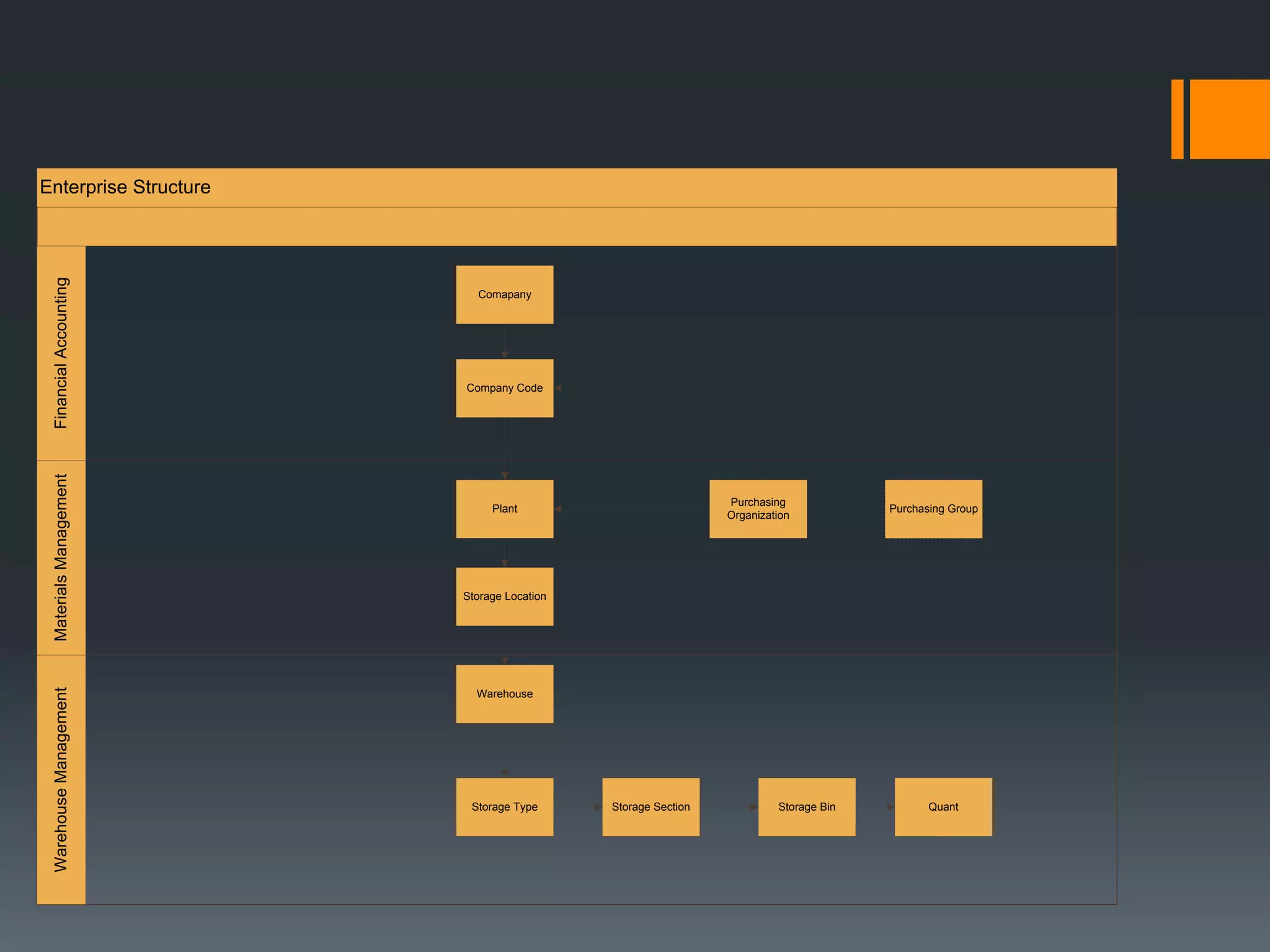

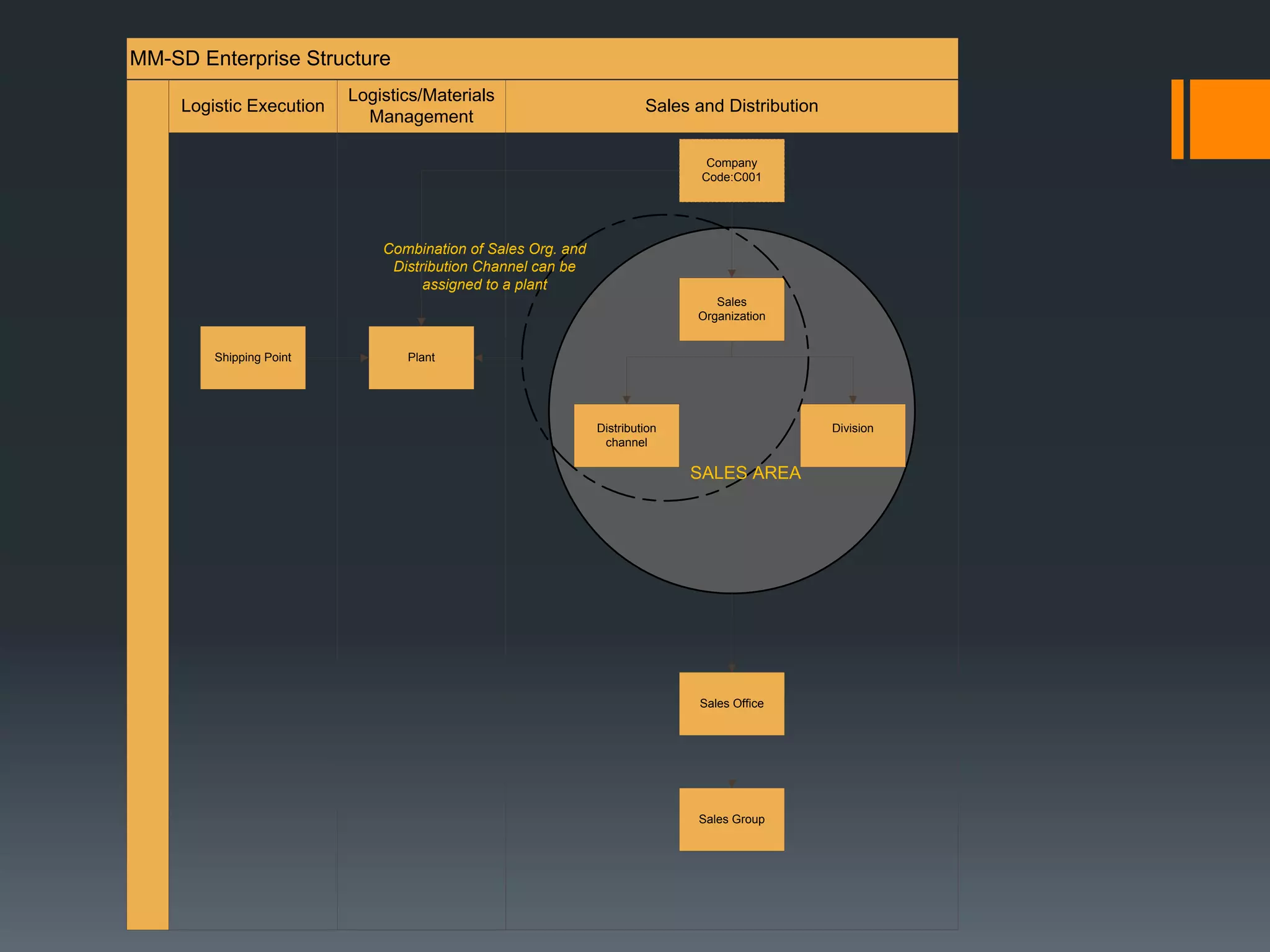

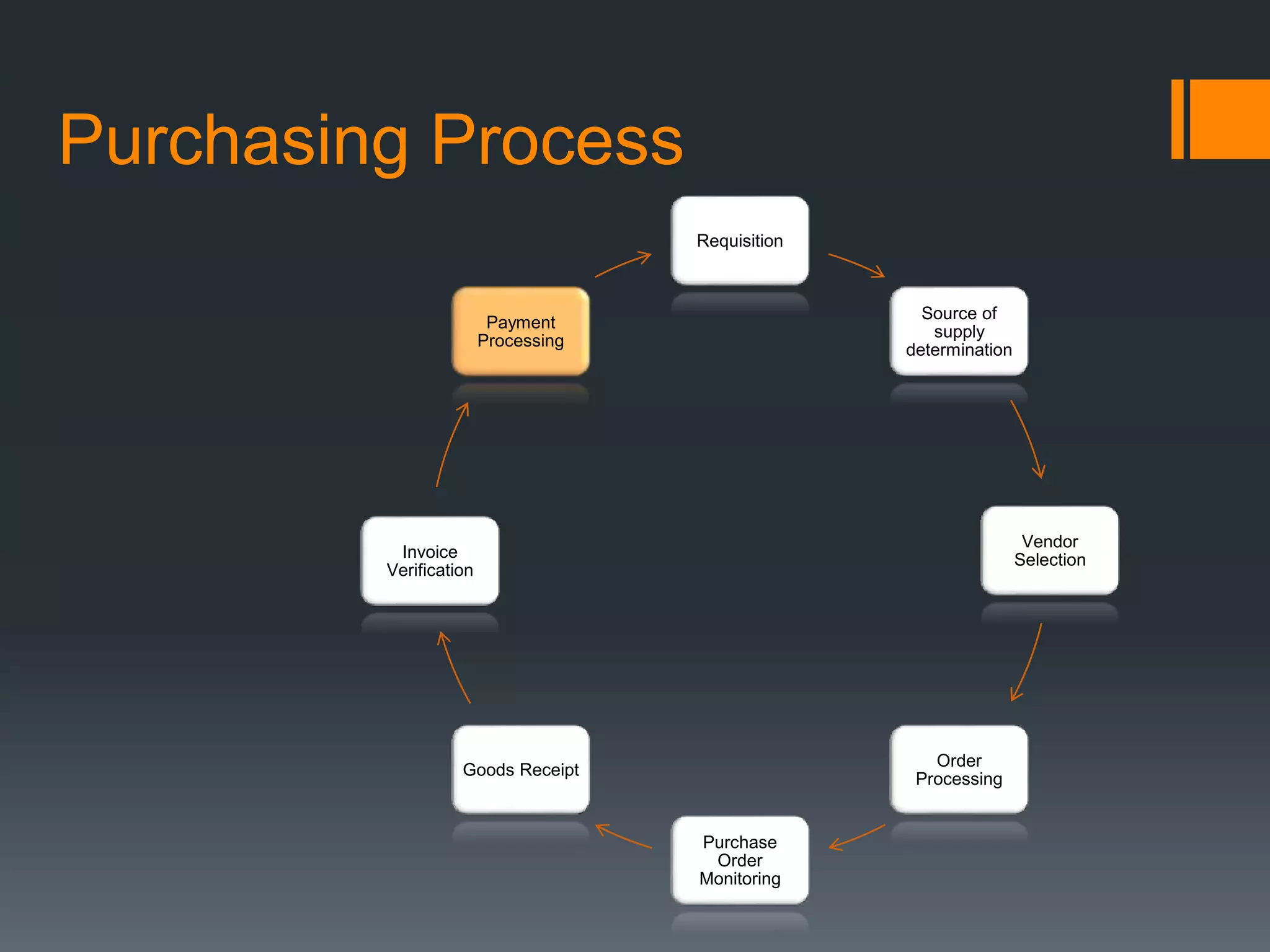

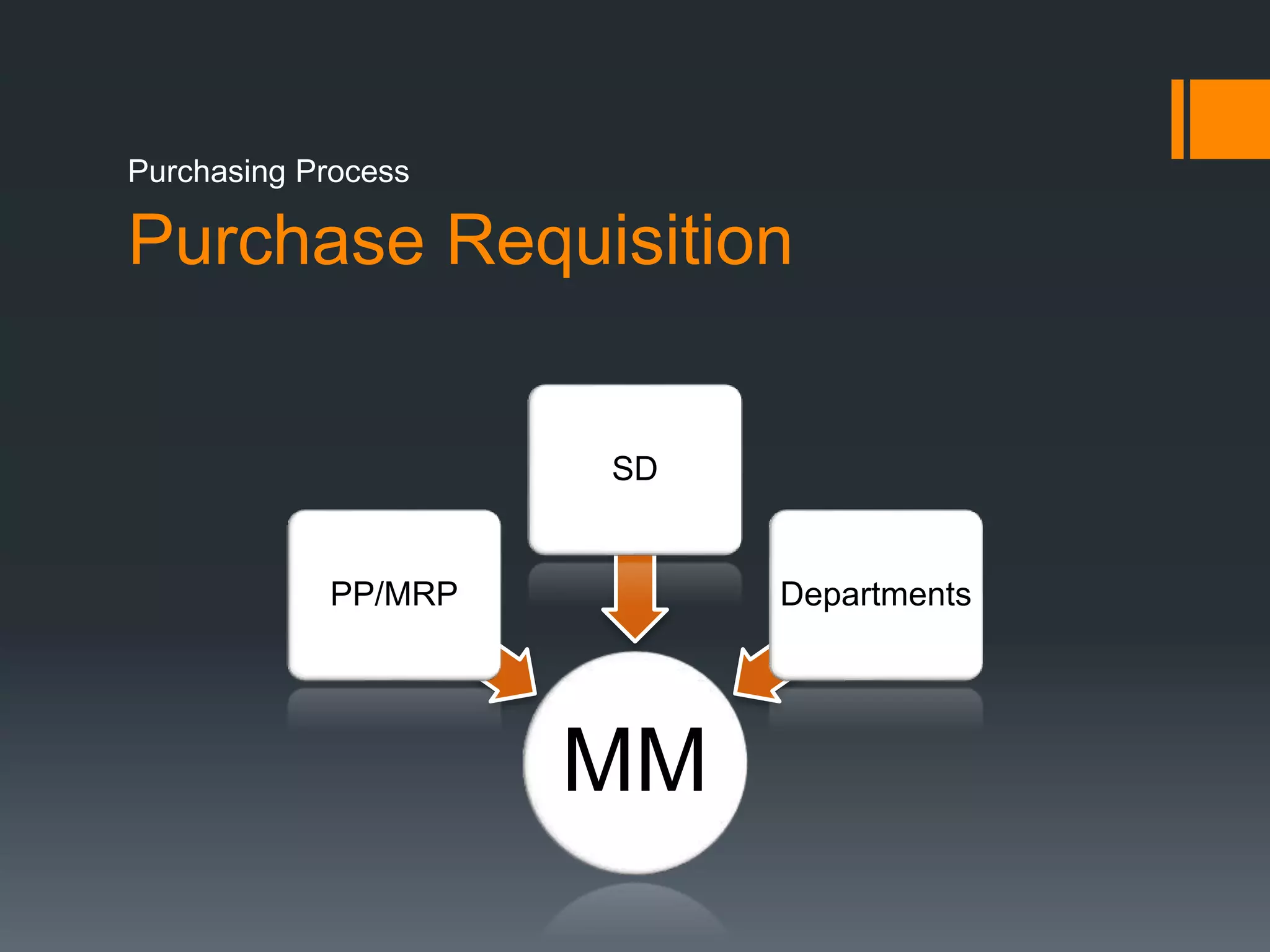

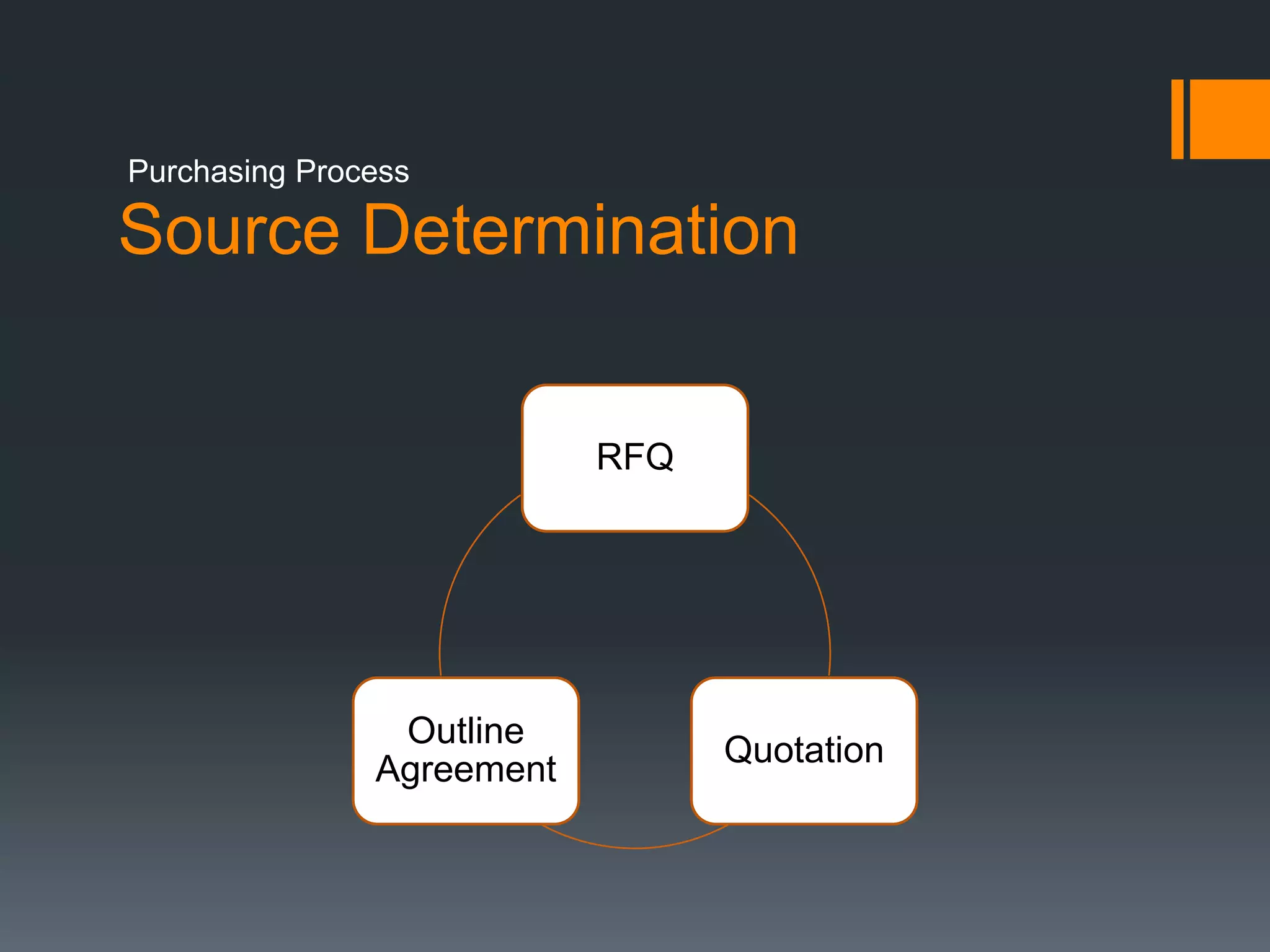

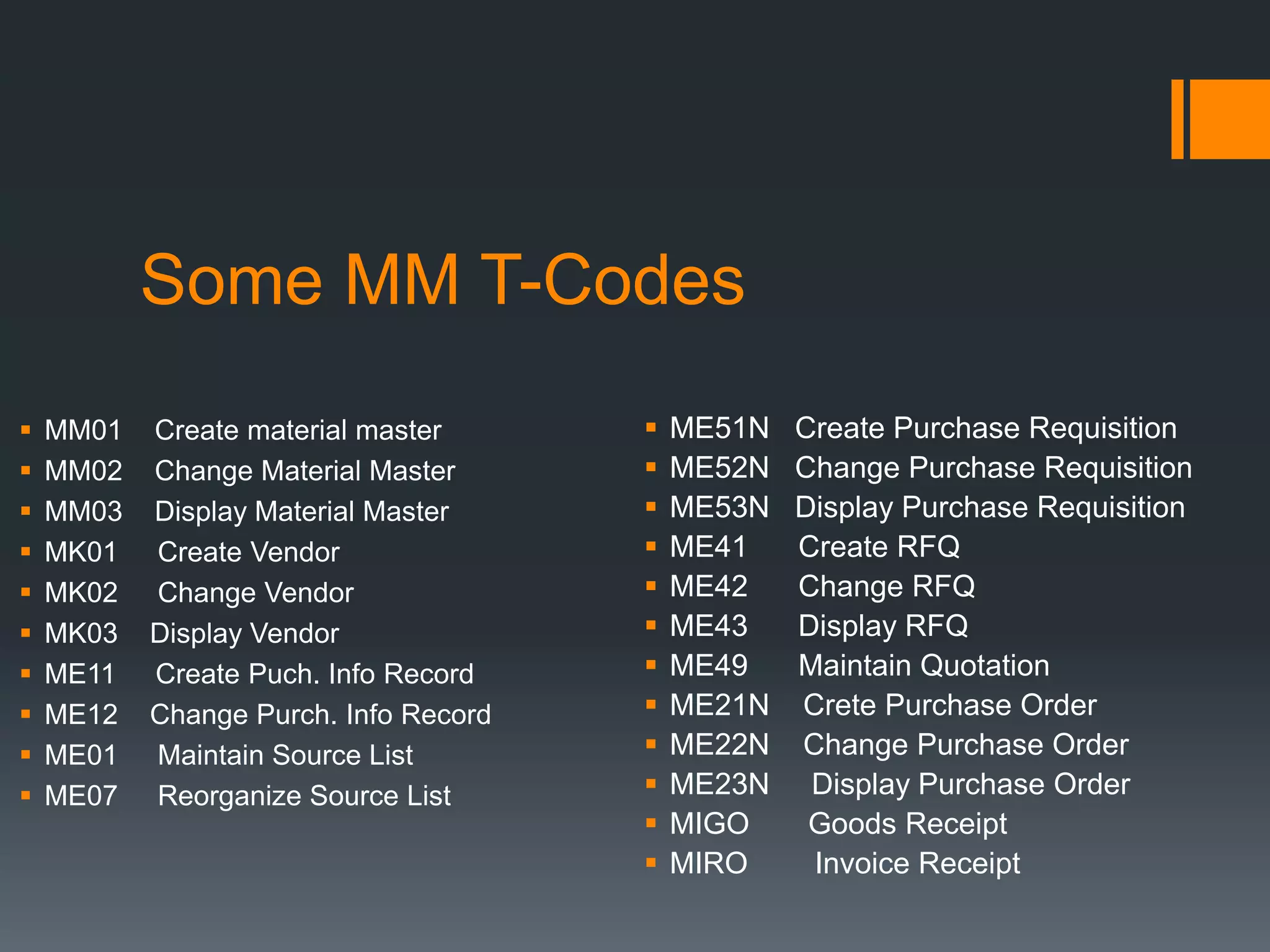

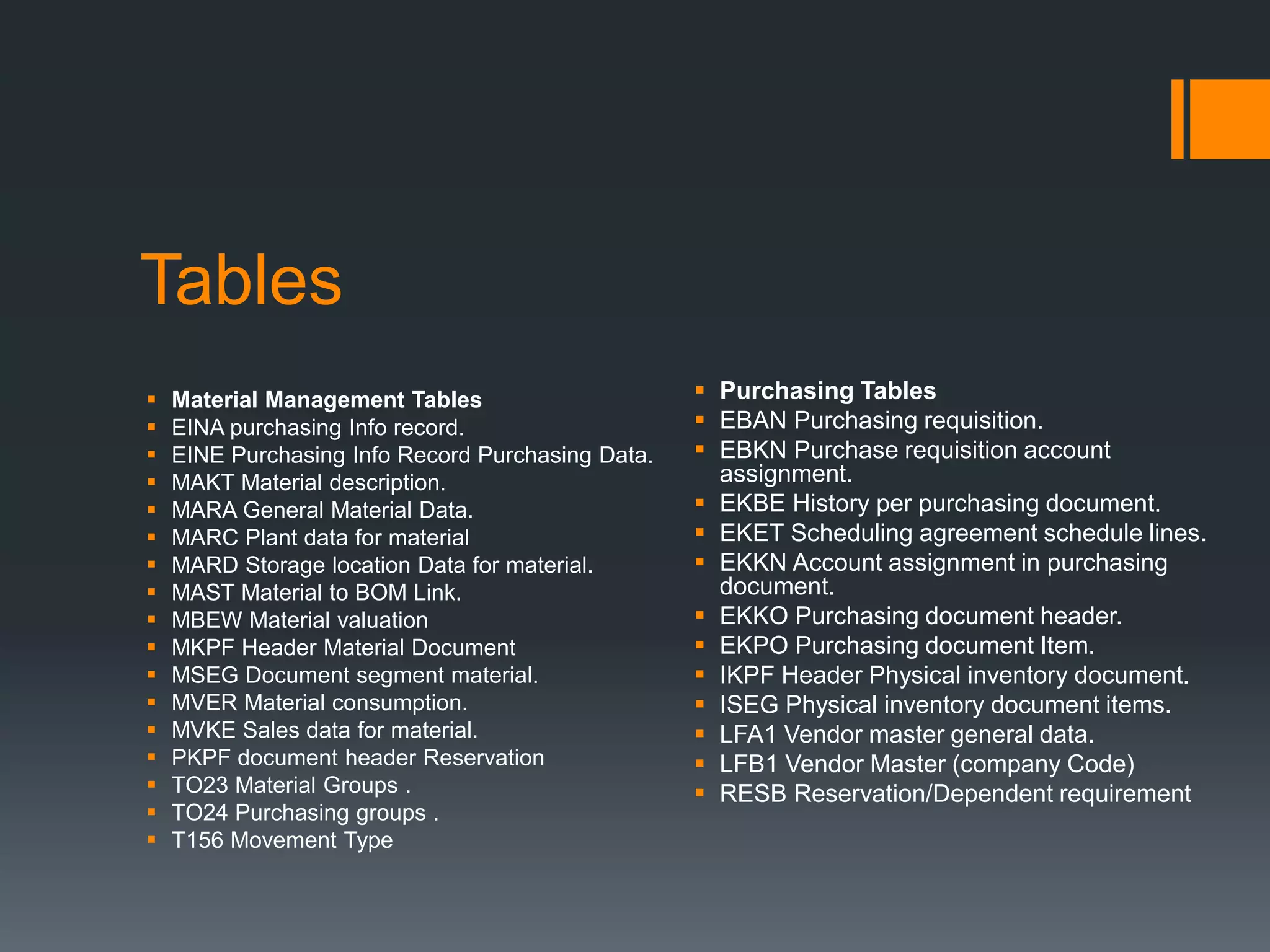

This document provides an overview of SAP MM (Materials Management) including key concepts like enterprise structure, procurement processes, master data, purchasing processes and configurations. It describes the basic organizational structure in SAP MM and how materials are planned and procured. It also lists some important transaction codes and tables used in SAP MM for tasks like creating purchase requisitions, purchase orders, vendor master data and more.