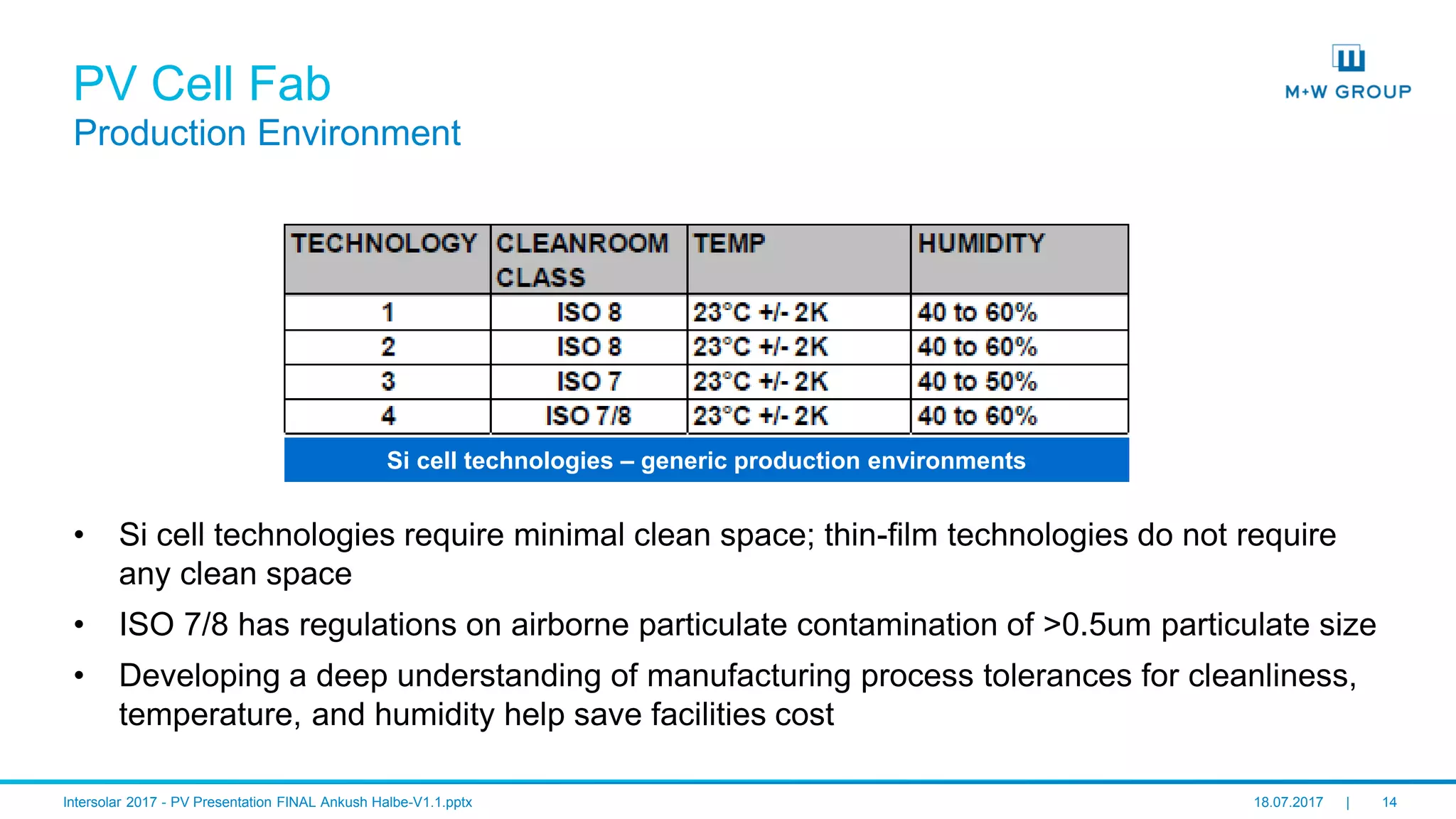

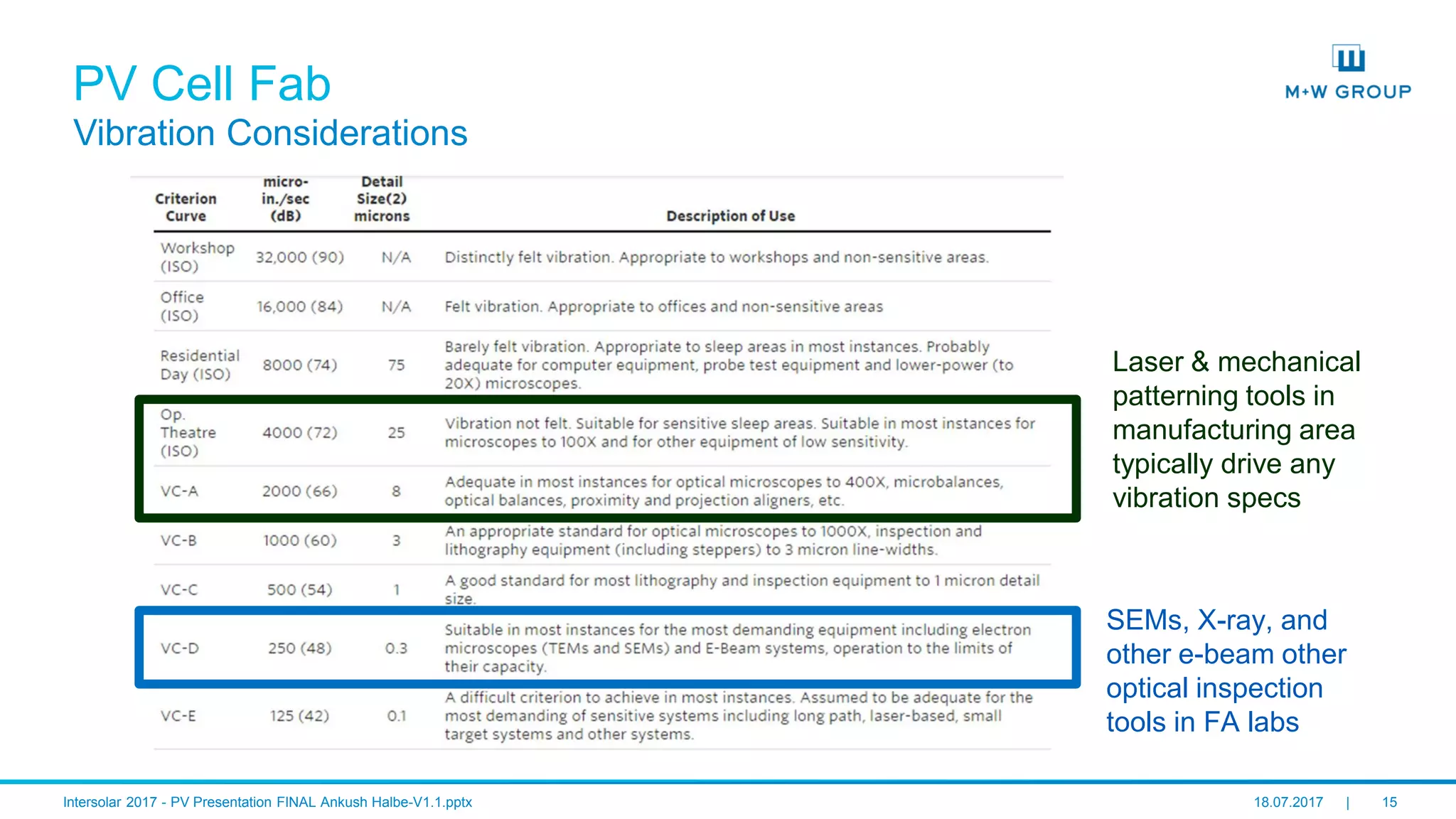

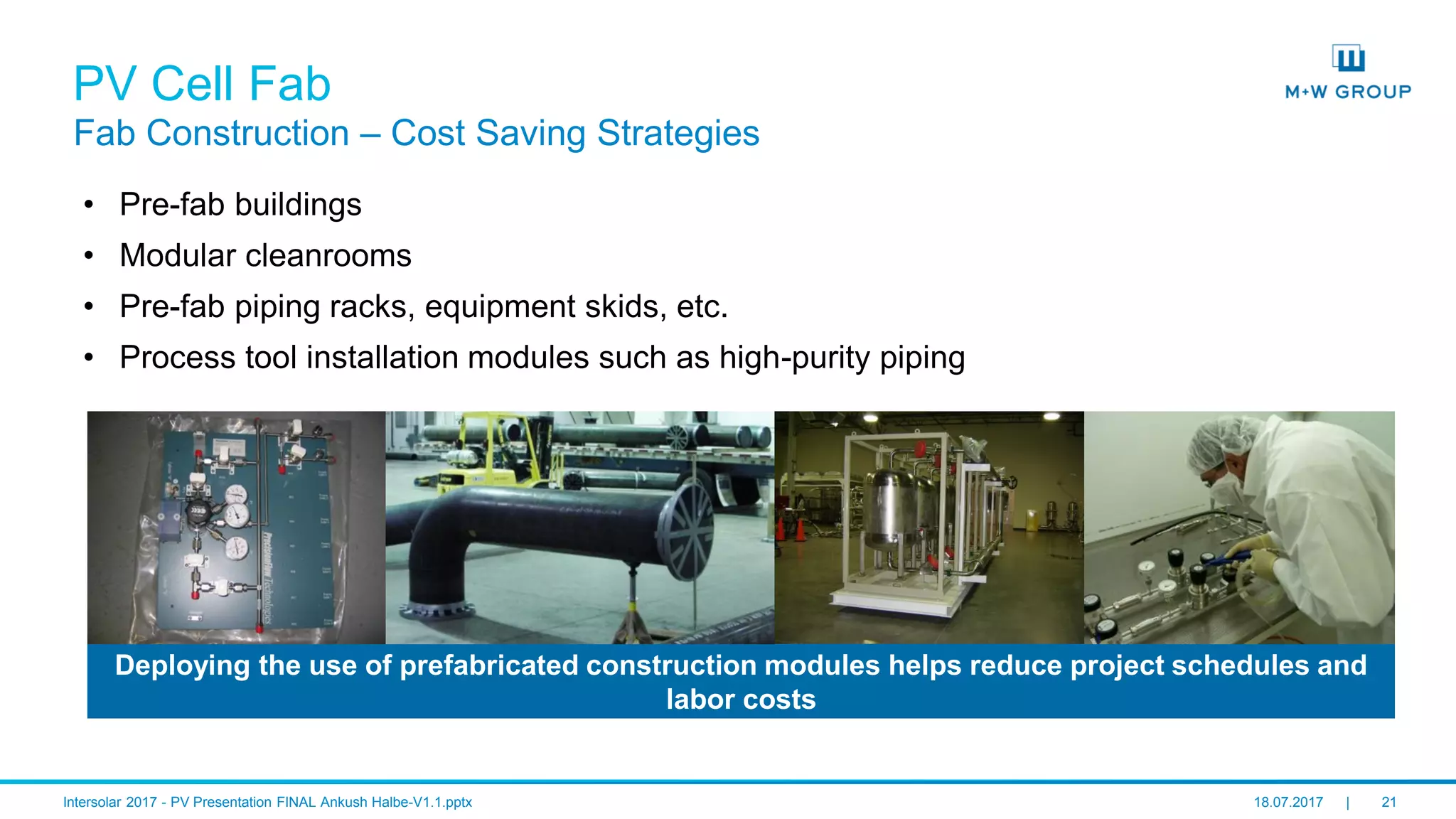

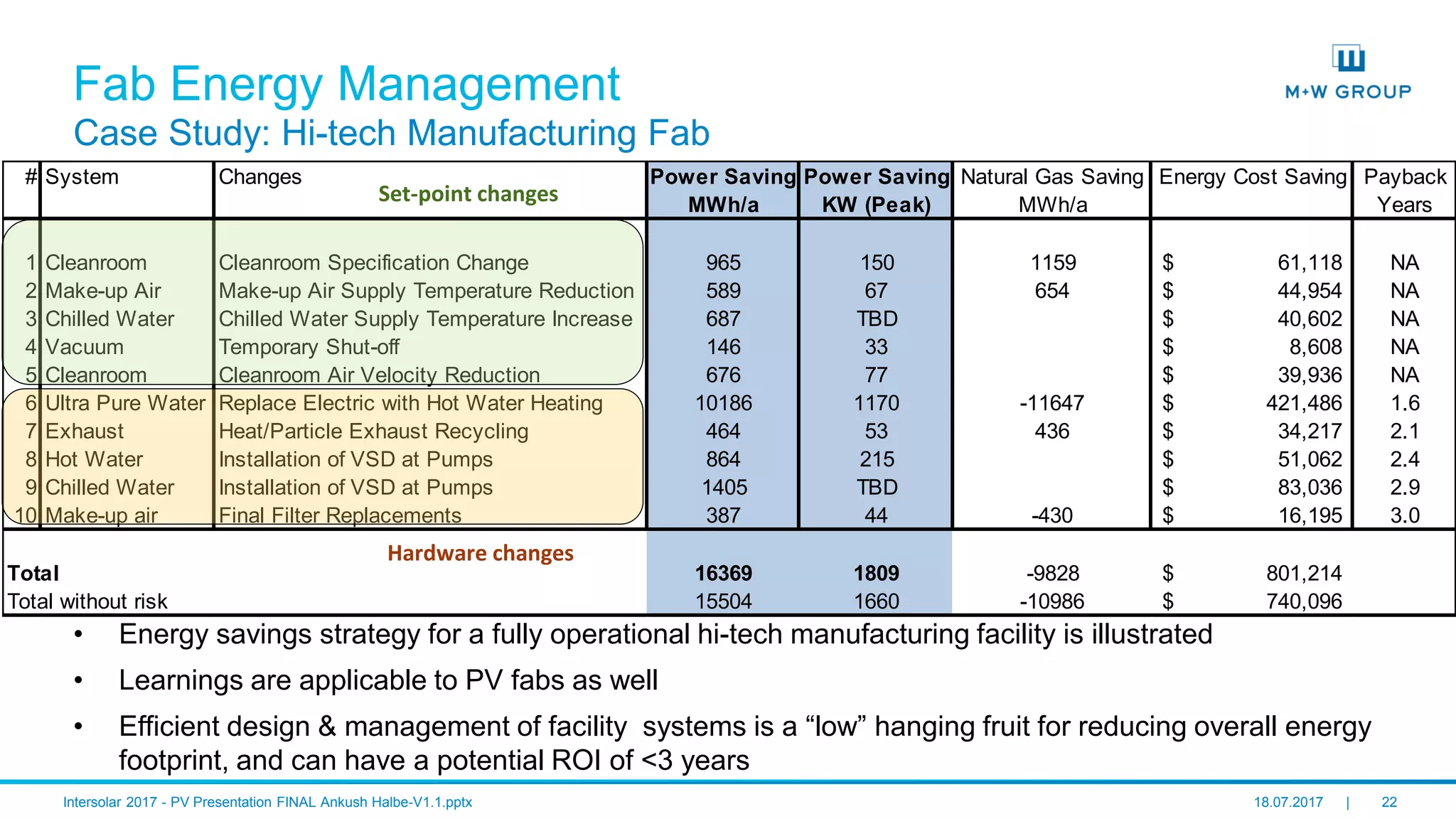

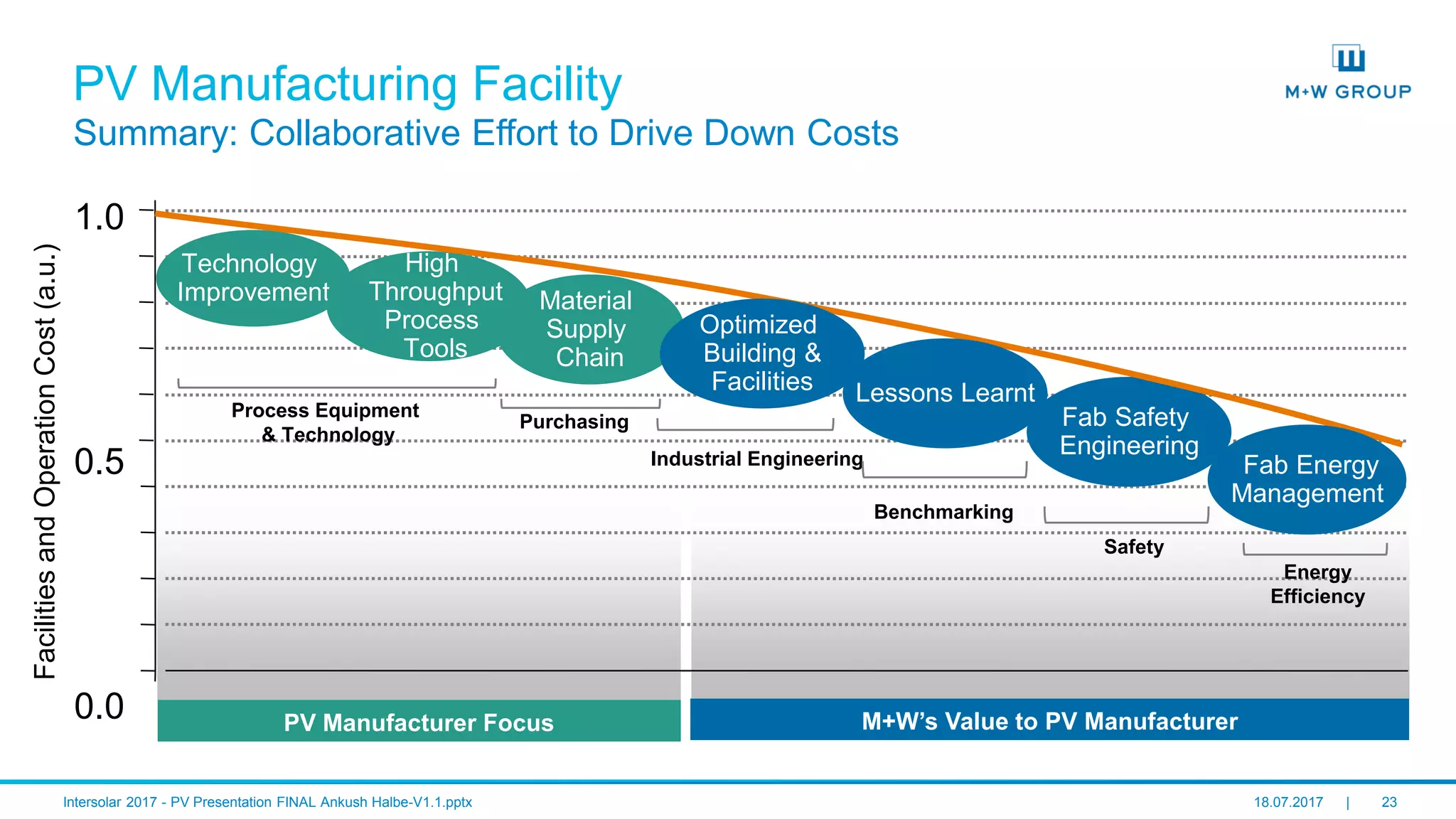

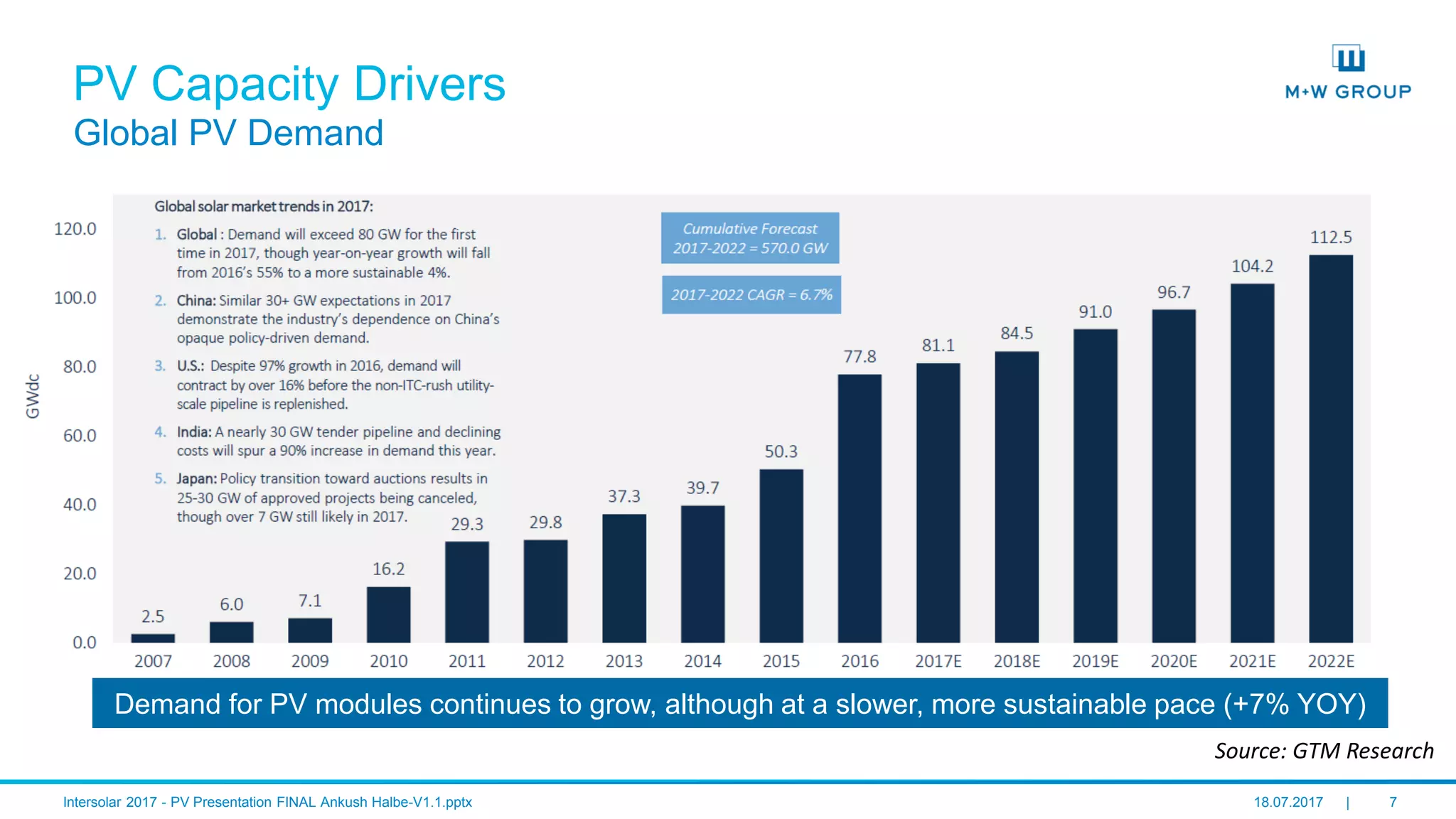

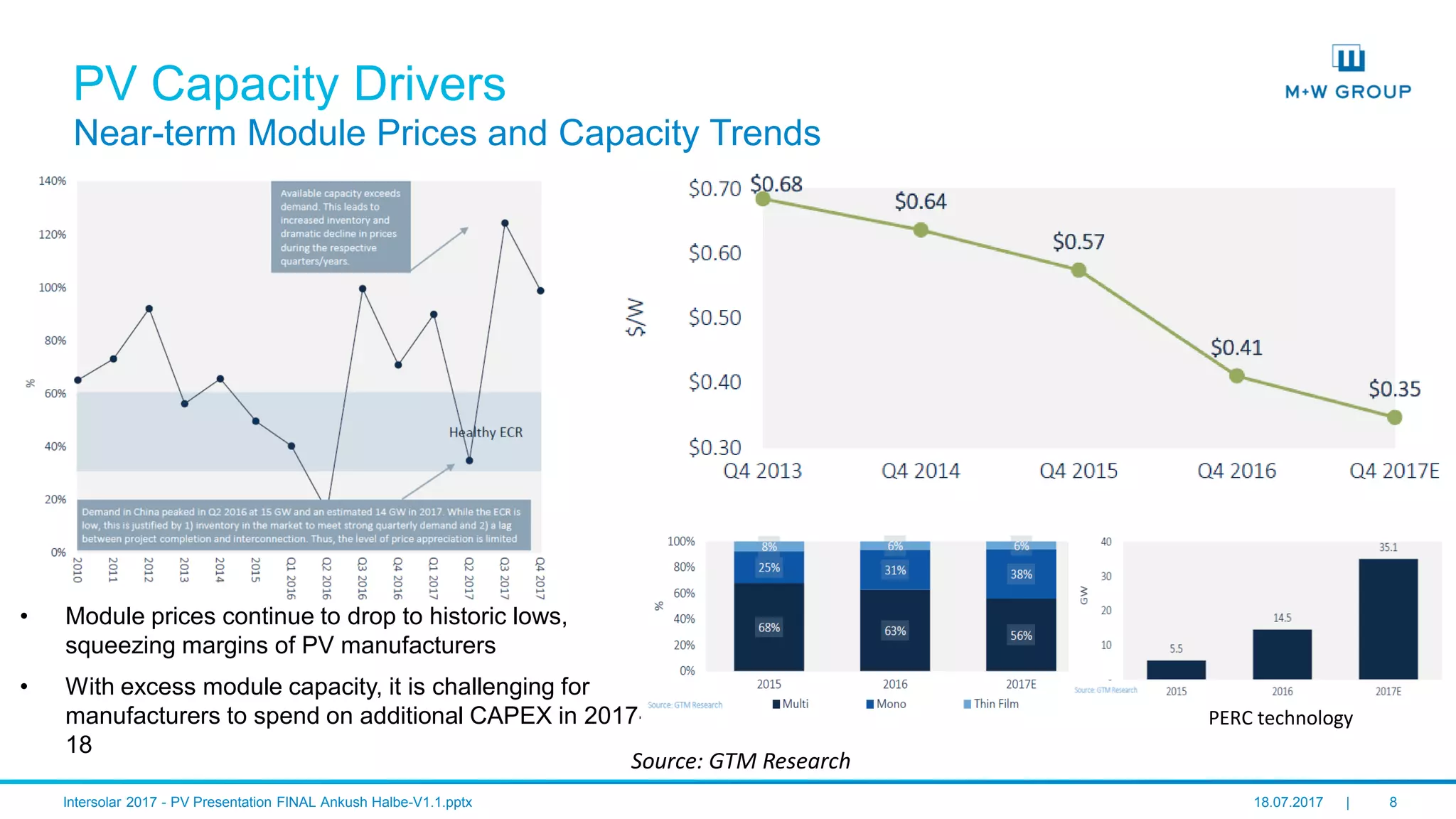

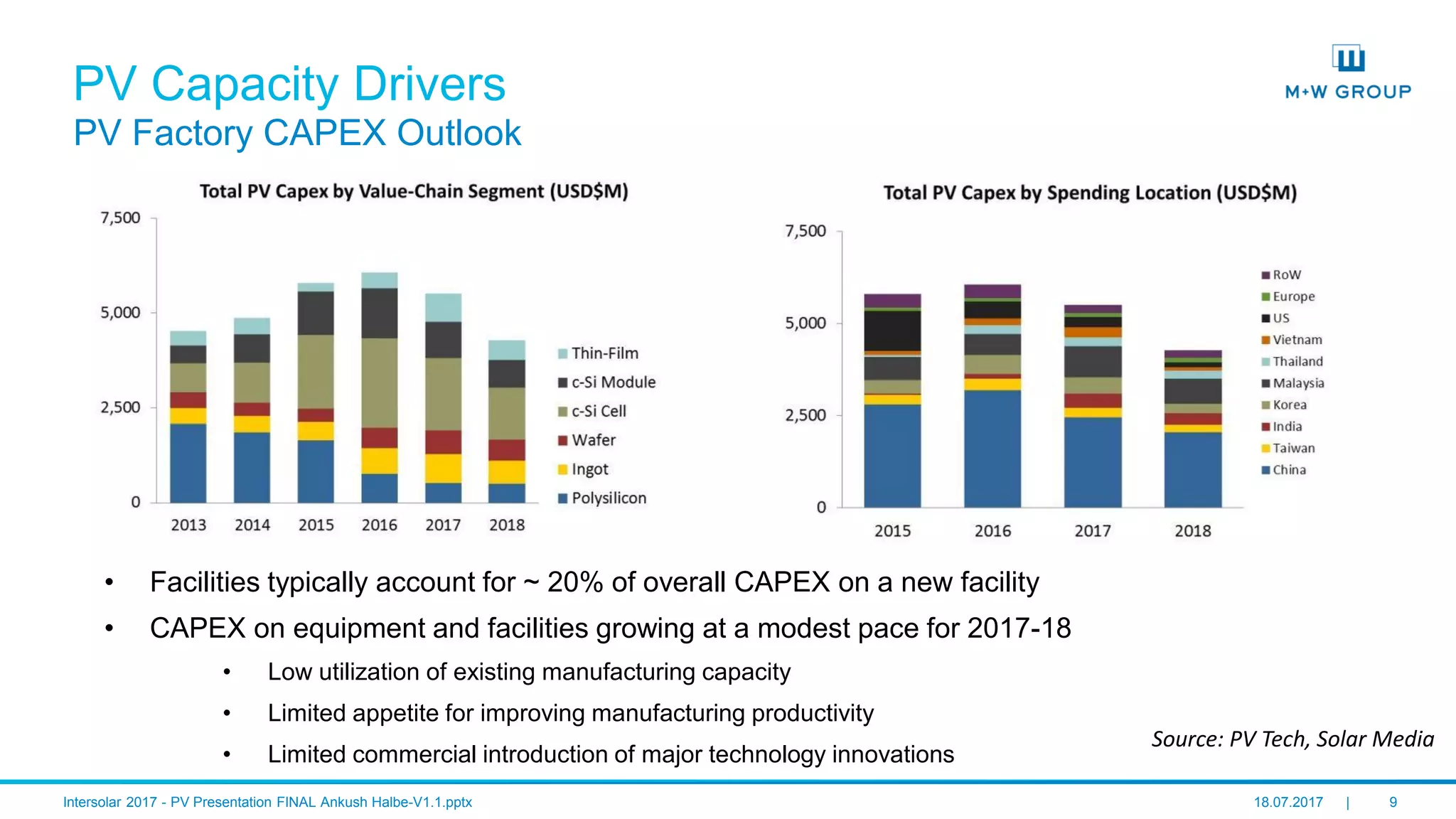

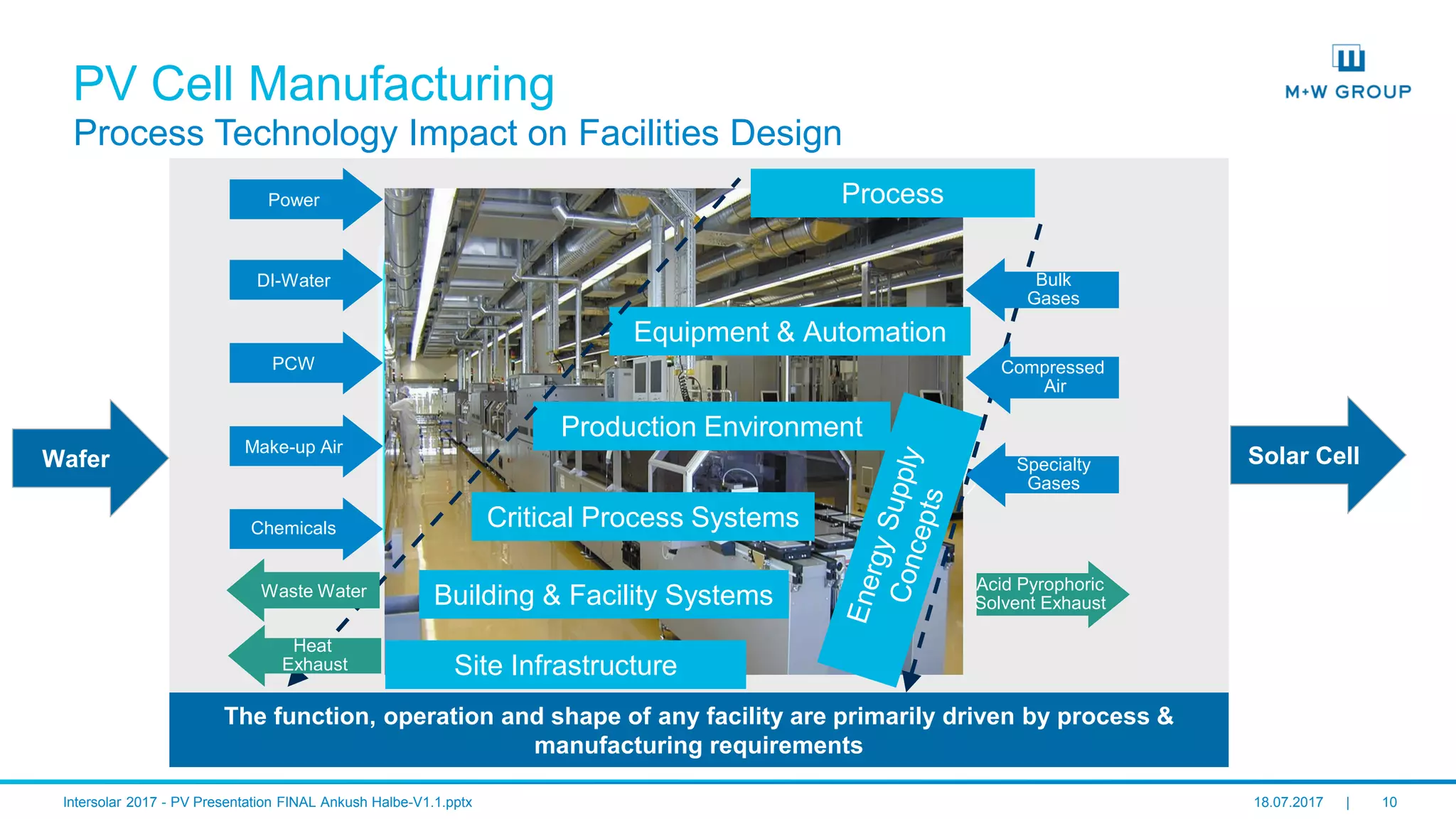

The document discusses the infrastructure and design considerations for photovoltaic (PV) manufacturing facilities, highlighting capacity drivers, environmental and safety considerations. It outlines M+W's extensive experience in building PV manufacturing capacity, their operational strategies, and a case study on energy management. The focus is on cost reduction, innovation in technology, and safety practices in PV manufacturing.

![© M+W U.S., Inc. I July 2017 11

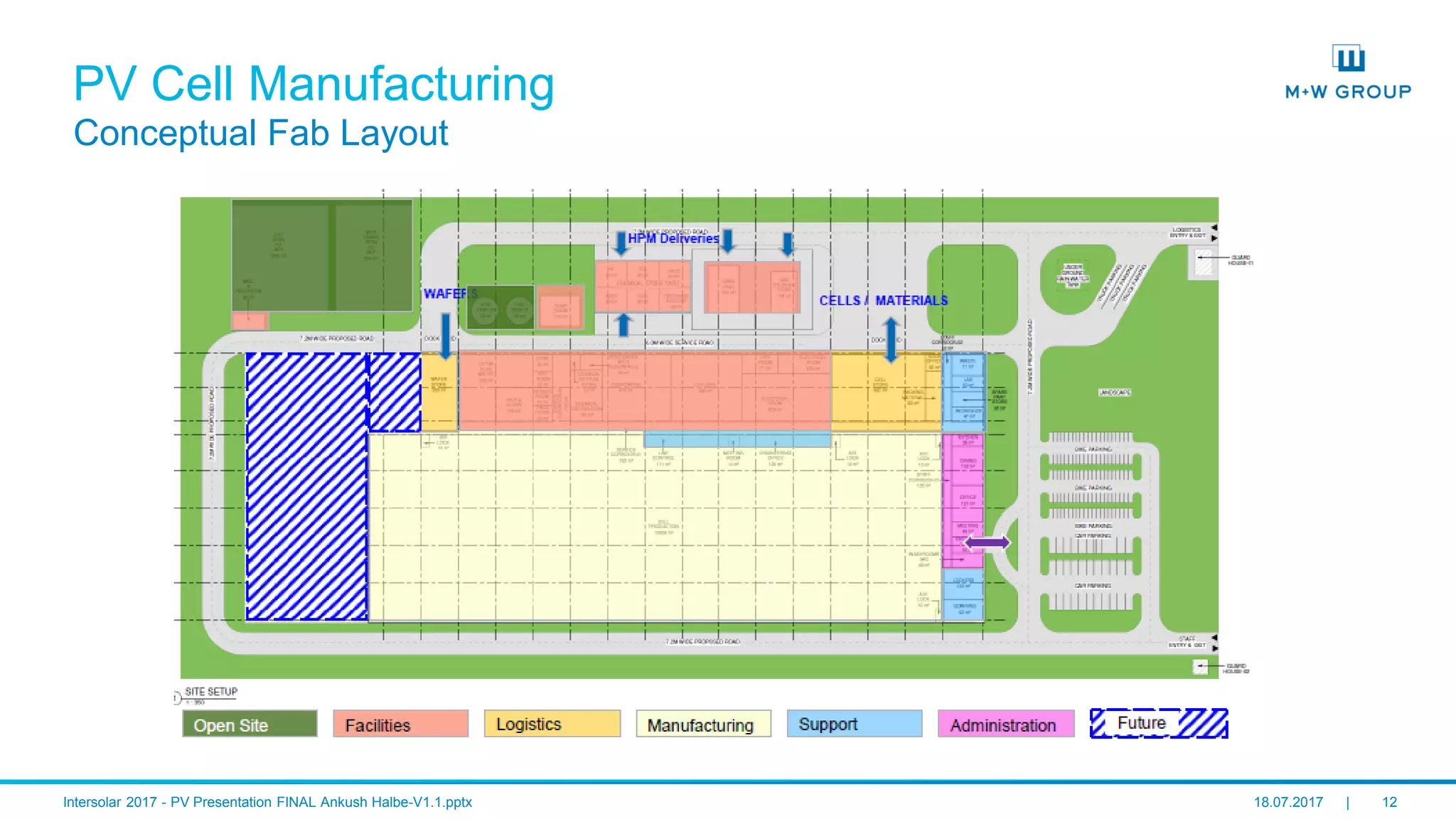

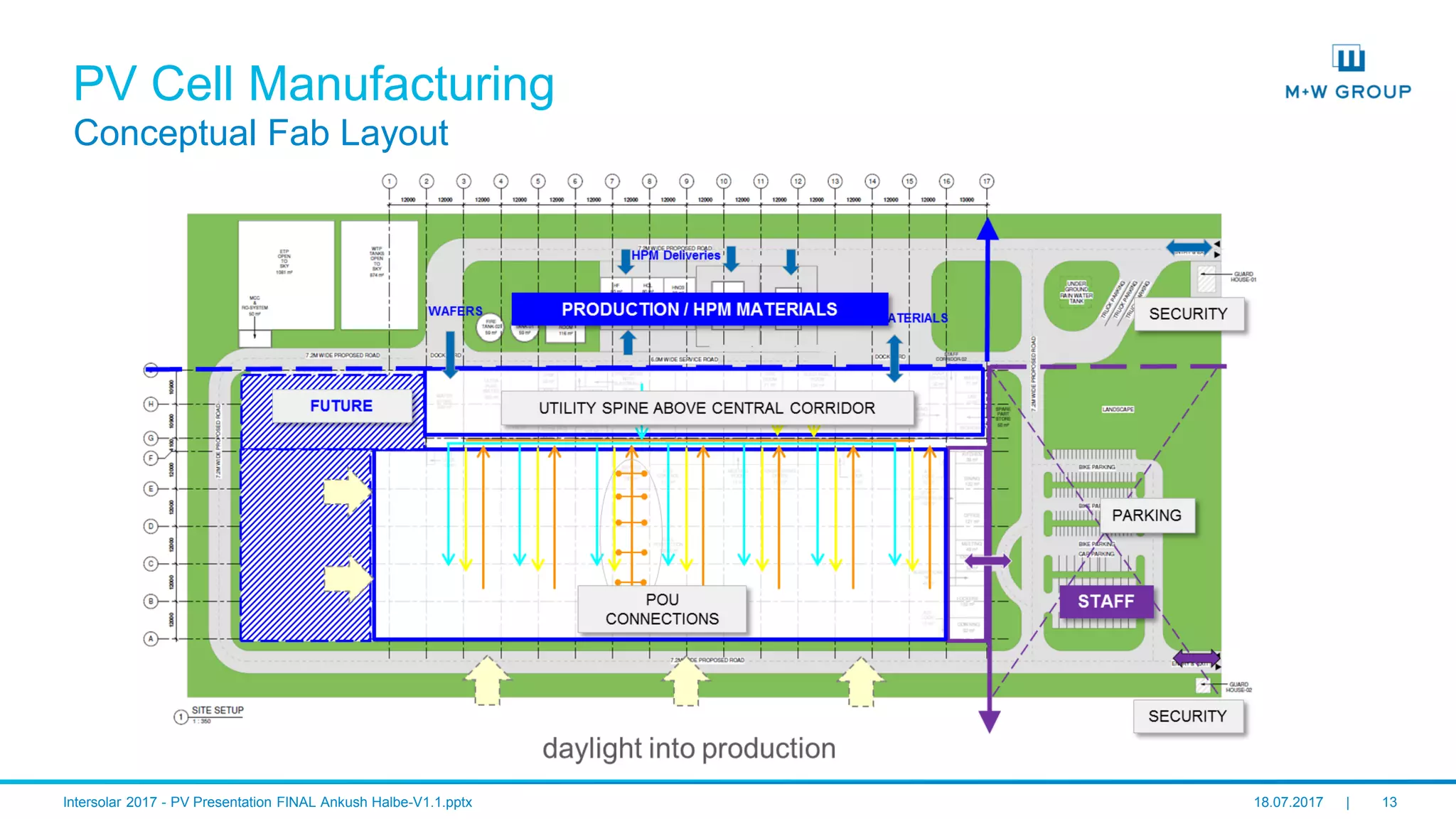

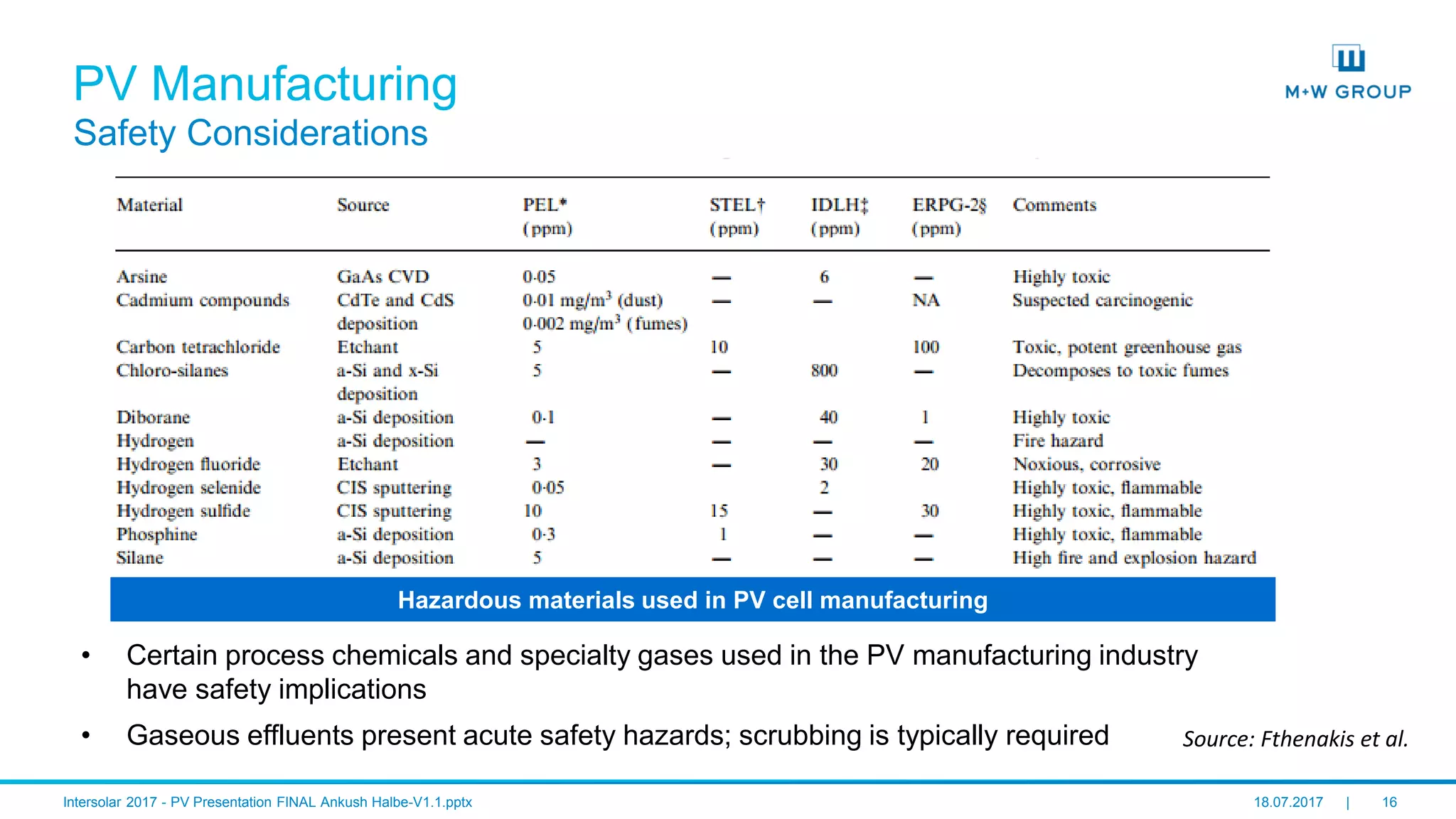

PV Cell Manufacturing

Sample Tool Utility Matrix

Utility consumption from process tools determines the type and capacity of facility systems for the

fab (e.g. for exhaust, abatement, water, bulk-gases, power, etc.)

Process

Category AF MF [kW] AF MF [kW] AF MF AF MF AF MF AF MF AF MF AF MF AF MF AF MF AF MF AF MF AF MF AF MF AF MF AF MF

Glass clean - substrate

20.00 230.00 0.5 1.0 2,500 2,500

3.0 3.0 12.2 0.50 2.00 15 50 2 10

0.50 2.00 10 30

3.0 3.0 12.2 2.00 500.00 0.50 2.00 15 50

15.80 80.00 20.00 230.00 0.5 1.0 2,500 2,500

3.0 3.0 12.2 0.50 2.00 15 50 2 10

0.50 2.00 10 30

3.0 3.0 12.2 2.00 500.00 0.50 2.00 15 50 2.00 500.00 2 10

Mo Sputter 12.0 12.0 41.8 1.00 3.00 50 250

400.00 400.00

18.5 18.5 107.4 1.00 3.00 20 80

12.0 12.0 41.8 1.00 3.00 50 250

11.0 11.0 63.9 1.00 3.00 20 80 600 600

P1-Laser 6 22 500 500

6 22 500 500

CIG Sputter 2.00 7.00 700.00 700.00 15 50 500 500

2.00 7.00 15 50 500 500

Selenization 12.00 12.00 41.8 28.00 40.00 50 80

12.00 12.00 41.8 28.00 40.00 0.06 0.12 50 80 1,000 1,000

0.06 0.12

CdS 1.00 1.00 24 70 n.a. n.a.

1.00 1.00 24 70 2.00 500.00 n.a. n.a.

1.50 1.50 28 82 2.00 500.00 n.a. n.a.

1.50 1.50 28 82 2.00 500.00 n.a. n.a.

Exhaust

PCW 1

[m3/h]

Liquids

IWD

[l/h]

Drain

CDA

Dew.P < -50°C

[Nm3/h]

SLA-D

[l/h]

Drain-OtherIndustrial Waste Drain

Electrical

CDA

Dew.P < -70°C

[Nm3/h]

NPS 220

[kVA]

General Exhaust

from Laser

N2

4.5

[Nm3/h]

Ar

5.0

[Nm3/h]

DI Water

< 10 µS/cm

[l/h]

Potable Water

[l/h]

General Exhaust

Bulkgases

GEEX

[Nm3/h]

H2S

5.0

[Nm3/h]

PCW 2

T in = 5°C (41°F)

[m3/h]

DEZ

5.0

[Nm3/h]

NPS 480

[kVA]

Laser-EX

[Nm3/h]](https://image.slidesharecdn.com/factoryinfrastructureforpvmanufacturing-170808082032/75/Factory-Infrastructure-for-PV-Manufacturing-11-2048.jpg)