Productos de sso

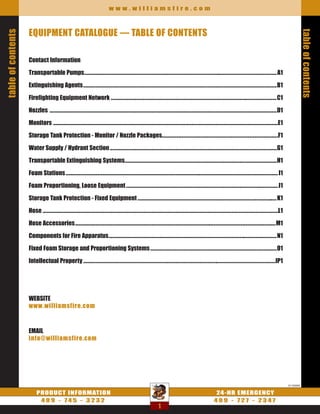

- 1. 01152005 EQUIPMENT CATALOGUE — TABLE OF CONTENTS Contact Information Transportable Pumps.......................................................................................................................................................................A1 Extinguishing Agents........................................................................................................................................................................B1 Firefighting Equipment Network ................................................................................................................................................C1 Nozzles .....................................................................................................................................................................................................D1 Monitors ...................................................................................................................................................................................................E1 Storage Tank Protection - Monitor / Nozzle Packages....................................................................................................F1 Water Supply / Hydrant Section.................................................................................................................................................G1 Transportable Extinguishing Systems....................................................................................................................................H1 Foam Stations........................................................................................................................................................................................I1 Foam Proportioning, Loose Equipment....................................................................................................................................J1 Storage Tank Protection - Fixed Equipment.........................................................................................................................K1 Hose............................................................................................................................................................................................................L1 Hose Accessories..............................................................................................................................................................................M1 Components for Fire Apparatus..................................................................................................................................................N1 Fixed Foam Storage and Proportioning Systems..............................................................................................................O1 Intellectual Property.......................................................................................................................................................................IP1 WEBSITE www.williamsfire.com EMAIL info@williamsfire.com w w w . w i l l i a m s f i r e . c o m tableofcontents tableofcontents 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY

- 2. 01152005 CORPORATE CONTACT INFORMATION contactinformation contactinformation 24-HR Emergency Toll Free U.S. Business Phone Physical Address Post Office Address Internet 409-727-2347 281-999-0276 800-231-4613 409-745-3232 TEL 409-745-3021 FAX 1675 Texla Rd Vidor, TX 77662 P.O. Box 1359 Mauriceville, TX 77626 CORPORATE CONTACT INFORMATION www.williamsfire.com info@williamsfire.com w w w . w i l l i a m s f i r e . c o m 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY

- 3. 01152005 TRANSPORTABLE PUMPS SECTION INDEX Dependapower DPPAT 4025 CAT-R.............................................................................................................................................A2 Patterson/Caterpillar 4,000 GPM Dependapower DPGOU 6040 CAT-R...........................................................................................................................................A3 Goulds/Caterpillar 6,000 GPM w w w . w i l l i a m s f i r e . c o m transportablepumps transportablepumps 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY A1

- 4. 01152005 Transportable Water Pump Systems Product: Dependapower DPPAT 4025 CAT-R Patterson/Caterpillar 4,000 GPM Description: The Dependapower DPPAT 4025 CAT-R is a trailer mounted, diesel driven horizontal split case centrifugal fire water pumping system. Nominal performance rating is 4,000 gpm @ 150 psi (10’ lift). The pump and driver come mounted on a skid containing an integral 325 gallon fuel cell with level indicator. The easily detachable skid is transported on a dual-axle trailer. The 12” suction and 10” discharge headers provide minimal pressure loss for maximum efficiency. The 24VDC electrical system comes standard with two group-D batteries. Paint is basic red polyurethane finish on pump, skid and trailer. (*Not on Driver) Total Package Weight with Fuel = 15,000 lbs. Trailer: Gooseneck style dual axle 14,000 lb. GAWR trailer, complete with: electric brakes coupler; DOT lighting package; 235/85 R16 LRF tires/wheels. Deck areas covered with safety “Grip” surface. Pump Detail: Manufacturer Patterson Series MAA Model 12 x 8 x 20.3 Fittings Cast iron casting, Bronze trim, SS packing sleeve Performance @ Shutoff 200 psi 4,000 gpm - 150 psi / 2,500 gpm - 175 psi Priming One 24 VDC Electric vane primer reservoir Driver Detail: Manufacturer Caterpillar Model 3406-DITA Power 500 BHP @ 2100 rpm Electrical System 24 VDC Cooling System Radiator with pusher fan *Paint Standard base unit Caterpillar yellow Suction Manifold: 12” diameter flange-fitted header furnished with: four (4) 6” (M) NH inlet connections, capped one (1) 2.5” valved (F) NST swivel w/plug. Discharge Manifold: 10” diameter flange-fitted header, furnished with: four (4) 5” storz discharge connections, capped, with gated discharge valves: (1) 2.5” (M) valved discharge connections. Control Panel: Includes: start/stop switch, tachometer, oil pressure gauge, coolant temperature gauge, amp meter, vernier throttle, com- pound suction gauge, discharge pressure gauge, fuel pressure gauge, primer valves switches, hour meter. Options: Manual clutch between pump driver Four suction hose racks (passenger side only) for use with 10’ hoses only SS Suction/Discharge Manifolds Jet pump back-up primer Automatic battery charger Retractable awning over pump operator 6” NH hard suction hoses (20’ each - 4 req’d) or (10’ each - 8 req’d) 6” NH “Light Weight” hard suction hoses (20’ each - 4 req’d) or (10’ each - 8 req’d) 6” Non-floating basket strainers (4 req’d) 6” Floating basket strainers (4 req’d) Full skid cover Add, 2.5” Discharge/Suction 4 Work Lights w w w . w i l l i a m s f i r e . c o m transportablepumps transportablepumps 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY A2

- 5. 01152005 Transportable Water Pump Systems Product: Dependapower DPGOU 6040 CAT-R Goulds/Caterpillar 6,000 GPM Description: The Dependapower DPGOU 6040 CAT-R is a trailer mounted, diesel driven horizontal split case centrifugal fire water pumping system. Nominal performance rating is 6,000 gpm @ 150 psi net (10’ lift). Designed to be moved from one location to another without having to realign the pump cou- pling. Entire assembly is built on a skid base which also serves as a fuel tank. Also includes structural frame with lifting lugs and work lights. Electric start with dual electric primers. Total Package Weight with Fuel = 20,000 lbs. Trailer: Triple axle 24,000 lb. GAWR steel decked trailer, complete with; electric brakes and coupler, DOT lighting package; leveling jack with rear stabilizer jacks; 235/85 R16 tires/wheels. Pump Detail: Manufacturer Goulds Series 3409 Model 10 x 14 x 20 L Fittings Cast iron casting, Bronze trim Performance @ Shutoff 200 psi 6,000 gpm - 150 psi 4,000 gpm - 175 psi Priming Dual 24 VDC Electric Driver Detail: Manufacturer Caterpillar Model 3412-DITA Power 750 BHP @ 1800 rpm Electrical System 24 VDC Cooling System Radiator with pusher fan Suction Manifold: 14” diameter header, furnished with: six (6) 6” (M) NH inlet con- nections - capped and one (1) 2.5” valved (F) NST swivel w/plug. Discharge Manifold: 10” diameter header, furnished with: six (6) 5” Storz discharge connections, capped, six (6) worm gear operated butterfly valves - 5”, two (2) 2.5” (M) auxiliary valved discharge connections - capped. Control Panel: Includes: start/stop switch, tachometer, oil pressure gauge, cool- ant temperature gauge, amp meter, vernier throttle, compound suction gauge, discharge pressure gauge, fuel pressure gauge, primer valves switches, hour meter. Options: Jet pump back-up primer 6” NH hard suction hoses (20’ each - 6 req’d) or (10’ each - 12 req’d) 6” Non-floating basket strainers (6 req’d) w w w . w i l l i a m s f i r e . c o m transportablepumps transportablepumps 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY A3

- 6. 01152005 EXTINGUISHING AGENTS ACCESSORIES SECTION INDEX ThunderStorm® ATC AR/AFFF — Intro....................................................................................................................................B2 ThunderStorm® ATC AR/AFFF — 1% x 3% F-601A........................................................................................................B3-B4 ThunderStorm® ATC AR/AFFF — 3% x 3% F-603A .....................................................................................................B5-B6 ThunderStorm® ATC AR/AFFF — 3% x 6% F-600 ........................................................................................................B7-B8 ThunderStorm® ATC AR/AFFF — 1% x 6% F-606 Freeze Protected ...............................................................B9-B10 ThunderStorm® ATC AR/AFFF — 3% x 3% F-604 Freeze Protected ..............................................................B11-B12 ThunderStorm® ATC AR/AFFF — 3% x 6% F-602A Freeze Protected ...........................................................B13-B14 T-STORM™ AR-AFFF 1% x 3% F-701A ...............................................................................................................................B15-B16 T-STORM™ AFFF 3% F-783A .................................................................................................................................................B17-B18 T-STORM™ AFFF 3% F-203A Freeze Protected ........................................................................................................B19-B20 T-STORM™ AR-AFFF 3% x6% F-787A Alcohol-Resistant AFFF .............................................................................B21-B22 “PKW™” Transportable Dry Chemical Skid Unit............................................................................................................B23 Williams “PKW™” Dry Chemical..............................................................................................................................................B24 w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B1

- 7. 01152005 ThunderStorm ® ATC AR/AFFF Product: Overview Description: ThunderStorm® ATC 1 x 3 Alcohol Resistant AFFF Concentrate is for- mulated using a new and proprietary technology. The foam concentrate has a dramatically reduced viscosity as compared to many other listed polar solvent type AFFF concentrates on the market. This reduced viscosity enhances per- formance in all types of foam proportioning equipment including in-line educ- tors, balanced pressure systems, and built-in systems aboard CFR vehicles. Additionally, the fire fighting performance of ThunderStorm® ATC is superior to other AR/AFFF foam concentrates. ThunderStorm® ATC 1 x 3 Concentrate offers many distinct advantages including ease of use and represents a continued commitment to quality by improving the fire performance of this type of agent on gasoline products while still maintaining high performance levels on other hydrocarbons as well as polar fuels. ThunderStorm® ATC 1 x 3 Concentrate is formulated from special fluorochemical and hydrocarbon surfactants, high molecular weight polymers and solvents. It is transported and stored as a concentrate to provide ease of use and considerable savings in weight and volume. It contains no PFOS or PFOA and is biodegradable. It is intended for use as a 1% proportioned solution on hydrocarbon fuels at .10 minimum application density, and as a 3% proportioned solution on polar fuels at .13 minimum application density in fresh, salt or hard water. It may also be stored and used as a premixed solution in fresh potable water. There are three fire extinguishing mechanisms in effect when using ThunderStorm® ATC 1 x 3 solution on either a con- ventional Class B hydrocarbon fuel such as gasoline, diesel fuel, etc., or a Class B polar solvent (water miscible fuel) such as methyl alcohol, acetone, etc. First, an aqueous film is formed in the case of a conventional hydrocarbon fuel, or a polymeric membrane in the case of a polar solvent fuel. This film or membrane forms a barrier to help prevent the release of fuel vapor. Second, regardless of the fuel type, a foam blanket is formed which excludes oxygen and from which drains the liquids that form the film or the polymeric membrane. Third, the water content of the foam produces a cooling effect. Proportioning ThunderStorm® ATC 1 x 3 Alcohol Resistant Concentrate can be easily proportioned (at the correct dilution) using most conventional proportioning equipment such as: 1. Hydro-Foam™ Nozzles 2. Balanced pressure and in-line balanced pressure pump proportioning equipment. 3. Balanced pressure bladder tank proportioners 4. Around-the-pump and Through-the-pump proportioners 5. Fixed or portable (in-line) venturi proportioners 6. Handline nozzles with fixed induction/pickup tubes The minimum and maximum usable temperature for ThunderStorm® ATC Concentrate in this equipment is 35°F (2°C) to 120°F (49°C) respectively. Typical Physiochemical Propoerties at 77°F/25°C Appearance Purple Gelled Liquid Density 1.02 ± 0.01 g/ml pH 7.5 – 8.5 Refractive Index 1.3600 ± 0.0015 Viscosity 2700 ± 500 CPS* Spreading Coefficient 4.0 – 6.0 *BROOKFIELD VISCOMETER Spindle #4, Speed 30 RPM Options: 1% x 3% concentrate 3% x 3% concentrate 3% x 6% concentrate w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B2

- 8. 01152005 ThunderStorm ® ATC AR/AFFF 1% x 3% F-601A Technical Information Description ThunderStorm® ATC 1X3 Alcohol Resistant AFFF Concentrate is formulated using a new and proprietary technology. The foam con- centrate has a dramatically reduced viscosity as compared to other 1X3 listed polar-solvent type AFFF concentrates on the market. This reduced viscosity enhances performance in all types of foam pro- portioning equipment including in-line eductors, balanced pressure systems, and built-in systems aboard CFR vehicles. Additionally, the fire fighting performance of ThunderStorm® ATC is superior to other AR/AFFF foam concentrates. This includes the blended gasoline additive Methyl Tertiary Butyl Ether (MTBE) which is being used as an oxygenate to make gasoline cleaner burn- ing. ThunderStorm® ATC 1X3 Concentrate offers many distinct advantages for ease of use and represents a continued commitment to quality by improving the fire performance of this type of agent on gasoline products while still maintaining high performance levels on other hydrocarbons and polar fuels. ThunderStorm® ATC 1X3 Concentrate is formulated from special fluorochemical and hydrocarbon surfactants, high molecular weight polymers and solvents. It is transported and stored as a concentrate to provide ease of use and considerable savings in weight and vol- ume. It contains no PFOS or PFOA. It is intended for use as a 1% proportioned solution on hydrocarbon fuels and as a 3% proportioned solution on polar fuels in fresh, salt or hard water. It may also be stored and used as a premixed solution in fresh potable water only. ThunderStorm® ATC 1 x 3 Concentrate is biodegradable. There are three fire extinguishing mechanisms in effect when using ThunderStorm® ATC 1x3 solution on either a conventional Class B hydrocarbon fuel such as gasoline, diesel fuel, etc., or a Class B polar solvent (water miscible fuel) such as methyl alcohol, acetone, etc. First, an aqueous film is formed in the case of a conventional hydrocarbon fuel, or a polymeric membrane in the case of a polar solvent fuel. This film or membrane forms a barrier to help prevent the release of fuel vapor. Second, regardless of the fuel type, a foam blanket is formed which excludes oxygen and from which drains the liquids that form the film or the polymeric membrane. Third, the water content of the foam produces a cooling effect. Typical Physiochemical Propoerties at 77°F/25°C Appearance Purple Gelled Liquid Density 1.02 ± 0.01 g/ml pH 7.5 – 8.5 Refractive Index 1.3600 ± 0.0015 Viscosity 2700 ± 500 CPS* Spreading Coefficient 4.0 – 6.0 *BROOKFIELD VISCOMETER Spindle #4, Speed 30 RPM ThunderStorm® ATC 1x3 Alcohol Resistant Concentrate is a non- Newtonian fluid that is both pseudoplastic and thixotropic. Because of these properties, dynamic viscosity will decrease as shear increases. Application ThunderStorm® ATC 1X3 can be used on either conventional Class B fuel or the polar solvent type Class B fuels. Its excellent wetting characteristics make it useful in combating Class A fires as well. Because of the low energy required to make foam, it can be used with both aspirating and non-aspirating discharge devices. To provide even greater fire protection capability, it may be used with “PKW™” dry chemical extinguishing agent without regard to the order of application. Hydro-Chem™ Technology is a recommended application for dual agent use on three dimensional fire. Due to the velocity of the dry chemical discharge, care must be taken not to sub- merge the polymeric membrane below the fuel surface when using twin agents on polar fuels. Fire Performance The fire performance of ThunderStorm® ATC 1X3 Alcohol Resistant Concentrate is measured primarily against Underwriters Laboratories Standard 162 (Latest Revision) and Williams Fire and Hazard Control’s fire test. The UL testing focuses on fuels such as heptane and isopropyl alcohol while the Williams Fire and Hazard Control test focuses on premium unleaded gasoline. ThunderStorm® ATC 1X3 was formulated to provide superior performance on all fire tests, especially important is performance on high octane gasoline. Foaming Properties When used with fresh, salt or hard water at the correct dilution with most conventional foam making equipment, the expansion will vary depending on the performance characteristics of the equipment. Aspirating discharge devices produce expansion ratios of 5:1 to 10:1 depending primarily on type of aspirating device and flow rate. Non-aspirating devices such as handline water fog/stream nozzles or standard sprinkler heads give expansion ratios of 2:1 to 4:1. Medium expansion discharge devices produce typical expansion ratios between 20:1 to 60:1 depending primarily upon type of device and operating conditions. Proportioning ThunderStorm® ATC 1X3 Alcohol Resistant Concentrate can be easily proportioned (at the correct dilution) using most conventional proportioning equipment such as: 1. Hydro-Foam™ Nozzles 2. Balanced pressure and in-line balanced pressure pump proportioning equipment 3. Balanced pressure bladder tank proportioner 4. Around-the-pump and Through-the-pump proportioners 5. Fixed or portable (in-line) venturi proportioners 6. Handline nozzles with fixed induction/ pickup tubes The minimum and maximum usable temperature for ThunderStorm® ATC Concentrate in this equipment is 35 °F (2 °C) to 120 °F (49 °C) respectively. Storage/Shelf Life When stored in the packaging supplied (polyethylene totes, drums or pails) or in equipment recommended by the manufac- turer and within the temperature ThunderStorm® ATC Technical Information AR/AFFF 1%x3% F-601A limits specified, the shelf life of ThunderStorm® ATC 1X3 Alcohol Resistant Concentrate is about 20-25 years. The factors affecting shelf life and stability for AFFF agents are discussed in detail in Ansul Technical Bulletin No. 54. Freezing of the product should be avoided. If, however, the product is frozen during transport or storage, it must be thawed and inspected for signs of separation. If separation has occurred, the product must be mechanically mixed until homogeneous. w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B3

- 9. 01152005 When the concentrate is to be stored in an atmospheric storage tank, a .125 to .25 in. (3 – 6 mm) layer of mineral oil should be added to seal the concentrate and minimize the effects of evaporation. Compatibility Since ThunderStorm® ATC 1X3 Alcohol Resistant Concentrate is a unique blend of surfactants, high molecular weight polymers, and solvents; it is recommended that it not be mixed with any other foam concentrates. Consult Williams Fire and Hazard Control or Ansul Incorporated with any questions of compatibility. Materials of Construction Compatibility Tests have been performed with ThunderStorm® ATC 1X3 Alcohol Resistant Concentrate verifying its compatibility with standard carbon steel “black” pipe and pipe manufactured from various stainless steel or brass compounds. Alternative pipe, plastic fittings, and valves may be used in some cases if acceptable to the customer and/or the authority having jurisdiction. Refer to Ansul Technical Bulletin No. 59, Form No. F-90109, addressing acceptable materials of construction for use with Ansul foam concentrates. Galvanized pipe and fittings must not be used in areas where undi- luted concentrate will contact them since corrosion will result. Please first consult Williams Fire and Hazard Control or Ansul Incorporated for specific guidelines concerning materials of con- struction. Inspection As with any fire extinguishing agent, ThunderStorm® ATC 1X3 Alcohol Resistant Concentrate, whether in the concentrate or pre- mixed form, should be inspected periodically. NFPA 11 ‘‘Standard for Low Expansion Foam and Combined Agent Systems’’ requires that foam concentrate samples be submitted to the manufacturer or other qualified laboratory for quality condition testing at least annu- ally. Contact Williams Fire and Hazard Control or Ansul for further information on annual inspection. Approvals and Listings Underwriters Laboratories successfully tested ThunderStorm® ATC 1X3 Concentrate to the requirements contained in U.L. Standard 162, ‘‘Standard for Air-Foam Equipment and Liquid Concentrates.’’ To receive a U.L. listing, the following tests had to be performed successfully: 1. Foam Quality Tests 2. Class B Hydrocarbon Fuel Fire Tests 3. Class B Polar Solvent Fuel Fire Tests 4. Foam Identification Tests 5. Tests of Shipping Containers Both 1X3 and 3X3 are currently UL Listed. The UL Listed Application rate for Hydrocarbons is 0.10 gpm/sq. ft. The UL Listed Application rate for Alcohols is 0.13 gpm/sq. ft. In addition to determining agent characteristics, Underwriters Laboratories lists ThunderStorm® ATC 1X3 concentrate for use with specific hardware components that also carry the U.L. listing. Ordering Information ThunderStorm® ATC Concentrate is available in pails, drums, totes or bulk shipment. 5 gallon pail Part No. 429965 55 gallon drum Part No. 429964 265 gallon tote Part No. 429963 Bulk Part No. 429962 Shipping Weight: 5 gal. (19 L) pail 45 lbs. (20.4 kg) 55 gal. (208.2 L) drum 495 lbs. (224.5 kg) 265 gal. (1000 L) tote 2463 lbs. (1117 kg) Cube: 5 gal. (19 L) pail 1.25 cu. ft. (.0354 m3) 55 gal. (208.2 L) drum 11.83 cu. ft. (.3350 m3) 265 gal. (1000 L) tote 31.50 cu. ft. (.8920 m3) ImportantNoticeto Purchaser: All statements, technical information and recommendations contained herein are based on tests conducted with ThunderStorm® ATC approved equipment, and are believed to be reliable. But the accuracy or completeness thereof is not guaran- teed, and the following is made in lieu of all warranties, expressed or implied, including the implied warranties of merchantability and fitness for purpose: Sellers and manufacturer’s only obligation shall be to replace such quantity of the product proved to be defective. Before using, user shall determine the suitability of the product for it’s intended use, and user assumes all risk and liability whatsoever in connection there within. NEITHER SELLER NOR MANUFACTURER SHALL BE LIABLE EITHER IN TORT OR IN CONTRACT FOR ANY LOSS OR DAMAGE, DIRECT, INCIDENTAL, OR COINCIDENTAL, ARISING OUT OF THE USE OF OR THE INABILITY TO USE THE PRODUCT. No statement or recommendation not contained herein shall have any force or effect unless in an agreement signed by officers of seller and manufacturer. Williams Fire Hazard Control, Inc. P.O. Box 1359 Mauriceville, Texas, USA 77626 24 Hour Emergency Number — 409 -727-2347 One Stanton Street, Marinette, WI 54143-2542 715-735-7411 ISO 9001 Registered UL w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B4

- 10. 01152005 ThunderStorm ® ATC AR/AFFF 3% x 3% F-603A Technical Information Description ThunderStorm® ATC 3X3 Alcohol Resistant AFFF Concentrate is formulated using a new and proprietary technology. The foam con- centrate has a dramatically reduced viscosity as compared to other 3x3 listed polar-solvent type AFFF concentrates on the market. This reduced viscosity enhances performance in all types of foam pro- portioning equipment including in-line eductors, balanced pressure systems, and built-in systems aboard CFR vehicles. Additionally, the fire fighting performance of ThunderStorm® ATC is superior to other AR/AFFF foam concentrates. This includes the blended gasoline additive Methyl Tertiary Butyl Ether (MTBE) which is being used as an oxygenate to make gasoline cleaner burn- ing. ThunderStorm® ATC 3x3 Concentrate offers many distinct advantages for ease of use and represents a continued commitment to quality by improving the fire performance of this type of agent on gasoline products while still maintaining high performance levels on other hydrocarbons and polar fuels. ThunderStorm® ATC 3x3 Concentrate is formulated from special fluorochemical and hydrocarbon surfactants, high molecular weight polymers and solvents. It is transported and stored as a concentrate to provide ease of use and considerable savings in weight and vol- ume. It contains no PFOS or PFOA. It is intended for use as a 3% proportioned solution on hydrocarbon fuels and a 3% proportioned solution on polar fuels in fresh, salt or hard water. It may also be stored and used as a premixed solution in fresh potable water only. ThunderStorm® ATC 3 x 3 Concentrate is biodegradable. There are three fire extinguishing mechanisms in effect when using ThunderStorm® ATC 3x3 solution on either a conventional Class B hydrocarbon fuel such as gasoline, diesel fuel, etc., or a Class B polar solvent (water miscible fuel) such as methyl alcohol, acetone, etc. First, an aqueous film is formed in the case of a conventional hydrocarbon fuel, or a polymeric membrane in the case of a polar solvent fuel. This film or membrane forms a barrier to help prevent the release of fuel vapor. Second, regardless of the fuel type, a foam blanket is formed which excludes oxygen and from which drains the liquids that form the film or the polymeric membrane. Third, the water content of the foam produces a cooling effect. Typical Physiochemical Propoerties at 77°F/25°C Appearance Green Gelled Liquid Density 1.01 ± 0.01 g/ml pH 7.5 – 8.5 Refractive Index 1.3550 ± 0.0015 Viscosity 2600 ± 500 CPS* Spreading Coefficient 4.5 – 6.5 *BROOKFIELD VISCOMETER Spindle #4, Speed 30 RPM ThunderStorm® ATC 3x3 Alcohol Resistant Concentrate is a non-Newtonian fluid that is both pseudoplastic and thixotropic. Because of these properties, dynamic viscosity will decrease as shear increases. Application ThunderStorm® ATC 3x3 can be used on either conventional Class B fuel or the polar solvent type Class B fuels. Its excellent wet- ting characteristics make it useful in combating Class A fires as well. Because of the low energy required to make foam, it can be used with both aspirating and non-aspirating discharge devices. To provide even greater fire protection capability, it may be used with “PKW™” dry chemical extinguishing agent without regard to the order of application. Hydro-Chem™ Technology is a recommended application for dual agent use on three dimensional fire. Due to the velocity of the dry chemical discharge, care must be taken not to sub- merge the polymeric membrane below the fuel surface when using twin agents on polar fuels. Fire Performance The fire performance of ThunderStorm® ATC 3x3 Alcohol Resistant Concentrate is measured primarily against Underwriters Laboratories Standard 162 (Latest Revision) and Williams Fire and Hazard Control’s fire test. The UL testing focuses on fuels such as heptane and isopropyl alcohol while the Williams Fire and Hazard Control test focuses on premium unleaded gasoline. ThunderStorm® ATC 3x3 was formulated to provide superior performance on all fire tests, especially important is performance on high octane gasoline. Foaming Properties When used with fresh, salt or hard water at the correct dilution with most conventional foam making equipment, the expansion will vary depending on the performance characteristics of the equipment. Aspirating discharge devices produce expansion ratios of 5:1 to 10: 1 depending primarily on type of aspirating device and flow rate. Non-aspirating devices such as handline water fog/stream nozzles or standard sprinkler heads give expansion ratios of 2:1 to 4:1. Medium expansion discharge devices produce typical expansion ratios between 20:1 to 60:1 depending primarily upon type of device and operating conditions. Proportioning ThunderStorm® ATC 3x3 Alcohol Resistant Concentrate can be easily proportioned (at the correct dilution) using most conventional proportioning equipment such as: 1. Hydro-Foam™ Nozzles 2. Balanced pressure and in-line balanced pressure pump proportioning equipment 3. Balanced pressure bladder tank proportioner 4. Around-the-pump and Through-the-pump proportioners 5. Fixed or portable (in-line) venturi proportioners 6. Handline nozzles with fixed induction/ pickup tubes The minimum and maximum usable temperature for ThunderStorm® ATC Concentrate in this equipment is 35 °F (2 °C) to 120 °F (49 °C) respectively. Storage/Shelf Life When stored in the packaging supplied (polyethylene totes, drums or pails) or in equipment recommended by the manufacturer and within the temperature limits specified, the shelf life of ThunderStorm® ATC 3x3 Alcohol Resistant Concentrate is about 20-25 years. The factors affecting shelf life and stability for AFFF agents are discussed in detail in Ansul Technical Bulletin No. 54. Freezing of the product should be avoided. If, however, the product is frozen during transport or storage, it must be thawed and inspected for signs of separation. If separation has occurred, the product must be mechanically mixed until homogeneous. w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B5

- 11. 01152005 When the concentrate is to be stored in an atmospheric storage tank, a .125 to .25 in. (3 – 6 mm) layer of mineral oil should be added to seal the concentrate and minimize the effects of evaporation. Compatibility Since ThunderStorm® ATC 3x3 Alcohol Resistant Concentrate is a unique blend of surfactants, high molecular weight polymers, and solvents; it is recommended that it not be mixed with any other foam concentrates. Consult Williams Fire and Hazard Control or Ansul Incorporated with any questions of compatibility. Materials of Construction Compatibility Tests have been performed with ThunderStorm® ATC 3x3 Alcohol Resistant Concentrate verifying its compatibility with standard carbon steel ‘‘black’’ pipe and pipe manufactured from various stainless steel or brass compounds. Alternative pipe, plastic fittings, and valves may be used in some cases if acceptable to the customer and/or the authority having jurisdiction. Refer to Ansul Technical Bulletin No. 59, Form No. F-90109, addressing acceptable materials of construction for use with Ansul foam concentrates. Galvanized pipe and fittings must not be used in areas where undi- luted concentrate will contact them since corrosion will result. Please first consult Williams Fire and Hazard Control or Ansul Incorporated for specific guidelines concerning materials of construction. Inspection As with any fire extinguishing agent, ThunderStorm® ATC 3x3 Alcohol Resistant Concentrate, whether in the concentrate or pre- mixed form, should be inspected periodically. NFPA 11 ‘‘Standard for Low Expansion Foam and Combined Agent Systems’’ requires that foam concentrate samples be submitted to the manufacturer or other qualified laboratory for quality condition testing at least annu- ally. Contact Williams Fire and Hazard Control or Ansul for further infor- mation on annual inspection. Approvals and Listings Underwriters Laboratories successfully tested ThunderStorm® ATC 3x3 Concentrate to the requirements contained in U.L. Standard 162, ‘‘Standard for Air-Foam Equipment and Liquid Concentrates.’’ To receive a U.L. listing, the following tests had to be performed successfully: 1. Foam Quality Tests 2. Class B Hydrocarbon Fuel Fire Tests 3. Class B Polar Solvent Fuel Fire Tests 4. Foam Identification Tests 5. Tests of Shipping Containers Both 1X3 and 3X3 are currently UL Listed. The UL Listed Application rate for Hydrocarbons is 0.10 gpm/sq. ft. The UL Listed Application rate for Alcohols is 0.13 gpm/sq. ft. In addition to determining agent characteristics, Underwriters Laboratories lists ThunderStorm® ATC 3x3 concentrate for use with specific hardware components that also carry the U.L. listing. Ordering Information ThunderStorm® ATC Concentrate is available in pails, drums, totes or bulk shipment. 5 gallon pail Part No. 430919 55 gallon drum Part No. 430921 265 gallon tote Part No. 430922 Bulk Part No. 430918 Shipping Weight: 5 gal. (19 L) pail 45 lbs. (20.4 kg) 55 gal. (208.2 L) drum 495 lbs. (224.5 kg) 265 gal. (1000 L) tote 2463 lbs. (1117 kg) Cube: 5 gal. (19 L) pail 1.25 cu. ft. (.0354 m3) 55 gal. (208.2 L) drum 11.83 cu. ft. (.3350 m3) 265 gal. (1000 L) tote 31.50 cu. ft. (.8920 m3) Important Notice to Purchaser: All statements, technical information and recommendations con- tained herein are based on tests conducted with ThunderStorm® ATC approved equipment, and are believed to be reliable. But the accuracy or completeness thereof is not guaranteed, and the follow- ing is made in lieu of all warranties, expressed or implied, including the implied warranties of merchantability and fitness for purpose: Sellers and manufacturer’s only obligation shall be to replace such quantity of the product proved to be defective. Before using, user shall determine the suitability of the product for it’s intended use, and user assumes all risk and liability whatsoever in connection there within. NEITHER SELLER NOR MANUFACTURER SHALL BE LIABLE EITHER IN TORT OR IN CONTRACT FOR ANY LOSS OR DAMAGE, DIRECT, INCIDENTAL, OR COINCIDENTAL, ARISING OUT OF THE USE OF OR THE INABILITY TO USE THE PRODUCT. No statement or recommendation not contained herein shall have any force or effect unless in an agreement signed by officers of seller and manufacturer. Williams Fire Hazard Control, Inc. P.O. Box 1359 Mauriceville, Texas, USA 77626 24 Hour Emergency Number — 409-727-2347 One Stanton Street, Marinette, WI 54143-2542 715-735-7411 ISO 9001 Registered For US and Foreign Patent and Trademark information, please refer to page IP2 UL® w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B6

- 12. 01152005 ThunderStorm ® ATC AR/AFFF 3% or 6% F-600 Technical Information Description ThunderStorm® F-600 3% or 6% Alcohol Resistant Concentrate is formulated from special fluorochemical and hydrocarbon surfactants, a high molecular weight polymer, and solvents. It is transported and stored as a concentrate to provide ease of use and considerable savings in weight and volume. It is intended for use as a 3% or 6% proportioned solu- tion (depending on the type of fuel) in fresh, salt or hard water. (Water hardness should not exceed 500 ppm expressed as calcium and magnesium.) It may also be used and stored as a premixed solution in fresh or potable water for use with the Ansul Model AR-33-D wheeled fire extinguisher. There are three fire extinguishing mechanisms in effect when using ThunderStorm® F-600 3% or 6% concentrate on either a conventional Class B hydrocarbon fuel such as gasoline, diesel fuel, etc., or a Class B polar solvent (water miscible fuel) such as methyl alcohol, acetone, etc. First, an aqueous film is formed in the case of a conventional hydro- carbon fuel, or a polymeric membrane in the case of a polar solvent fuel. This film or membrane forms a barrier to help prevent the release of fuel vapor. Second, regardless of the fuel type, a foam blanket is formed which excludes oxygen and from which drains the liquids that form the film or the polymeric membrane. Third, the water content of the foam produces a cooling effect. Typical Physiochemical Propoerties at 77°F/25°C Appearance Light Amber Gel-Like Liquid Density 0.985 ± 0.050 gm/ml pH 7.0 - .8.5 Refractive Index 1.3475 ± 0.025 Viscosity 2500 ± 500 centipoise* Spreading 5.7 ± 1.5 Coefficient *Brookfield Viscometer Spindle #4, Speed 30 ThunderStorm® F-600 3% or 6% Alcohol Resistant Concentrate is a non-Newtonian fluid that is both pseudo- plastic and thixotropic. Because of these properties, dynamic viscosity will decrease as shear increases. (1) TYPE II DISCHARGE OUTLET - A device that delivers foam onto the burning liquid and partially submerges the foam or produces restricted agitation of the surface as described in U.L. 162. (2) U.L. builds in a 5/3 safety factor from its test rate to its recommended rate of application. (3) TYPE III DISCHARGE OUTLET - A device that delivers the foam directly onto the burning liquid as described in U.L. 162. Application ThunderStorm® F-600 3% or 6% AFFF is unique among the AFFF agents in that it can be used on either conventional Class B fuels or the polar solvent type Class B fuels. Its excel- lent wetting characteristics make it useful in combating Class A Fires as well. Because of the low energy to make foam, it can be used with both aspirating and non-aspirating dis- charge devices. To provide even greater fire protection capability, it can be used with dry chemical extinguishing agents without regard to the order of application to provide even greater fire protection capability. Due to the velocity of the dry chemical discharge, care must be taken not to submerge the polymeric mem- brane below the fuel surface. Fire Performance Fire Performance - The fire performance of ThunderStorm® F-600 3% or 6% AFFF is measured primarily against Underwriters Laboratories Standard 162, 5th Edition. There are no U.S. or foreign government specifica- tions on this type of product. APPLICATION RATES Application Rates using U.L. 162 Standard 50 ft.2 Fire Test on representative hydrocarbon and polar solvent fuels are listed below. U.L. Type II Application(1) - Polar Solvents U.L. Test U.L.(2) Recommended Application Rate Application Rate Fuel Group Concentration gpm/ft2 (Lpm/m2) gpm/ft.2 (Lpm/m2) Alcohol Methanol (MeOH) 6% .06 (2.5) .10 (4.1) Ethanol (EtOH) 6% .06 (2.5) .10 (4.1) Isopropanol (IPA) 6% .09 (3.7) .15 (6.1) Ketone Acetone 6% .09 (3.7) .15 (6.1) Methyl Ethyl Ketone 6% .09 (3.7) .15 (6.1) (MEK) Carboxylic Acid Acetic Acid 6% .10 (4.1) .17 (6.9) Aldehyde Propionaldehyde 6% .10 (4.1) .17 (6.9) Ester Ethyl Acetate 6% .06 (2.4) .10 (4.1) Butyl Acetate 6% .06 (2.4) .10 (4.1) U.L. Type III Application(3) - Hydrocarbons Heptane 3% .04 (1.6) .10 (4.1) Toluene 3% .04 (1.6) .10 (4.1) Gasoline 3% .04 (1.6) .10 (4.1) 10% Gasohol (EtOH) 3% .04 (1.6) .10 (4.1) w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B7

- 13. 01152005 Foaming Properties When used with fresh, salt or hard water, at the correct dilution with most conventional foam making equipment, the expansion will vary depending on the performance characteristics of the equipment. Aspirating discharge devices produce expansion ratios of from 5:1 to 10:1 depending primarily on type of aspirating device and flow rate. Non-aspirating devices such as handline water fog/stream nozzles or standard sprinkler heads give expansion ratios of 2:1 to 4:1. Proportioning ThunderStorm® F-600 3% or 6% Alcohol Resistant Concentrate (ARC) AFFF Concentrate can be easily pro- portioned (at the correct dilution) using most conventional proportioning equipment such as: 1. Balanced pressure and in-line balanced pressure pumped proportioning equipment 2. Balanced pressure bladder tank type proportioner 3. Around-the-pump proportioners 4. Fixed or portable (in-line) venturi type proportioners 5. Handline nozzles with fixed induction/ pickup tubes The minimum and maximum usable temperature for ThunderStorm® F-600 3% or 6% Concentrate in this equip- ment is 35 °F (2 °C) to 120 °F (49 °C) respectively. Storage/Shelf Life When stored in the packaging supplied (polyethylene drums or pails) or in equipment recommended by the manufacturer and within the temperature limits specified, the shelf life of ThunderStorm® F-600 3% or 6% AFFF is about 20-25 years. The factors affecting shelf life and stability for AFFF Agents are discussed in detail in Ansul Technical Bulletin No. 54. Freezing of the product should be avoided. If, however, the product is frozen during transport or storage, it must be thawed and inspected for signs of separation. If separation has occurred, the product must be mechanically mixed until homogeneous. When the concentrate is to be stored in an atmospheric storage tank, a .125 to .25 in. (3 - 6 mm) layer of mineral oil should be added to seal the concentrate and minimize the effects of evaporation. Compatibility Since ThunderStorm® F-600 3% or 6% Alcohol Resistant Concentrate (ARC) is a unique blend of surfactants, high molecular weight polymers, and solvents; it is recom- mended that Williams Fire and Hazard Control or Ansul Incorporated be consulted before concentrate is mixed with any other concentrates. Materials of Construction Compatibility Tests have been performed with ThunderStorm® F- 600 3% or 6% Concentrate verifying its compatibility with standard carbon steel ‘’black’’ pipe and pipe manufactured from various stainless steel or brass compounds. Alternative pipe, plastic fittings, and valves may be used in some cases if acceptable to the customer and/or the authority having juris- diction. Refer to Ansul Technical Bulletin No. 59, Form No. F-90109, addressing acceptable materials of construction for use with Ansul foam concentrates. Galvanized pipe and fittings must not be used in areas where undiluted concentrate will contact them since corrosion will result. Please first consult Williams Fire and Hazard Control or Ansul Incorporated for specific guidelines concerning materials of construction. Inspection As with any fire extinguishing agent, ThunderStorm® F-600 Concentrate, whether in the concentrate or pre-mixed form, should be inspected periodically. Please refer to the Field Inspection Manual, (Part No. 31274-01), for the detailed procedures to perform this inspection. An annual inspection is recommended unless unusual conditions of exposure occur such as are described in Ansul Technical Bulletin No. 54. In such cases, Ansul’s recommendation should be sought. Approvals and Listings Underwriters Laboratories successfully tested ThunderStorm® F-600 3% or 6% AFFF to the requirements contained in the U.L. Standard 162, ‘’Standard for Air-Foam Equipment and Liquid Concentrates.’’ To receive the U.L. listing, the following tests had to be performed successfully: 1. Foam Quality Tests 2. Class B Hydrocarbon Fuel Fire Tests 3. Class B Polar Solvent Fuel Fire Tests 4. Foam Identification Tests 5. Tests of Shipping Containers 6. Class B Hydrocarbon and Polar Solvent Fuel Sprinkler Tests (Standard type both upright and pendent) 7. Subsurface Injection Besides determining agent characteristics, Underwriters Laboratories lists ThunderStorm® F-600 3% or 6% foam concentrate for use with specific hardware components that also carry the U.L. listing. Ordering Information ThunderStorm® F-600 3% or 6% Alcohol Resistant AFFF Concentrate is available in pails, drums, totes, or bulk shipment. Part No. 431983 5 Gallon Pail Part No. 431984 55 Gallon Drum Part No. 431985 256 Gallon Tote Part No. 431986 Bulk Shipping Weight: 5 gal. (19 L) pail - 45 lbs. (20.4 kg) 55 gal. (208.1 L) drum - 495 lbs. (224.5 kg) 265 gal. (1000 L) tote - 2463 lbs. (1117 kg) Cube: 5 gal. (19 L) pail - 1.25 cu. ft. (.0353 m3) 55 gal. (208.1 L) drum - 11.83 cu. ft. (.3350 m3) 265 gal. (1000 L) tote - 31.50 cu. ft. (.892 m3) w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B8

- 14. 01152005 ThunderStorm ® ATC AR/AFFF 1% x 6% F-606 Freeze Protected Technical Information Description ThunderStorm® ATC 1X6 Freeze Protected Concentrate is formulated from special fluorochemical and hydrocarbon surfac- tants, high molecular weight polymers and solvents. It is transported and stored as a concentrate to provide ease of use and considerable savings in weight and volume. It contains no PFOS or PFOA. It is intended for use as a 1% proportioned solution on hydrocarbon fuels and as a 6% proportioned solution on polar solvent fuels in fresh, salt or hard water. It may also be stored and used as a premixed solution in fresh potable water only. There are three fire extinguishing mechanisms in effect when using ThunderStorm® ATC 1X6 Freeze Protected solution on either a conventional Class B hydrocarbon fuel such as gasoline, diesel fuel, etc., or a Class B polar solvent (water miscible fuel) such as methyl alcohol, acetone, etc. First, an aqueous film is formed in the case of a conventional hydrocarbon fuel, or a polymeric membrane in the case of a polar solvent fuel. This film or membrane forms a barrier to help prevent the release of fuel vapor. Second, regardless of the fuel type, a foam blanket is formed which excludes oxygen and from which drains the liquids that form the film or the polymeric membrane. Third, the water content of the foam produces a cooling effect. Typical Physiochemical Propoerties at 77°F/25°C Appearance Amber Gelled Liquid Density 1.07 ± 0.01 g/ml pH 7.5 - 8.5 Refractive Index 1.3894 ± 0.0015 Viscosity 1000 ± 300 cps* Spreading Coefficient 4.0 - 6.0 *Brookfield Viscometer Spindle #4, Speed 30 rpm ThunderStorm® ATC 1X6 Freeze Protected Alcohol-Resistant Concentrate is a non-Newtonian fluid that is both pseudoplastic and thixotropic. Because of these properties, dynamic viscosity will decrease as shear increases. Application ThunderStorm® ATC 1X6 Freeze Protected Alcohol-Resistant Concentrate can be used on either conventional Class B fuel or the polar solvent type Class B fuels. Its excellent wetting characteristics make it useful in combating Class A fires as well. Because of the low energy required to make foam, it can be used with both aspirating and non-aspirating discharge devices. To provide even greater fire protection capability, it may be used with “PKW” dry chemical extinguishing agent without regard to the order of application. HYDRO-CHEM™ Technology is a rec- ommended application for dual agent use on three-dimensional fires. Due to the velocity of the dry chemical discharge, care must be taken not to submerge the polymeric membrane below the fuel surface when using the twin agent method on polar solvent fuels. Fire Performance The fire performance of ThunderStorm® ATC 1X6 Freeze Protected Alcohol-Resistant Concentrate is measured primarily against Underwriters Laboratories Standard 162 (Latest Revision) and Williams Fire Hazard Control, Inc® fire tests. The UL test- ing focuses on fuels such as heptane and isopropyl alcohol while the Williams Fire Hazard Control, Inc® test focuses on premium unleaded gasoline. ThunderStorm® ATC 1X6 Freeze Protected Alcohol-Resistant Concentrate was formulated to provide superior performance on all fire tests; especially on high octane gasoline. Foaming Properties When used with fresh, salt or hard water at the correct dilution with most conventional foam making equipment; the expansion will vary depending on the performance characteristics of the equip- ment. Aspirating discharge devices produce expansion ratios of 5: 1 to 10:1 depending primarily on the type of aspirating device and flow rate. Non-aspirating devices such as hand-line water fog/stream nozzles or standard sprinkler heads give expansion ratios of 2:1 to 4: 1. Medium expansion discharge devices produce typical expansion ratios between 20:1 and 60:1 depending primarily on the type of device and operating conditions. Proportioning ThunderStorm® ATC 1X6 Freeze Protected Alcohol-Resistant Concentrate can be easily proportioned (at the correct dilution) using most conventional proportioning equipment such as: 1.HYDRO-FOAM™ Nozzles 2.Balanced pressure and in-line balanced pressure pump pro- portioning equipment. 3.Balanced pressure bladder tank proportioners 4.Around-the-pump and through-the-pump proportioners 5.Fixed or portable (in-line) venturi proportioners 6.Hand-line nozzles with fixed induction/pickup tubes The minimum and maximum usable temperature for ThunderStorm® ATC Concentrate in this equipment is 0°F (-18°C) to 120°F (49°C) respectively. Storage/Shelf Life When stored in the packaging supplied (polyethylene totes, drums or pails) or in equipment recommended by the manufac- turer and within the temperature limits specified, the shelf life of ThunderStorm® ATC 1X6 Freeze Protected Alcohol-Resistant Concentrate is about 20-25 years. The factors affecting shelf life and stability for AFFF agents are discussed in detail in Ansul Technical Bulletin No. 54. Freezing of the product should be avoided. If, however, the product is frozen during transport or storage, it must be thawed and inspected for signs of separation. If separation has occurred, the product must be mechanically mixed until homoge- neous. When the concentrate is to be stored in an atmospheric storage tank, a .125 to .25 in. (3-6 mm) layer of mineral oil should be added to seal the concentrate and minimize the effects of evaporation. Compatibility Since it is a unique blend of surfactants, high molecular weight polymers, and solvents; it is recommended that ThunderStorm® ATC 1X6 Freeze Protected Alcohol-Resistant Concentrate not be mixed with any other foam concentrates. Consult Williams Fire Hazard Control, Inc® or Ansul Incorporated with any questions of compatibility. w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B9

- 15. 01152005 Materials of Construction Compatibility Tests have been performed with ThunderStorm® ATC 1X6 Freeze Protected Alcohol-Resistant Concentrate verifying its com- patibility with standard carbon steel ‘’black’’ pipe and pipe manu- factured from various stainless steel or brass compounds. Alternative pipe, plastic fittings, and valves may be used in some cases if accept- able to the customer and/or the authority having jurisdiction. Refer to Ansul Technical Bulletin No. 59, Form No. F-90109, addressing acceptable materials of construction for use with Ansul foam con- centrates. To help prevent corrosion, galvanized pipe and fittings must not be used in areas where they will contact the undiluted concentrate. Please first consult Williams Fire Hazard Control, Inc® or Ansul Incorporated for specific guidelines concerning materials of construction. Inspection As with any fire extinguishing agent, ThunderStorm® ATC 1X6 Freeze Protected Alcohol-Resistant Concentrate, whether in the concentrate or pre-mixed form, should be inspected periodically. NFPA 11 “Standard for Low Expansion Foam and Combined Agent Systems”’ requires that foam concentrate samples be submitted to the manufacturer or other qualified laboratory for quality condition testing at least annually. Contact Williams Fire Hazard Control, Inc® or Ansul Incorporated for further information on annual inspection. Ordering Information ThunderStorm® ATC Concentrate is available in pails, drums, totes or bulk shipment. Part No. 432043 5 gallon pail Part No. 432046 55 gallon drum Part No. 432048 265 gallon tote Part No. 432049 Bulk Shipping Weight: 5 gal. (19 L) pail 48 lb. (21.8 kg) 55 gal. (208.2 L) drum 504 lb.(228.6 kg) 265 gal. (1000 L) tote 2750 lb. (1247 kg) Cube: 5 gal. (19 L) pail 1.25 cu. ft. (.0354 m3) 55 gal. (208.2 L) drum 11.83 cu. ft. (.3350 m3) 265 gal. (1000 L) tote 31.50 cu. ft. (.8920 m3) Important Notice to Purchaser: All statements, technical information and recommendations contained herein are based on tests conducted with ThunderStorm® ATC approved equipment, and are believed to be reliable. But the accuracy or completeness thereof is not guaranteed, and the follow- ing is made in lieu of all warranties, expressed or implied, including the implied warranties of merchantability and fitness for purpose: Sellers and manufacturer’s only obligation shall be to replace such quantity of the product proved to be defective. Before using, user shall determine the suitability of the product for it’s intended use, and user assumes all risk and liability whatsoever in connection there within. NEITHER SELLER NOR MANUFACTURER SHALL BE LIABLE EITHER IN TORT OR IN CONTRACT FOR ANY LOSS OR DAMAGE, DIRECT, INCIDENTAL, OR COINCIDENTAL, ARISING OUT OF THE USE OF OR THE INABILITY TO USE THE PRODUCT. No statement or recommendation not contained herein shall have any force or effect unless in an agreement signed by officers of seller and manufacturer. Williams Fire Hazard Control, Inc. P.O. Box 1359 Mauriceville, Texas, USA 77626 24 Hour Emergency Number — 409-727-2347 One Stanton Street, Marinette, WI 54143-2542 715-735-7411 ISO 9001 Registered w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B10

- 16. 01152005 ThunderStorm® ATC AR/AFFF 3% x 3% F-604 Freeze Protected Technical Information Description Freeze Protected ThunderStorm® AR-AFFF 3% Concentrate is formulated from special fluorochemical and hydrocarbon surfactants, a high molecular weight polymer, and solvents. It is transported and stored as a concentrate to provide ease of use and to provide considerable savings in weight and volume. It is intended for use as a 3% proportioned solution in fresh, salt or hard water (water hardness should not exceed 500 ppm expressed as calcium and magnesium). It may also be used and stored as a premixed solution in fresh or potable water for use with the Ansul Model AR-33-D wheeled fire extinguisher. The foam concentrate may be stored at tem- peratures to 0˚F (-18˚C) without freezing. If stored below the minimum use temperature freezing may occur. If frozen the concentrate can be thawed and remixed before use. There are three fire extinguishing mechanisms in effect when using Freeze Protected ThunderStorm® AR-AFFF 3% Concentrate on either a conventional Class B hydrocarbon fuel such as gasoline, diesel fuel, etc., or a Class B polar solvent (water miscible fuel) such as methyl alcohol, acetone, etc. First, an aqueous film is formed in the case of a conven- tional hydrocarbon fuel, or a polymeric membrane in the case of a polar solvent fuel. This film or membrane forms a barrier to help prevent the release of fuel vapor. Second, regardless of the fuel type, a foam blanket is formed which excludes oxygen and from which drains the liquids that form the film or the polymeric membrane. Third, the water content of the foam produces a cooling effect. Typical Physiochemical Propoerties at 77°F/25°C Appearance Gel-Like Liquid Density 1.078 ± 0.050 gm/ml pH 7.0 – .8.5 Refractive Index 1.3980 ± .0020 Viscosity 2000 ± 300 centipoise* Spreading 5.3 ± 1.5 dynes/cm Coefficient *Brookfield Viscometer Spindle #4, Speed 30 Freeze Protected ThunderStorm® AR-AFFF 3% Concentrate is a non-Newtonian fluid that is both pseudo- plastic and thixotropic. Because of these properties, dynamic viscosity will decrease as shear increases. Application Freeze Protected ThunderStorm® AR-AFFF 3% Concentrate is unique among 3% AR-AFFF agents in that the minimum use temperature is the lowest of all conventional 3% AR-AFFF products on the market. This product can be used on either conventional Class B fuels or the polar solvent type Class B fuels. Its excellent wetting characteristics make it useful in combating Class A Fires as well. Because of the low energy to make foam, it can be used with both aspirating and non-aspirating discharge devices. To provide even greater fire protection capability, it can be used with dry chemical extinguishing agents without regard to the order of application to provide even greater fire protection capability. Due to the velocity of the dry chemical discharge, care must be taken not to submerge the polymeric membrane below the fuel surface. Fire Performance Fire Performance – The fire performance of Freeze Protected ThunderStorm® AR-AFFF 3% Concentrate is mea- sured primarily against Underwriters Laboratories Standard 162, 5th Edition and the Williams Fire Hazard Control plunging fire test. Foaming Properties When used with fresh, salt or hard water, at the correct dilution with most conventional foam making equipment, the expansion will vary depending on the performance character- istics of the equipment. Aspirating discharge devices produce expansion ratios of from 5:1 to 10:1 depending primarily on type of aspirating device and flow rate. Non-aspirating devices such as handline water fog/stream nozzles or standard sprinkler heads give expansion ratios of 2:1 to 4:1. Proportioning Freeze Protected ThunderStorm® AR-AFFF 3% Concentrate can be proportioned (at the correct dilution) using most conventional proportioning equipment such as: 1.Balanced pressure and in-line balanced pressure pumped proportioning equipment 2.Balanced pressure bladder tank type proportioner 3.Around-the-pump proportioners 4.Fixed or portable (in-line) venturi type proportioners 5.Handline nozzles with fixed induction/pickup tubes 6.Hydro-foam™ Nozzles The minimum and maximum usable temperature for Freeze Protected ThunderStorm® AR-AFFF 3% Concentrate in this equipment is 0˚ F (-18˚C) to 120˚ F (49˚ C) respectively. Storage/Shelf Life When stored in the packaging supplied (polyethyl- ene drums or pails) or in equipment recommended by the manufacturer and within the temperature limits specified, the shelf life of Freeze Protected ThunderStorm® AR-AFFF 3% Concentrate is 15-20 years. The factors affecting shelf life and stability for AFFF Agents are discussed in detail in Ansul Technical Bulletin No. 54. Freezing of the product should be avoided. If, however, the product is frozen during transport or storage, it must be thawed and inspected for signs of separa- tion. If separation has occurred, the product must be mechani- cally mixed until homogeneous. When the concentrate is to be stored in an atmospheric storage tank, or in containers with large surface area to vol- w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B11

- 17. 01152005 ume ratios, a .125 to .25 in. (3-6 mm) layer of mineral oil should be added to seal the concentrate and minimize the effects of evaporation. Compatibility Since Freeze Protected ThunderStorm® AR-AFFF 3% Concentrate is a unique blend of surfactants, high molecular weight polymers, and solvents; it is recommended that Williams Fire and Hazard Control, Inc® or Ansul Incorporated be consulted before concentrate is mixed with any other concentrates. Materials of Construction Compatibility Tests have been performed with Freeze Protected ThunderStorm® AR-AFFF 3% Concentrate verifying its compatibility with standard carbon steel ‘‘black’’ pipe and pipe manufactured from various stainless steel or brass compounds. Alternative pipe, plastic fittings, and valves may be used in some cases if acceptable to the customer and/or the authority having jurisdiction. Refer to Ansul Technical Bulletin No. 59, Form No. F-90109, addressing acceptable materials of construction for use with Ansul foam concen- trates. Galvanized pipe and fittings must not be used in areas where undiluted concentrate will contact them since corrosion will result. Please first consult Williams Fire and Hazard Control, Inc® or Ansul Incorporated for specific guidelines concern- ing materials of construction. Inspection The National Fire Protection Association in NFPA 11, Standard for Low, Medium, and High Expansion Foam, para- graph 11.6.1 states that fire extinguishing agent, whether in the concentrate or pre-mixed form, should be inspected annu- ally. Please refer to the Field Inspection Manual, (Part No. 31274-01), for the detailed procedures to perform this inspec- tion. An annual inspection is recommended unless unusual conditions of exposure occur such as are described in Ansul Technical Bulletin No. 54. In such cases, Ansul’s recommen- dation should be sought. Ordering Information Freeze Protected ThunderStorm® AR-AFFF 3% Concentrate is available in pails, drums, totes, or bulk shipment. Part No. 432531 5 Gallon Pail Part No. 432532 55 Gallon Drum Part No. 432533 256 Gallon Tote Part No. 432530 Bulk Shipping Weight: 5 gal. (19 L) pail – 45 lbs. (20.4 kg) 55 gal. (208.1 L) drum – 495 lbs. (224.5 kg) 265 gal. (1000 L) tote – 2463 lbs. (1117 kg) Cube: 5 gal. (19 L) pail – 1.25 cu. ft. (.0353 m3) 55 gal. (208.1 L) drum – 11.83 cu. ft. (.3350 m3) 265 gal. (1000 L) tote – 31.50 cu. ft. (.892 m3) Williams Fire Hazard Control, Inc. P.O. Box 1359 Mauriceville, Texas, USA 77626 24 Hour Emergency Number — 409-727-2347 One Stanton Street, Marinette, WI 54143-2542 715-735-7411 ISO 9001 Registered w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B12

- 18. 01152005 ThunderStorm ® ATC AR/AFFF 3% or 6% F-602A Freeze Protected Technical Information Description Freeze Protected ThunderStorm® AR-AFFF 3% or 6% Concentrate is formulated from special fluorochemical and hydrocarbon surfactants, a high molecular weight polymer, and solvents. It is transported and stored as a concentrate to provide ease of use and to provide considerable savings in weight and volume. It is intended for use as a 3% or 6% proportioned solu- tion (depending on the type of fuel) in fresh, salt or hard water. (Water hardness should not exceed 500 ppm expressed as calcium and magnesium.) It may also be used and stored as a premixed solution in fresh or potable water for use with the Ansul Model AR-33-D wheeled fire extinguisher. The foam con- centrate may be stored at temperatures to 0° F (-18° C) without freezing. If stored below the minimum use temperature freezing may occur. If frozen the concentrate can be thawed and remixed before use. There are three fire extinguishing mechanisms in effect when using Freeze Protected ThunderStorm® AR-AFFF 3% or 6% Concentrate on either a conventional Class B hydrocarbon fuel such as gasoline, diesel fuel, etc., or a Class B polar solvent (water miscible fuel) such as methyl alcohol, acetone, etc. First, an aqueous film is formed in the case of a conventional hydro- carbon fuel, or a polymeric membrane in the case of a polar sol- vent fuel. This film or membrane forms a barrier to help prevent the release of fuel vapor. Second, regardless of the fuel type, a foam blanket is formed which excludes oxygen and from which drains the liquids that form the film or the polymeric membrane. Third, the water content of the foam produces a cooling effect. Typical Physiochemical Propoerties at 77°F/25°C Appearance Light Amber Gel-Like Liquid Density 1.000 ± 0.050 gm/ml pH 7.0 - .8.5 Refractive Index 1.3920 ± .0020 Viscosity 1800 ± 300 centipoise* Spreading 6.3 ± 1.5 dynes/cm Coefficient *Brookfield Viscometer Spindle #4, Speed 30 Freeze Protected ThunderStorm® AR-AFFF 3% or 6% Concentrate is a non-Newtonian fluid that is both pseudoplastic and thixotropic. Because of these properties, dynamic viscosity will decrease as shear increases. Application Freeze Protected ThunderStorm® AR-AFFF 3% or 6% Concentrate is unique among 3% or 6% AR-AFFF agents in that the minimum use temperature is the lowest of all conventional AR-AFFF products on the market. This product can be used on either conventional Class B fuels or the polar solvent type Class B fuels. Its excellent wetting characteristics make it useful in combating Class A Fires as well. Because of the low energy to make foam, it can be used with both aspirating and non-aspirat- ing discharge devices. To provide even greater fire protection capability, it can be used with dry chemical extinguishing agents without regard to the order of application to provide even greater fire protection capability. Due to the velocity of the dry chemical discharge, care must be taken not to submerge the polymeric membrane below the fuel surface. Fire Performance The fire performance of Freeze Protected ThunderStorm® AR-AFFF 3% or 6% Concentrate is measured primarily against Underwriters Laboratories Standard 162, 5th Edition and the Williams Fire Hazard Control plunging fire test. There are no U.S. or foreign government specifications on this type of product. Foaming Properties When used with fresh, salt or hard water, at the correct dilu- tion with most conventional foam making equipment, the expan- sion will vary depending on the performance characteristics of the equipment. Aspirating discharge devices produce expansion ratios of from 5:1 to 10:1 depending primarily on type of aspi- rating device and flow rate. Non-aspirating devices such as han- dline water fog/stream nozzles or standard sprinkler heads give expansion ratios of 2:1 to 4:1. Proportioning Freeze Protected ThunderStorm® AR-AFFF 3% or 6% Concentrate can be proportioned (at the correct dilution) using most conventional proportioning equipment such as: 1.Balanced pressure and in-line balanced pressure pumped proportioning equipment 2.Balanced pressure bladder tank type proportioner 3.Around-the-pump proportioners 4.Fixed or portable (in-line) venturi type proportioners 5.Handline nozzles with fixed induction/pickup tubes The minimum and maximum usable temperature for Freeze Protected ThunderStorm® AR-AFFF 3% or 6% Concentrate in this equipment is -20°F (-29 °C) to 120 °F (49 °C) respectively. Storage/Shelf Life When stored in the packaging supplied (polyethylene drums or pails) or in equipment recommended by the manufacturer and within the temperature limits specified, the shelf life of Freeze Protected ThunderStorm® AR-AFFF 3% or 6% Concentrate is about 15-20 years. The factors affecting shelf life and stability for AFFF Agents are discussed in detail in Ansul Technical Bulletin No. 54. Freezing of the product should be avoided. If, however, the product is frozen during transport or storage, it must be thawed and inspected for signs of separation. If separation has occurred, the product must be mechanically mixed until homogeneous. When the concentrate is to be stored in an atmospheric storage tank, or in containers with large surface area to volume ratios, a .125 to .25 in. (3-6 mm) layer of mineral oil should be added to seal the concentrate and minimize the effects of evapo- ration. w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B13

- 19. 01152005 Compatibility Since Freeze Protected ThunderStorm® AR-AFFF 3% or 6% Concentrate is a unique blend of surfactants, high molecular weight polymers, and solvents; it is recommended that Williams Fire and Hazard Control or Ansul Incorporated be consulted before concentrate is mixed with any other concentrates. Materials of Construction Compatibility Tests have been performed with Freeze Protected ThunderStorm® AR-AFFF 3% or 6% Concentrate verifying its compatibility with standard carbon steel ‘’black’’ pipe and pipe manufactured from various stainless steel or brass compounds. Alternative pipe, plastic fittings, and valves may be used in some cases if acceptable to the customer and/or the authority having jurisdiction. Refer to Ansul Technical Bulletin No. 59, Form No. F-90109, addressing acceptable materials of construction for use with Ansul foam concentrates. Galvanized pipe and fittings must not be used in areas where undiluted concentrate will contact them since corrosion will result. Please first consult Williams Fire and Hazard Control or Ansul Incorporated for specific guidelines concerning materials of construction. Inspection The National Fire Protection Association in NFPA 11, Standard for Low, Medium, and High Expansion Foam, para- graph 11.6.1 states that fire extinguishing agent, whether in the concentrate or pre-mixed form, should be inspected annually. Please refer to the Field Inspection Manual, (Part No. 31274-01), for the detailed procedures to perform this inspection. An annual inspection is recommended unless unusual conditions of expo- sure occur such as are described in Ansul Technical Bulletin No. 54. In such cases, Ansul’s recommendation should be sought. Ordering Information Freeze Protected ThunderStorm® AR-AFFF 3% or 6% Concentrate is available in pails, drums, totes, or bulk ship- ment. Part No. 432609 5 Gallon Pail Part No. 432610 55 Gallon Drum Part No. 432611 256 Gallon Tote Part No. 432612 Bulk Shipping Weight: 5 gal. (19 L) pail 45 lbs. (20.4 kg) 55 gal. (208.1 L) drum 495 lbs. (224.5 kg) 265 gal. (1000 L) tote 2463 lbs. (1117 kg) Cube: 5 gal. (19 L) pail 1.25 cu. ft. (.0353 m3) 55 gal. (208.1 L) drum 11.83 cu. ft. (.3350 m3) 265 gal. (1000 L) tote 31.50 cu. ft. (.892 m3) Important Notice to Purchaser: All statements, technical information and recommen- dations contained herein are based on tests conducted with ThunderStorm® ATC approved equipment, and are believed to be reliable. But the accuracy or completeness thereof is not guaranteed, and the following is made in lieu of all warran- ties, expressed or implied, including the implied warranties of merchantability and fitness for purpose: Sellers and manufacturer’s only obligation shall be to replace such quantity of the product proved to be defective. Before using, user shall determine the suitability of the prod- uct for it’s intended use, and user assumes all risk and liability whatsoever in connection there within. NEITHER SELLER NOR MANUFACTURER SHALL BE LIABLE EITHER IN TORT OR IN CONTRACT FOR ANY LOSS OR DAMAGE, DIRECT, INCIDENTAL, OR COINCIDENTAL, ARISING OUT OF THE USE OF OR THE INABILITY TO USE THE PRODUCT. No statement or recommendation not contained herein shall have any force or effect unless in an agreement signed by officers of seller and manufacturer. Williams Fire Hazard Control, Inc. P.O. Box 1359 Mauriceville, Texas, USA 77626 24 Hour Emergency Number — 409-727-2347 One Stanton Street, Marinette, WI 54143-2542 715-735-7411 ISO 9001 Registered w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B14

- 20. 01152005 T-STORM™ AR-AFFF 1% x 3% F-701A ALCOHOL-RESISTANT AFFF Technical Information Description T-STORM™ 1X3 Alcohol-Resistant AFFF (AR-AFFF), F- 701A, is formulated to meet the performance requirements of UNDERWRITERS LABORATORIES, Standard for Safety for Foam Equipment and Liquid Concentrates, UL 162. The foam con- centrate has reduced viscosity for use in a wide range of proportion- ing equipment. T-STORM™ 1X3 AR-AFFF, F-701A, Concentrate is formulat- ed from the same fluorochemical and hydrocarbon surfactants, high molecular weight polymers and solvents as THUNDERSTORM® ATC AR-AFFF, F-601A, but is designed for compliance applica- tions. T-STORM™ is transported and stored as a concentrate to provide ease of use and savings in weight and volume. It contains no PFOS or PFOA. It is intended for use as a 1% proportioned solution on hydrocarbon fuels and as a 3% proportioned solution on polar solvent fuels in fresh, salt or hard water. It may also be stored and used as a premixed solution in fresh potable water only. There are three fire extinguishing mechanisms in effect when using T-STORM™ 1X3 AR-AFFF, F-701A, solution on either a conventional Class B hydrocarbon fuel such as gasoline, diesel fuel, etc., or a Class B polar solvent (water miscible fuel) such as methyl alcohol, acetone, etc. First, an aqueous film is formed in the case of a conventional hydrocarbon fuel, or a polymeric membrane in the case of a polar solvent fuel. This film or membrane forms a barrier to help prevent the release of fuel vapor. Second, regardless of the fuel type, a foam blanket is formed which excludes oxygen and from which drains the liquids that form the film or the polymeric membrane. Third, the water content of the foam produces a cooling effect. Typical Physiochemical Propoerties at 77°F/25°C Appearance Yellow Gelled Liquid Density 1.02 ± 0.01 g/ml pH 7.5-8.5 Refractive Index 1.3540 ± 0.0015 Viscosity 2700 ± 500 cps* Spreading Coefficient 3.0 - 5.0 *Brookfield Viscometer Spindle #4, Speed 30 rpm T-STORM™ 1X3 AR-AFFF, F-701A, is a non-Newtonian fluid that is both pseudoplastic and thixotropic. Because of these proper- ties, dynamic viscosity will decrease as shear increases. Application T-STORM™ 1X3 AR-AFFF, F-701A, can be used on either conventional Class B fuel or the polar solvent type Class B fuels. Because of the low energy required to make foam, it can be used with both aspirating and non-aspirating discharge devices. To provide even greater fire protection capability, it may be used with “PKW” dry chemical extinguishing agent without regard to the order of application. HYDRO-CHEM™ Technology is a rec- ommended application for dual agent use on three-dimensional fires. Due to the velocity of the dry chemical discharge, care must be taken not to submerge the polymeric membrane below the fuel surface when using the twin agent method on polar solvent fuels. Fire Performance The fire performance of T-STORM™ 1X3 AR-AFFF, F-701A, is measured against Underwriters Laboratories Standard 162 (Latest Revision). Foaming Properties When used with fresh, salt or hard water at the correct dilution with most conventional foam making equipment; the expansion will vary depending on the performance characteristics of the equipment. Aspirating discharge devices produce expansion ratios of 5:1 to 10: 1 depending primarily on the type of aspirating device and flow rate. Non-aspirating devices such as hand line water fog/stream nozzles give expansion ratios of 2:1 to 4:1. Proportioning T-STORM™ 1X3 AR-AFFF, F-701A, can be easily propor- tioned (at the correct dilution) using most conventional proportion- ing equipment such as: 1. HYDRO-FOAM™ Nozzles 2. Balanced pressure and in-line balanced pressure pump pro- portioning equipment. 3. Balanced pressure bladder tank proportioners 4. Around-the-pump and through-the-pump proportioners 5. Fixed or portable (in-line) venturi proportioners 6. Hand line nozzles with fixed induction/pickup tubes The minimum and maximum usable temperature for T- STORM™ 1X3 AR-AFFF, F-701A, in this equipment is 35 °F (2 °C) to 120 °F (49 °C) respectively. Storage/Shelf Life When stored in the packaging supplied (polyethylene totes, drums or pails) or in equipment recommended by the manufac- turer and within the temperature limits specified, the shelf life of T-STORM™ 1X3 AR-AFFF, F-701A, is about 15-20 years. The fac- tors affecting shelf life and stability for AFFF agents are discussed in detail in Ansul Technical Bulletin No. 54. Freezing of the product should be avoided. If, however, the product is frozen during transport or storage, it must be thawed and inspected for signs of separation. If separation has occurred, the product must be mechanically mixed until homogeneous. When the concentrate is to be stored in an atmospheric storage tank, a 1/8 to 1/4 in. (3-6 mm) layer of mineral oil should be added to seal the concentrate and minimize the effects of evaporation. Compatibility It is recommended that T-STORM™ 1X3 AR-AFFF, F-701A, not be mixed with any other foam concentrates. Consult Williams Fire and Hazard Control or Ansul Incorporated with any questions of compatibility. w w w . w i l l i a m s f i r e . c o m extinguishingagentsaccessories extinguishingagentsaccessories 4 0 9 - 7 4 5 - 3 2 3 2 4 0 9 - 7 2 7 - 2 3 4 7 PRODUCT INFORMATION 24-HR EMERGENCY B15