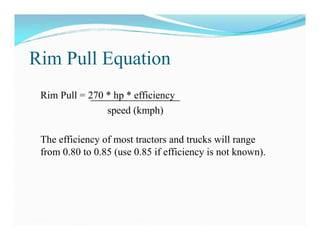

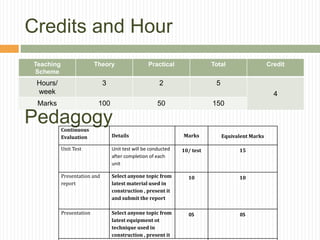

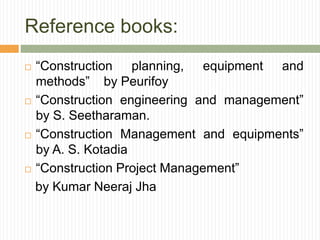

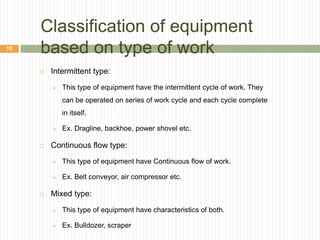

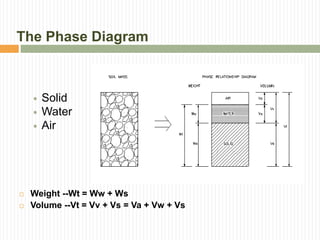

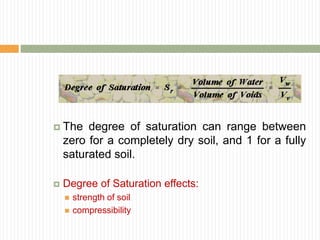

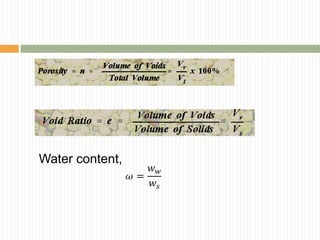

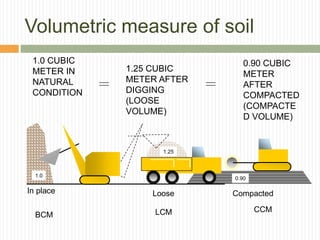

This document provides information about the CL 380 Construction Technology course, including details about credits, teaching scheme, pedagogy, and introduction. It discusses requirements for construction equipment, considerations for equipment selection, classification of equipment by type of work and function. It also covers engineering fundamentals of construction materials like soil and rock, including concepts like phase diagram, density, water content and volumetric measures. Finally, it discusses machine power requirements and factors like payload and power needed for equipment operation.

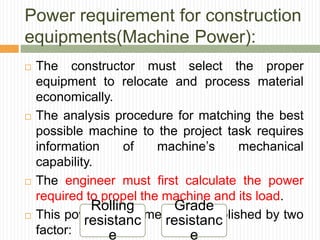

![Rolling Resistance

When tire penetration is known, an approximate

rolling resistance value for a wheeled vehicle can be

calculated . . .

RR = [20 + (6* TP)] * GVW

Where:

RR = Rolling resistance in kg

TP = Tire penetration in cm

GVW = Gross vehicle weight in kg](https://image.slidesharecdn.com/cl380unit-11-221213092132-dde28276/85/CL-380_Unit-1-1-pptx-36-320.jpg)