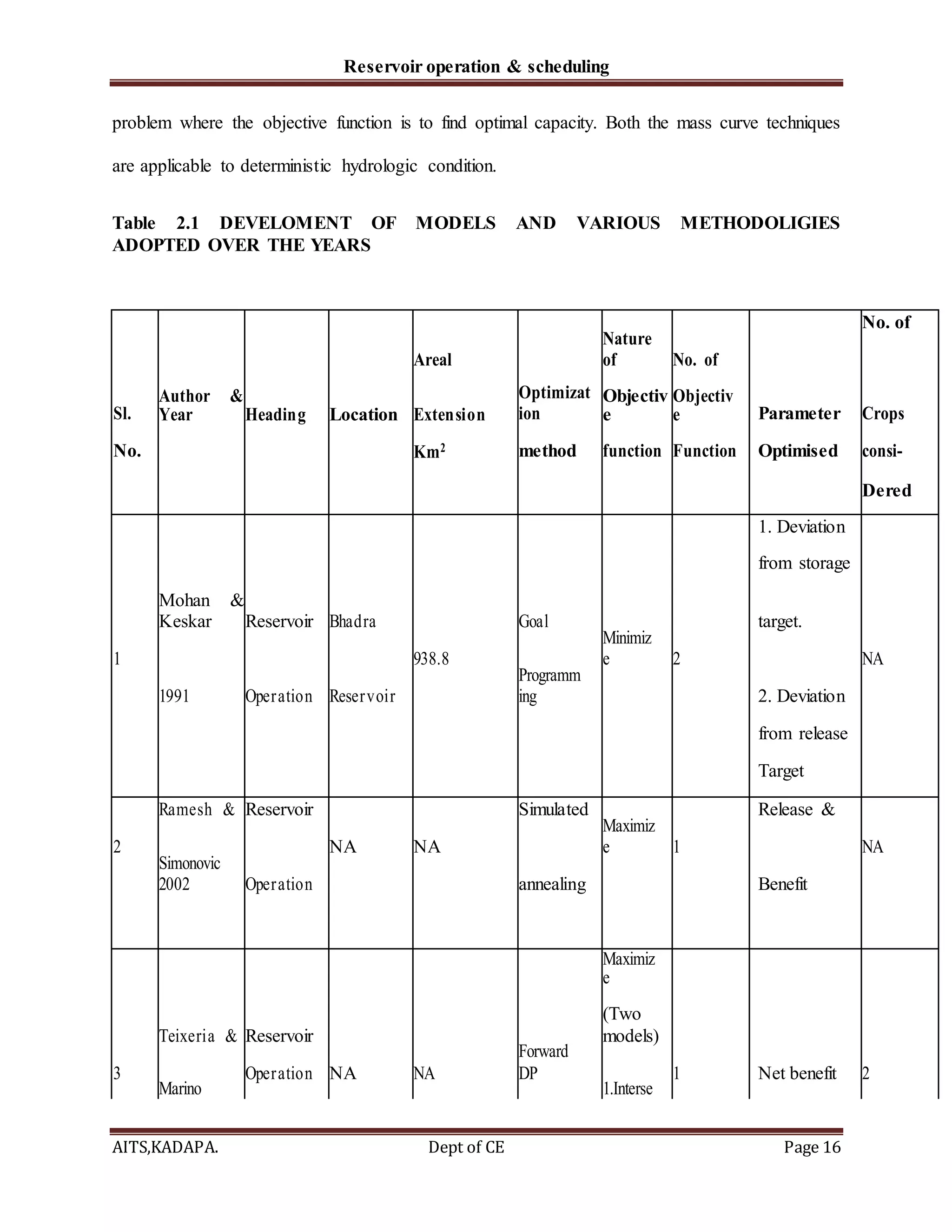

Assumption is

B1t

i = Bt

1

B2t

i = Bt

2 ∀ t

B3t

i = Bt

3

Where B1t

i

, B2t

i , B3t

i are the net unit benefits from the reservoir i.

Bt

1 is the release , Bt

2 is the flood control and Bt

3 is the storage at respective reservoirs.

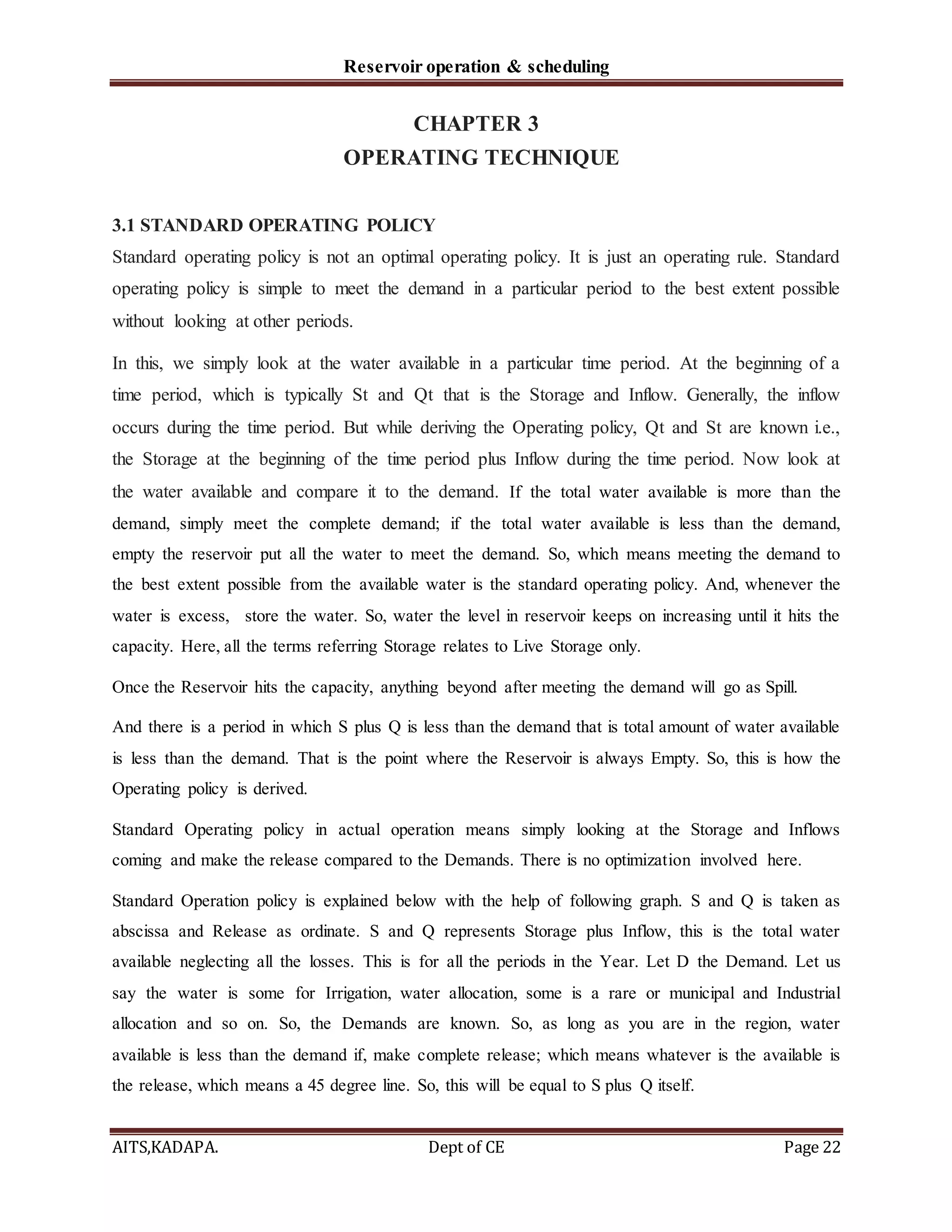

LP FORMULATION :

Max ∑3

𝑖=1 ∑ 𝑇

𝑡=1 [Bt

1Rt

1 + Bt

2 (Kt - St

i) + Bt

3St

i]

St+1

i = St

i + Qt

i – Et

i - Rt

i - Ot

i , ∀ t ,i=1,2

St+1

i = St

i + Qt

i + α1 Rt

1 + α 2Rt

2 – Et

i - Rt

i - Ot

i , ∀ t ,i=3

St

i ≤ Kt

i

, i=1,2,3; ∀ t

Kt - St

i ≥ Fmax

i , i= 1,2,3; ∀ t € Flood season

Rt

i ≤ Rmax

i ∀ t

Rt

i ≥ 0 ; St

i ≥ 0 ∀ t

St+1

i = St

i

Where

o i refers to reservoir (i =1,2,3)

o t is time period (t = 1,2,3,……,12)

o Q is inflow

o K is reservoir capacity

o S is storage

o R is release

o O is overflow or spill

o St is the storage at the beginning of the time period t.](https://image.slidesharecdn.com/12354565681-190216052454/75/1235456568-1-33-2048.jpg)