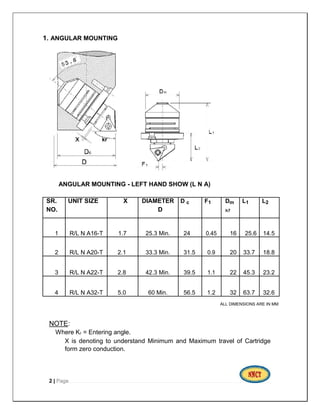

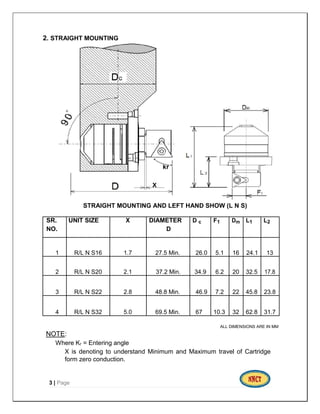

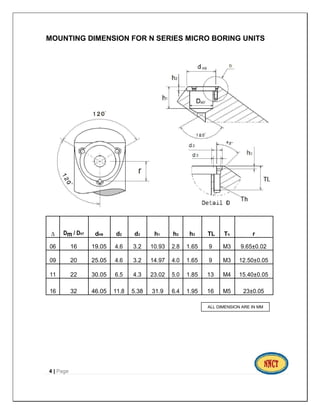

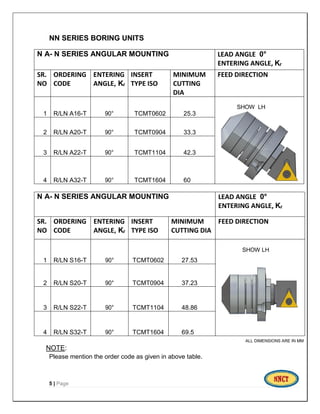

This document provides a catalogue for N.N. Cutting Tools' NN Series micro boring units. It includes specifications for angular and straight mounting units in various sizes, with minimum cutting diameters ranging from 24mm to 67mm. Dimensional drawings and ordering information is provided to help customers properly select and implement these high-precision micro boring units in their boring bar tooling. Adjustment and safe usage guidelines are also outlined.