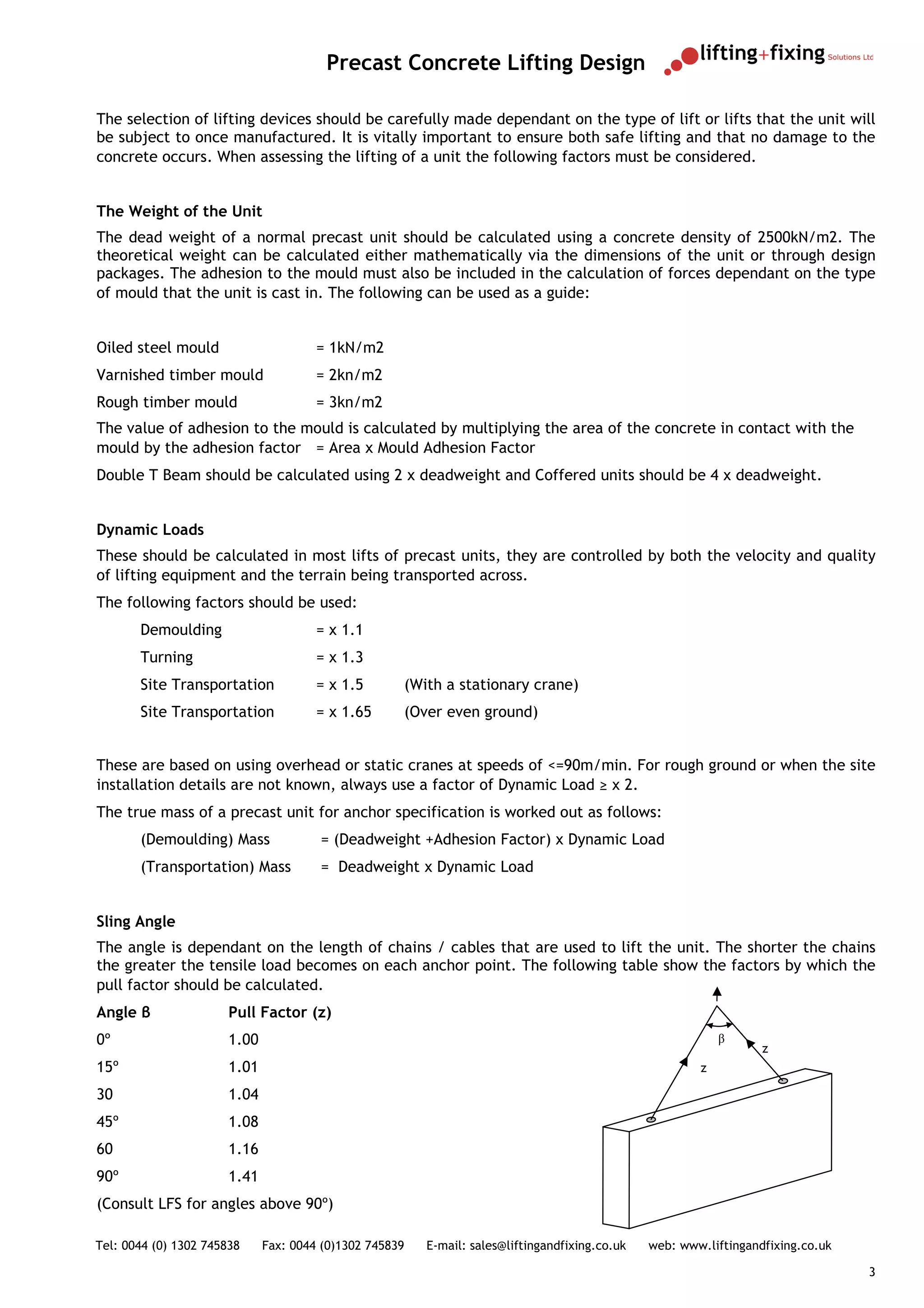

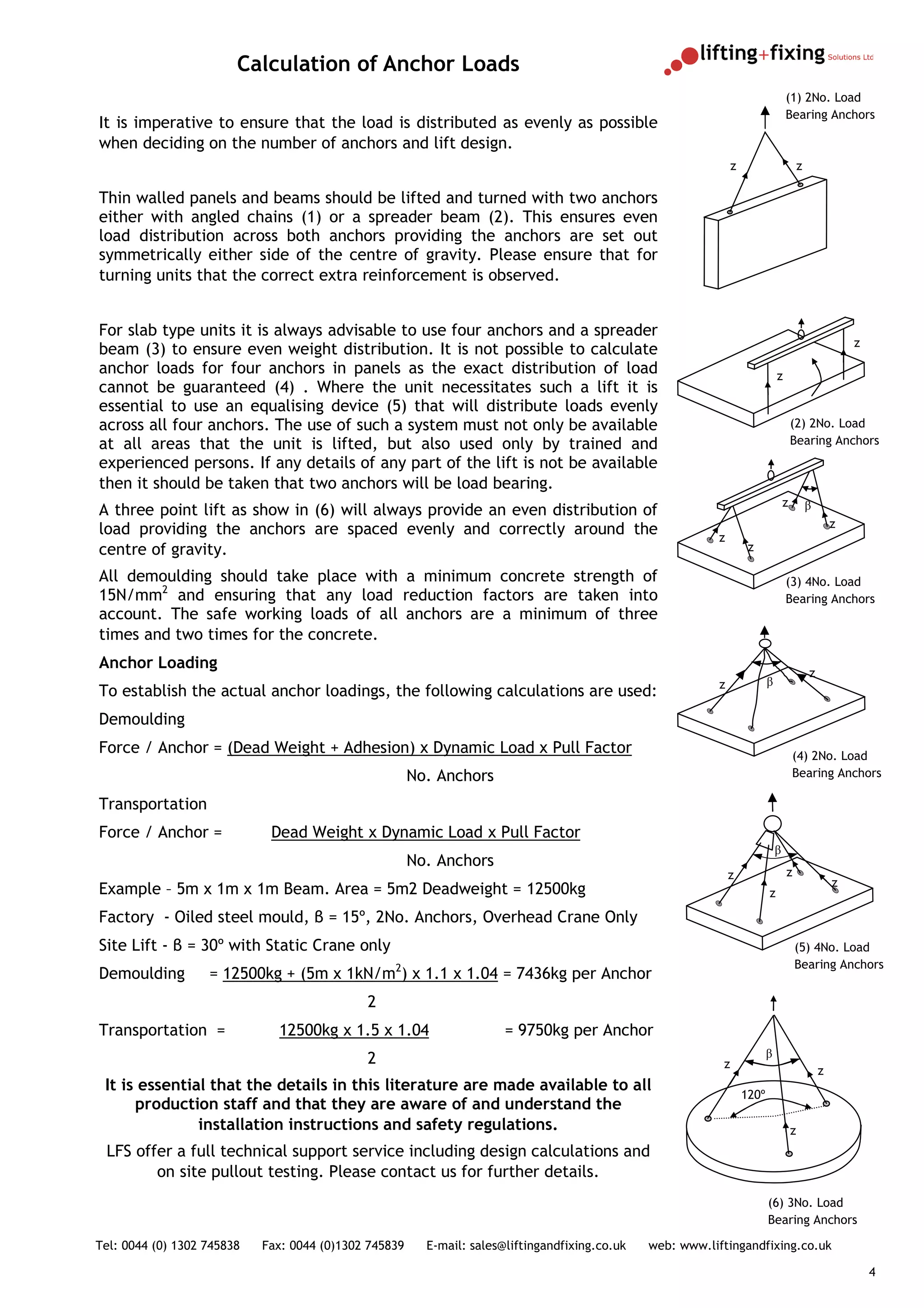

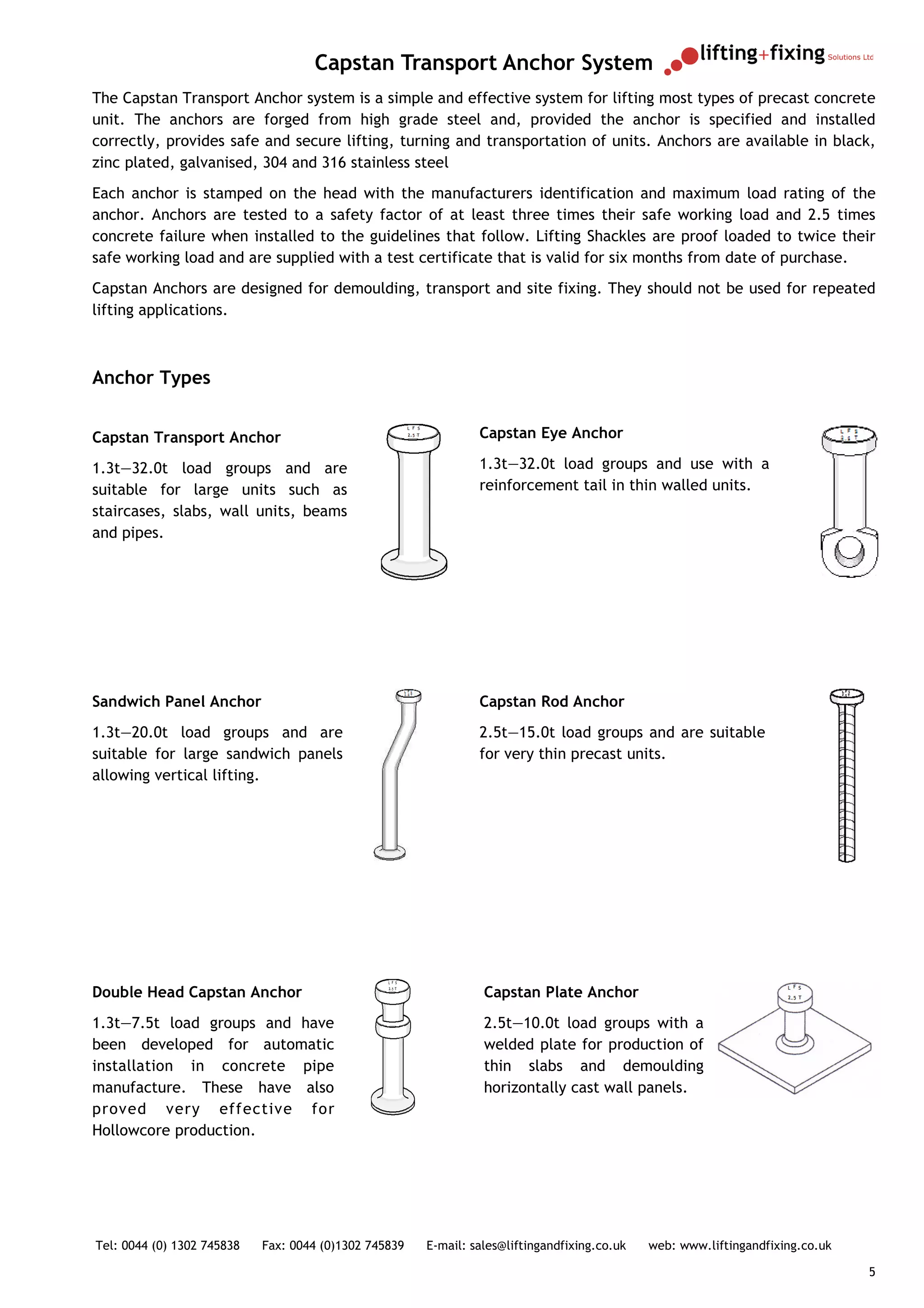

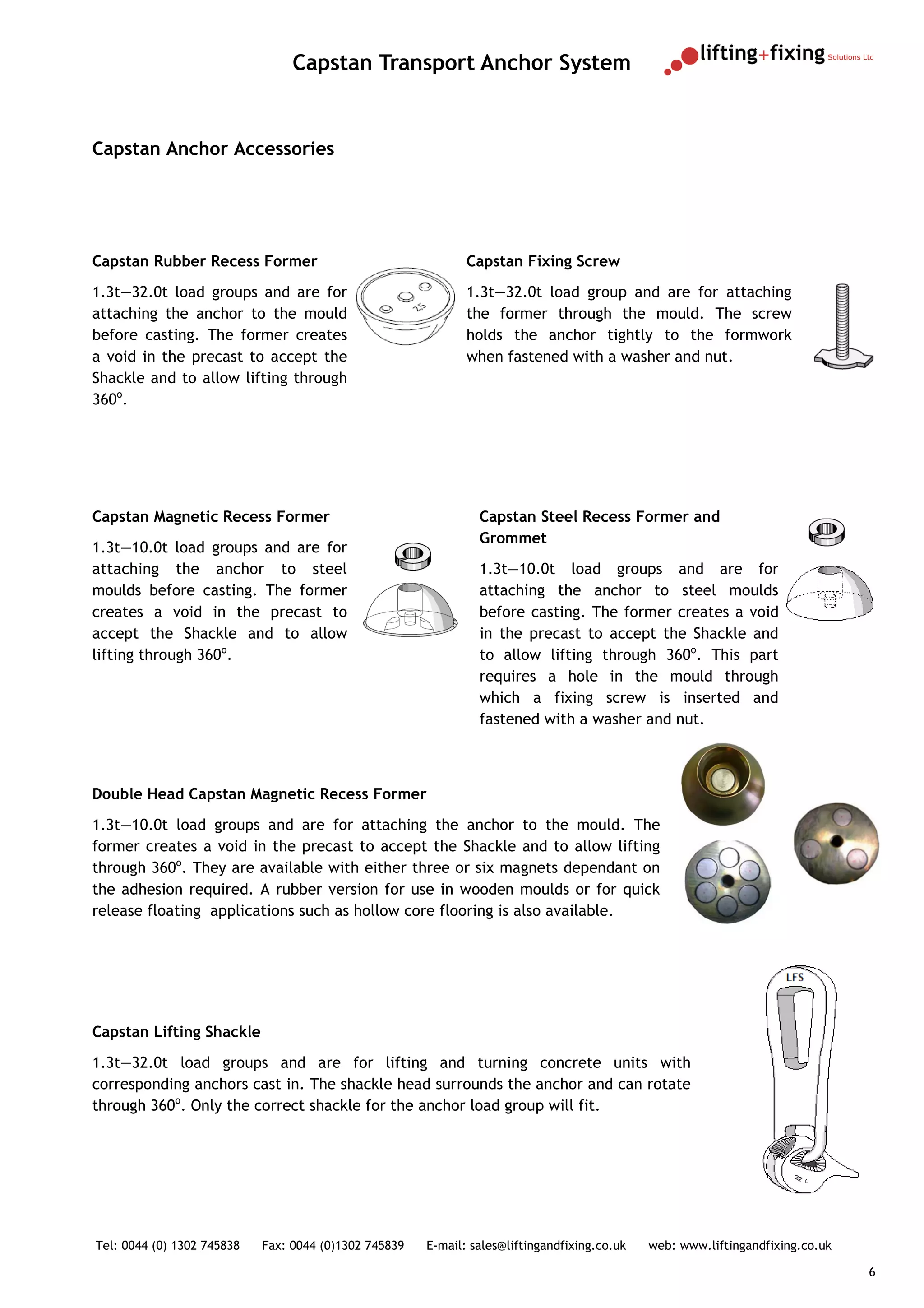

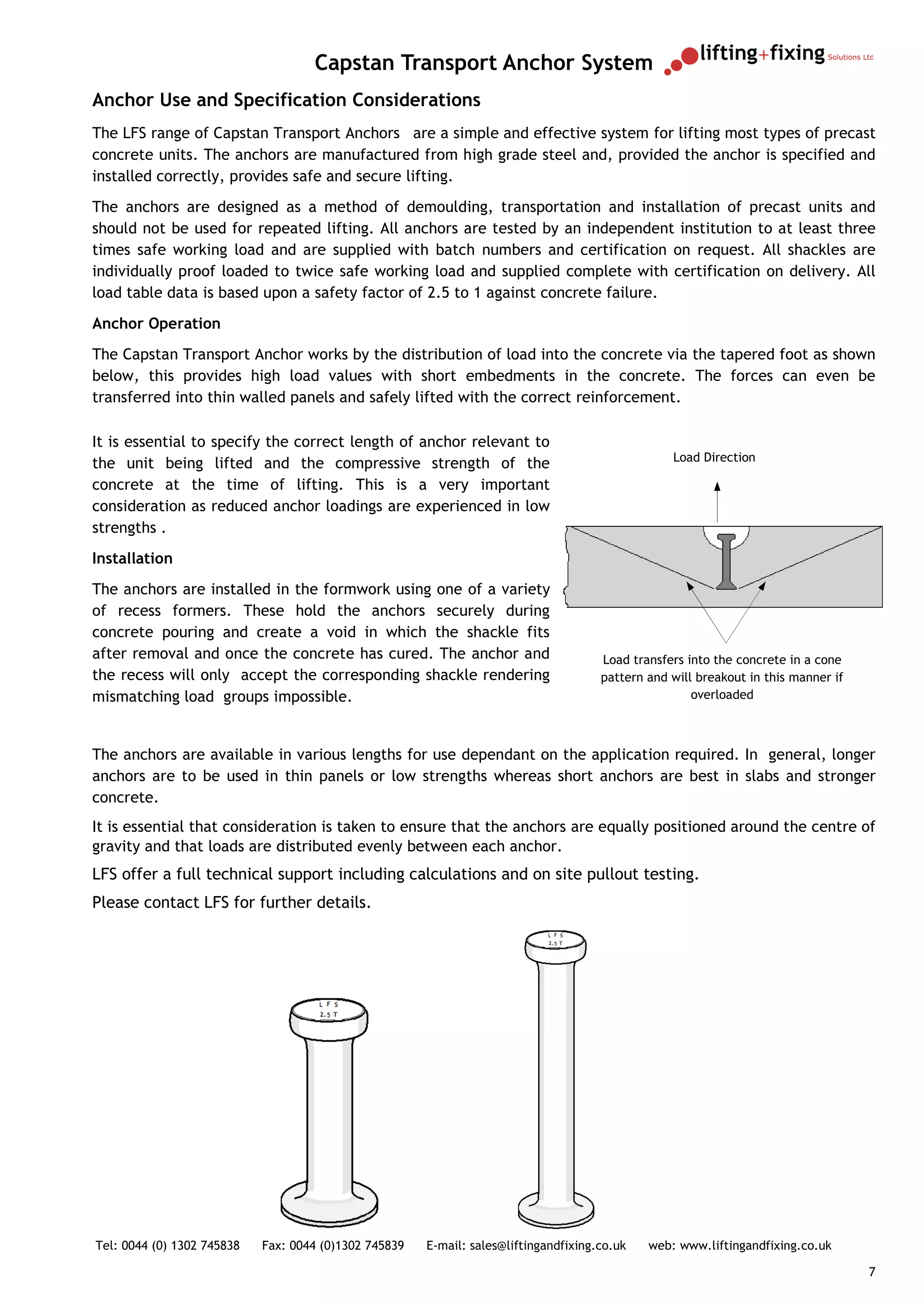

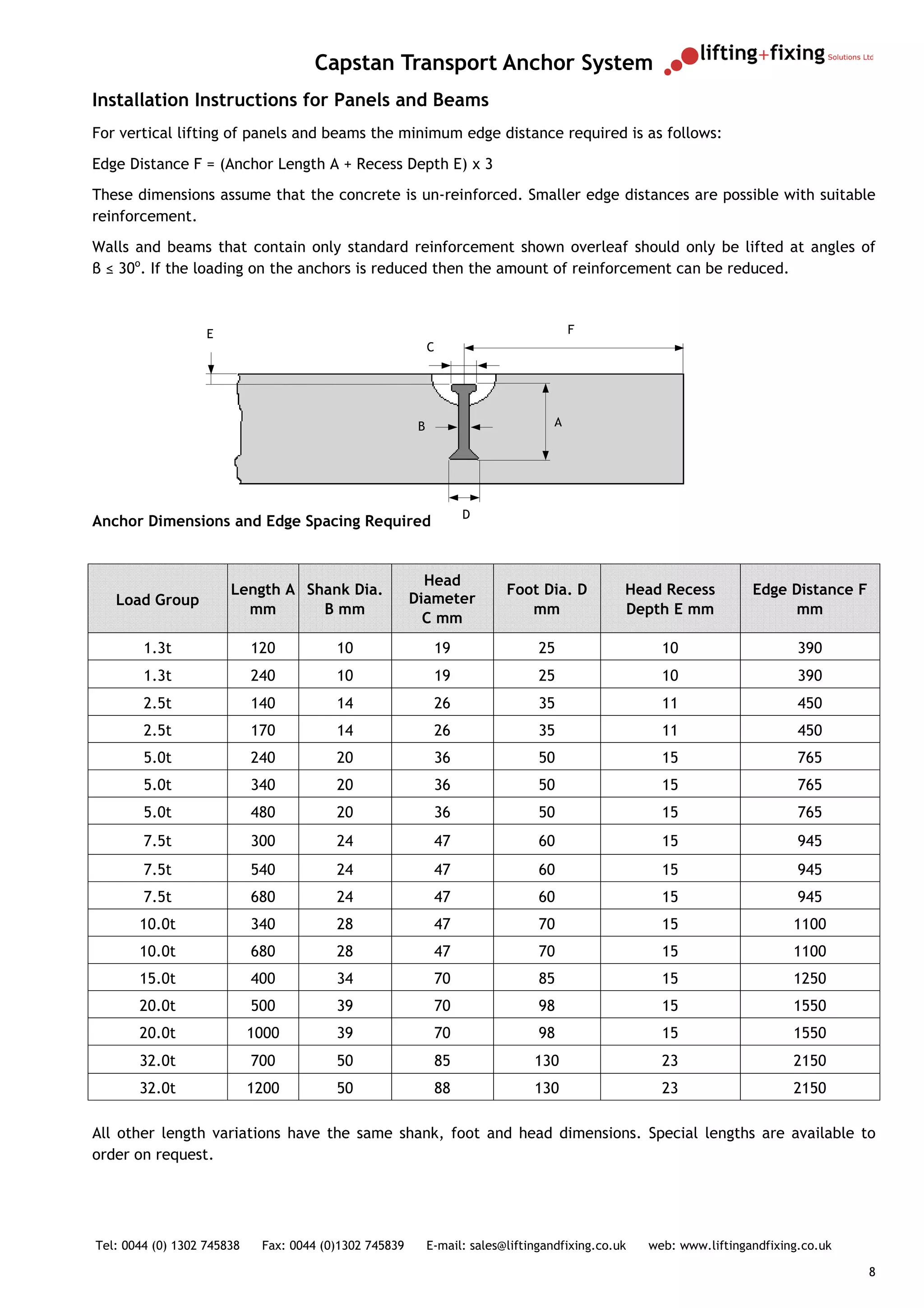

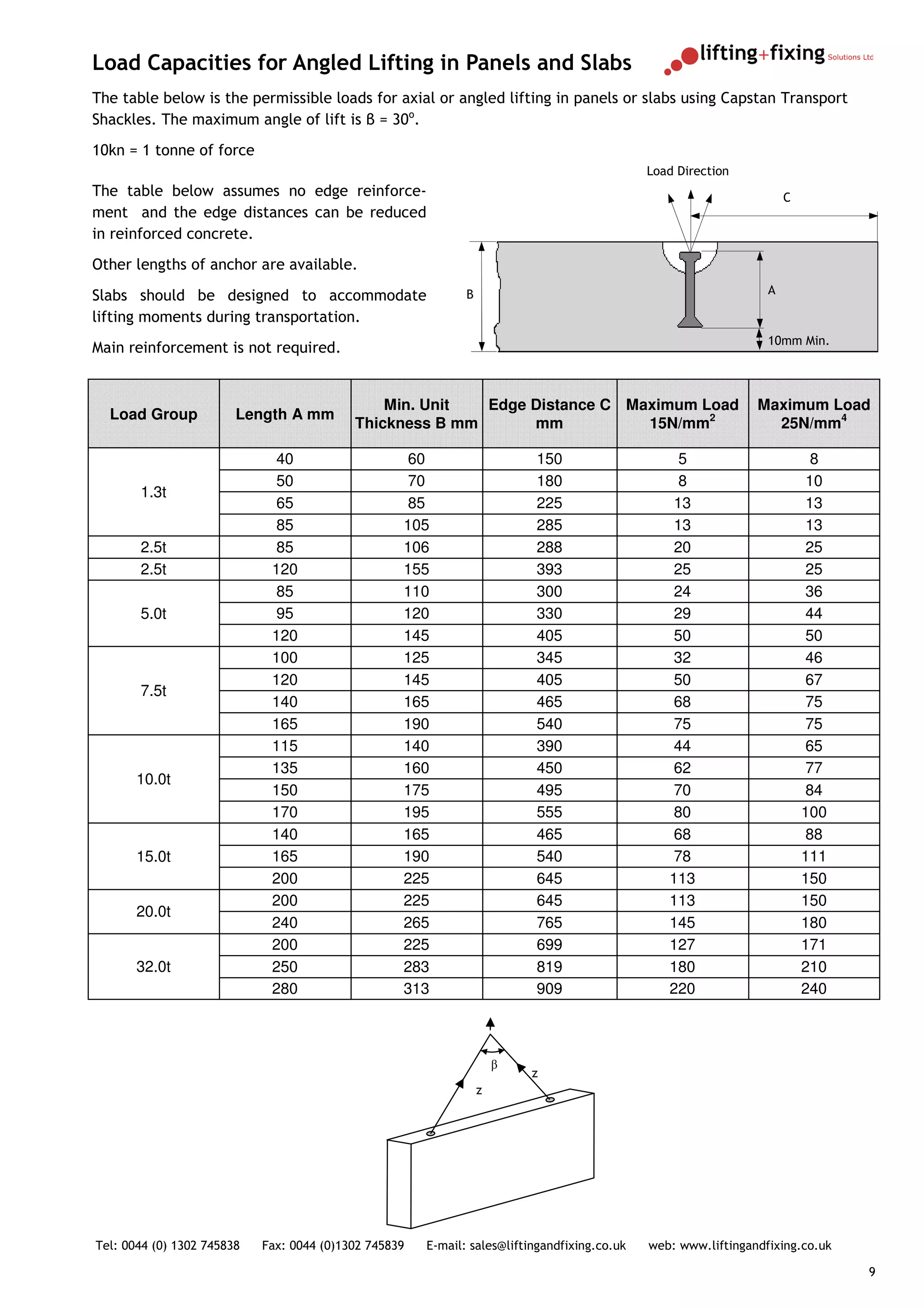

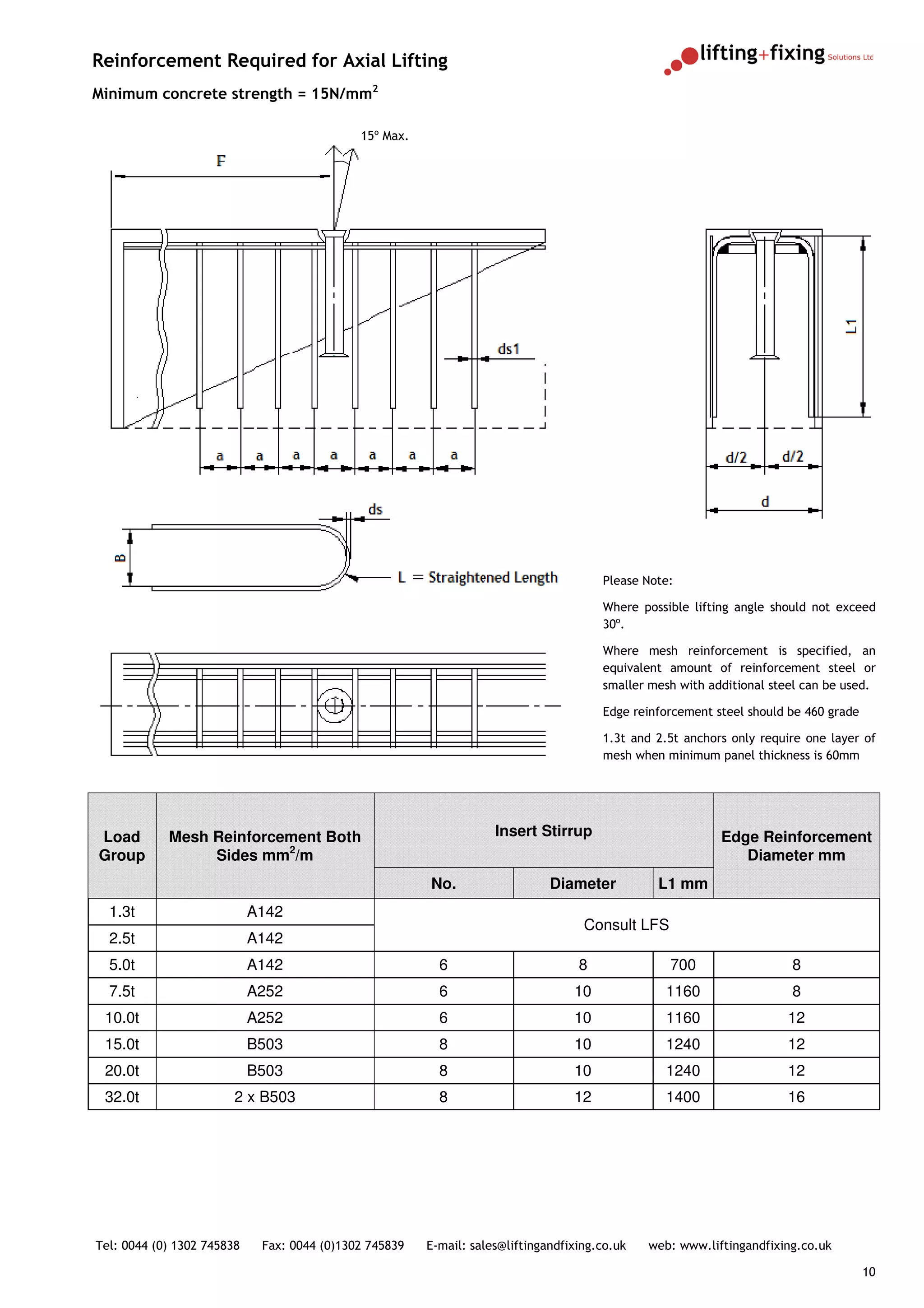

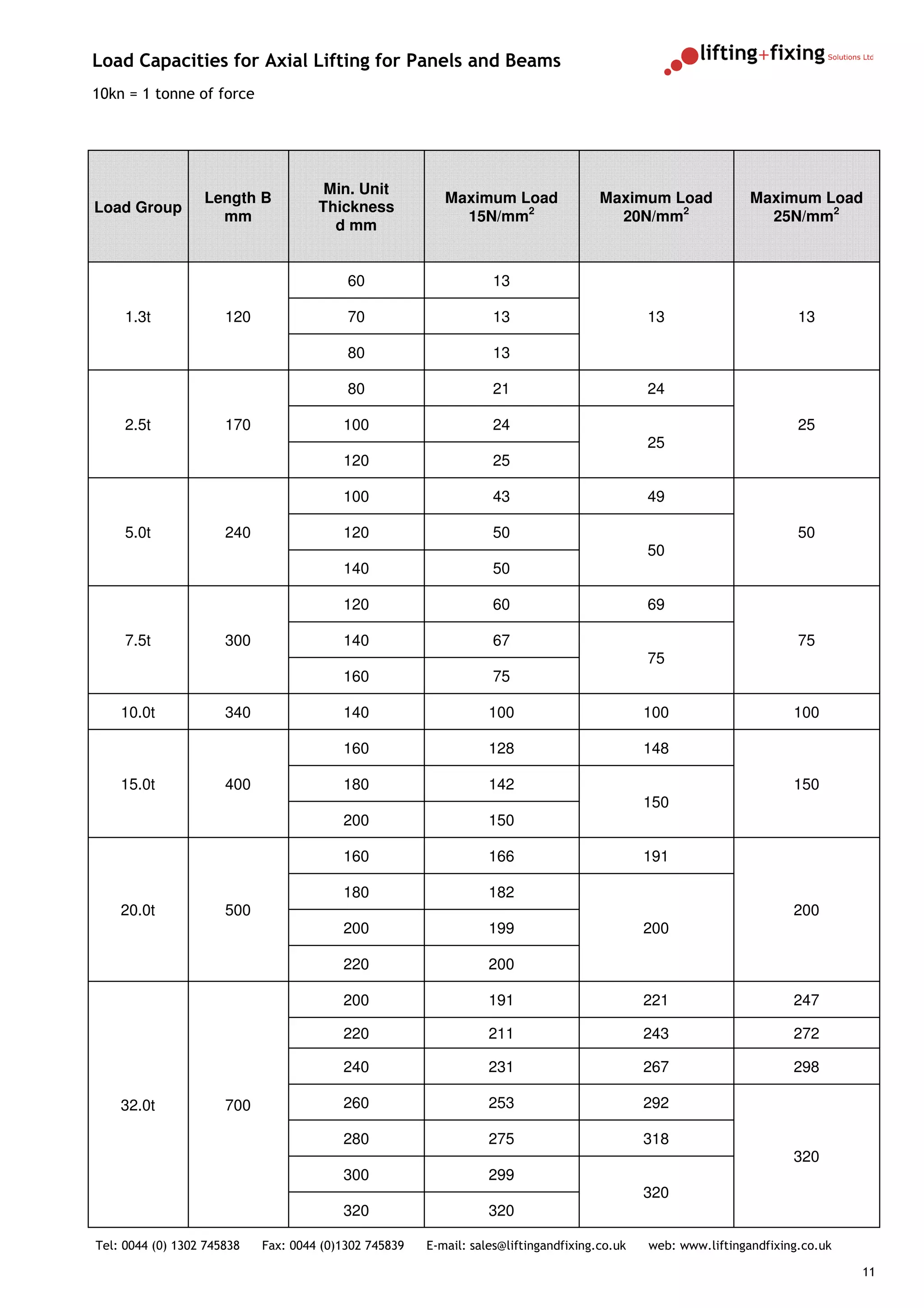

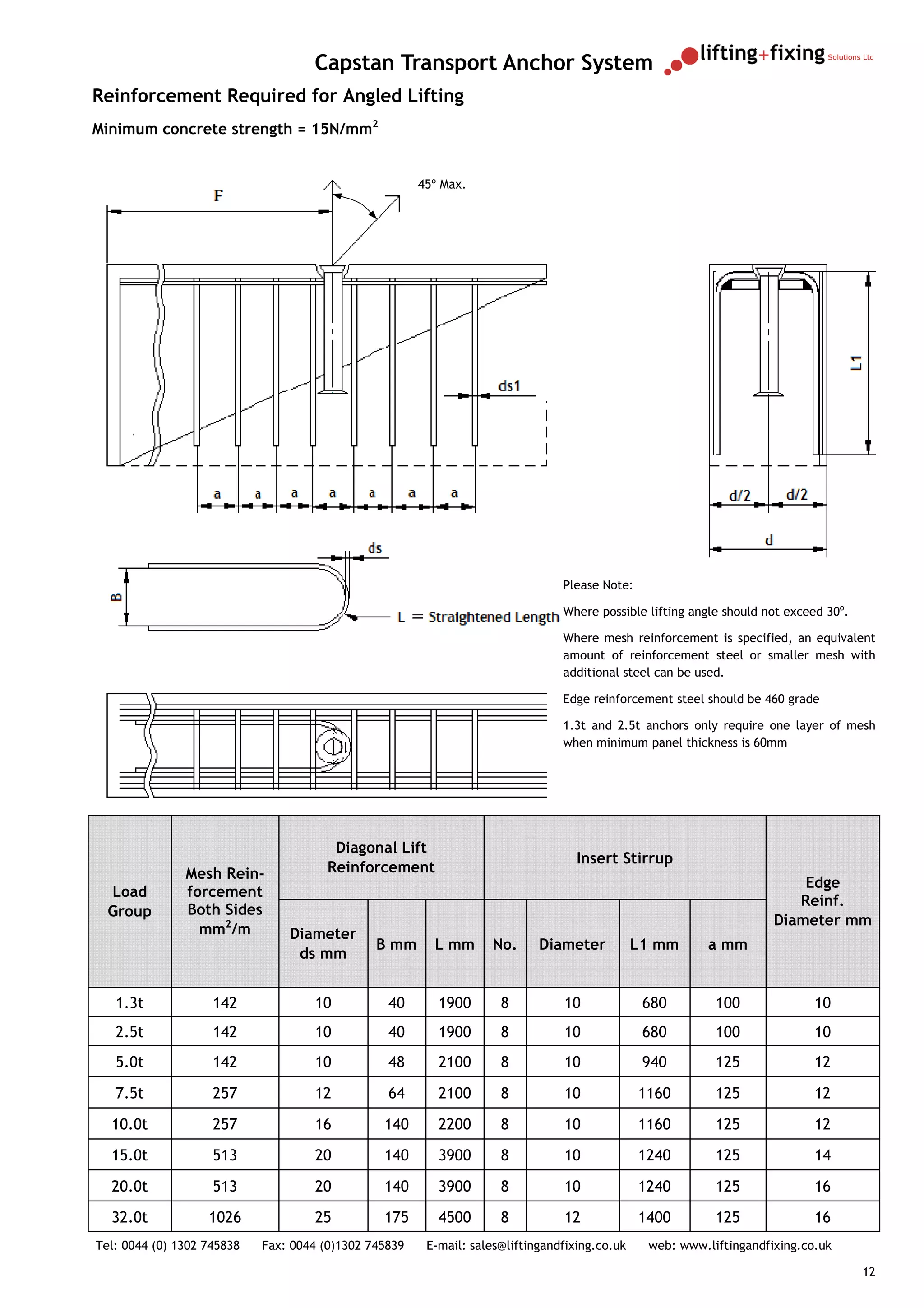

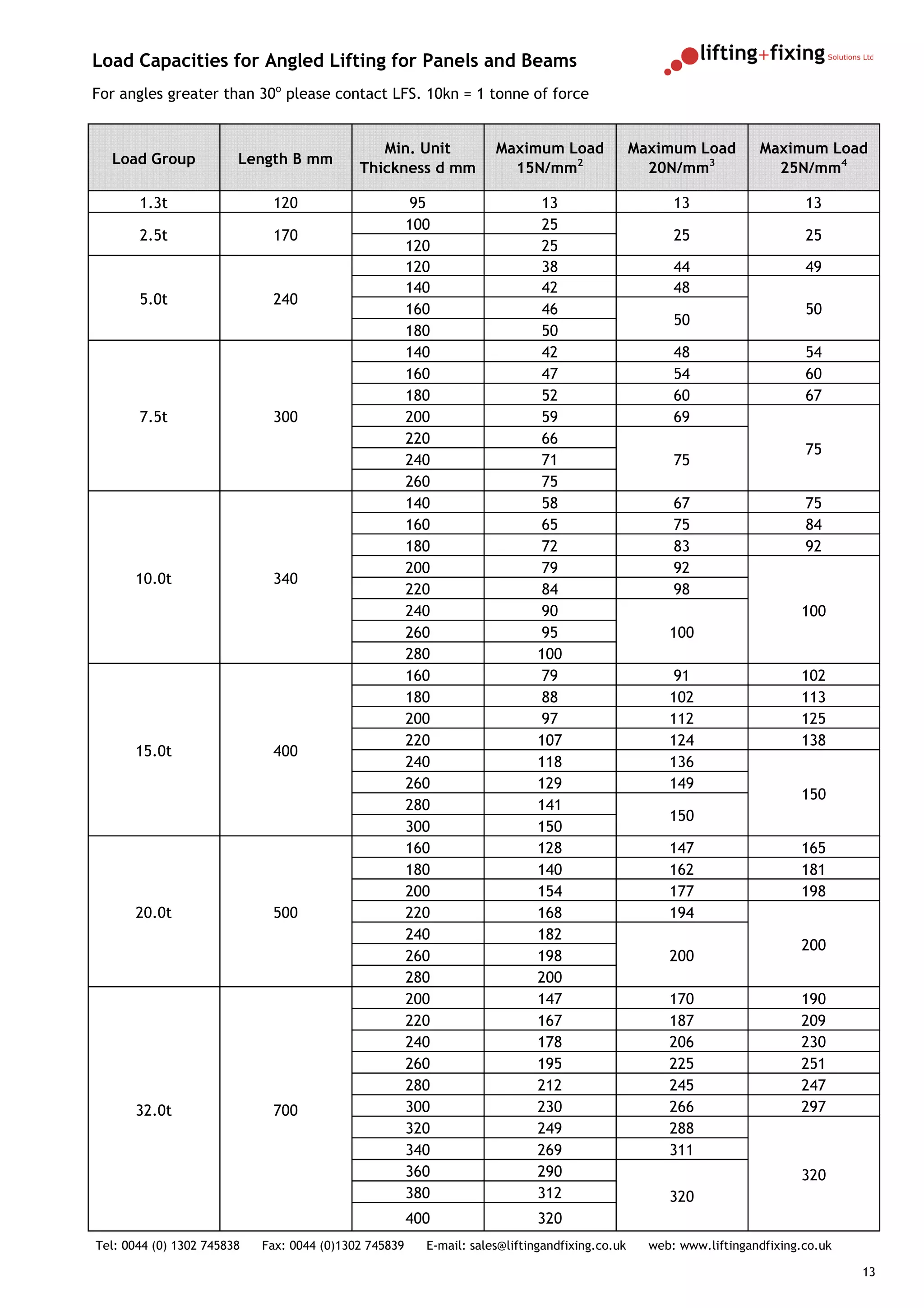

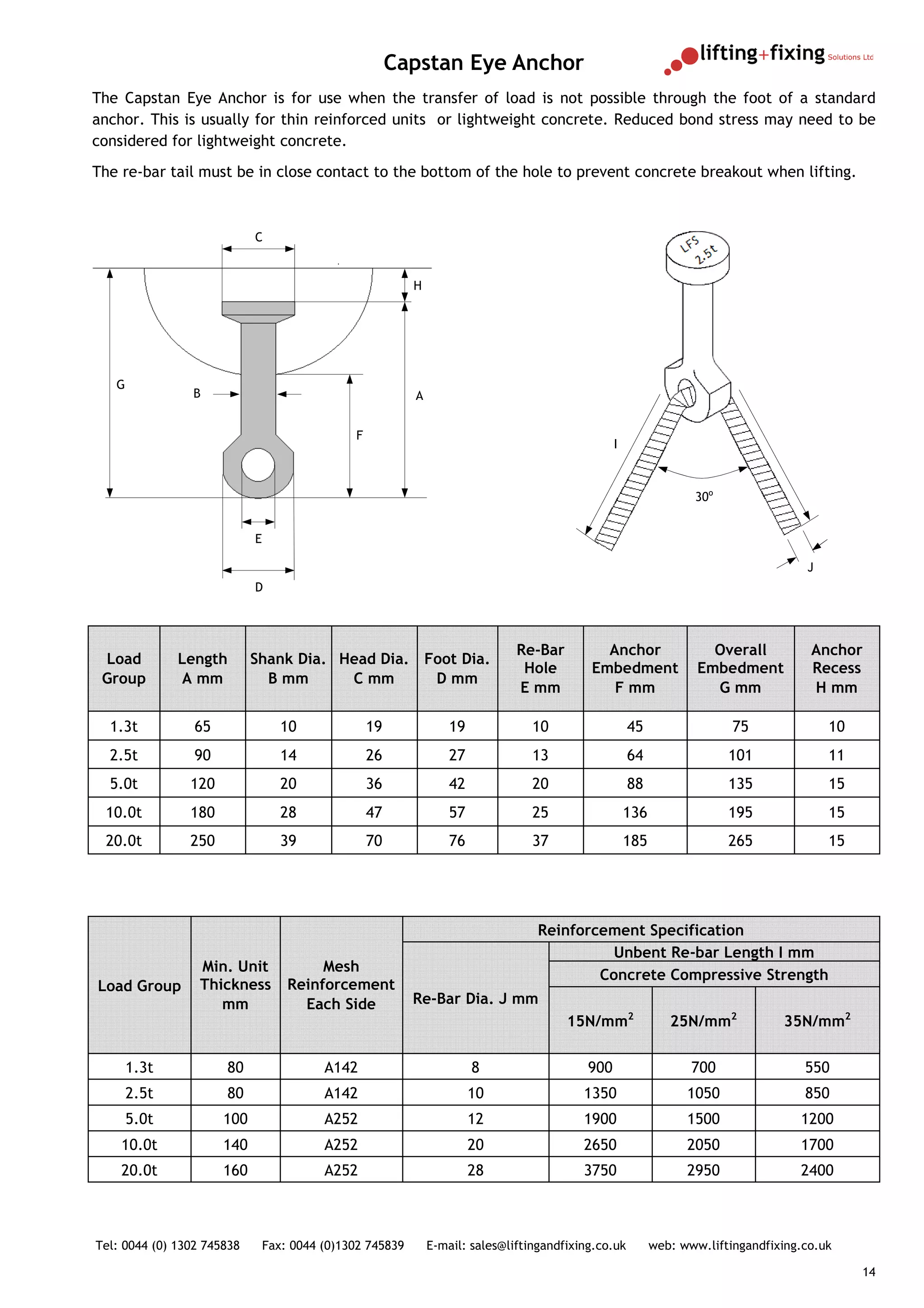

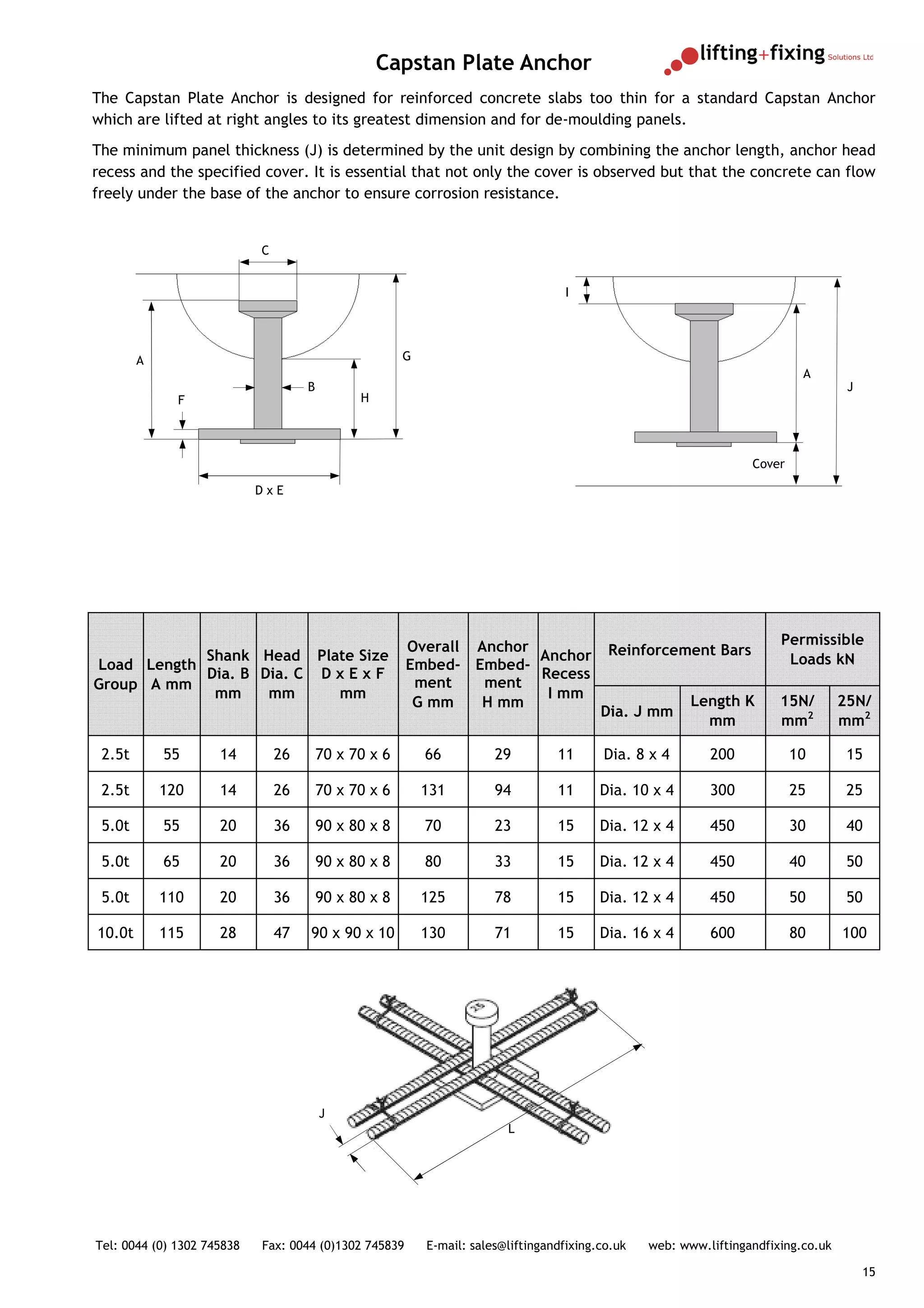

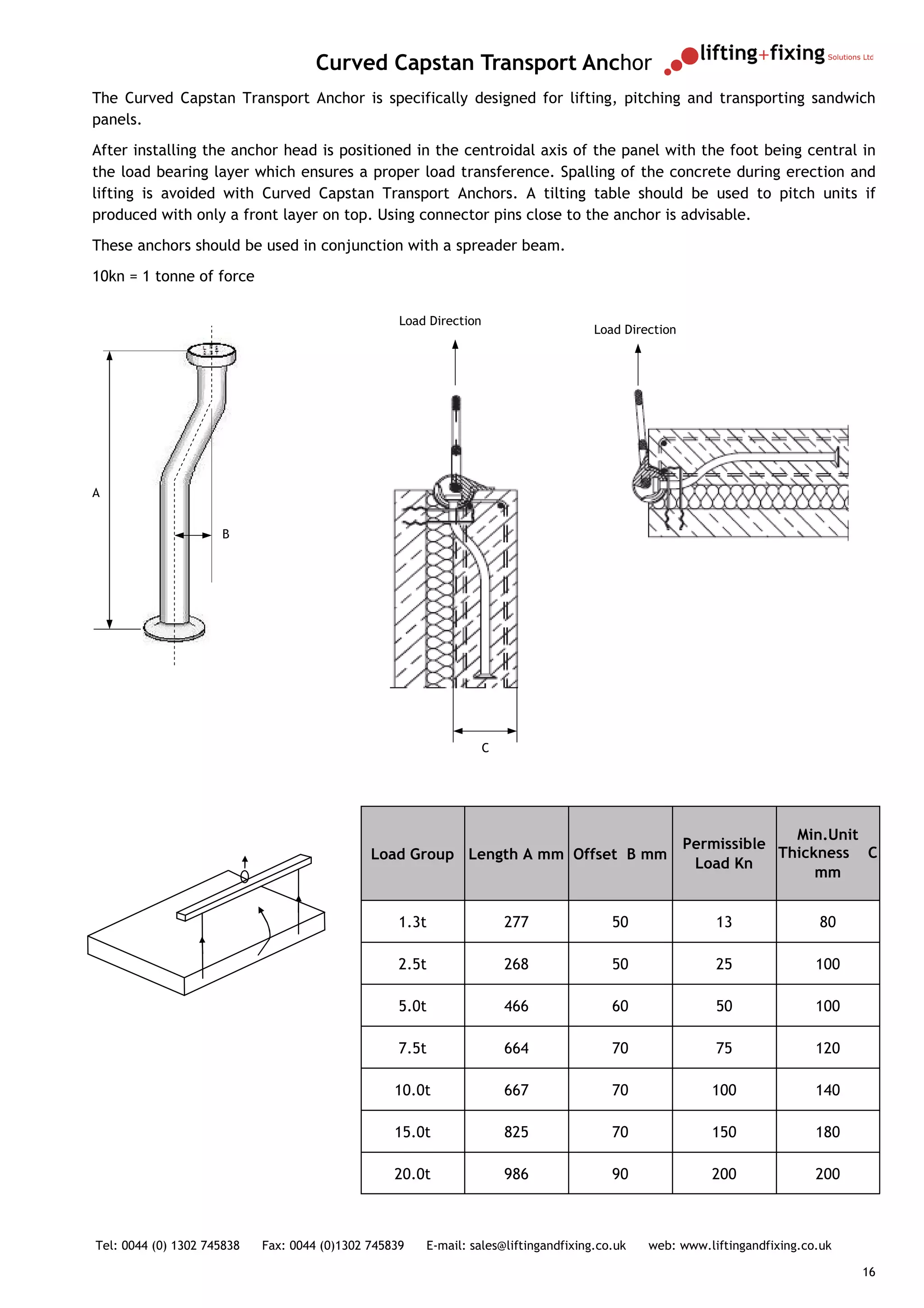

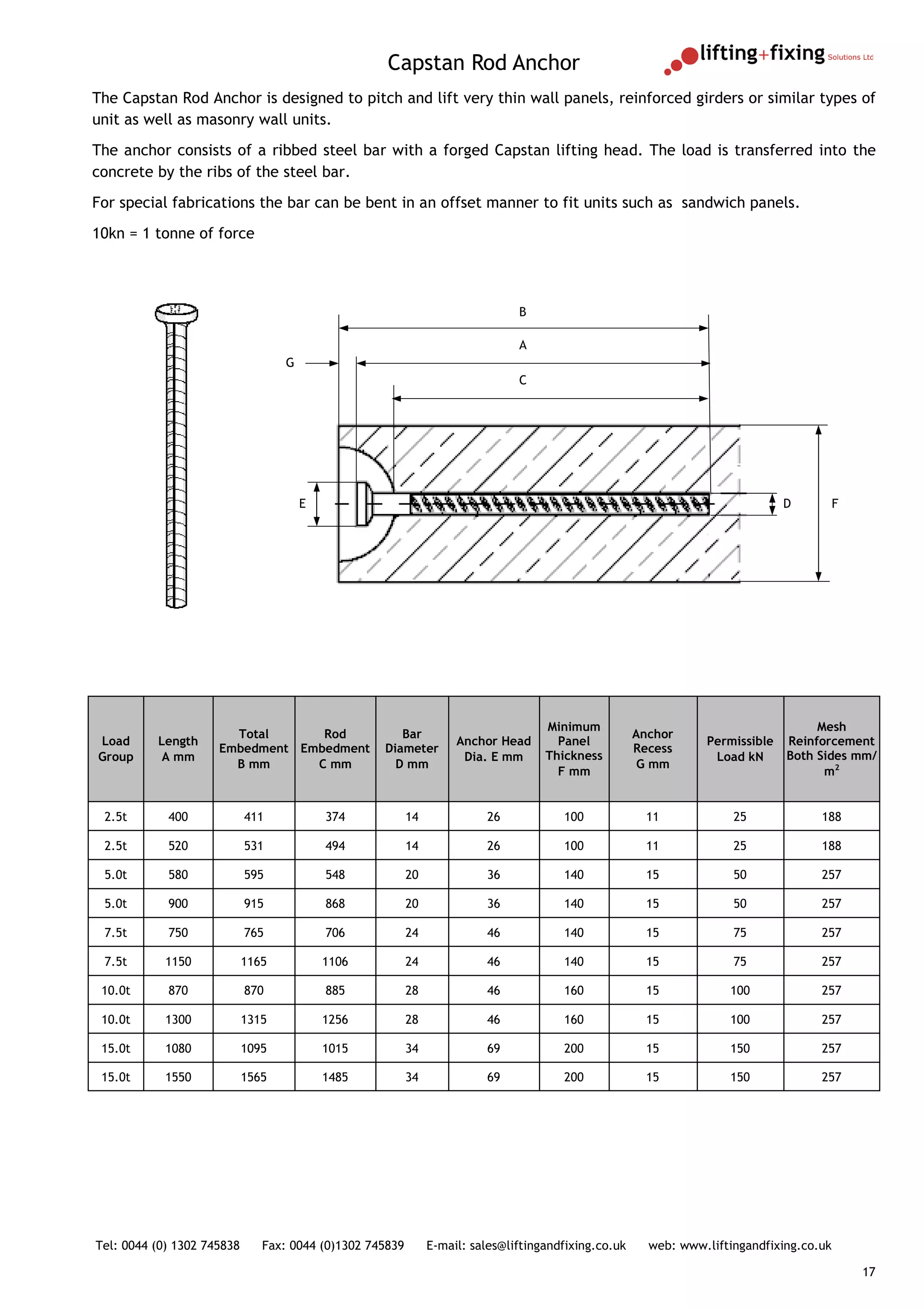

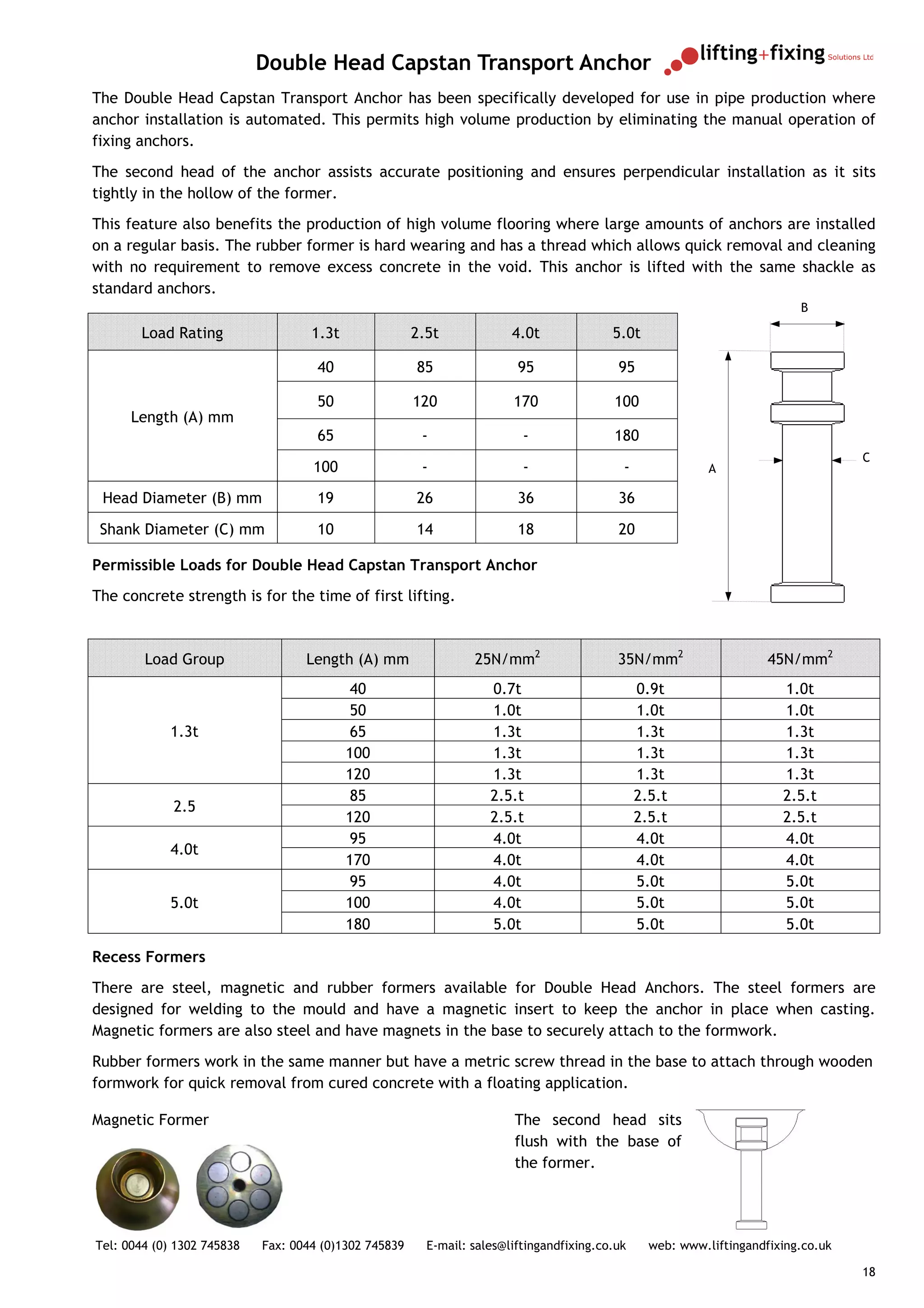

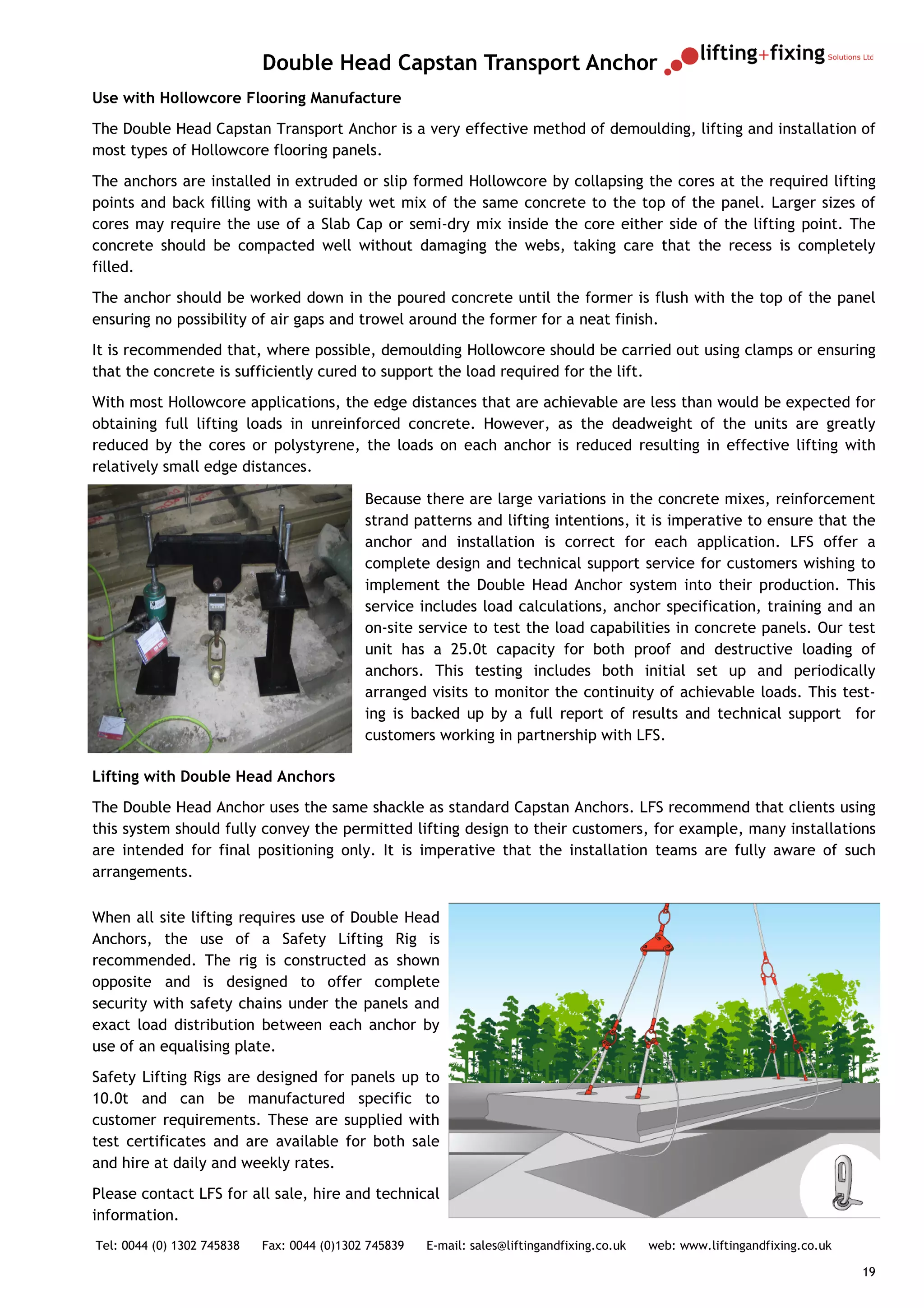

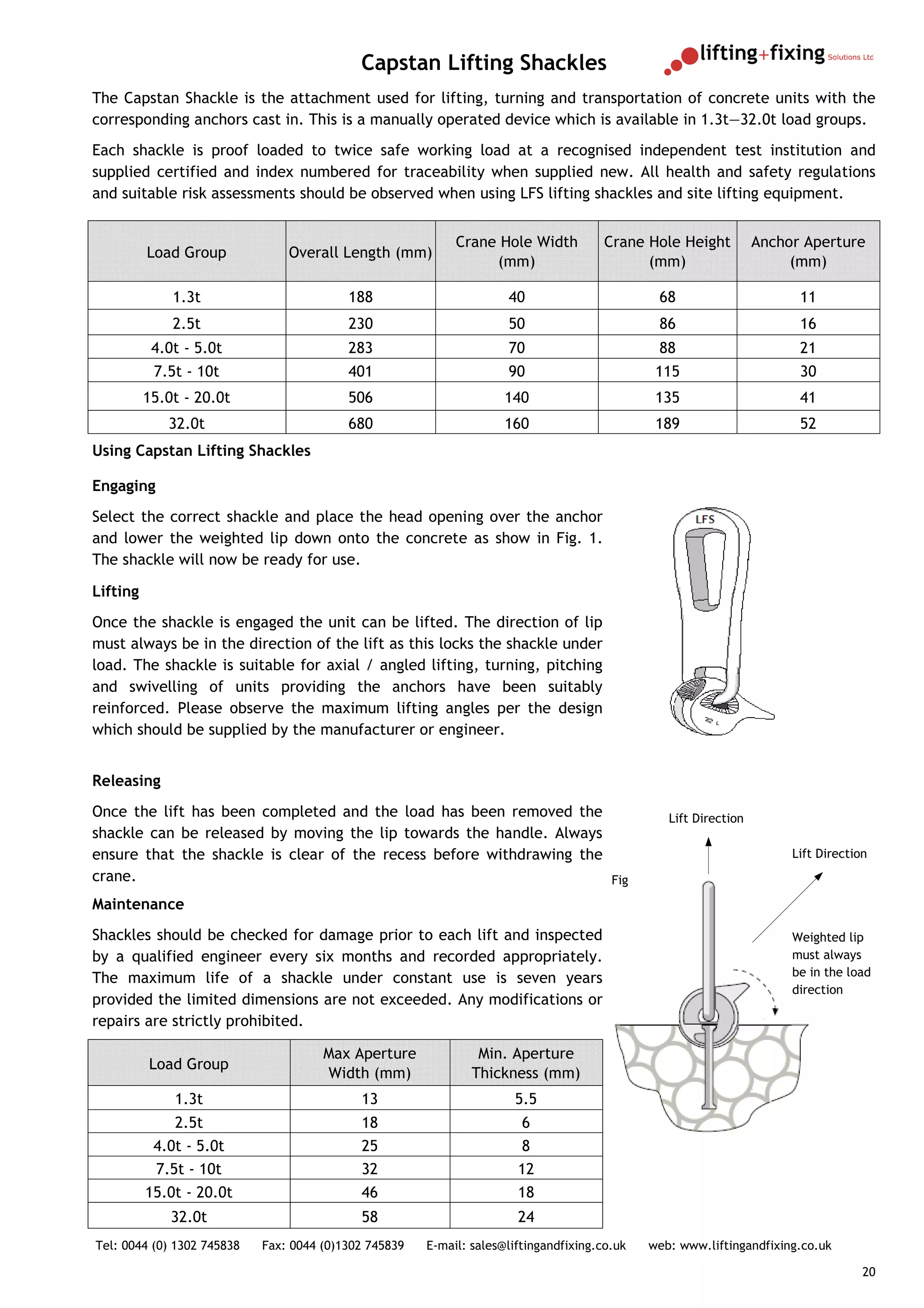

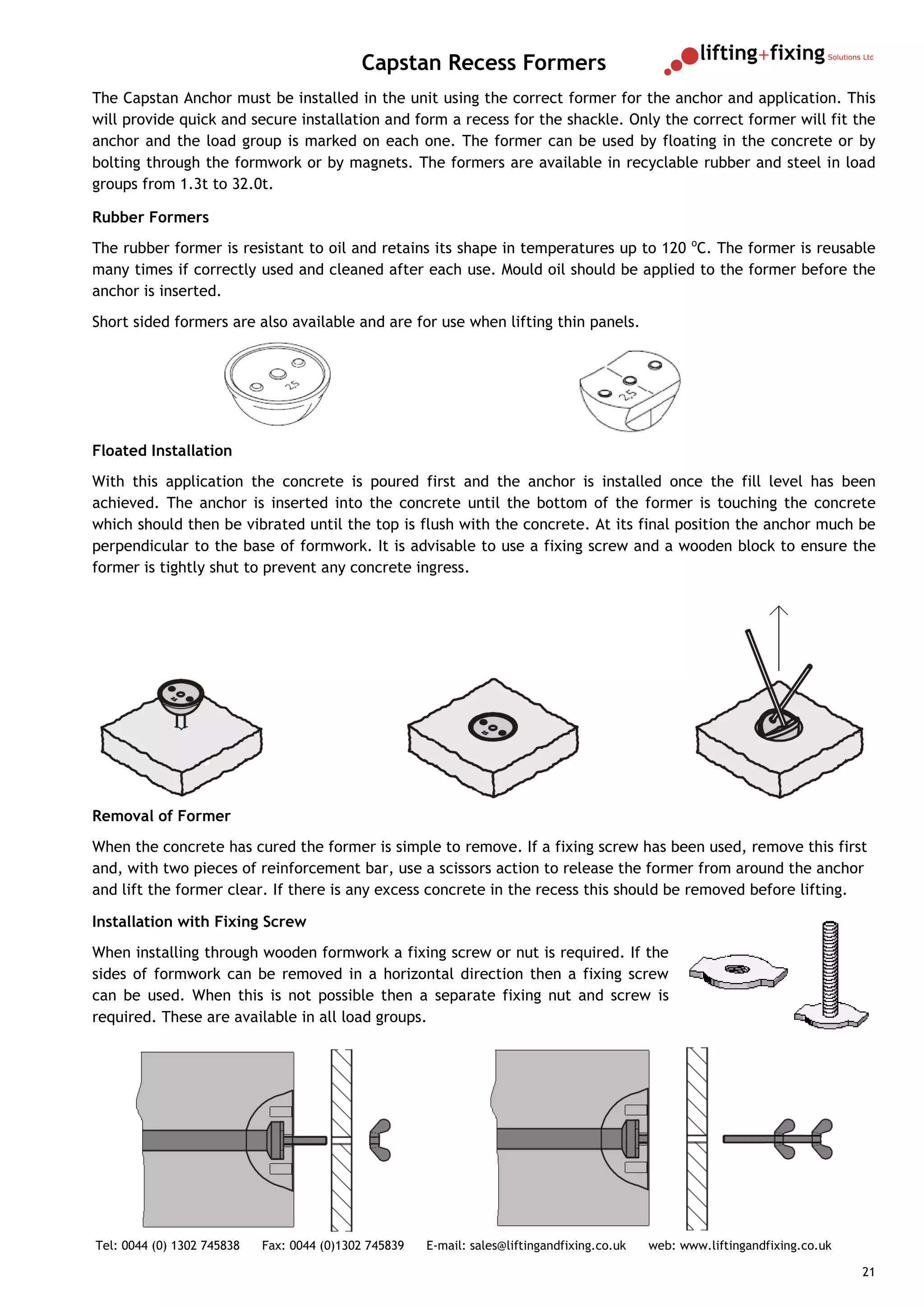

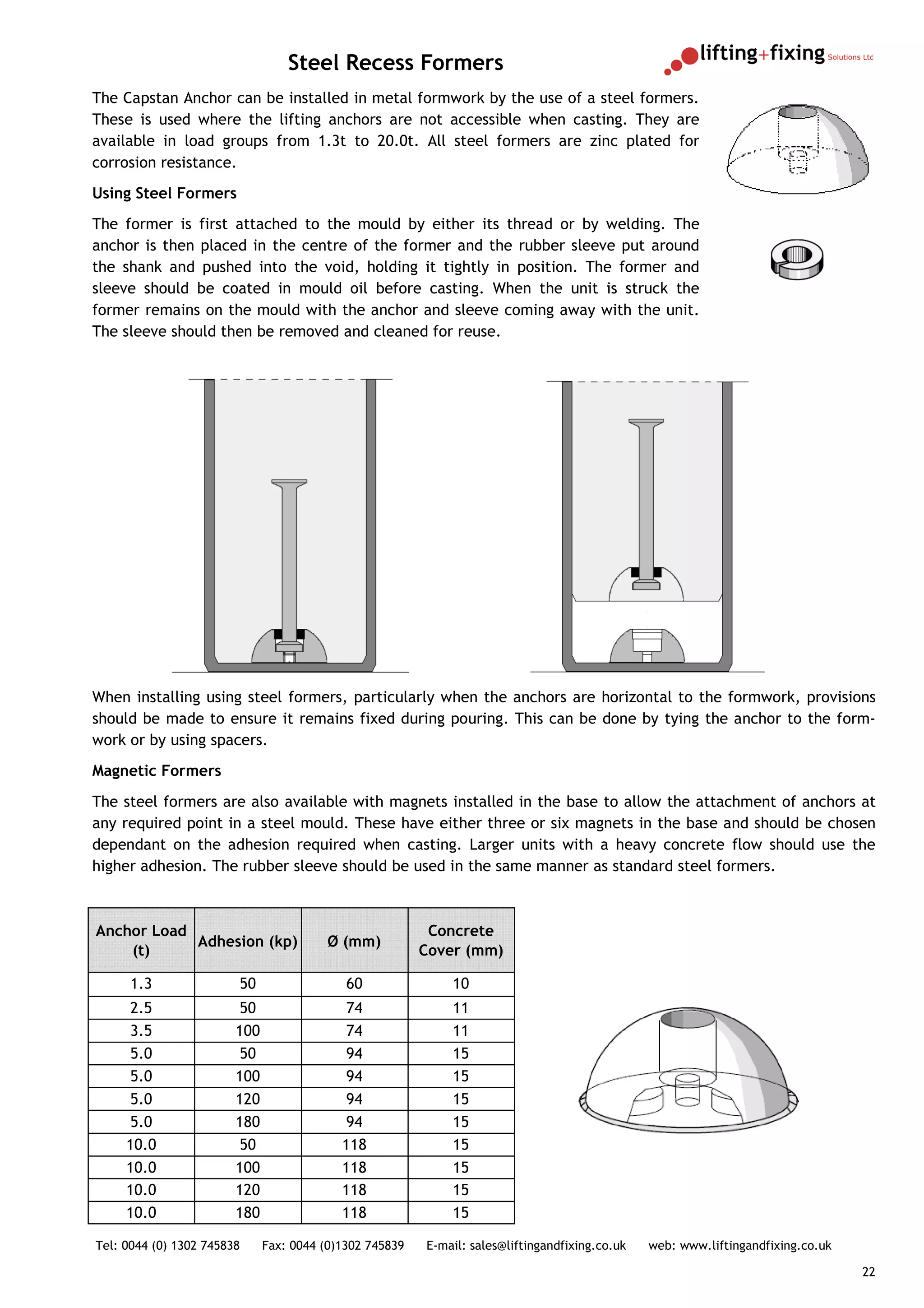

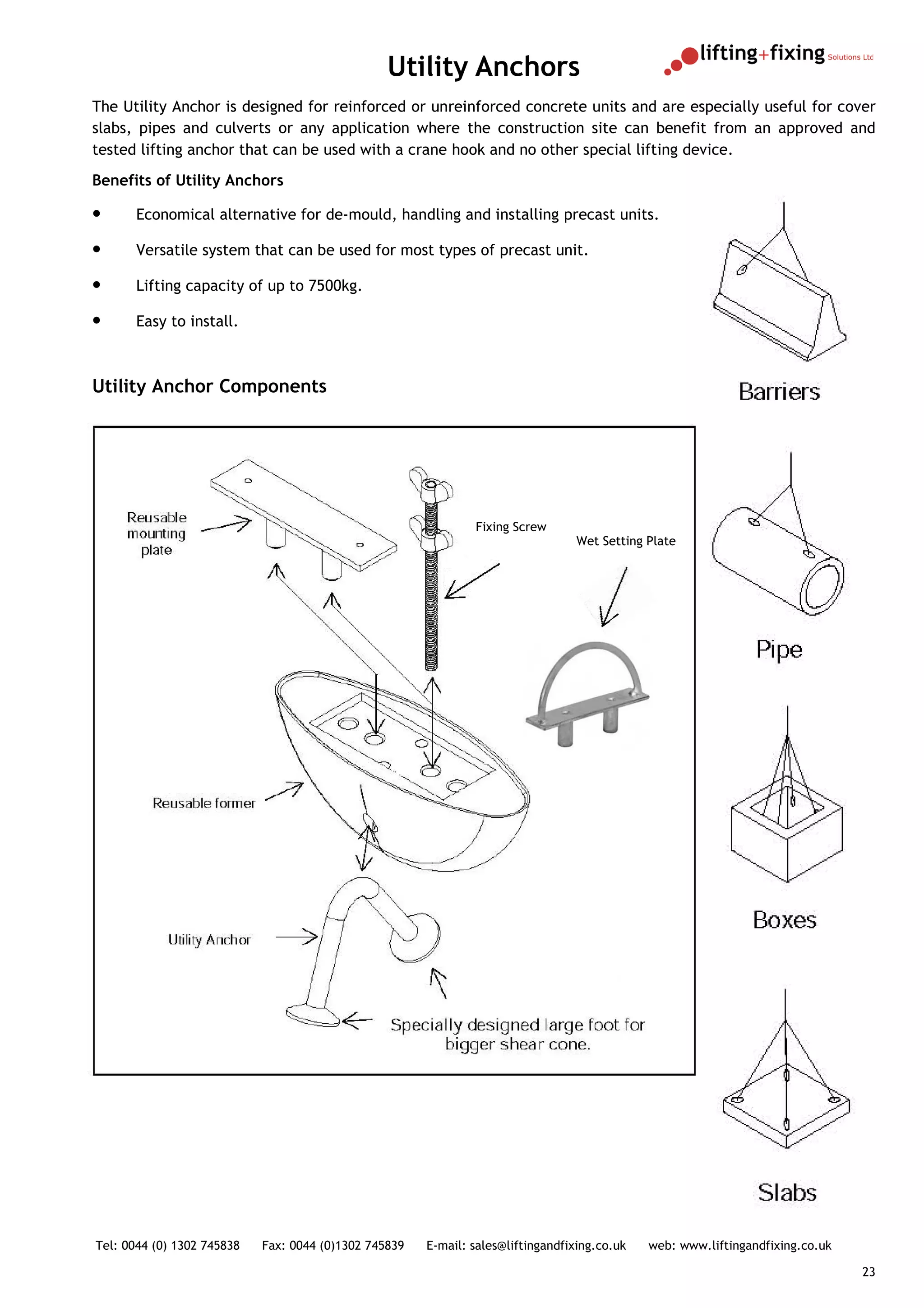

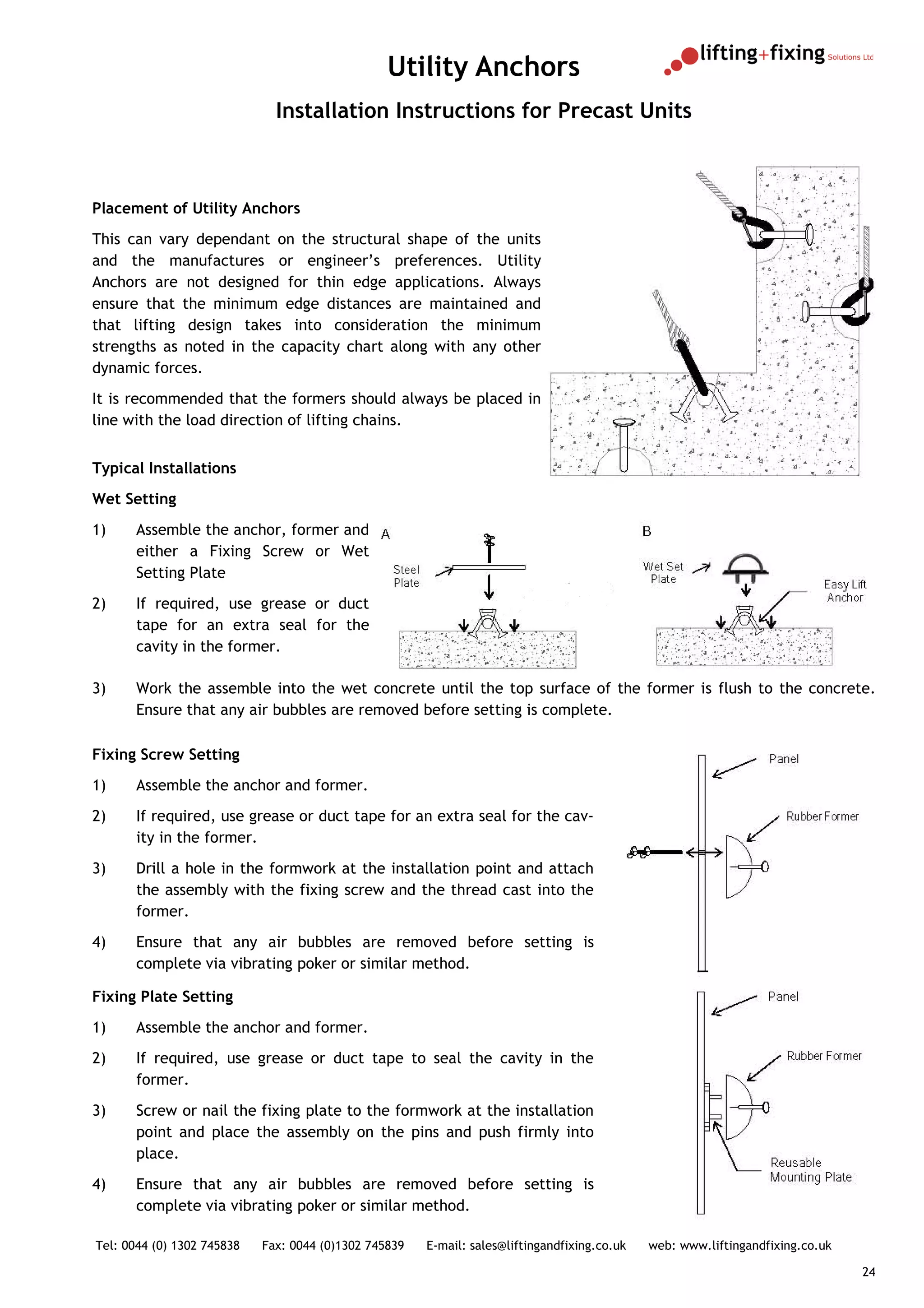

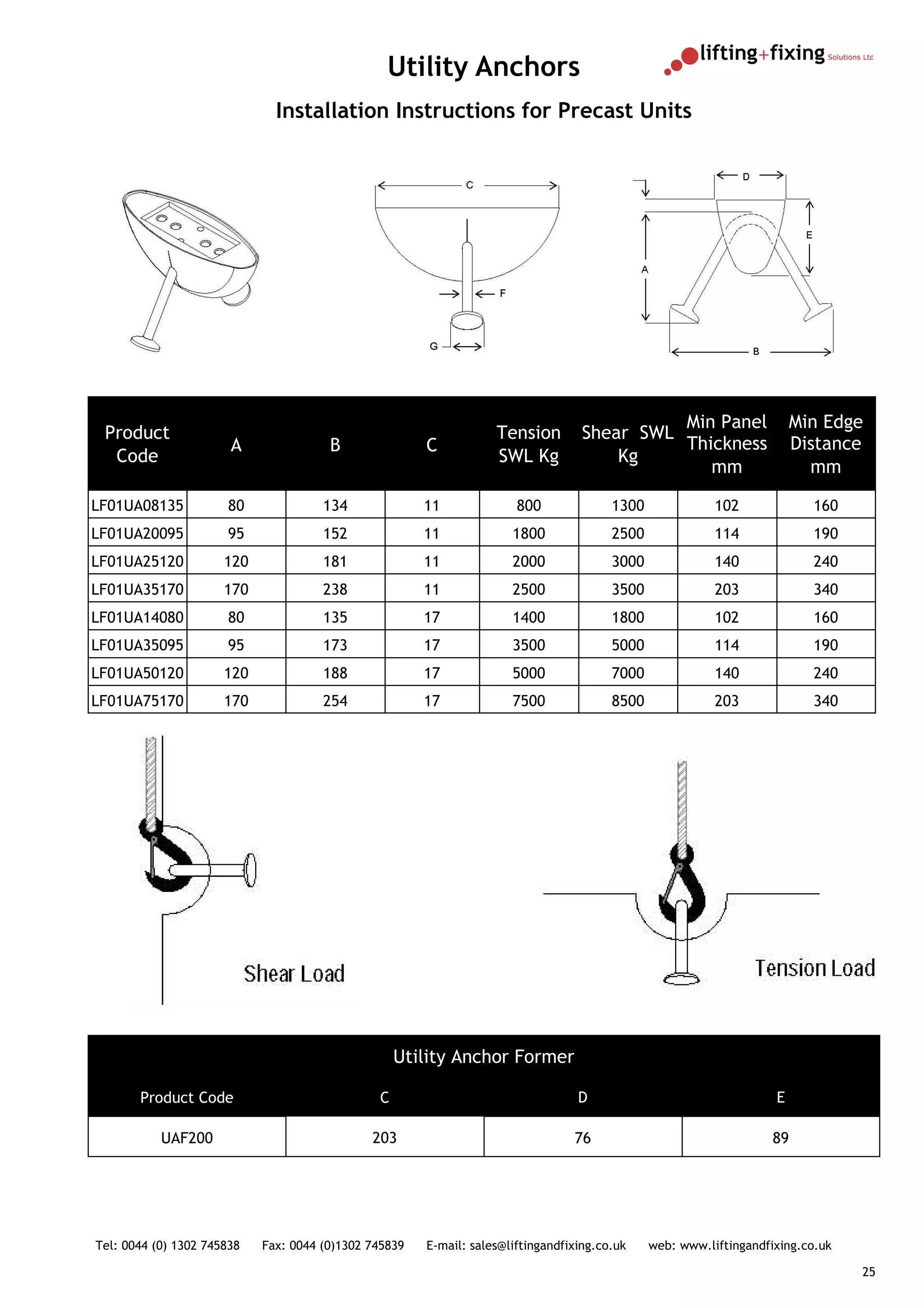

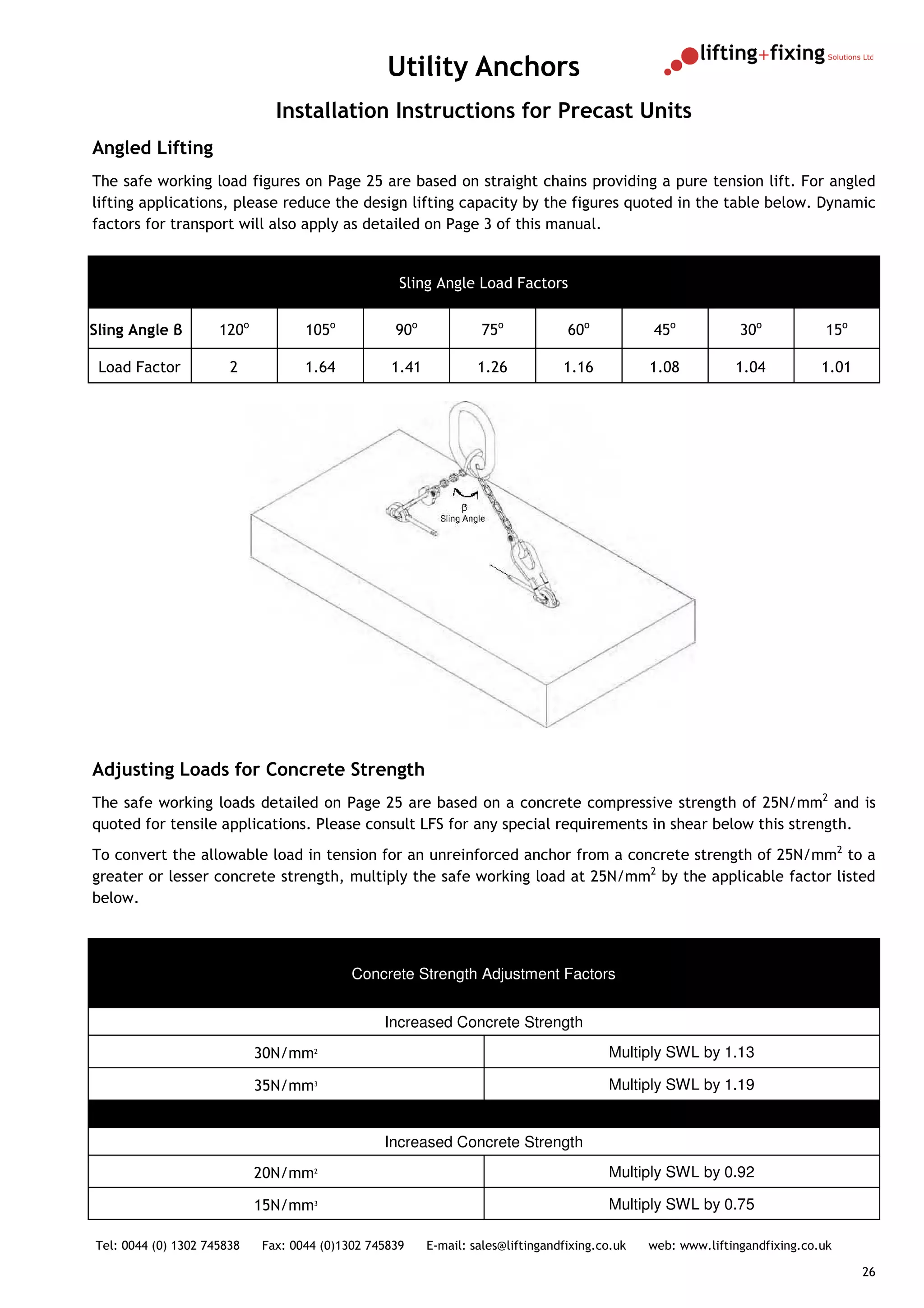

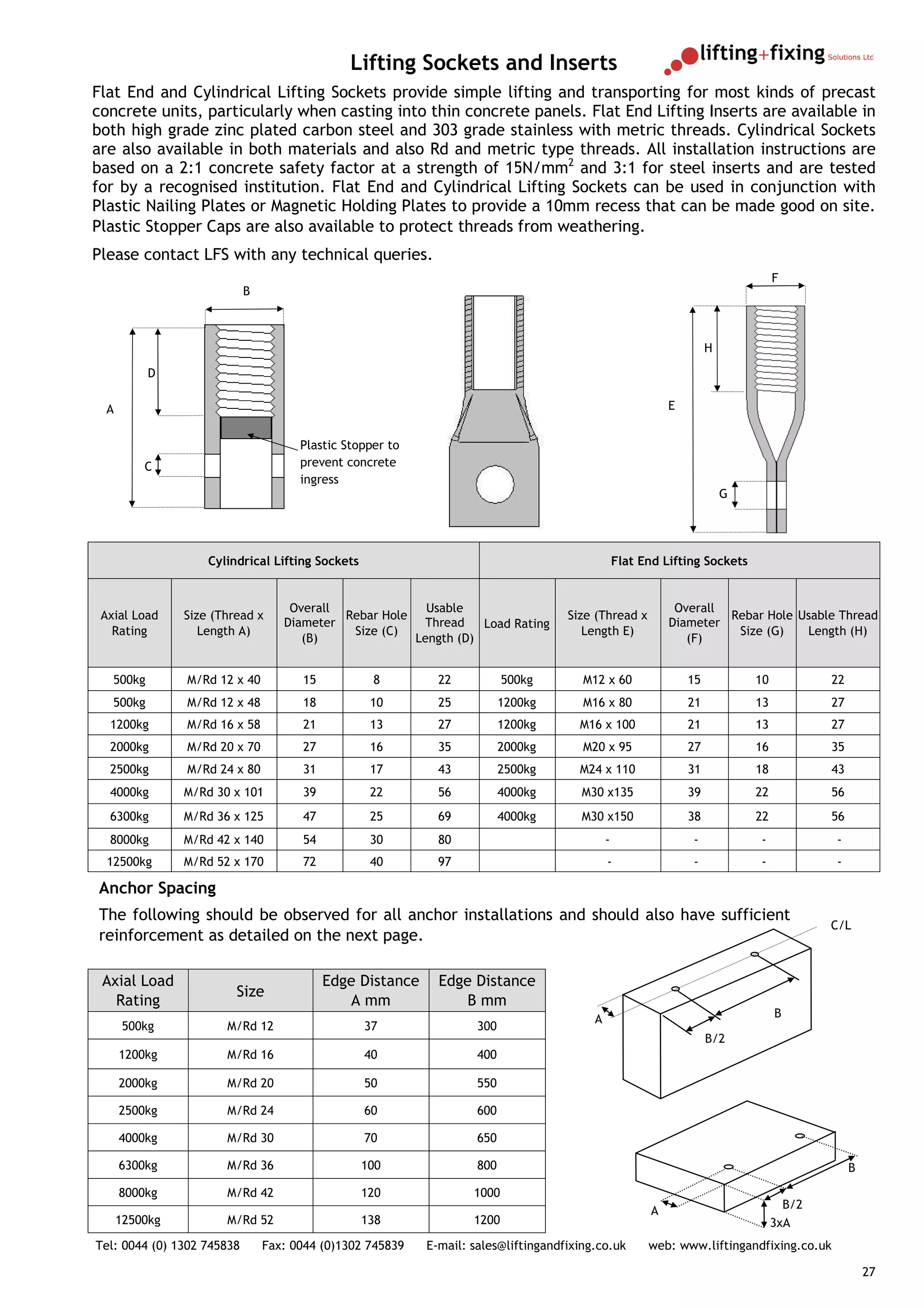

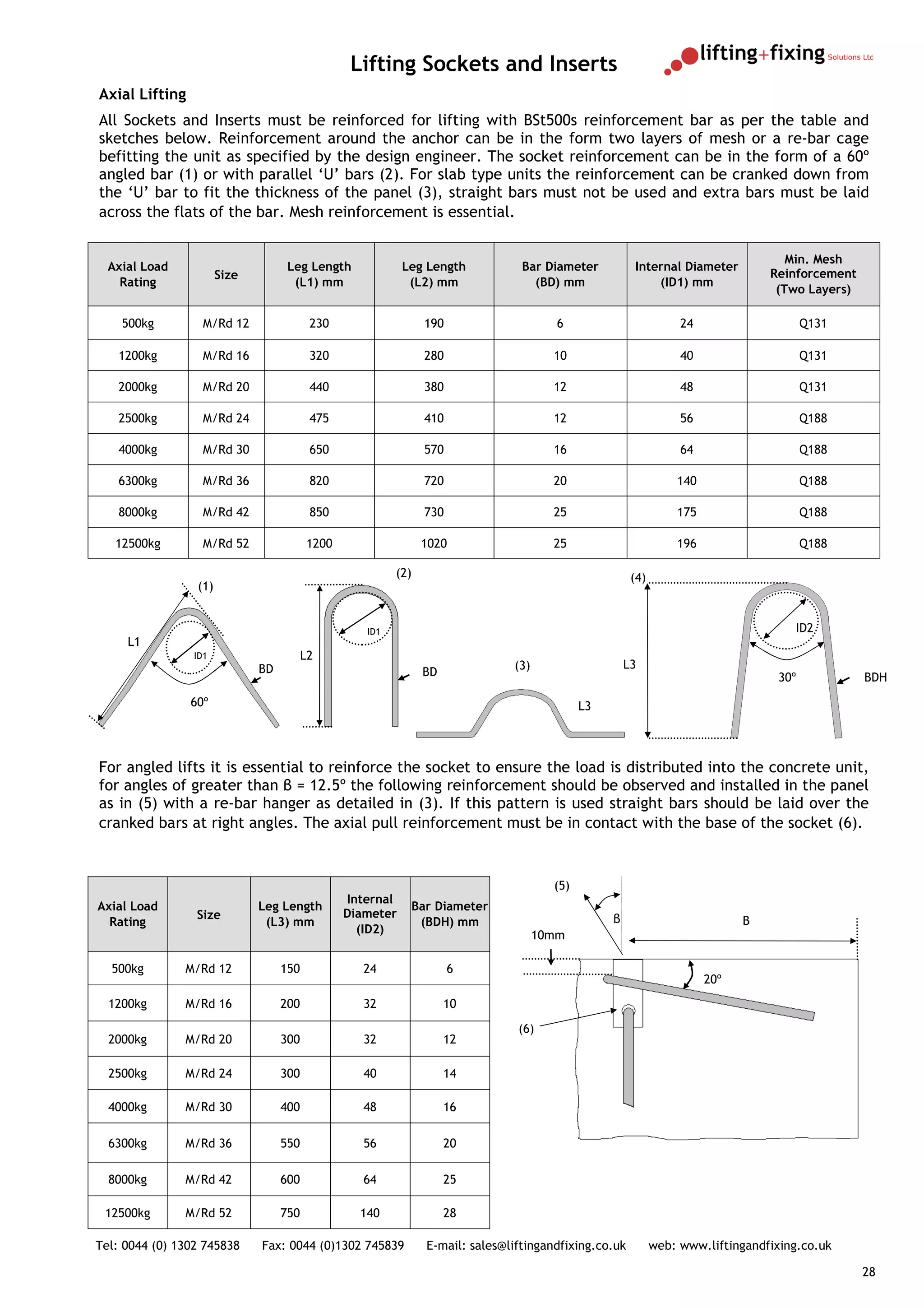

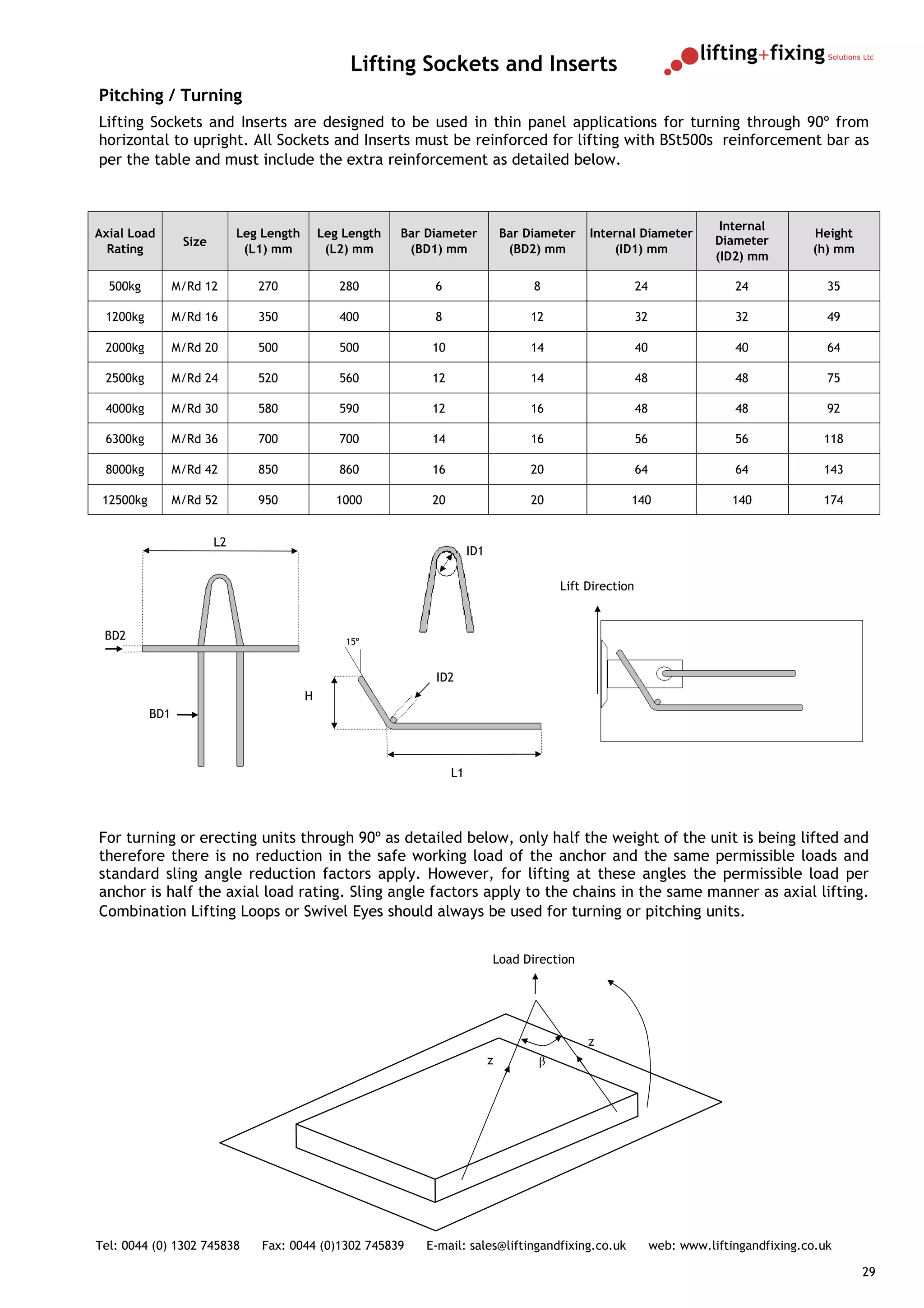

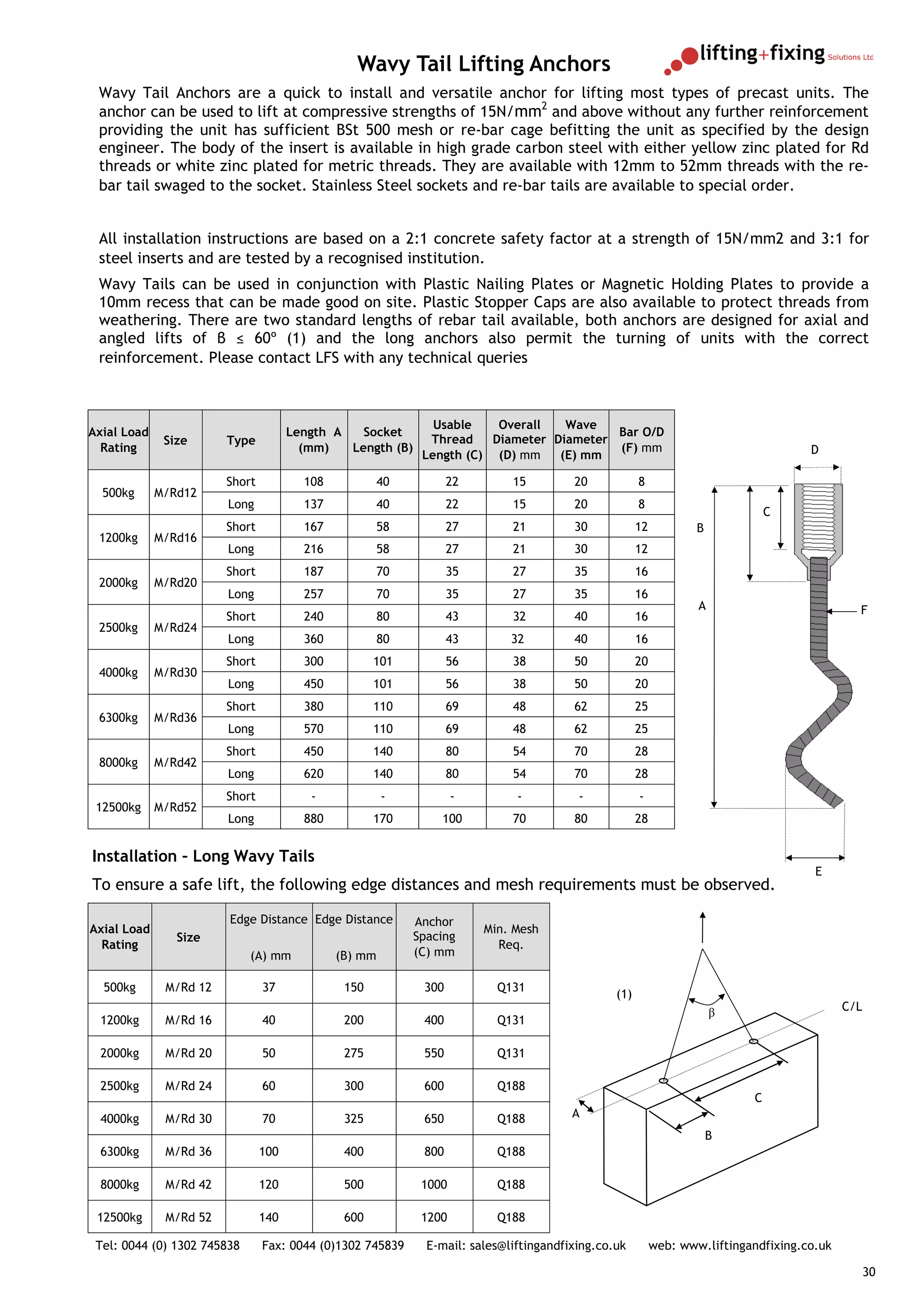

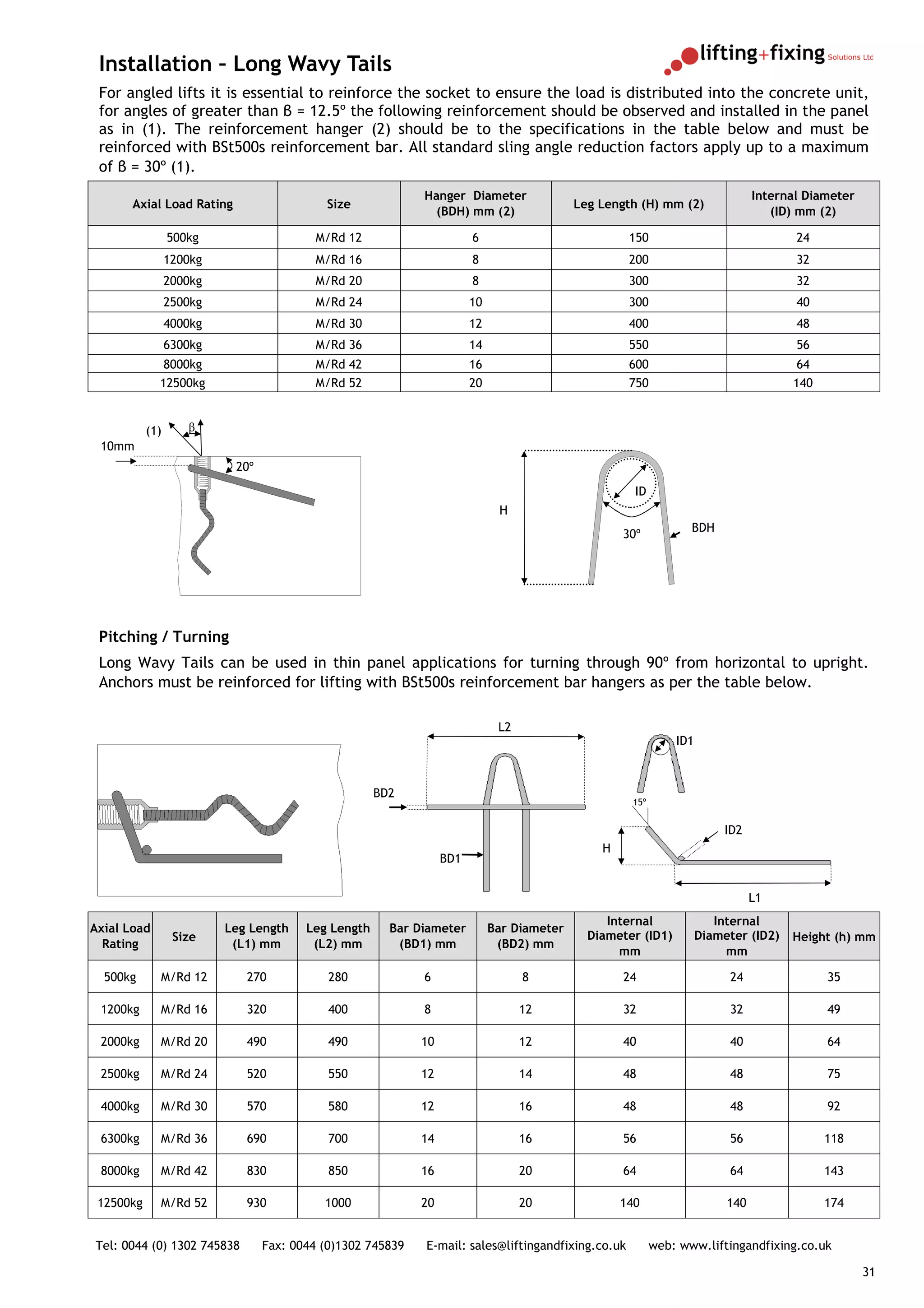

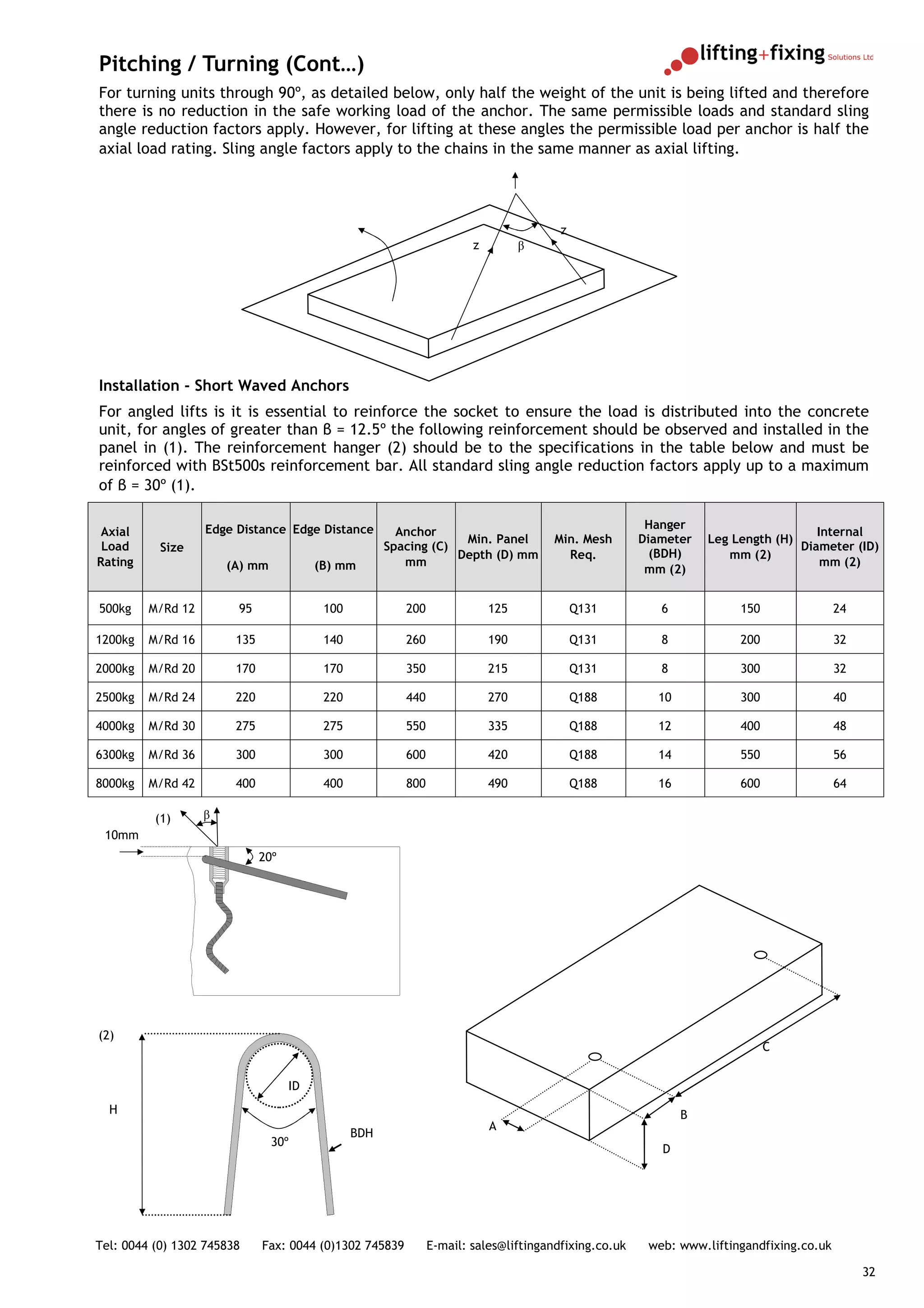

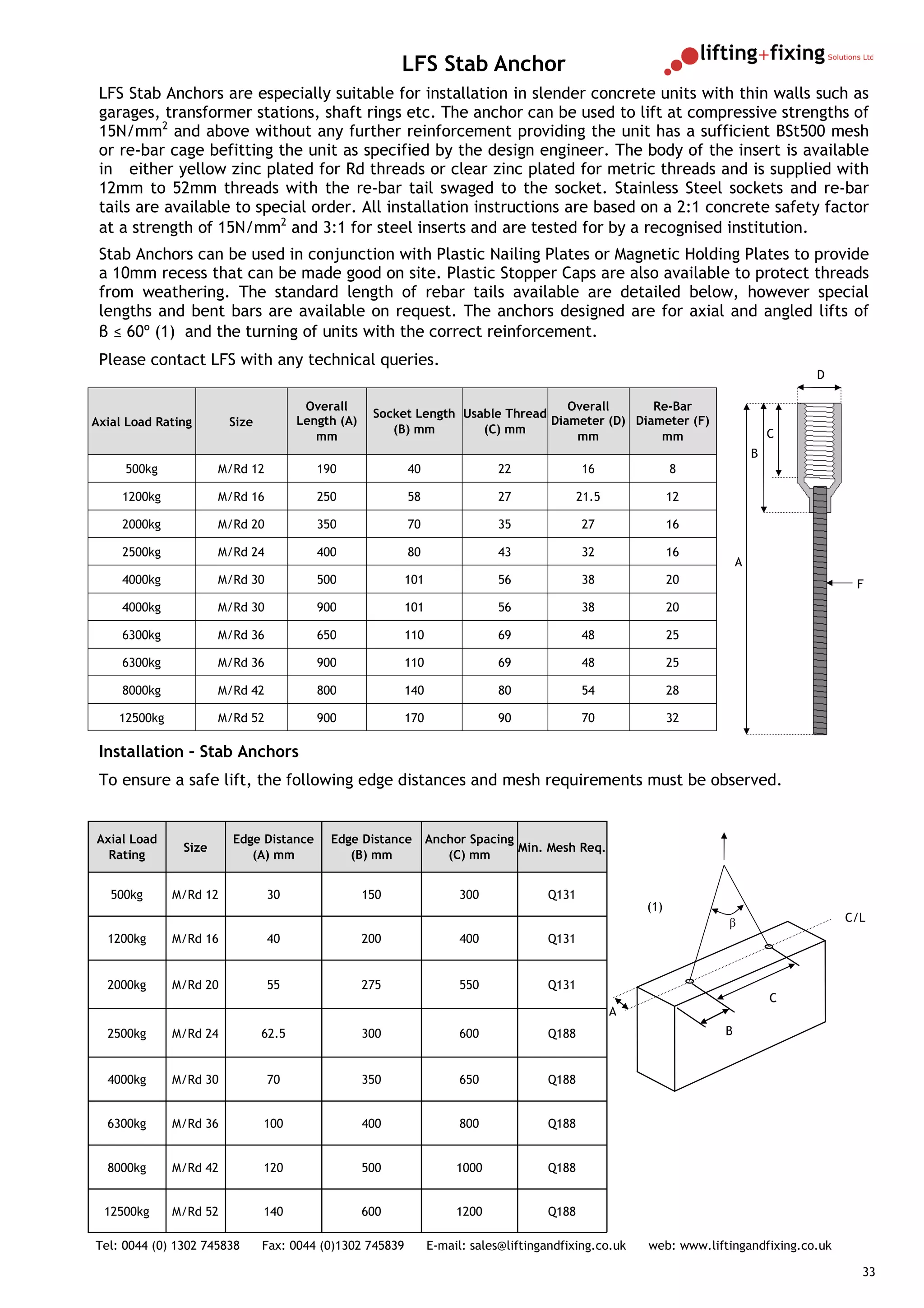

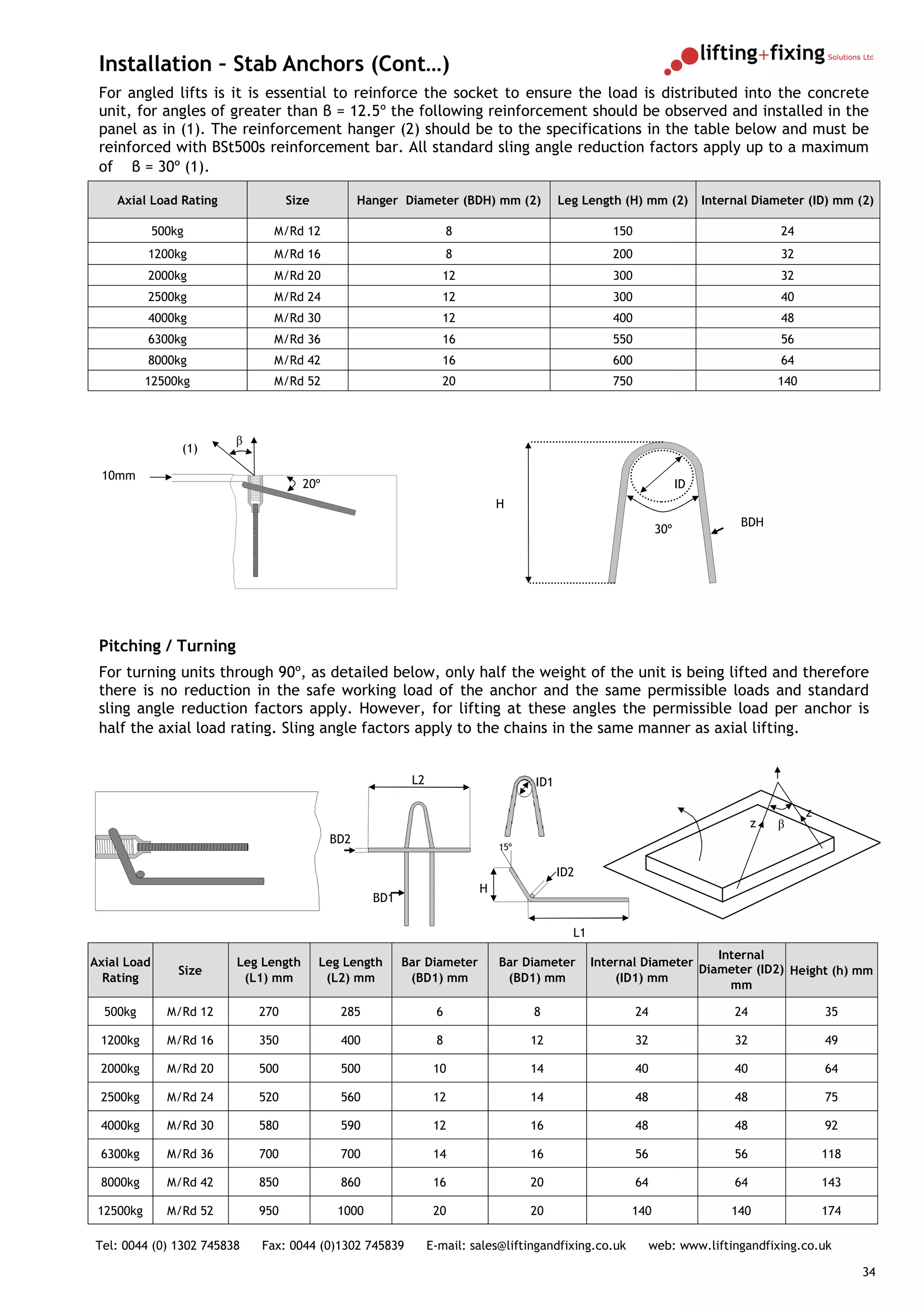

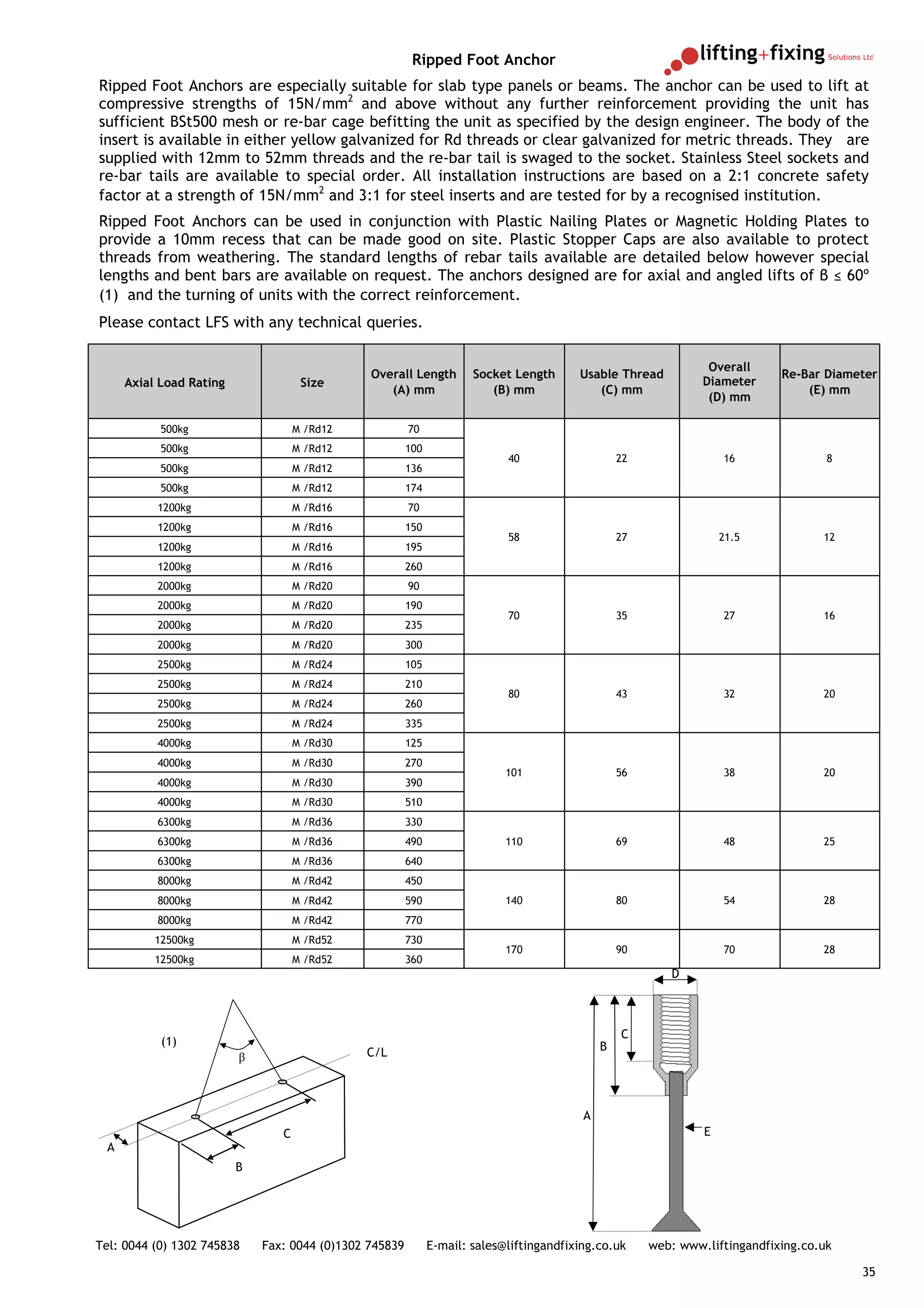

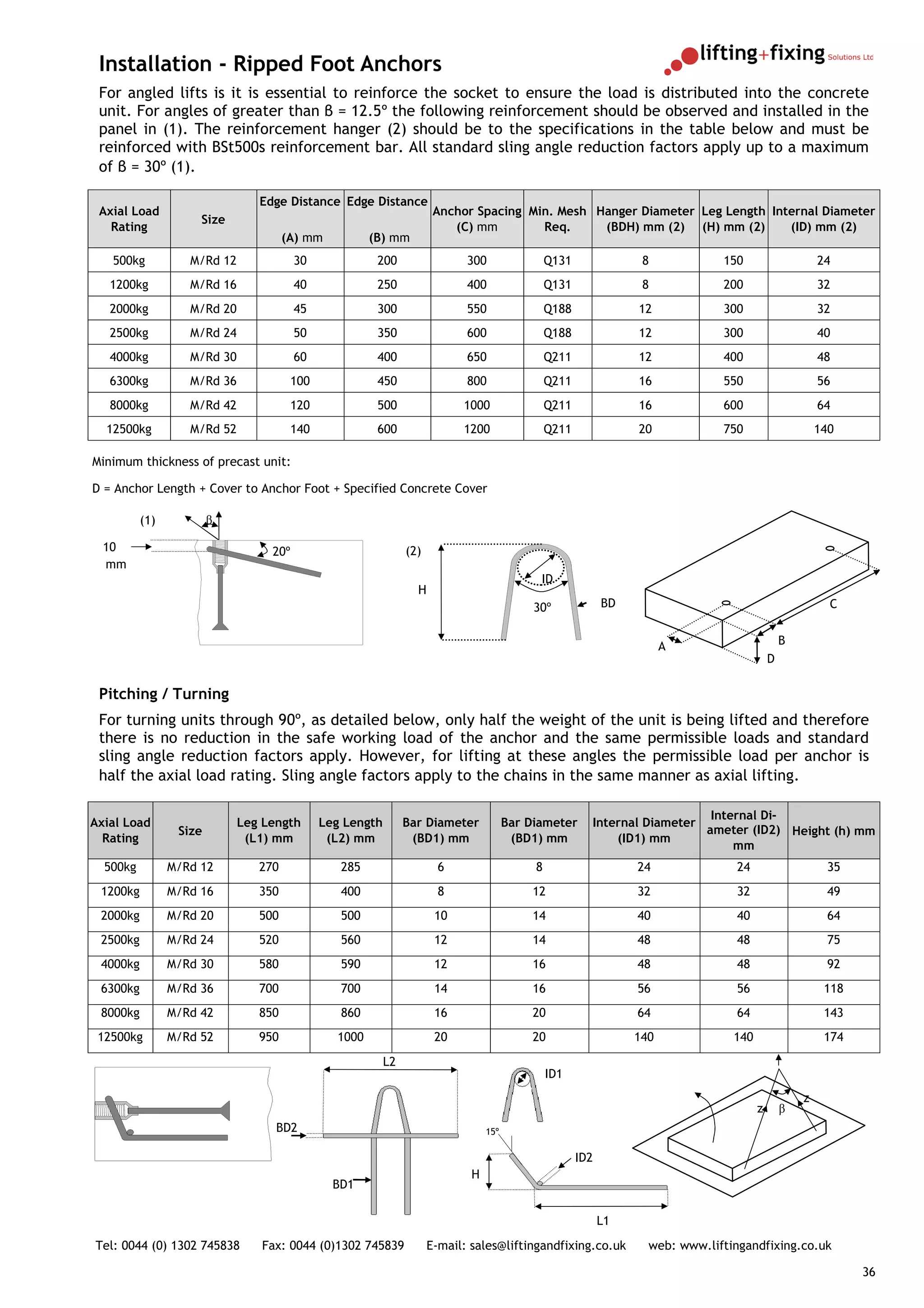

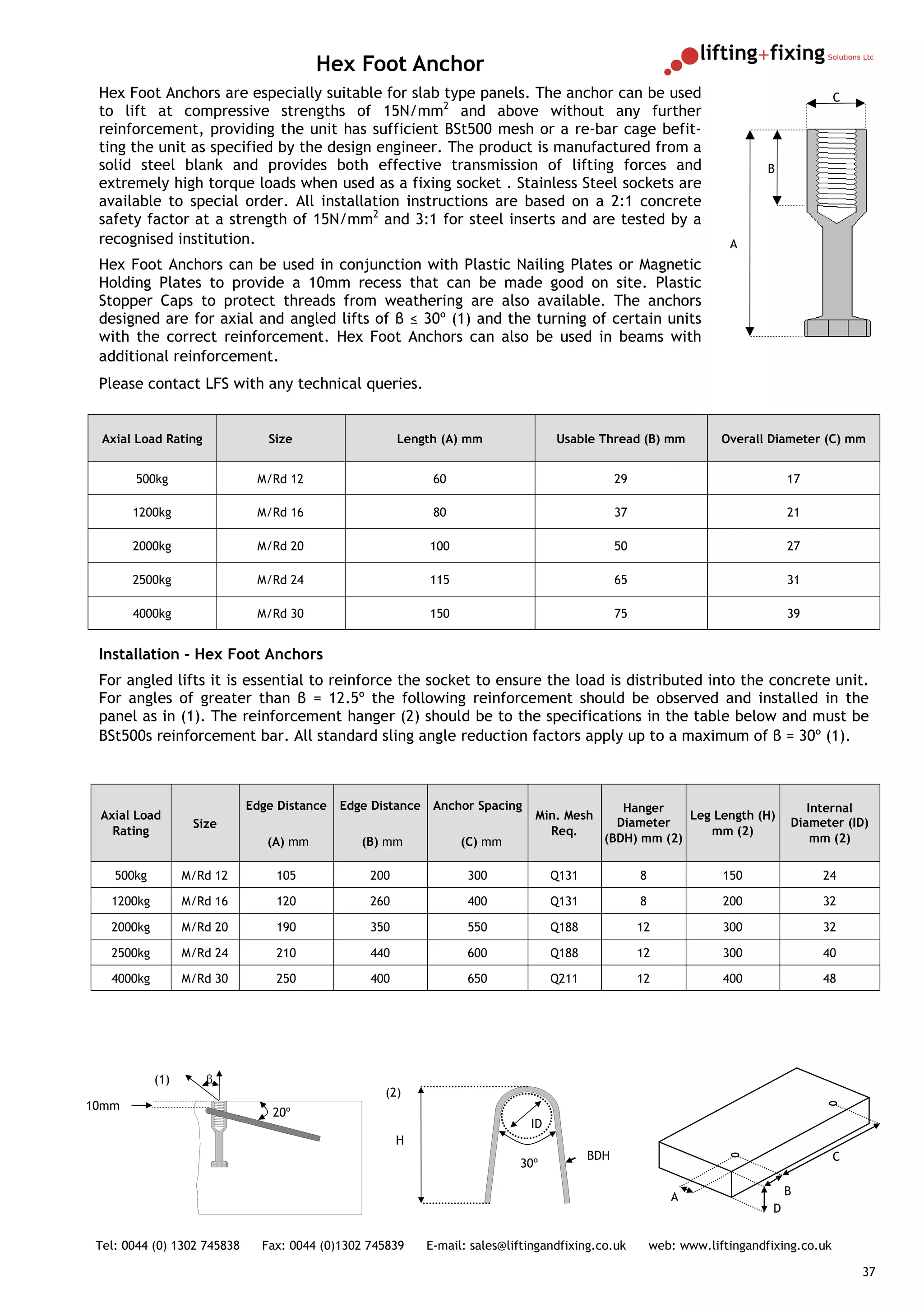

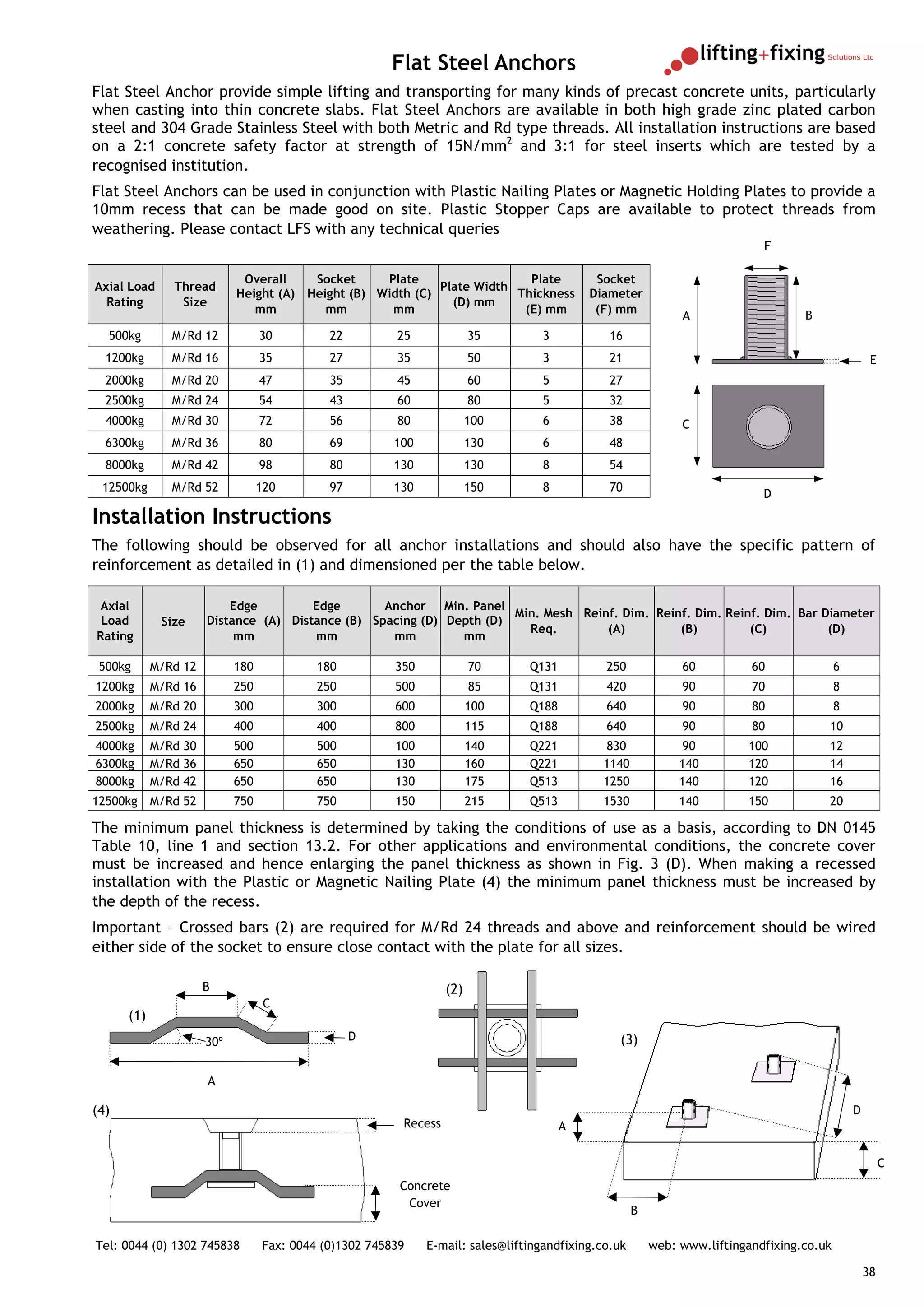

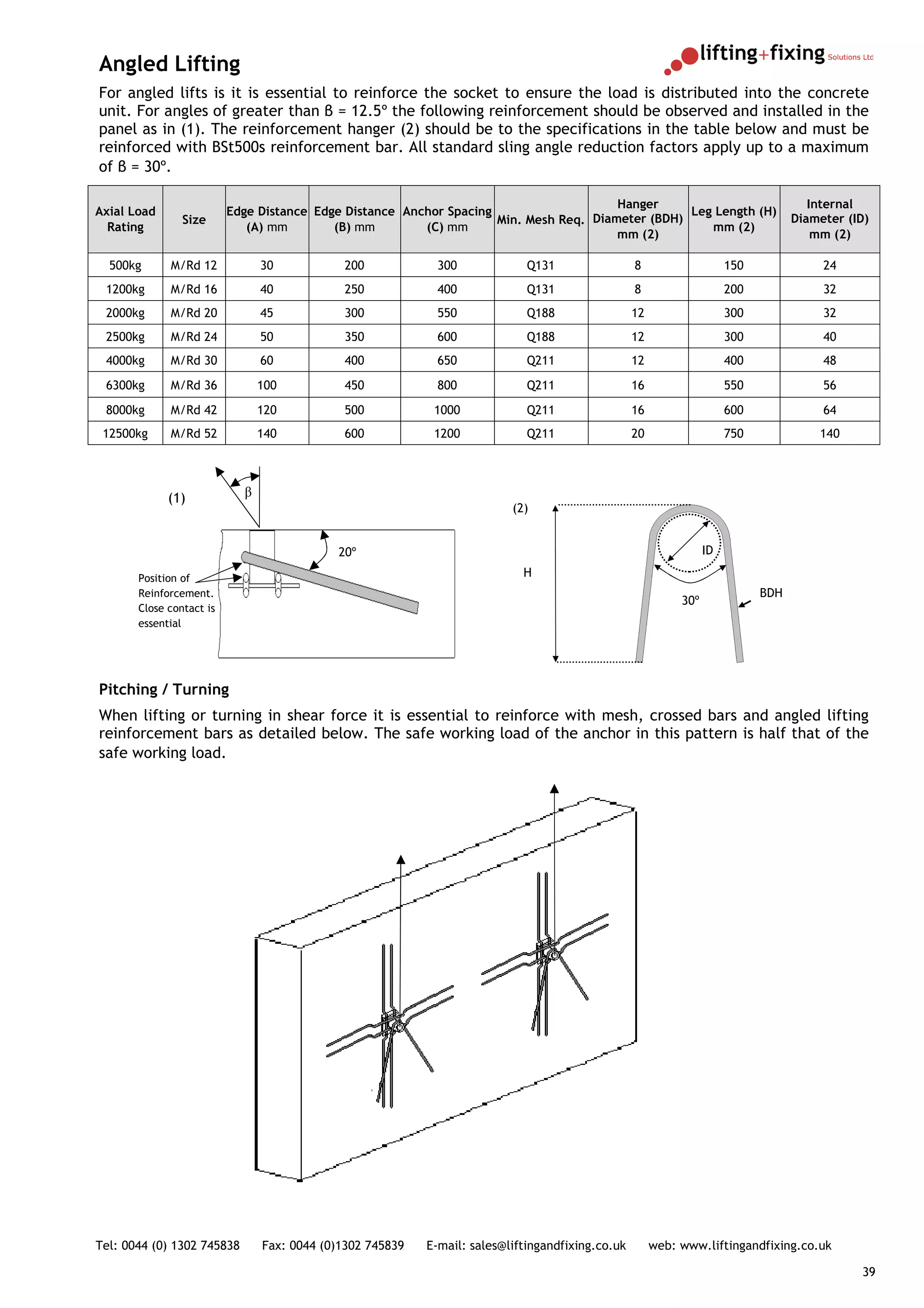

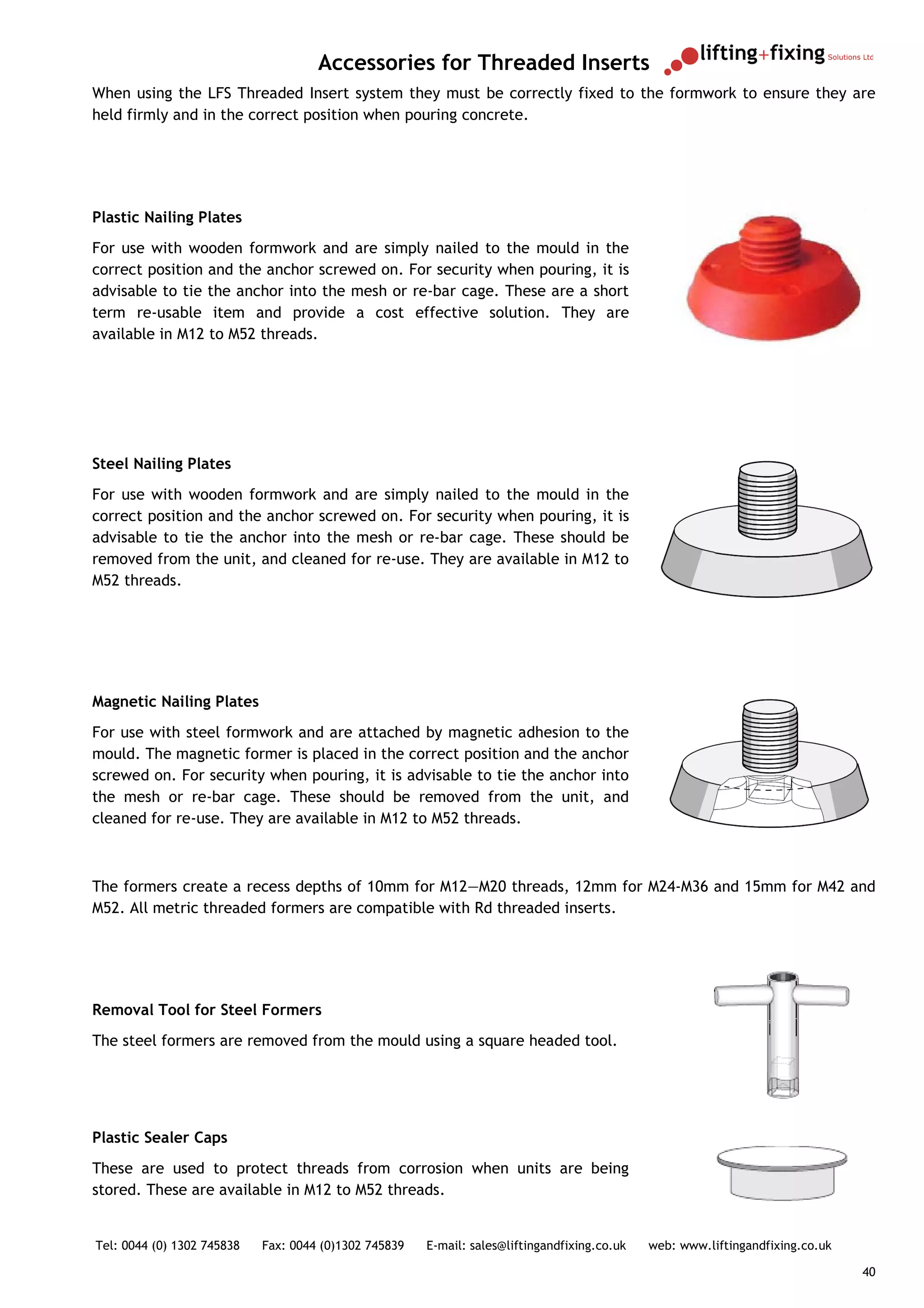

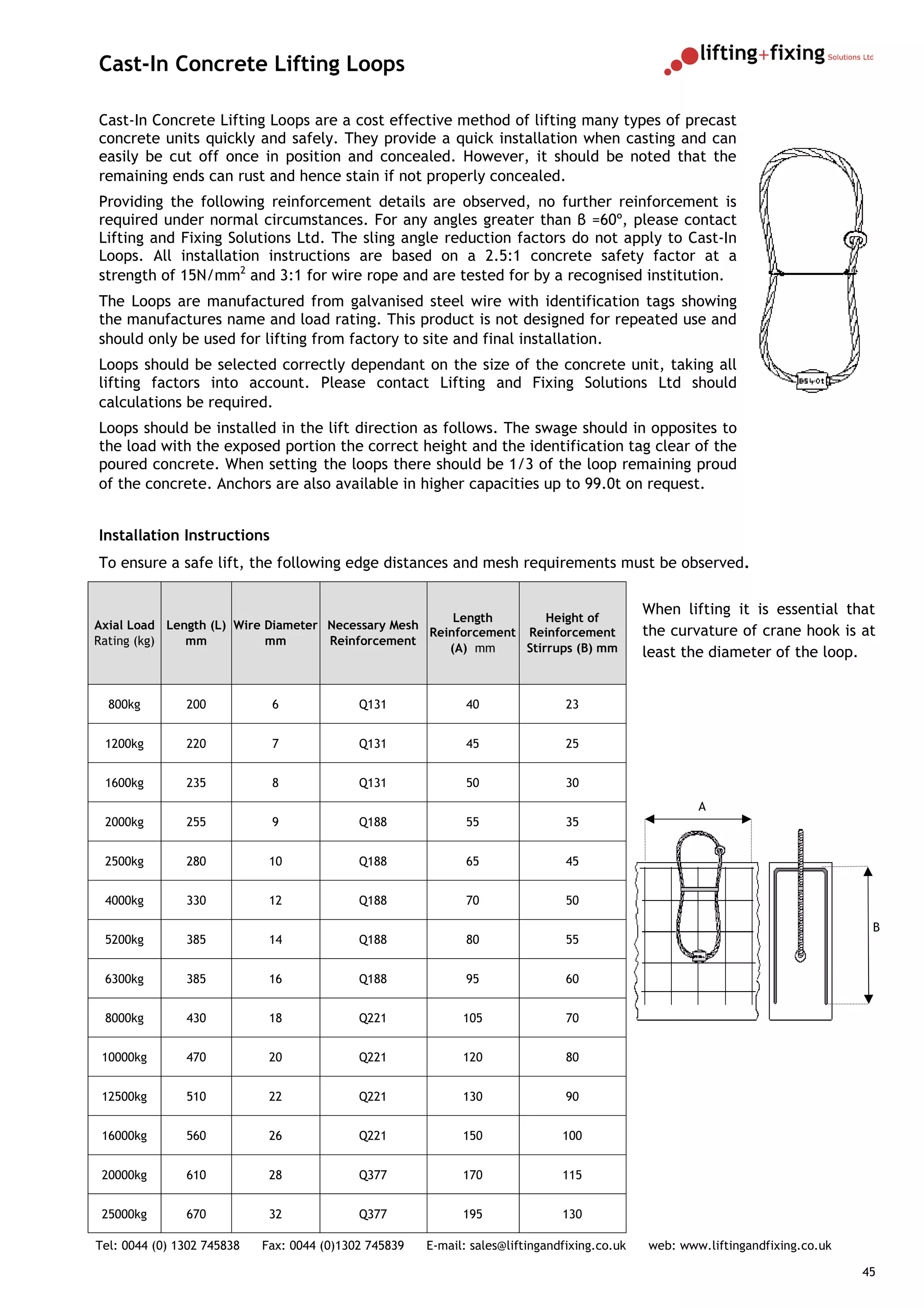

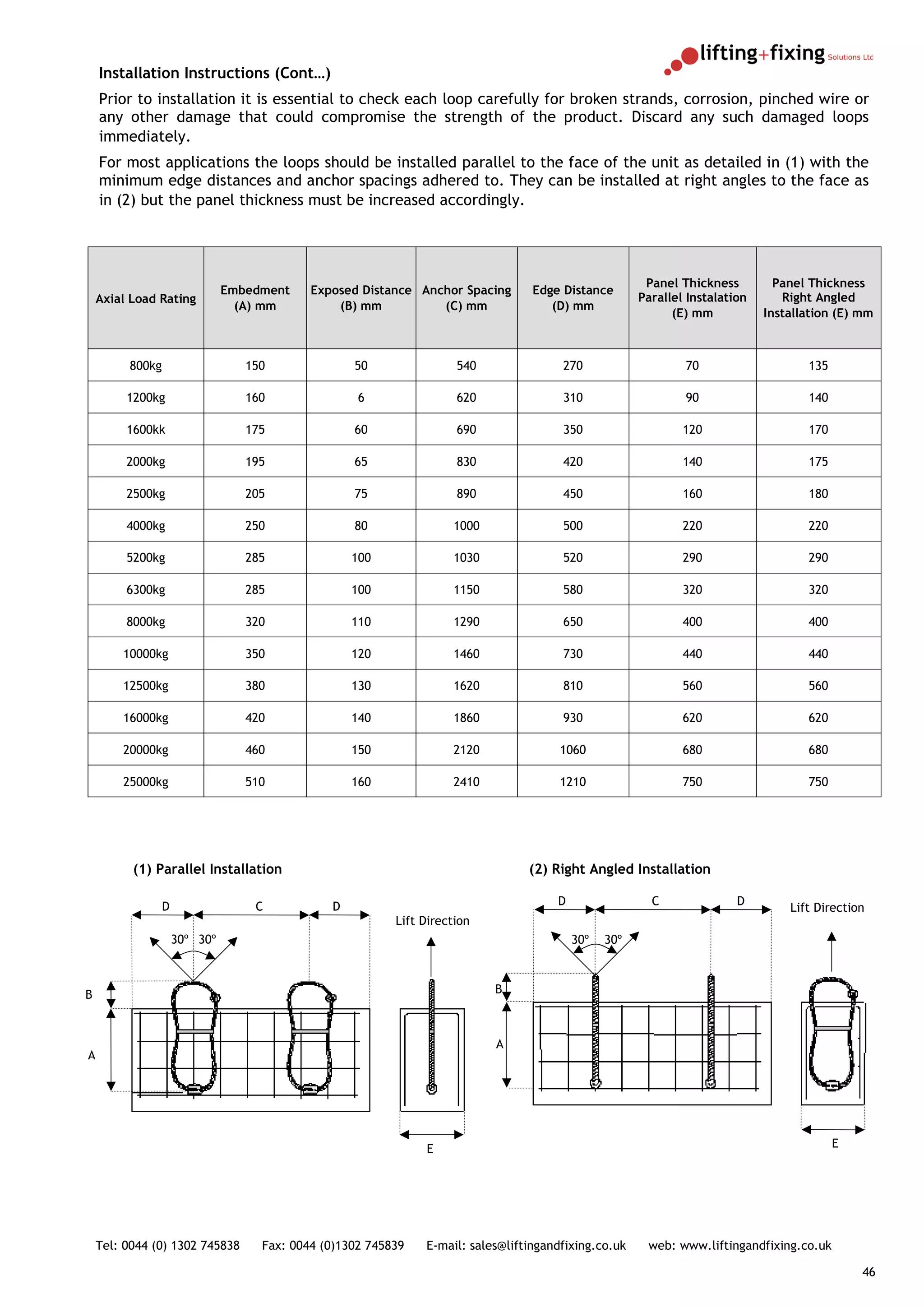

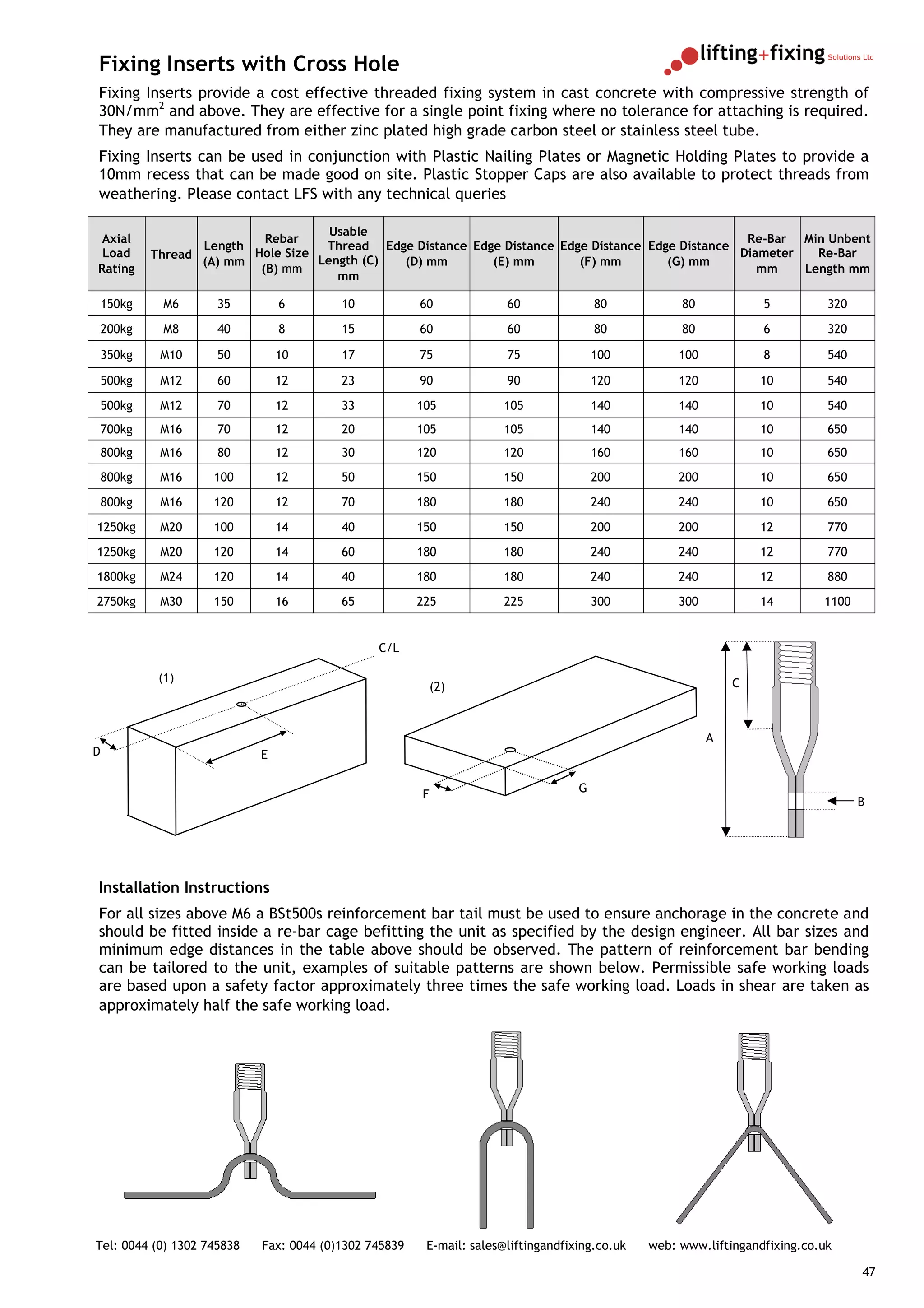

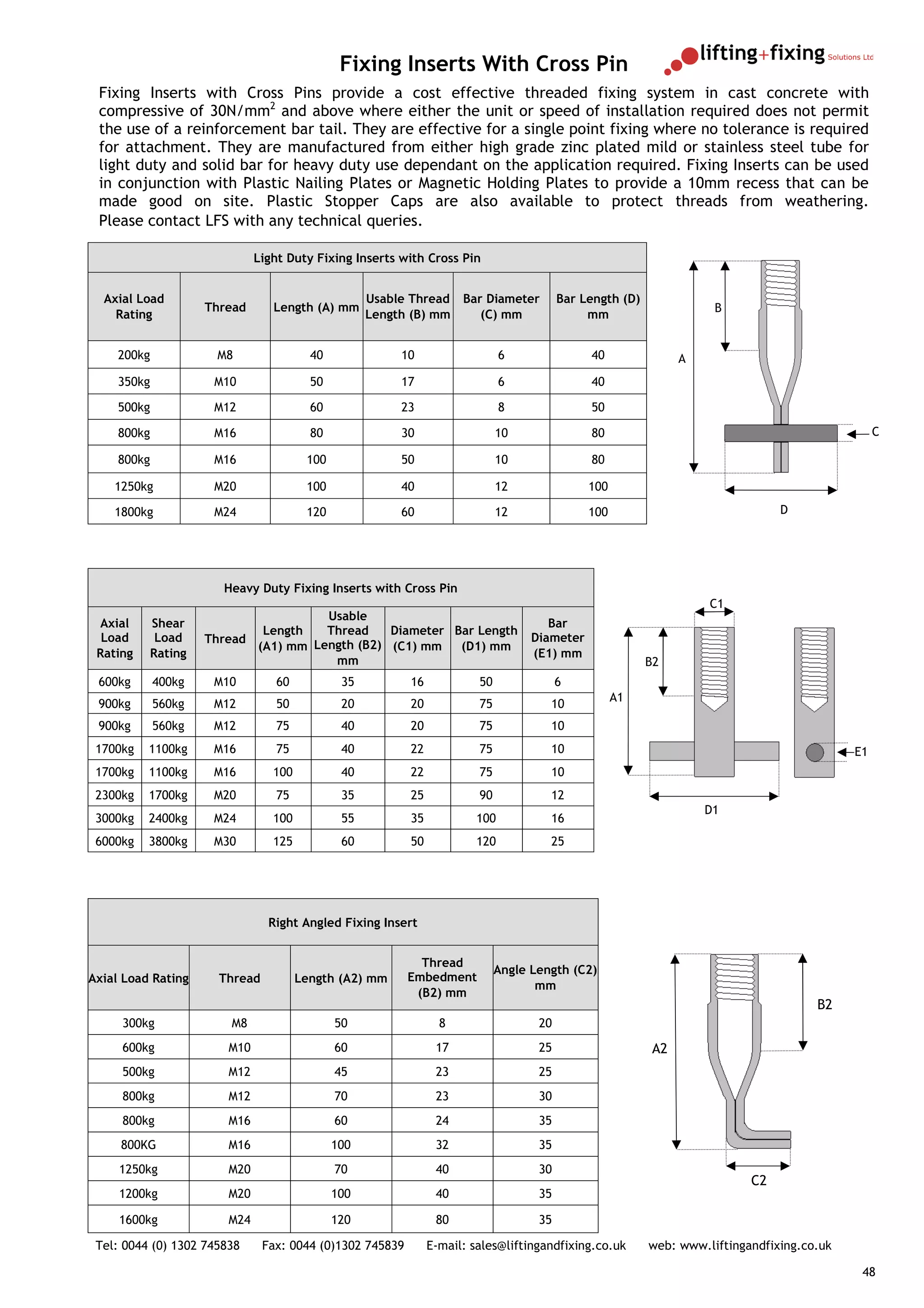

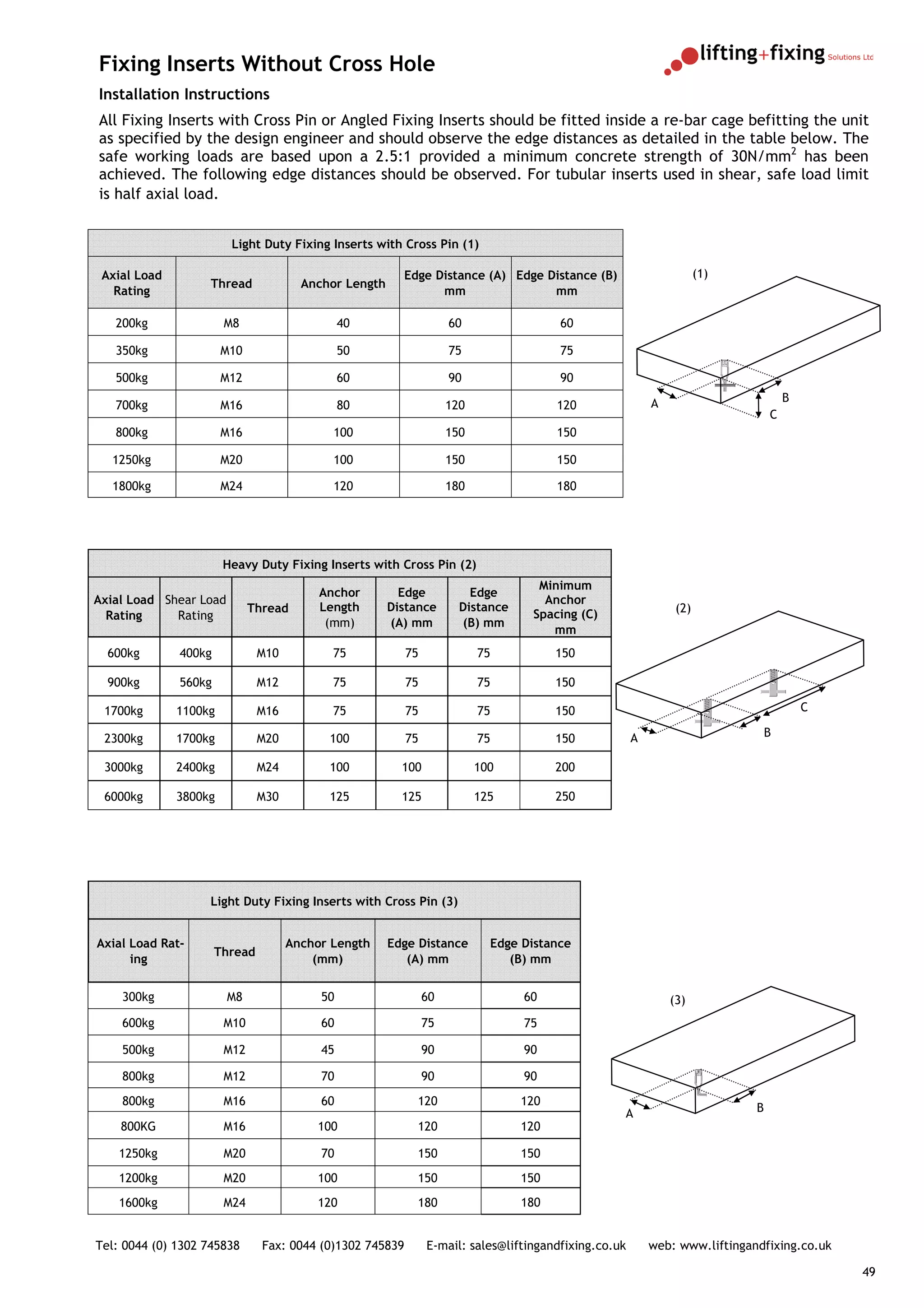

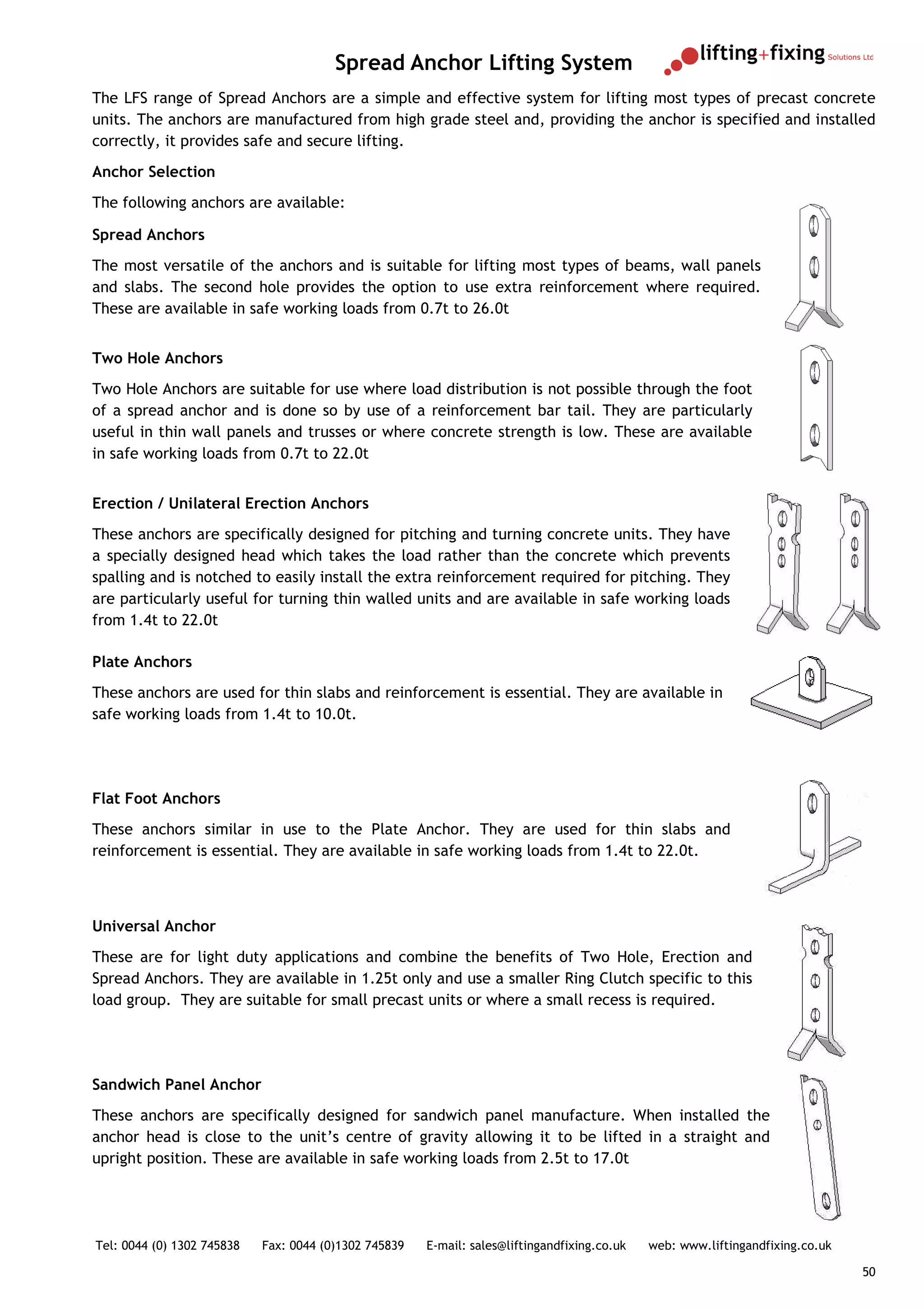

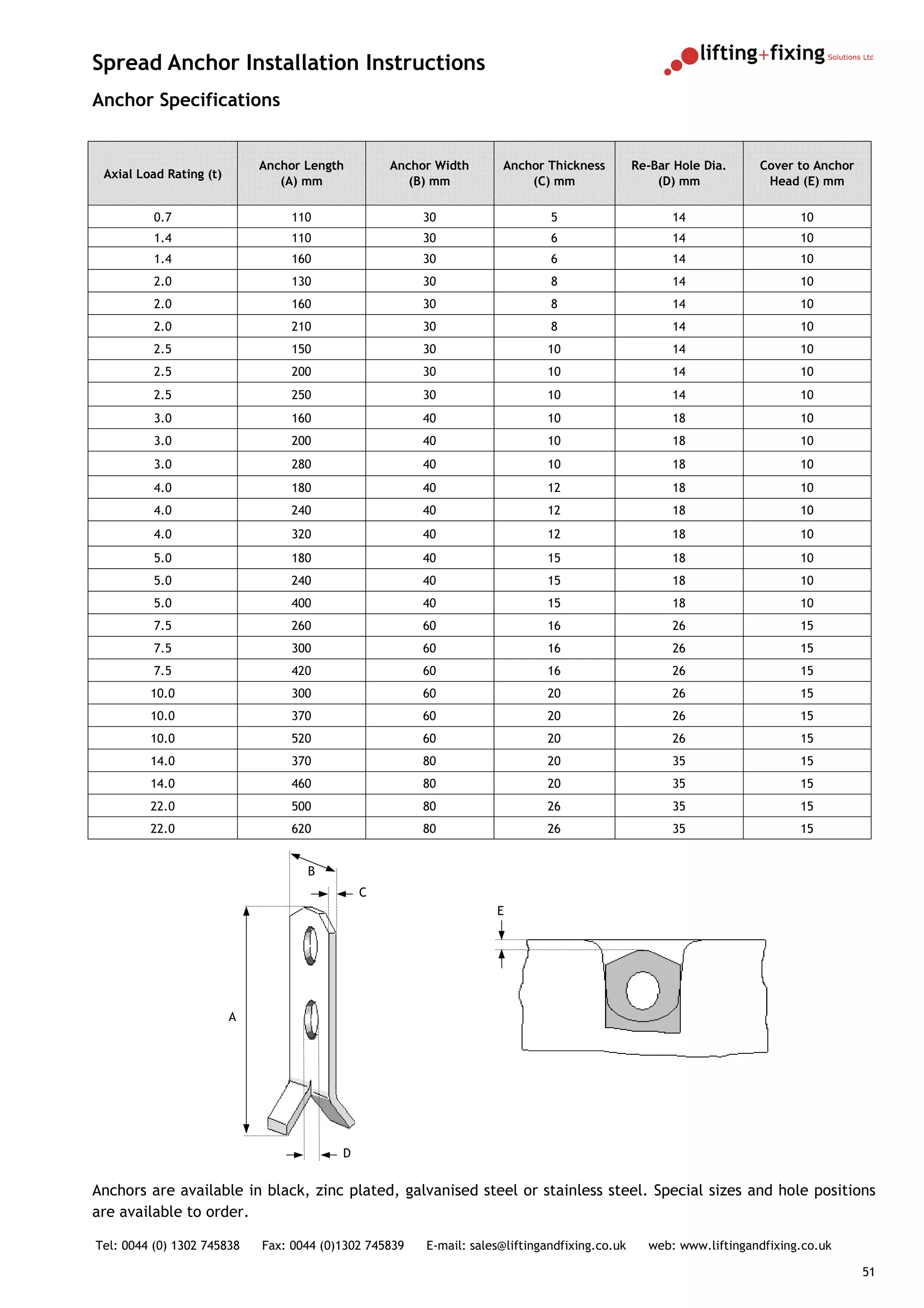

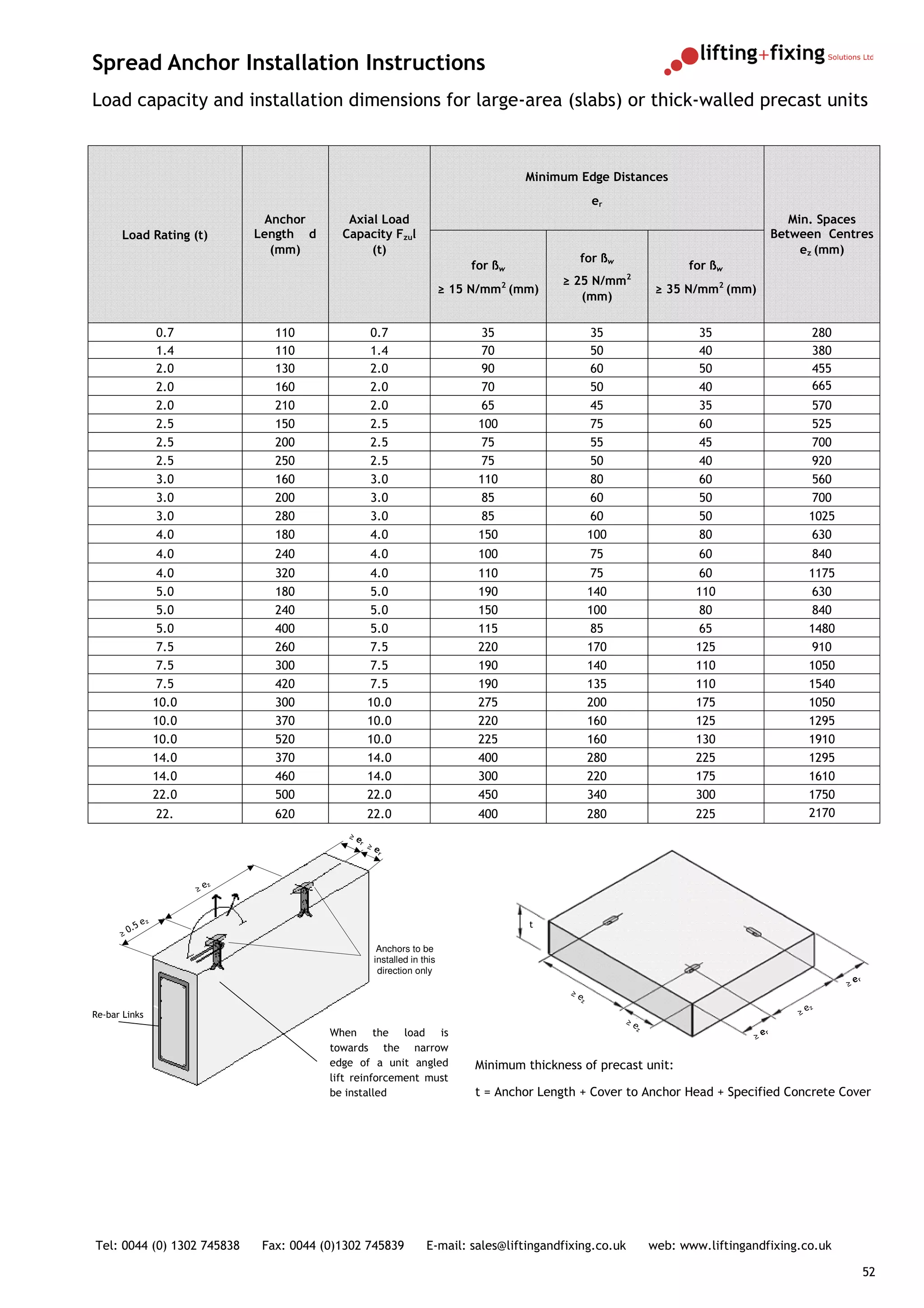

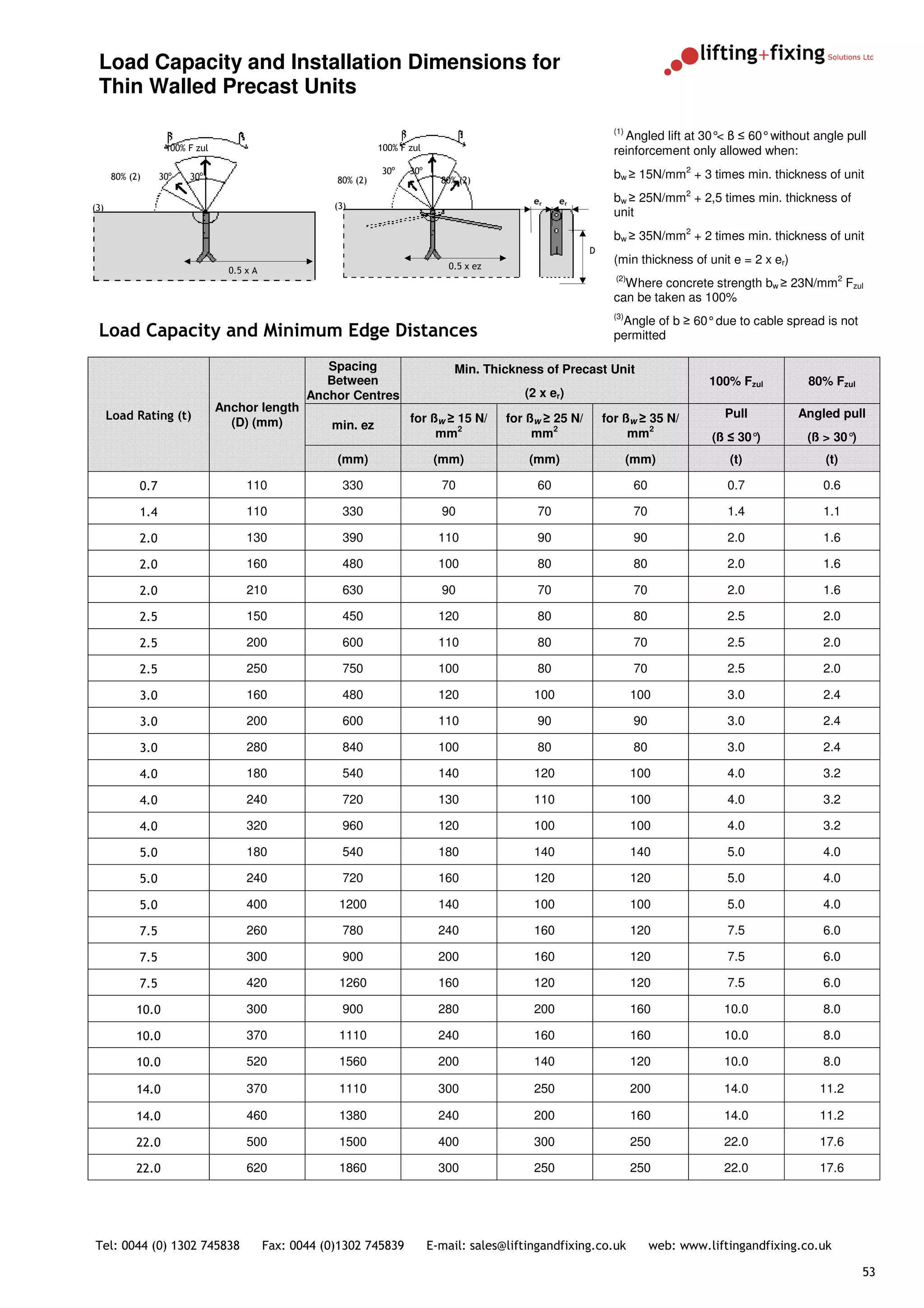

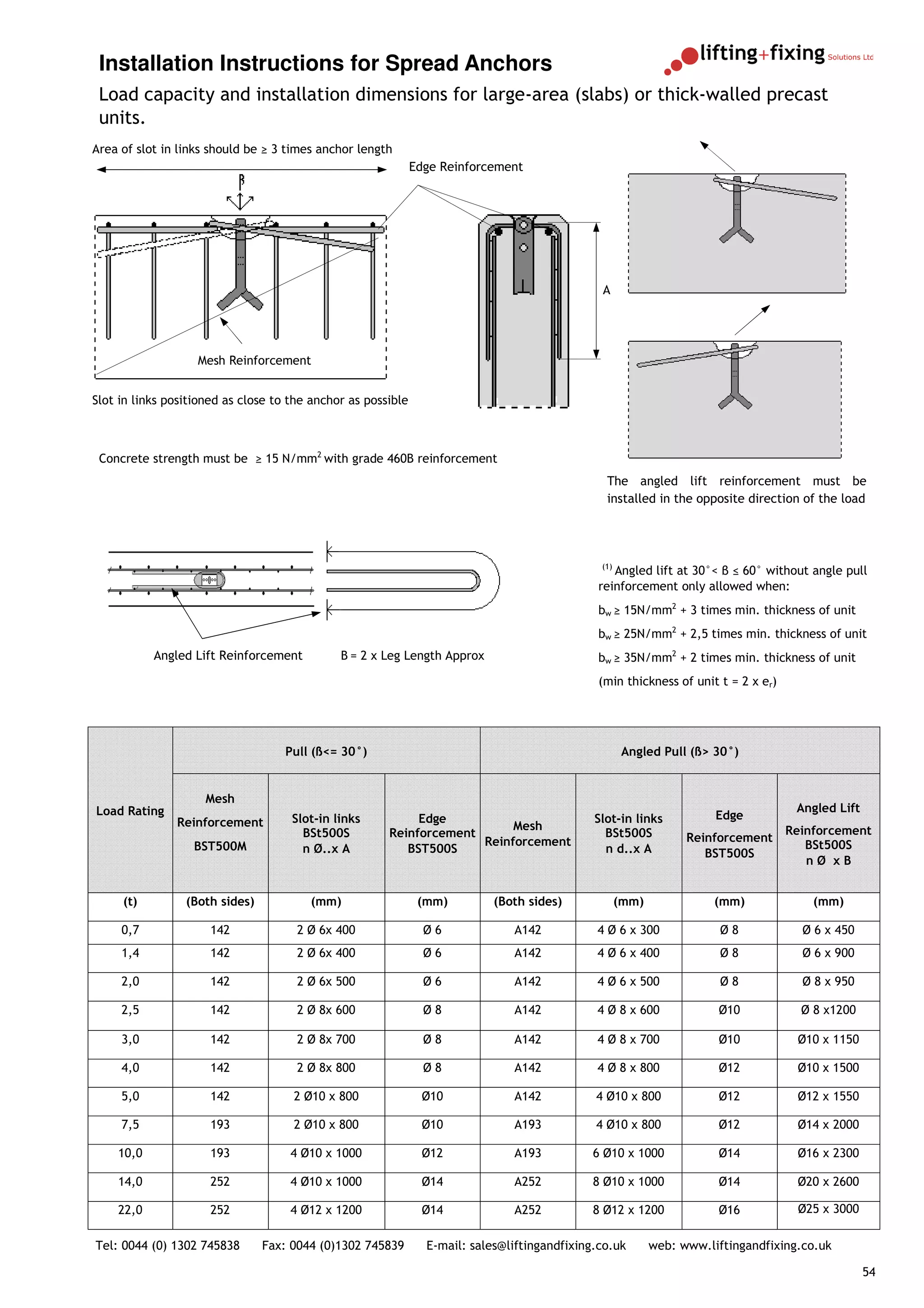

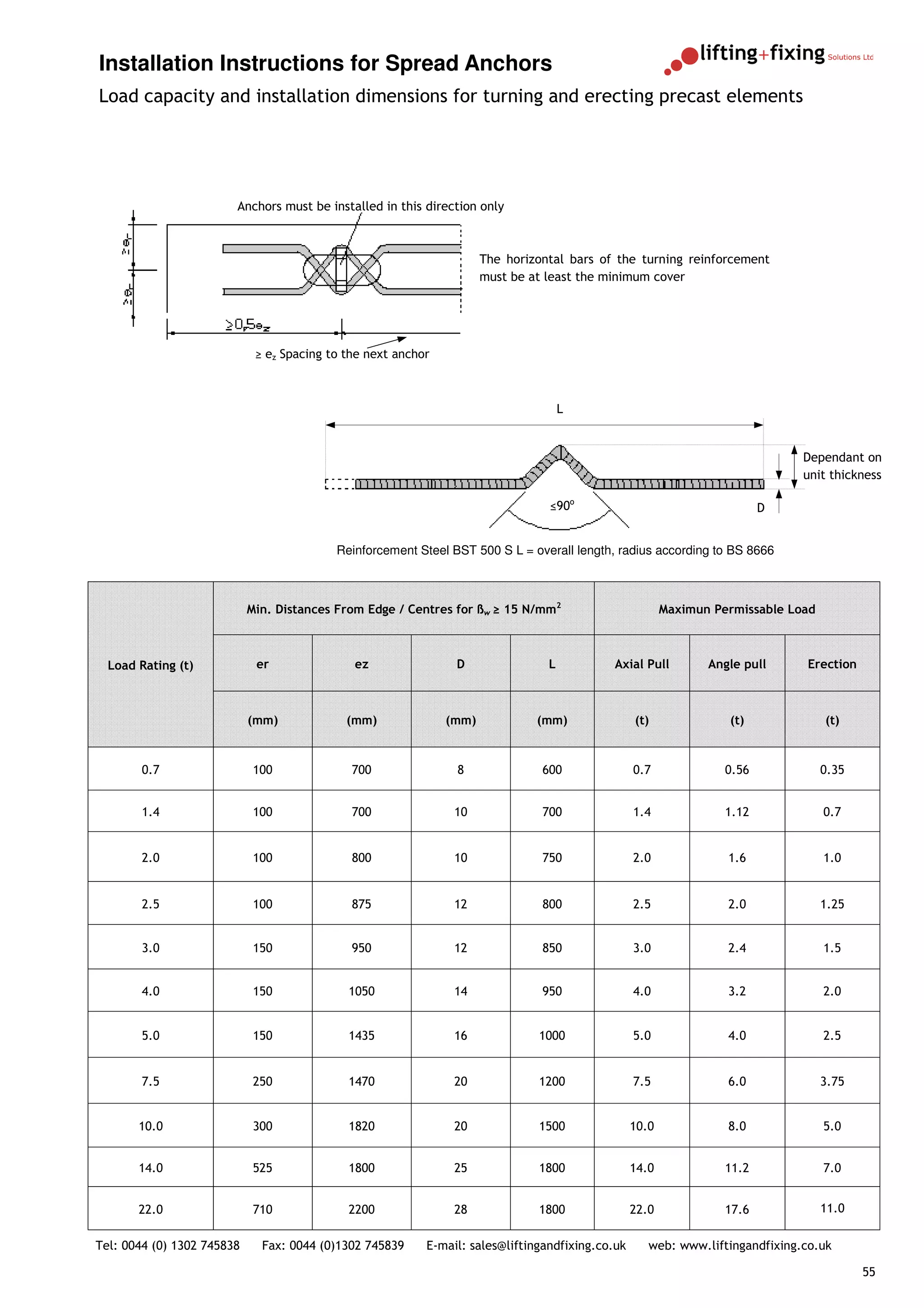

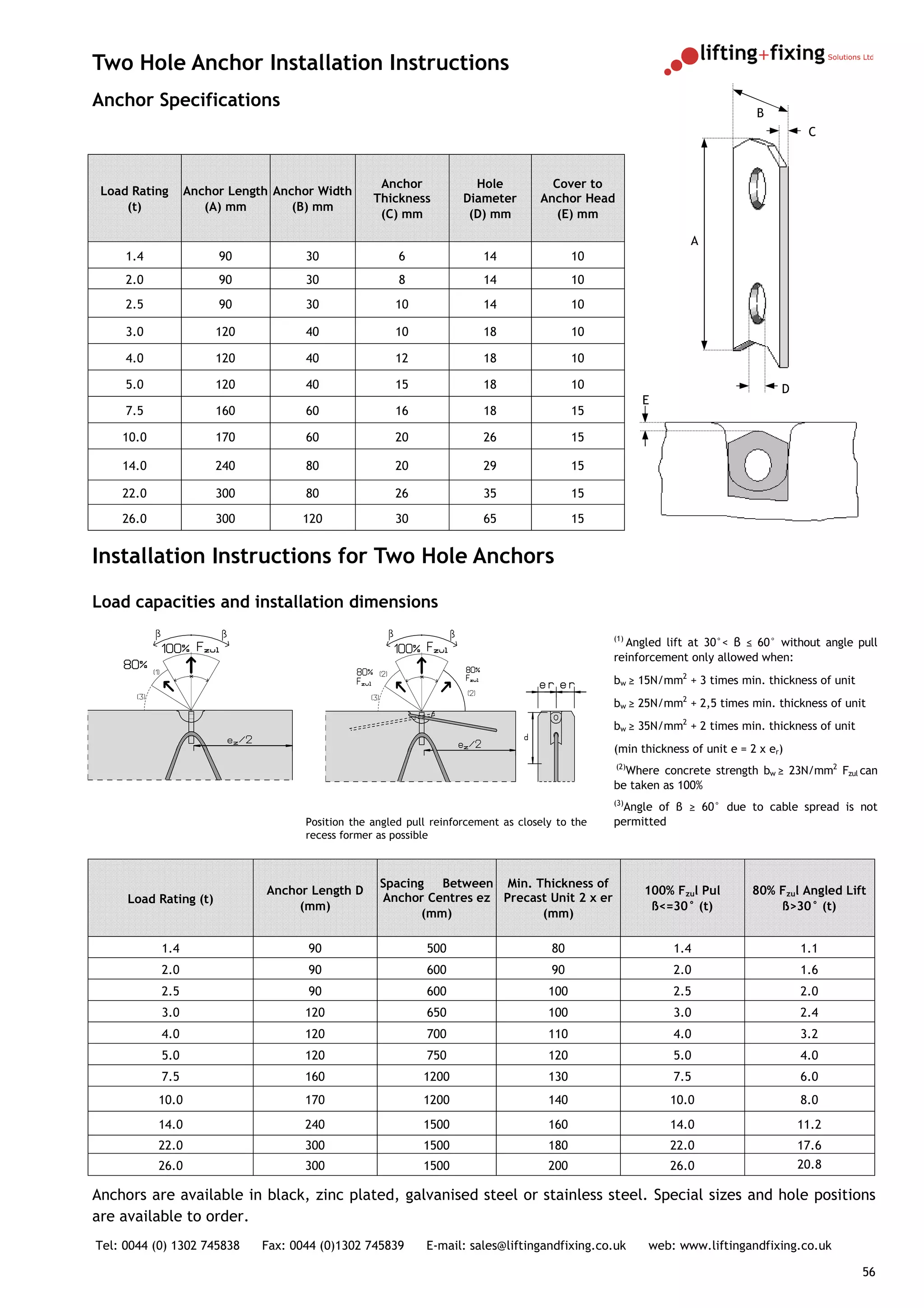

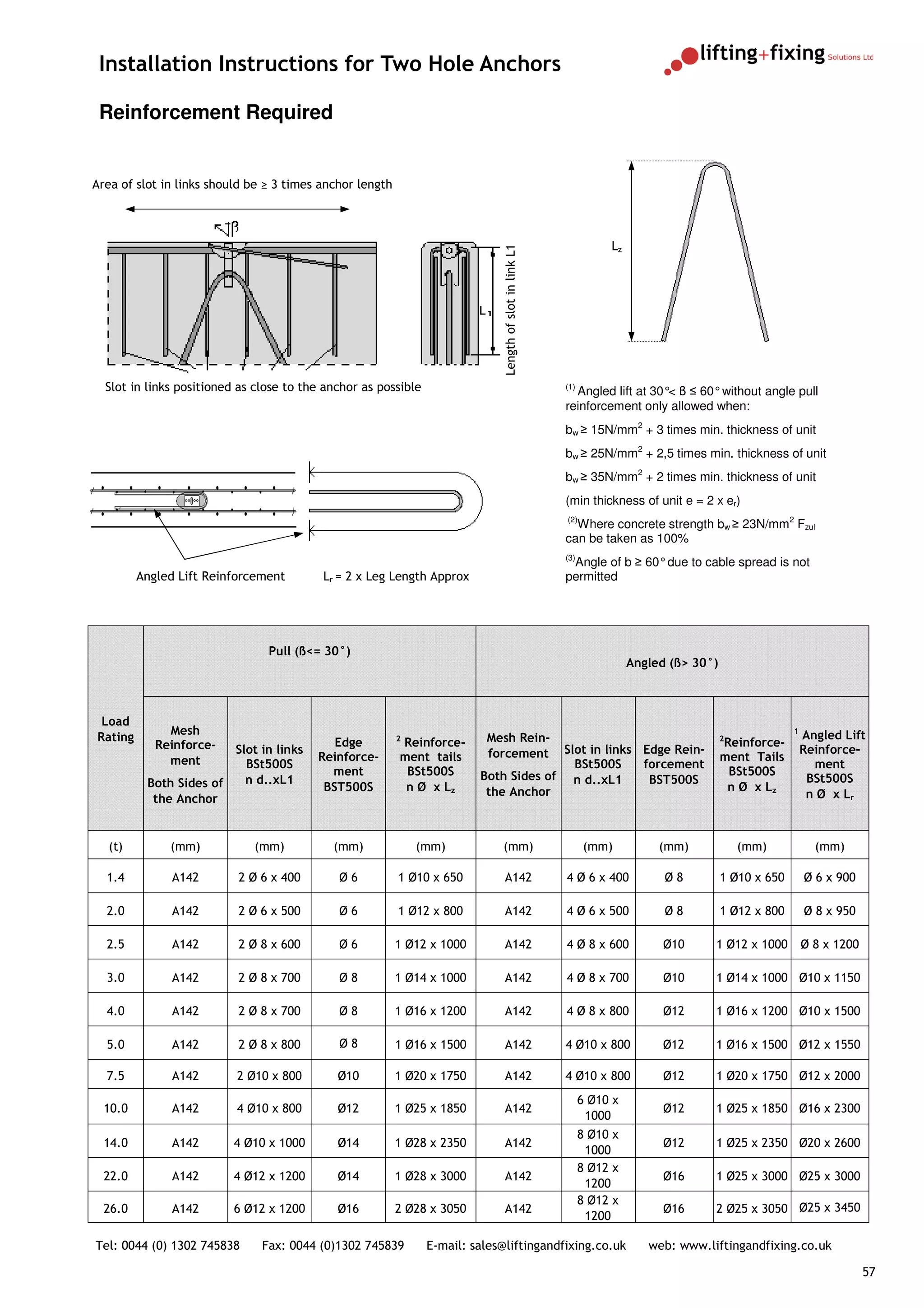

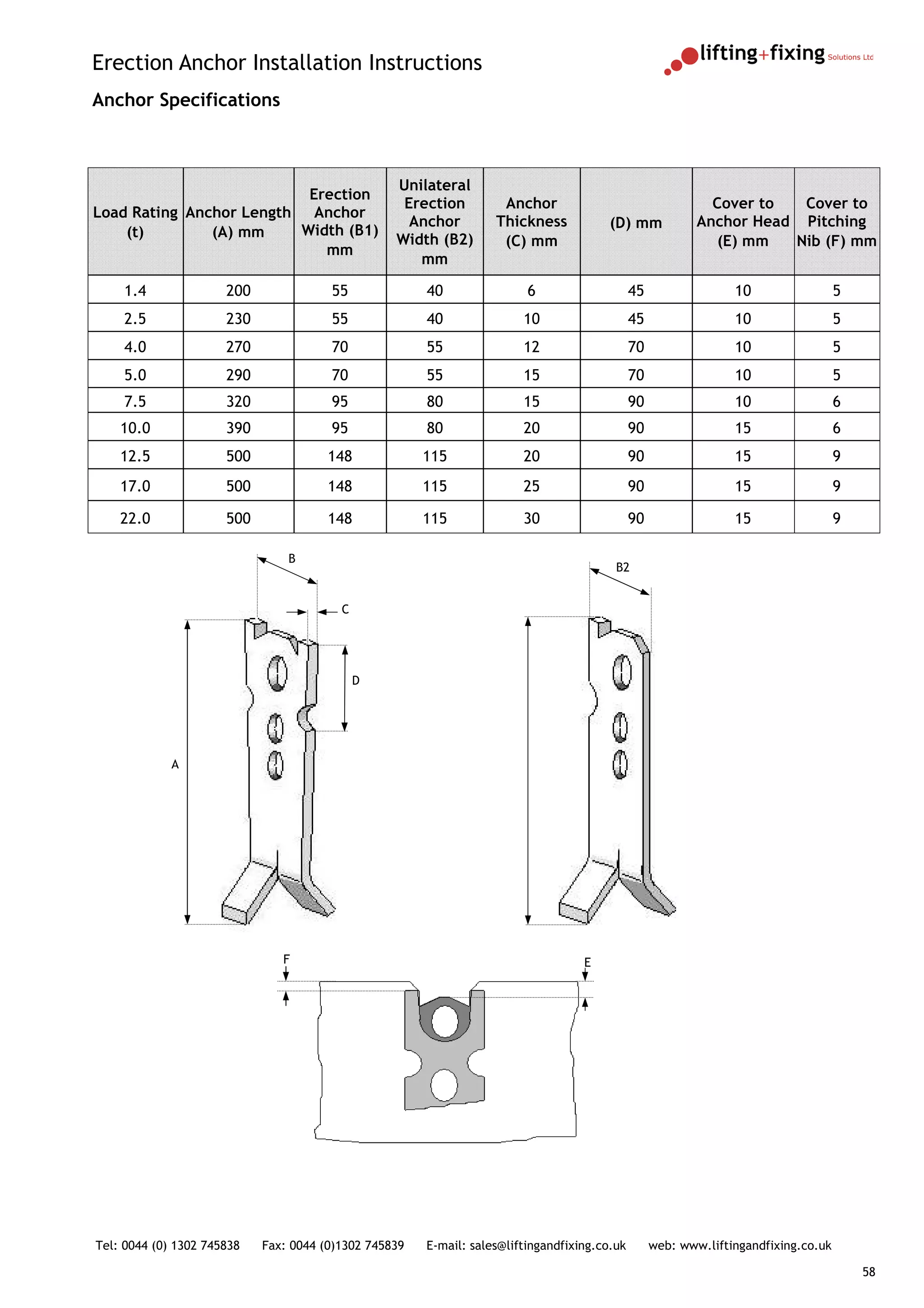

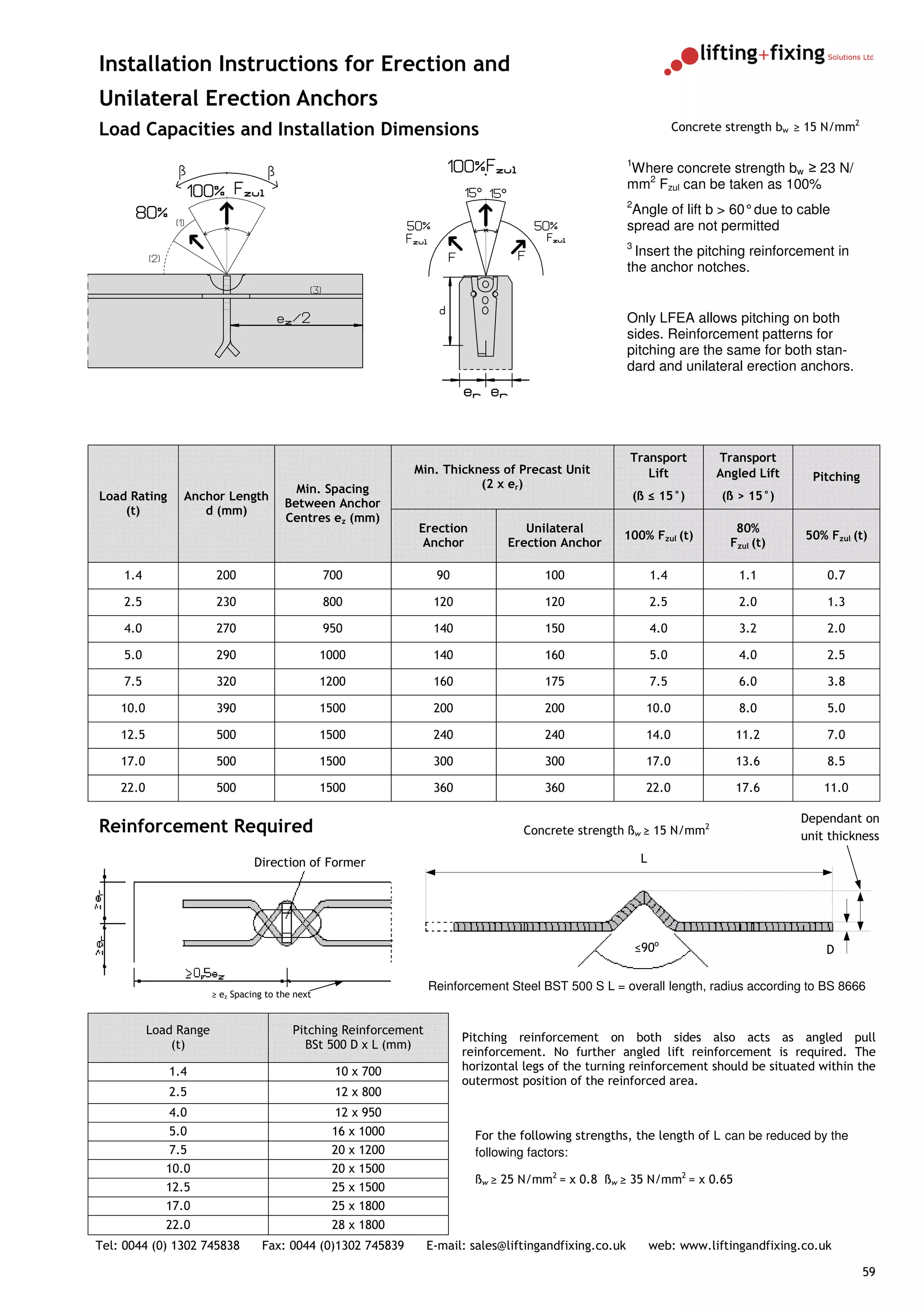

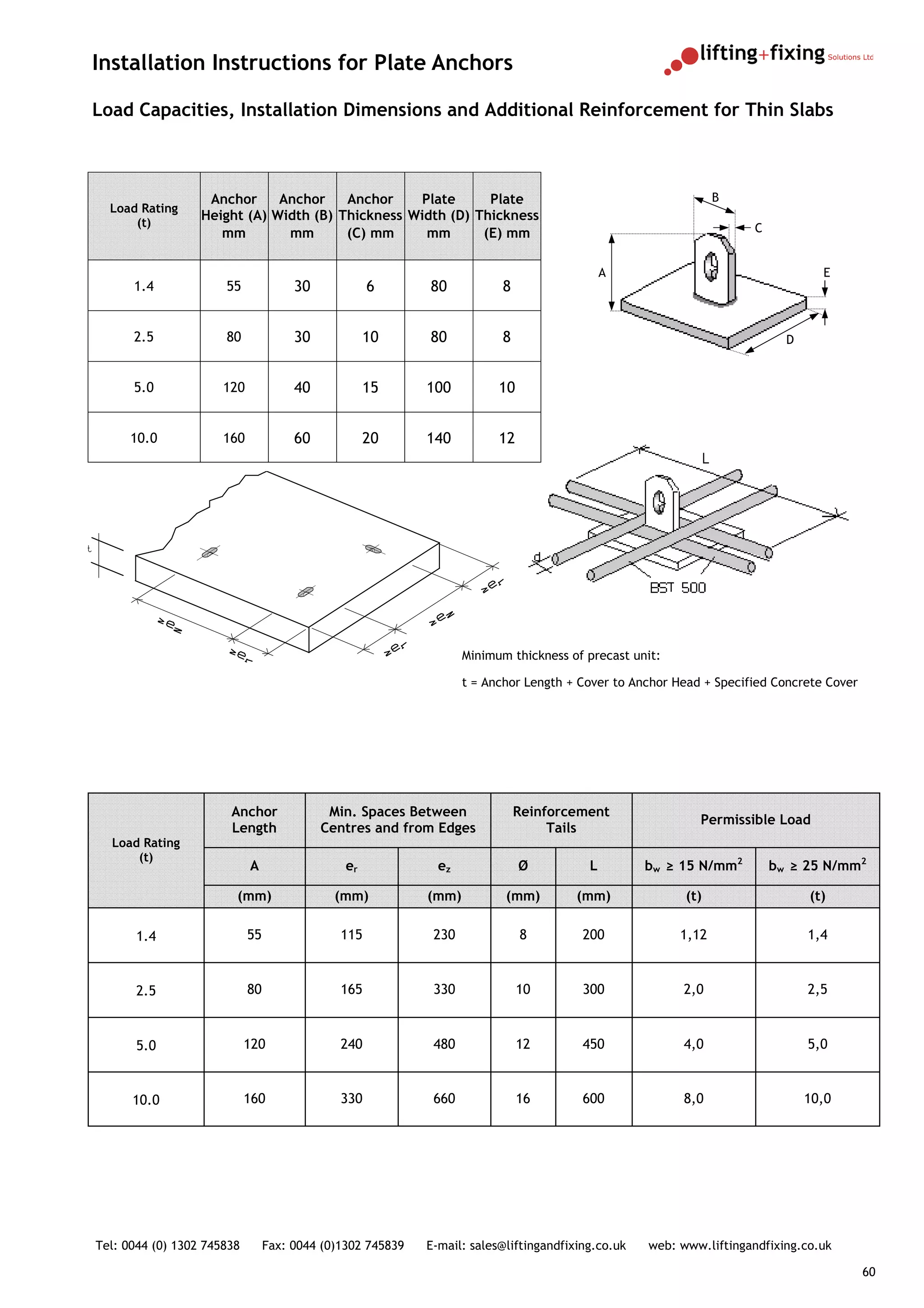

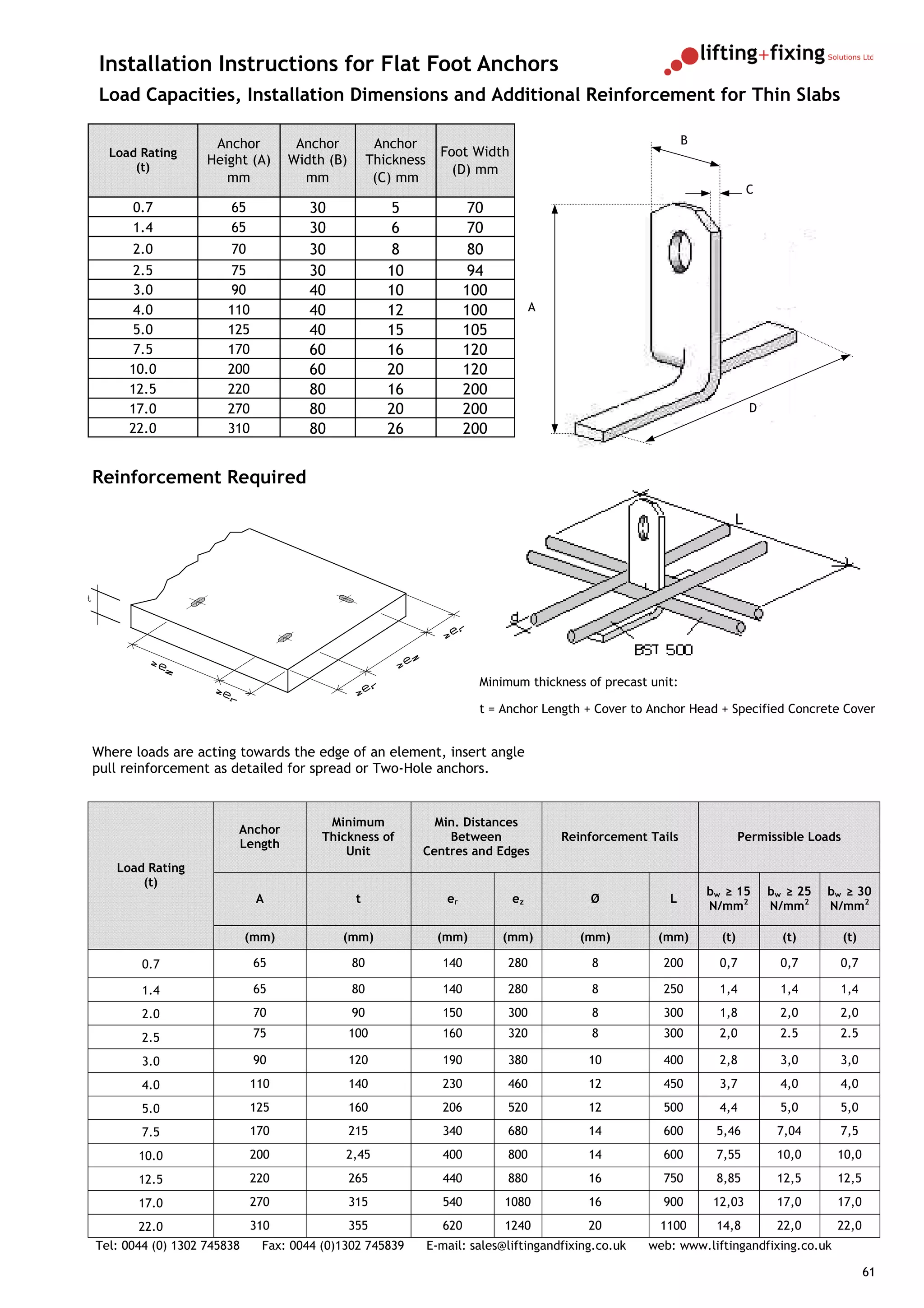

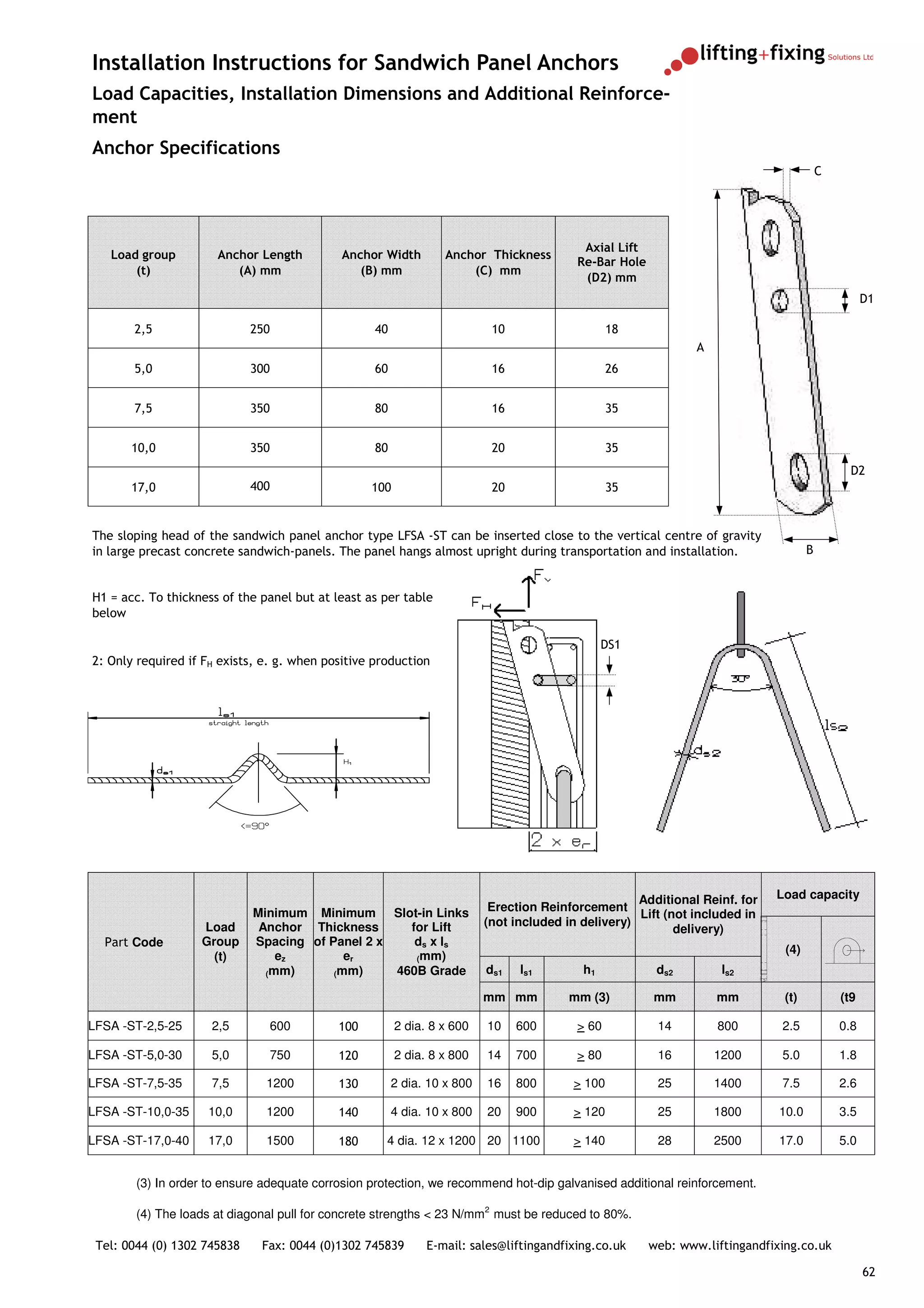

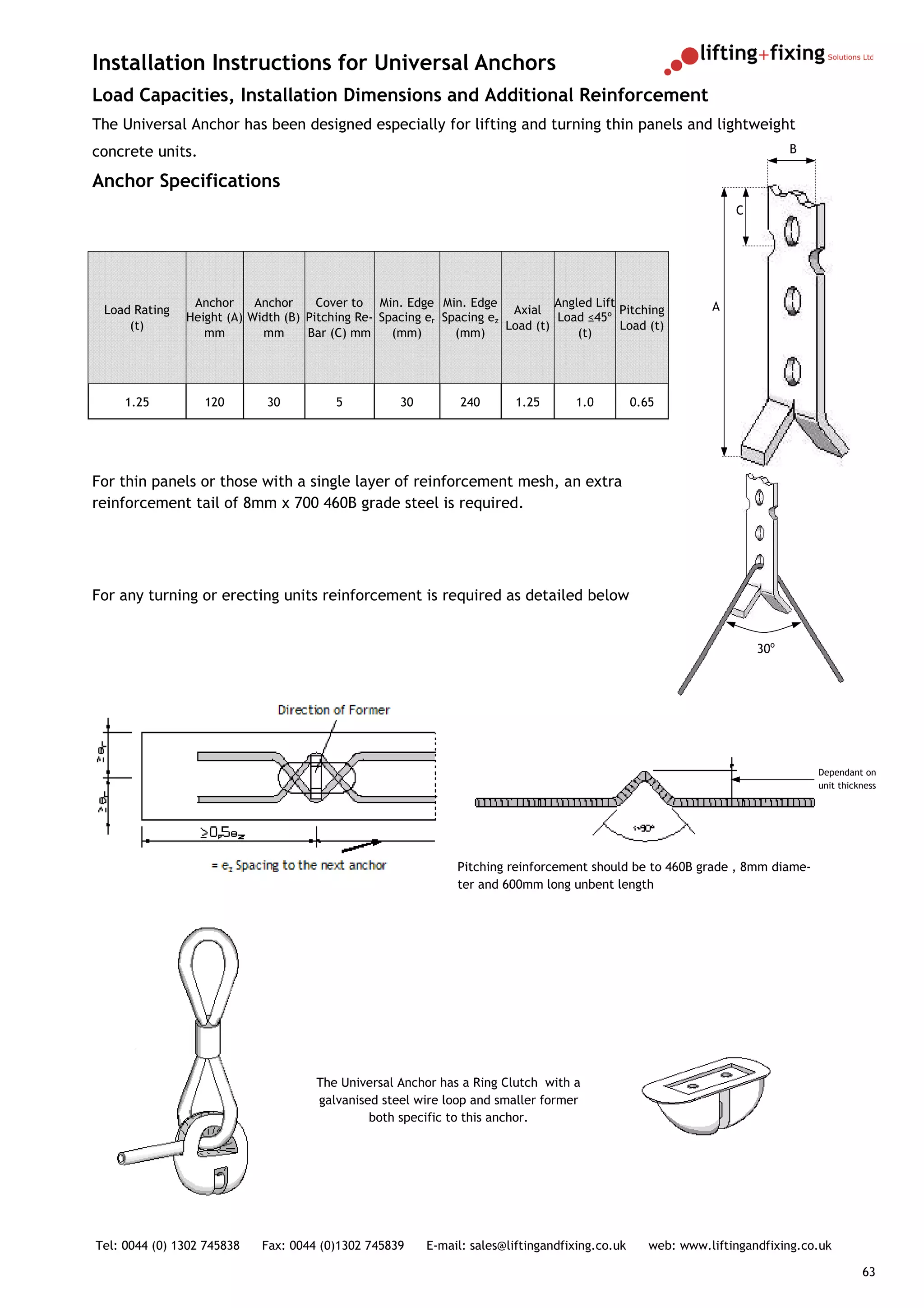

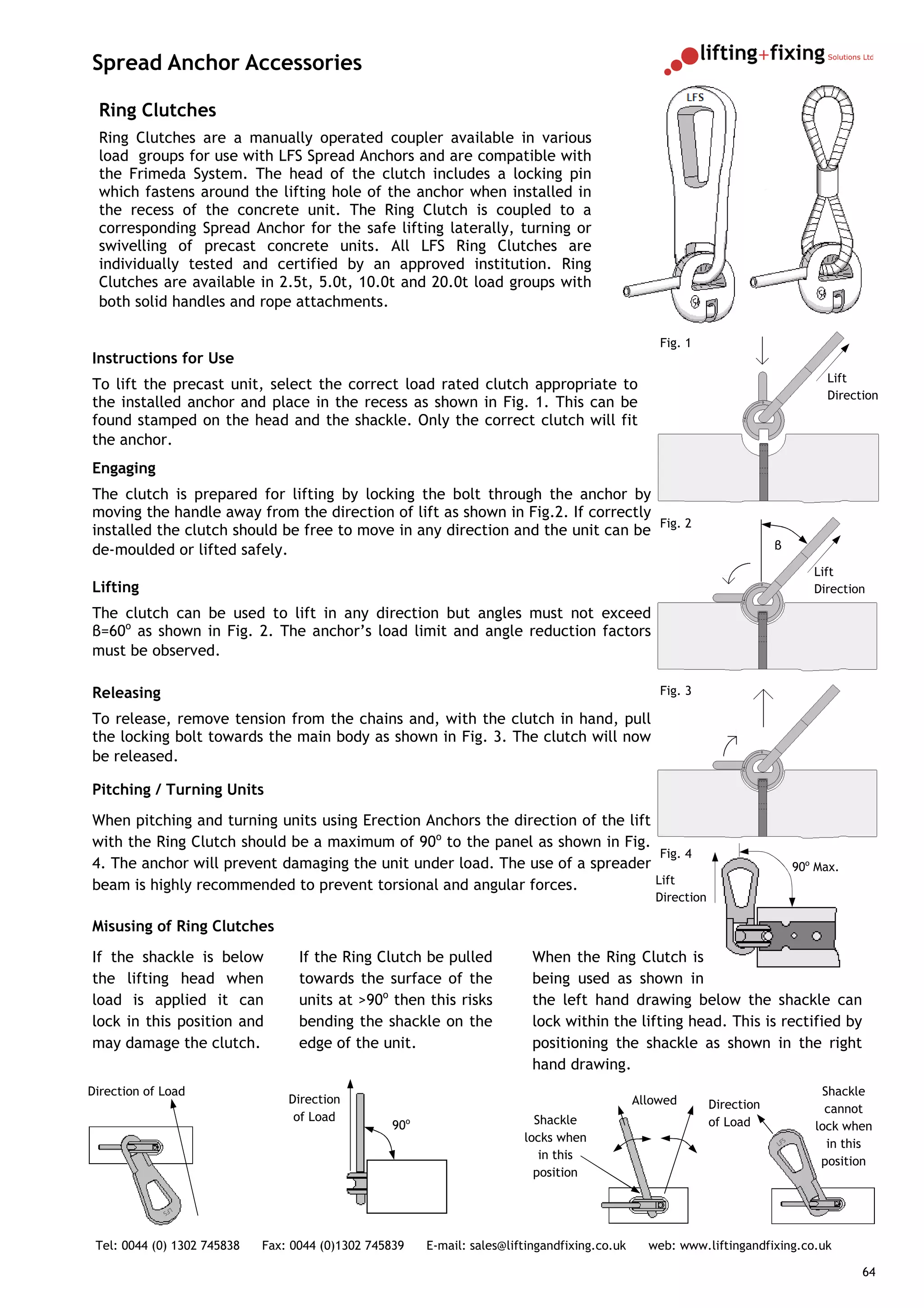

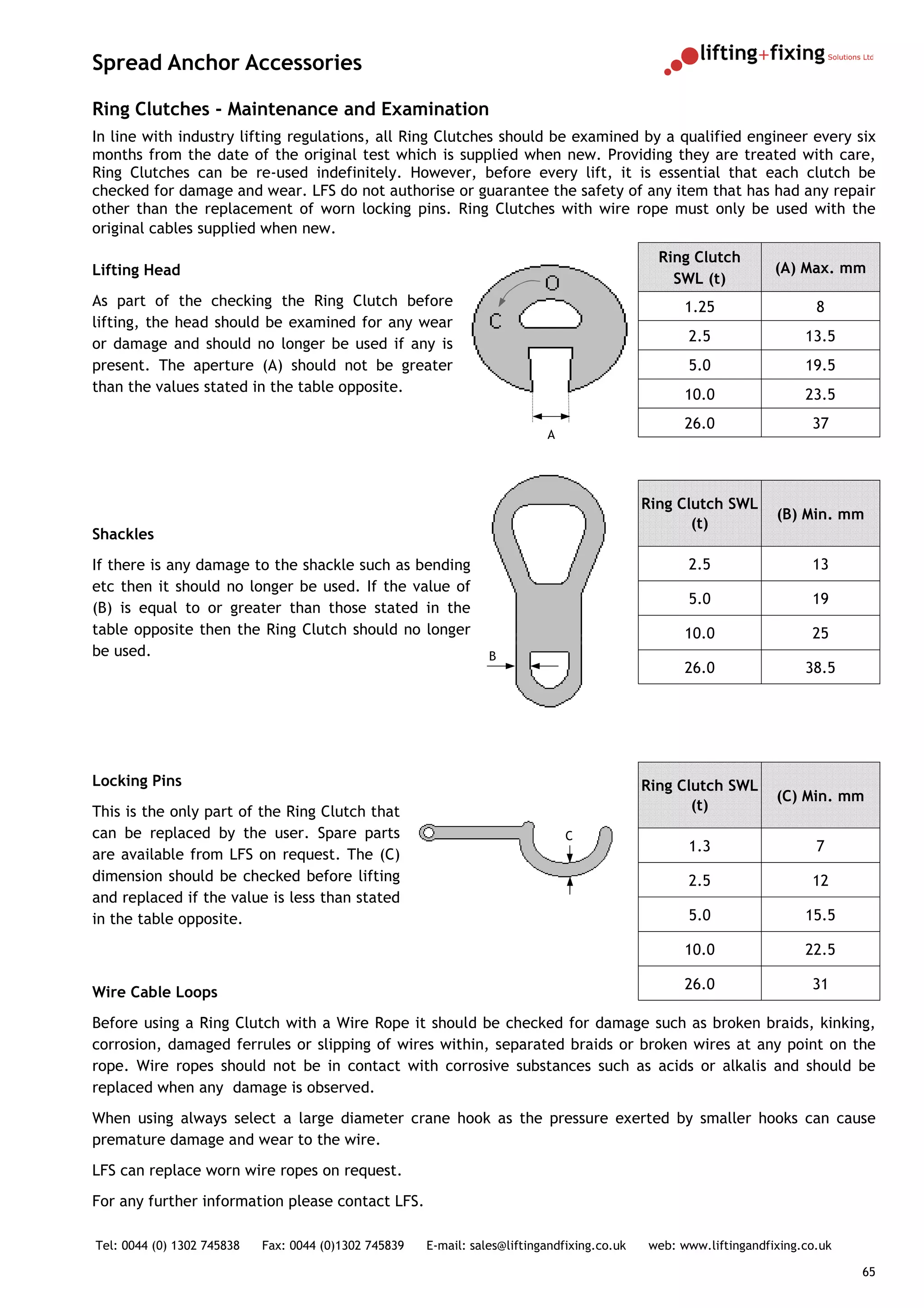

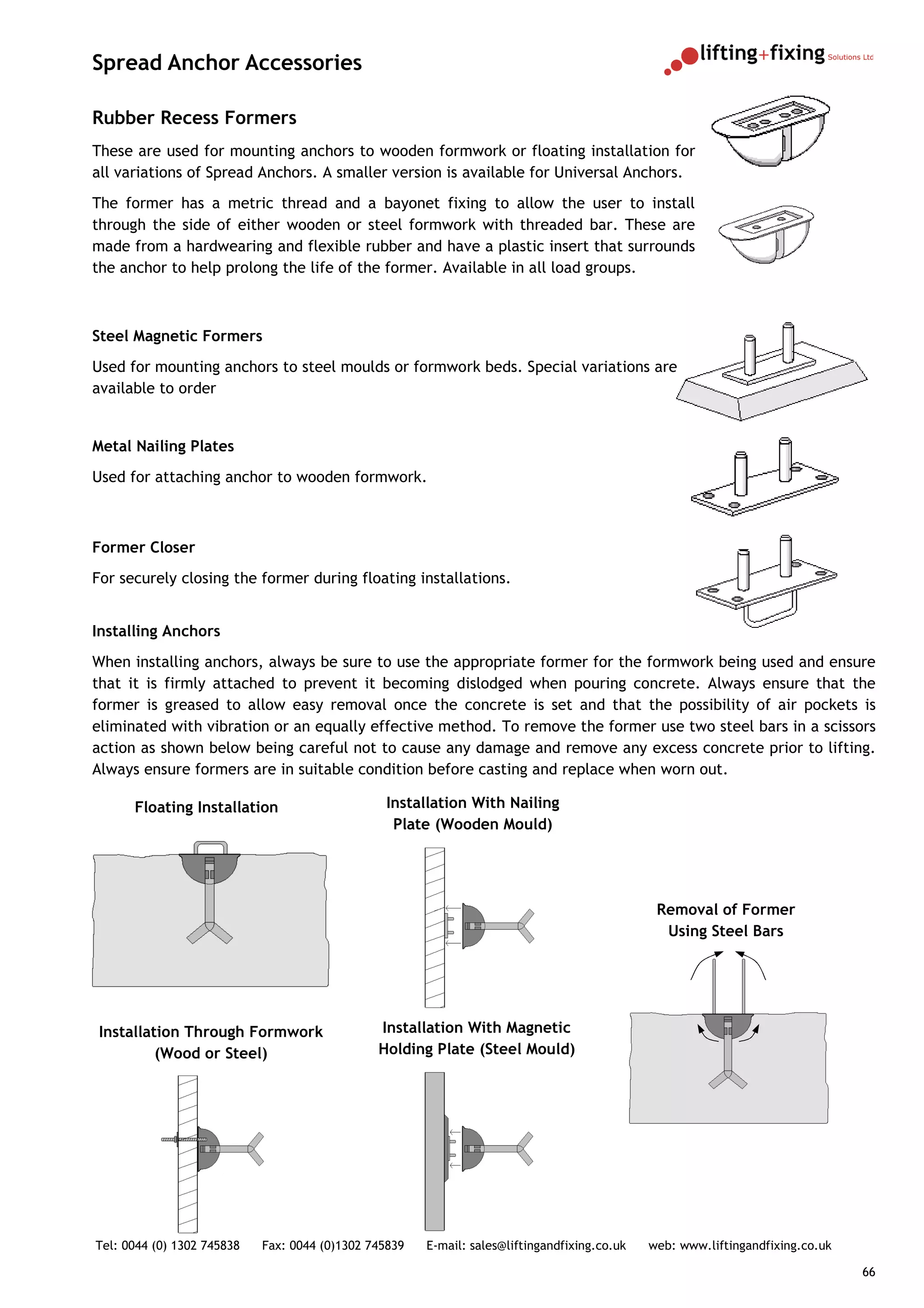

The document provides guidance on selecting and specifying lifting anchors for precast concrete structures. It discusses factors to consider such as the weight and dynamic loads of units, sling angles, and calculating anchor loads. The bulk of the document then describes the Capstan transport anchor system, including different anchor types, accessories, use, specification, and installation instructions. The system is designed for safely lifting, turning, and transporting precast concrete units with minimum embedment depths and edge distances provided.