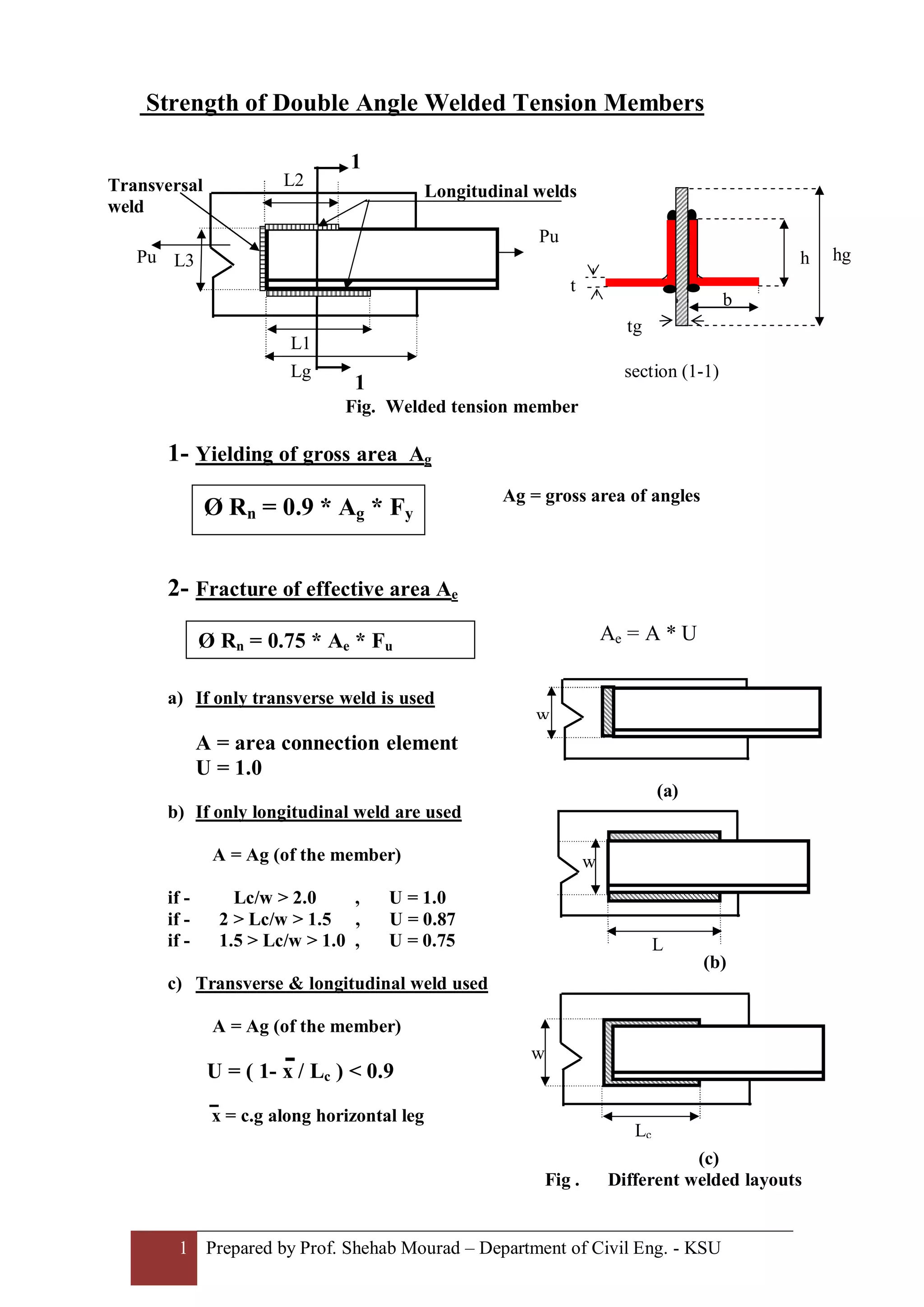

1. The document discusses the strength of double angle welded tension members. It describes three failure modes: yielding of the gross area, fracture of the effective area, and block shear rupture in the angle.

2. Formulas are provided to calculate the nominal resistance (Rn) for each failure mode based on the yield strength, ultimate tensile strength, and dimensions of the angles.

3. An example problem is worked through to determine the governing strength of a specific welded double angle configuration based on the provided dimensions and material properties. The yielding of the gross area controls with a nominal resistance of 459 kN.