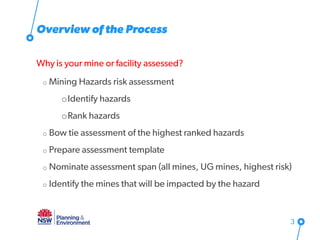

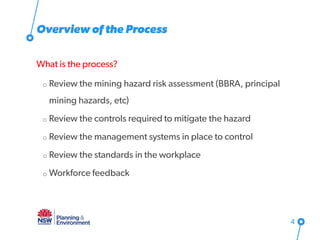

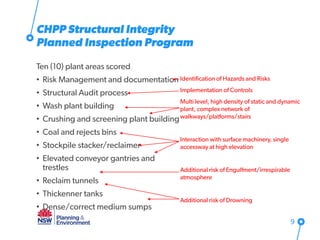

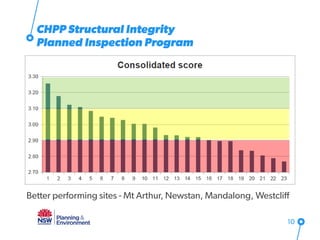

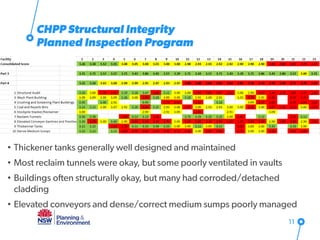

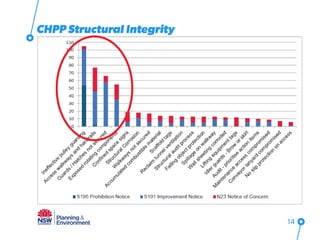

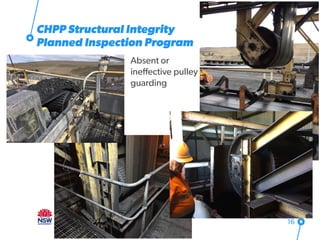

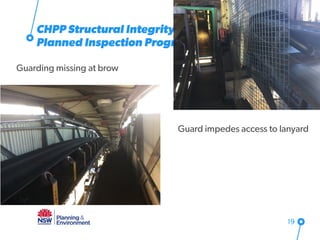

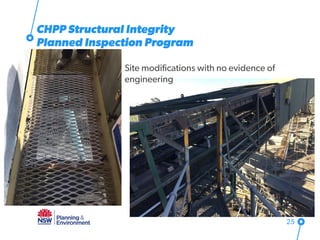

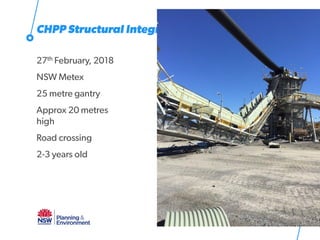

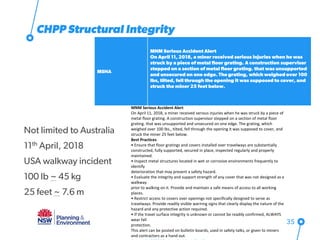

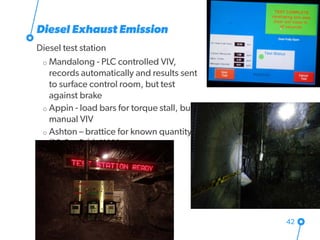

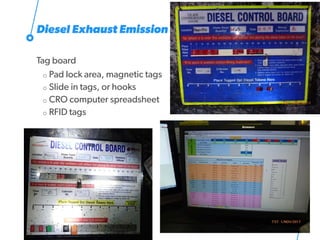

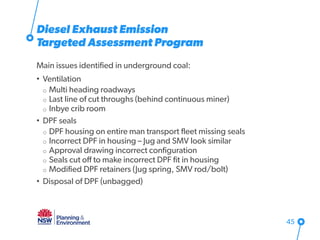

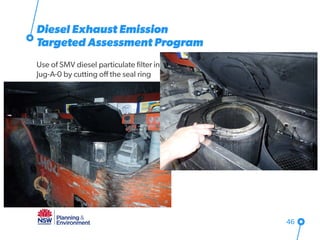

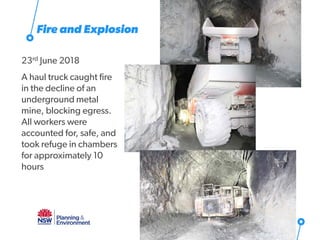

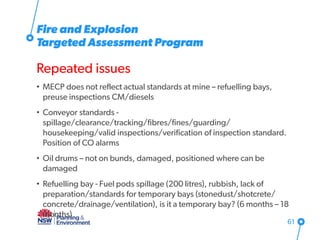

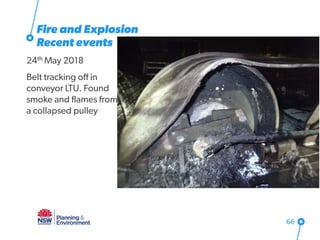

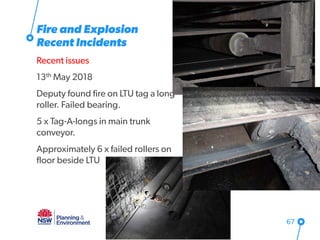

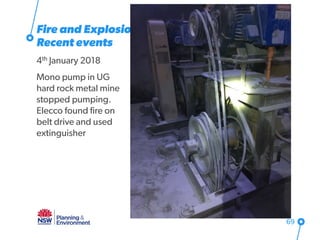

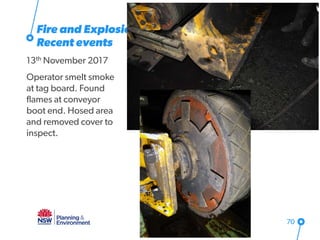

The document provides an overview of targeted assessment programs focusing on mechanical hazards at mines, specifically structural integrity of coal handling and preparation plants, diesel exhaust emissions, and fire and explosions. It describes the process, focus areas, issues identified, and good practices noted during inspections. Repeated issues found included absent or ineffective guarding, corrosion, and lack of effective controls for conveyor fires, diesel engines, flammable liquid storage, and hot work.