Rebirth Of The Clamshell

- 1. Clamshell Diecutting ROBERT WEIDHAAS, JR. AND The clamshell diecutting press arguably has its NICHOLAS CRABTREE OF MY roots in the corrugated industry and was once considered the workhouse of most sheet plants. PRESS NEEDS EXPLORE THE The challenge initially for most sheet plants was LOVE-HATE RELATIONSHIP keeping up with the volume of production. The BETWEEN THE CORRUGATED clamshell was, let’s face it, considered slow and labor intensive. The solution was the automatic SHEET PLANT AND THE high-speed diecutter. As a result, many thought CLAMSHELL DIECUTTING PRESS. the days of the clamshell were over. Today, the long runs are not as plentiful and REBIRTH OF THE the focus is shifting to quick turnaround, which is to get the corrugated board diecut, off press, and out the door as quickly as possible. Despite CLAMSHELL the notion that the clamshell’s days are over, they remain in many sheet plants and are in fact contributing to productive diecutting more now 46 Corrugated Today May/June 2012

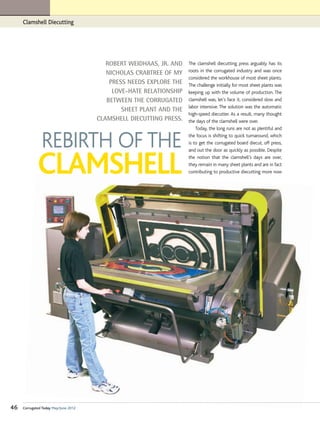

- 2. Clamshell Diecutting than even just a few years ago. prevents press action if the Why? Because the clamshell operator is in the hazard area. press remains the most The scanner is particularly efficient and profitable short important on “jumbo” clamshell run solution for today’s sheet presses, such as a 60- x 120-inch plant. because the operator may not be able to reach a traditional mechanical safety device if he or What About Safety? she is adjusting the die in the If this is the case, why then do press. The scanner protects the some companies want to operator like no other safety eliminate their clamshell device or technology, making presses in favor of less efficient the press extremely safe to systems, such as roller presses operate while not interfering and the like? One word: Safety. with productivity. The clamshell has a stigma of not being ABOVE: THE CREST a safe press to operate. Let’s be honest. CLAMSHELL Expanding into Many of the old clamshell presses, namely DIECUTTER those manufactured in the 1940s, had WITH THE P-O-P AUTOMATED limited or no safety devices. In the 1950s With larger and safer SHEET FEED and 1960s, however, air clutches were AND DELIVERY clamshell presses many introduced along with improved safety STACKING sheet plants are SYSTEM.. guards. Today’s presses, on the other hand, diversifying into the RIGHT: THE feature additional safety circuitry and ANSI SAFETY growing point-of-purchase devices that quickly and safely stop the REQUIREMENTS markets. In fact, over the FOR GRAPHIC press action. last several years, the large TECHNOLOGY Interestingly, the automobile has a very EQUIPMENT format market exploded similar past. Early models were often AND SYSTEMS in packaging, P-O-P and STANDARD, considered unreliable and even harmful. As SPECIFICALLY digital print. Therefore, with today’s presses, cars evolved to THE B65-5:2011 how does today’s P-O-P include improved safety devices and PART 5: STAND- and corrugated sheet plant finish work ALONE PLATEN PRESSES, IS A “HOW TO,” TO technology, such as crumple zones and ACHIEVE OPTIMAL CLAMSHELL PRESS SAFETY. coming off a high speed printer? What advanced engineering to make the about the trending digital printers that run automobile lighter and safer than the old circuitry that creates a redundancy in the sheet sizes as large as 62- x 102-inch at heavy-gauge steel models. safety circuit, much like the redundant speeds up to 175 an hour, and gaining Yet another example is the aircraft systems on airplanes. Today’s sheet plants speed seemingly every quarter? Initially industry. While Wilbur and Orville Wright have access to the ANSI Safety many thought the digital diecutter (laser achieved flight in 1903, air travel would Requirements for Graphic Technology and plotter) would meet this demand; not have been defined as safe. Today, due Equipment and Systems Standard, however, the average digital diecutter runs to advances in safety technology, air travel specifically the B65-5:2011 Part 5: Stand- only 15-30 sheets an hour, creating a is indeed the safest way to travel. alone platen presses. This standard is bottleneck in this high speed, large format Today the clamshell press is safer than essentially a “How To,” to achieve optimal production environment. ever and offers the fastest setup times, clamshell press safety. In many instances, diecutting teams high-tonnage, and precision registration One new technology described in the returned to traditional steel rule die for the ever increasing demand from ANSI standard and found on the large technologies that allowed them to cut an printed corrugated packaging. Presses, such clamshells is laser scanner technology, entire sheet with multiple parts in one as the Crest Clamshell, have safety relay which scans the moving platen area and impression, moving away from slower Corrugated Today May/June 2012 47

- 3. continued Clamshell Diecutting ability to handle awkward materials that may be flimsy or warped. To coin the phase, if it’s not broke don’t fix it; hand feeding is fast and efficient when dealing with today’s short runs. Setting up the machine is also very simple. This is because the operator has immediate access to the entire work area: the die, the cutting area (referred to as the platen), the feed pile as well as the delivery or stack pile. The operator quickly installs the steel rule in the press either with a chaseless die system (typically screws) or a more automated system such as an automatic die chase found on the Crest Clamshell. Once the die is installed, the operator aligns the sheet to be diecut, mounts the register / sheet stops and BECAUSE THE OPERATOR HAS ACCESS TO THE WORKING AREA, THE MAKEREADY AND SPOT UP begins a makeready process. Because the PROCESS IS SIMPLE AND FAST. operator has access to the working area digital systems. As a result diecutting IT IS THE ABILITY TO DIECUT and many presses have hinged or departments realized significant IN REGISTRATION THAT pneumatically actuated cutting plates, the production gains when they installed a makeready and spot up process is simple MAKES IT SUPERIOR TO clamshell or flatbed diecutter, where the and fast. The operator simply adds ALTERNATIVE TECHNOLOGIES issue then becomes how fast can the press makeready tape to an area or two within setup, run, and start the next job. This IN THIS SHORT RUN CLASS. the die that is not cutting and the job environment of more jobs per shift lends meters) to 120 inches (3 meters). The moves directly into production. itself to the clamshell diecutter. most common Crest Clamshell is the 40- x This unique access to the work area is 56-inch used in sheet plants; however, you what has some concerned with safety; will also frequently find the Thomson 38- x however, it is this access that offers the Productive & Versatile 54-inch and 44- x 66-inch clamshell in incredibly fast setup and operation of the Clamshell diecutting is one of the most corrugated plants. The clamshell can cut press. This fact is why advances in safety versatile forms of diecutting available to very thin or very thick materials to precise such as the laser are so valuable for new any converting plant. It cuts a wide range tolerances; it is the ability to diecut in presses being installed and also for existing of materials from warped corrugated registration that makes it superior to presses. sheets, heavy duty grades, P-O-P displays alternative technologies in this short run Safety is not the only technological and just about any job found within a class. improvement with today’s clamshell. corrugated sheet plant. To give you an idea of the types of Valley Container in Bridgeport, Conn., With the ability to diecut, crease, and materials and products cut on these purchased the Crest Clamshell to replace score sheets as well as emboss or machines, below is a sample list: its Thomson press. At the time, the sheet physically imprint sheets, there is no press • Foam Core plant was looking for a quality press that more versatile than the clamshell. Add to • Corrugated (all flutes) offered the same level of reliability but this versatility ease of setup, high tonnage • P-O-P Displays with improved technology and setup capabilities, and minimal operator learning • Folding Cartons times. The Crest Clamshell is known as the curve and the clamshell stands out as a • Plastic corrugated cut and sealed “No More Make-Ready” Clamshell as a valuable tool for today’s sheet plants. The These machines are generally hand fed for result of new technology in press design machines range in size from 28 inches (.75 ease of operation with large sheets and the and manufacturing processes. Specifically, 48 Corrugated Today May/June 2012

- 4. continued Clamshell Diecutting the anti-deflection platen on the Crest is using heat to cut plastic is the added knife Heat can also be added under the steel engineered using a science called finite penetration into the material and the cutting plate, which helps some materials analysis, which measures the deflection of improved cut quality as a result. to lay flat during the cutting process. the press at full load. From this data, it is Using heat along with a timed dwell in Cintra is a good example because it cuts engineered using a proprietary design, the cutting action can greatly increase the without fracturing when warm. honey-comb steel construction, and possibility of a clean cut. The dwell simply The clamshell press has been a solid welding techniques. Valley Container means physically stopping the press on choice of diecutters for many years. It offers purchased the press because it will set impression for a predetermined period of fast, efficient operation and versatility up and begin production within 10 time to allow added heat transfer from the found in no other press technology. Today, minutes. die to the material — another unique the clamshell has undergone significant benefit with the clamshell press. This developments in engineering. Mechanical, option can also be used to seal or fuse the electrical, operational, and safety Automation edges of materials together; plastic engineering advances in the clamshell press While hand feeding the clamshell is fast corrugated or plastic laminated foam core have set the stage for the rebirth of this old and efficient, today you can have the best can now have a cleanly sealed edge. This is workhorse. of both worlds, which is the ability to hand helpful in preventing moisture from feed short runs and automate medium- entering the fluted edges or the softer Robert Weidhaas, Jr. is President and long runs with one press system. For inner cores for certain indoor and outdoor Nicholas Crabtree is Vice President of example, the Imperia and the Crest packaging applications. Technical Sales of My Press Needs LLC. clamshell are both available with automatic Weidhaas has spent 23 years in the sheet feed and delivery stacking systems TODAY YOU CAN HAVE converting industry with a special emphasis — one press, two methods of operation. on clamshell press technology. He is an THE BEST OF BOTH active observing committee member for the WORLDS, WHICH IS THE ANSI B65 safety standard for stand- alone Plastic Corrugated ABILITY TO HAND FEED platen presses. Crabtree has more than 30 The clamshell diecutting presses also come SHORT RUNS AND years of converting industry experience. He with other features that assist operators in contributes to a technical blog AUTOMATE MEDIUM- cutting a variety of substrates. Most www.mydiecuttingblog.com about die clamshell manufacturers offer the option LONG RUNS WITH ONE design, applications and helping to solve of a heated platen; this allows the back of PRESS SYSTEM. today’s diecutter challenges. the die to be heated. By heating the die, the heat is conducted through the steel rule resulting in a hot knife edge to improve the quality of the diecut. It should be noted that when diecutting, you are actually compressing the material under the knife edge to the point of explosive penetration, not actually cutting in the true sense of the word. When cutting plastics, the challenge is developing enough knife penetration to prevent cracking prior to this explosive separation. Heat assists with penetration and thereby improves the quality of the cut edge by helping to reduce cracking. This process also reduces tonnage, or the force required to cut the plastic, but the key benefit in 50 Corrugated Today May/June 2012