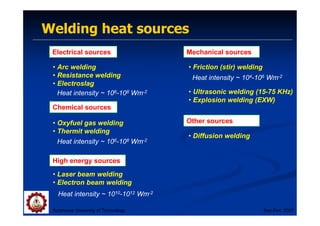

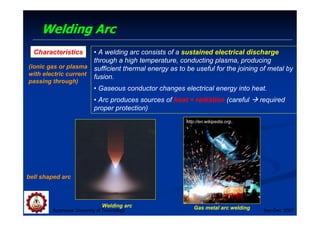

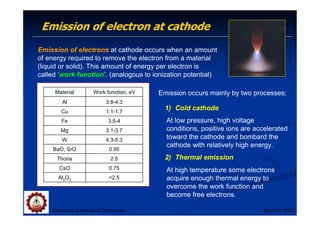

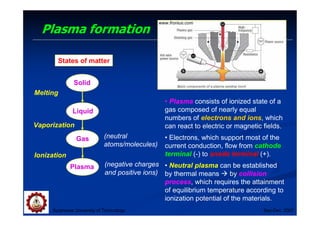

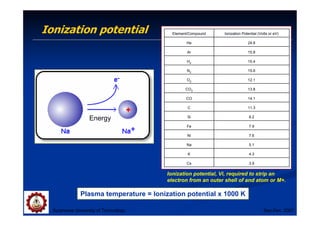

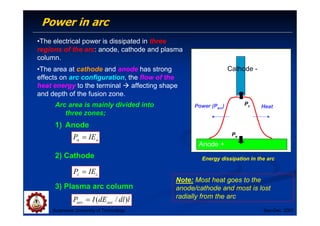

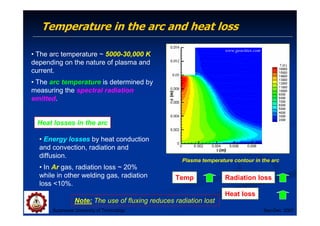

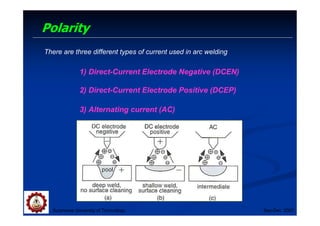

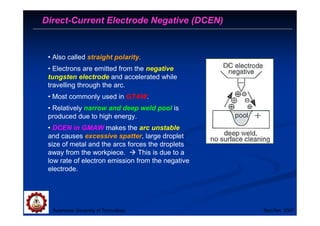

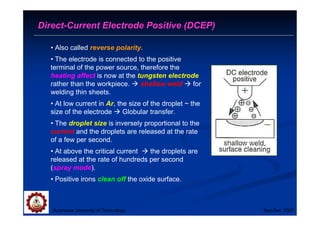

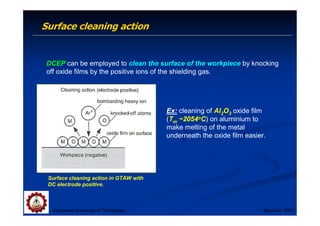

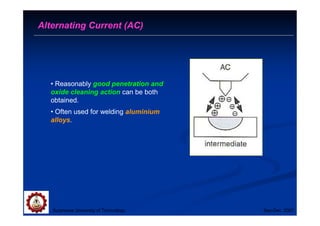

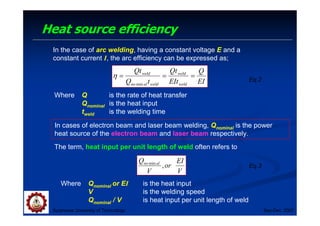

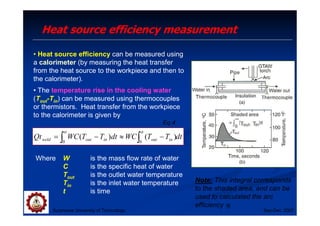

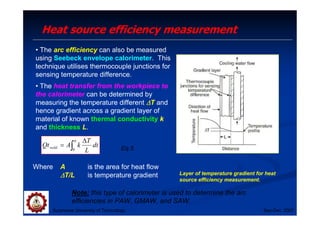

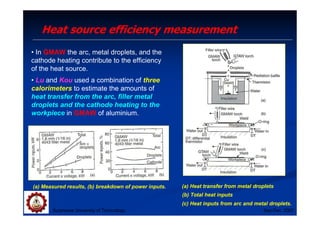

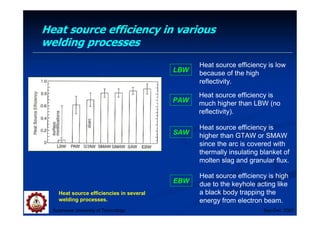

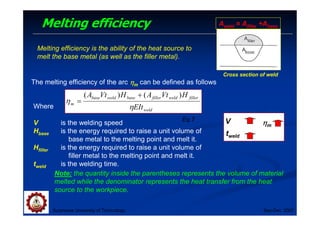

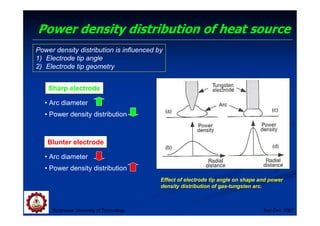

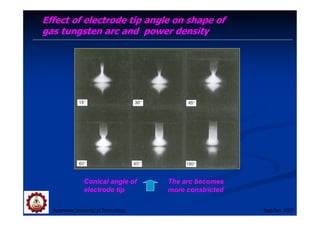

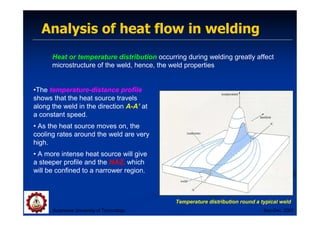

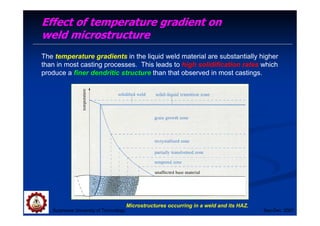

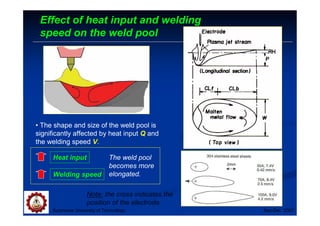

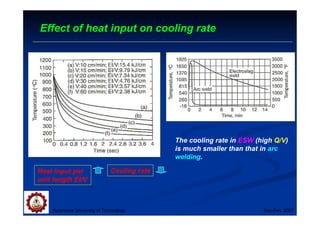

This document discusses heat flow during welding. It covers topics such as heat sources in welding like arc, resistance, laser, and friction welding. It describes the welding arc and plasma formation. It also discusses parameters that affect heat flow like polarity, heat source efficiency, and methods to measure efficiency. The objectives are to provide information on heat flow during welding and how it influences microstructure and properties, and identify heat sources and power density in different welding methods.