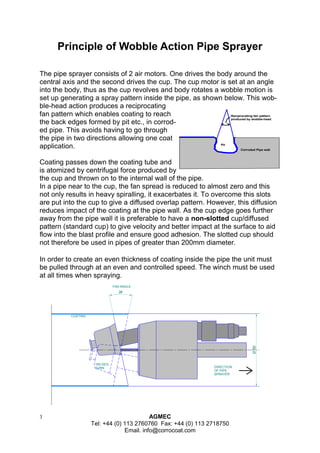

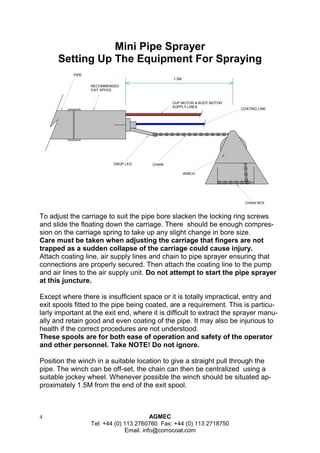

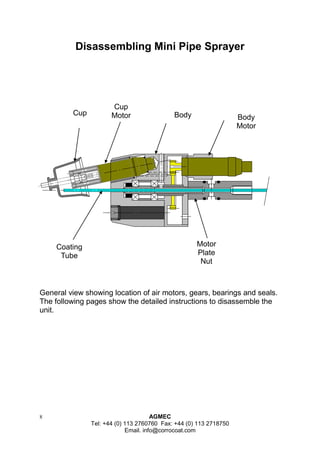

The document is an operation and maintenance manual for the AGMEC Mini Pipe Sprayer, detailing its setup, operation, and disassembly. It describes the principle of the wobble action used for spraying coatings inside pipes, along with instructions for equipment setup, safety precautions, and maintenance requirements. Additionally, it provides technical specifications and procedures for calculating winch speed and flow rates to achieve the desired coating thickness.