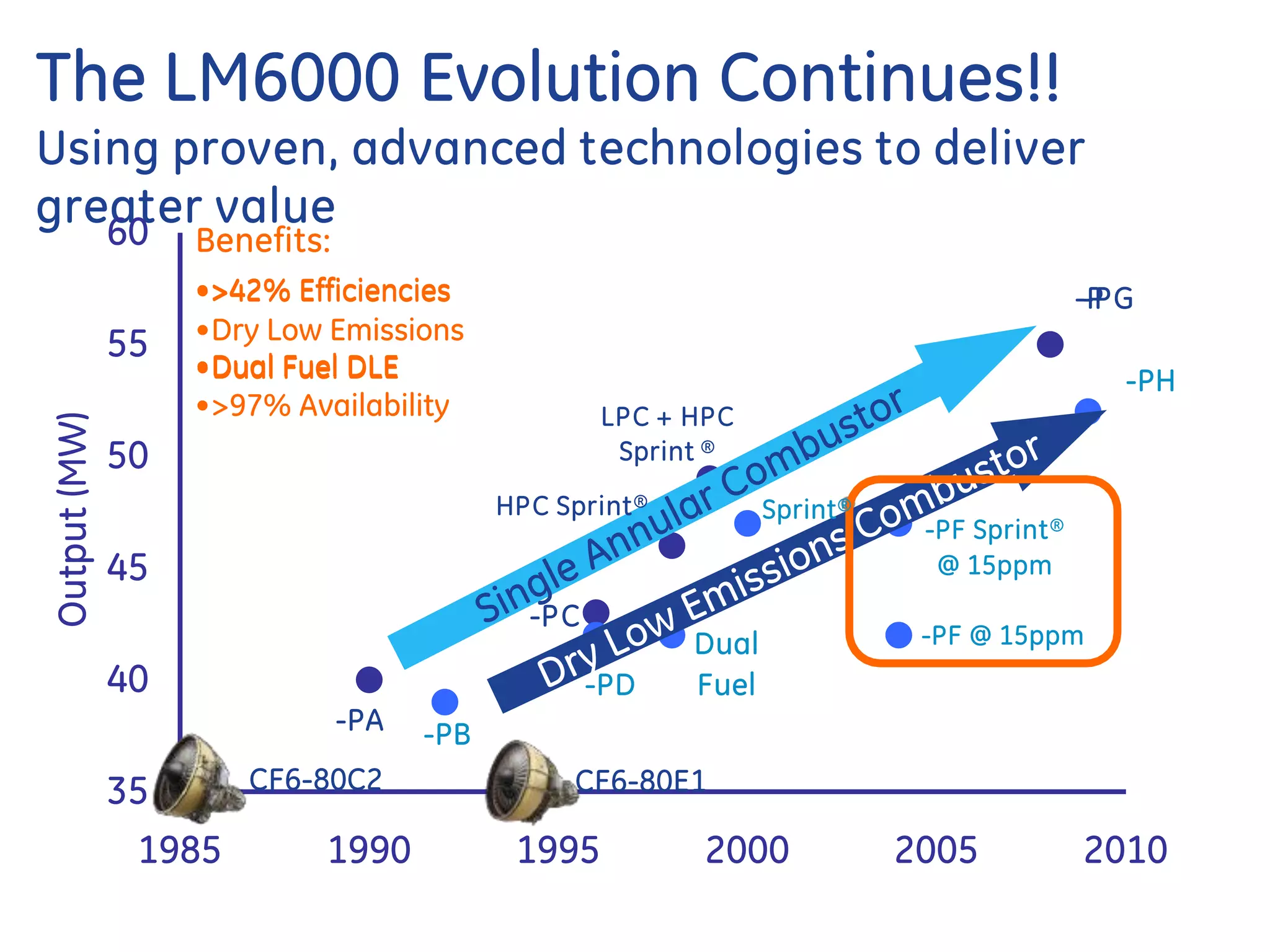

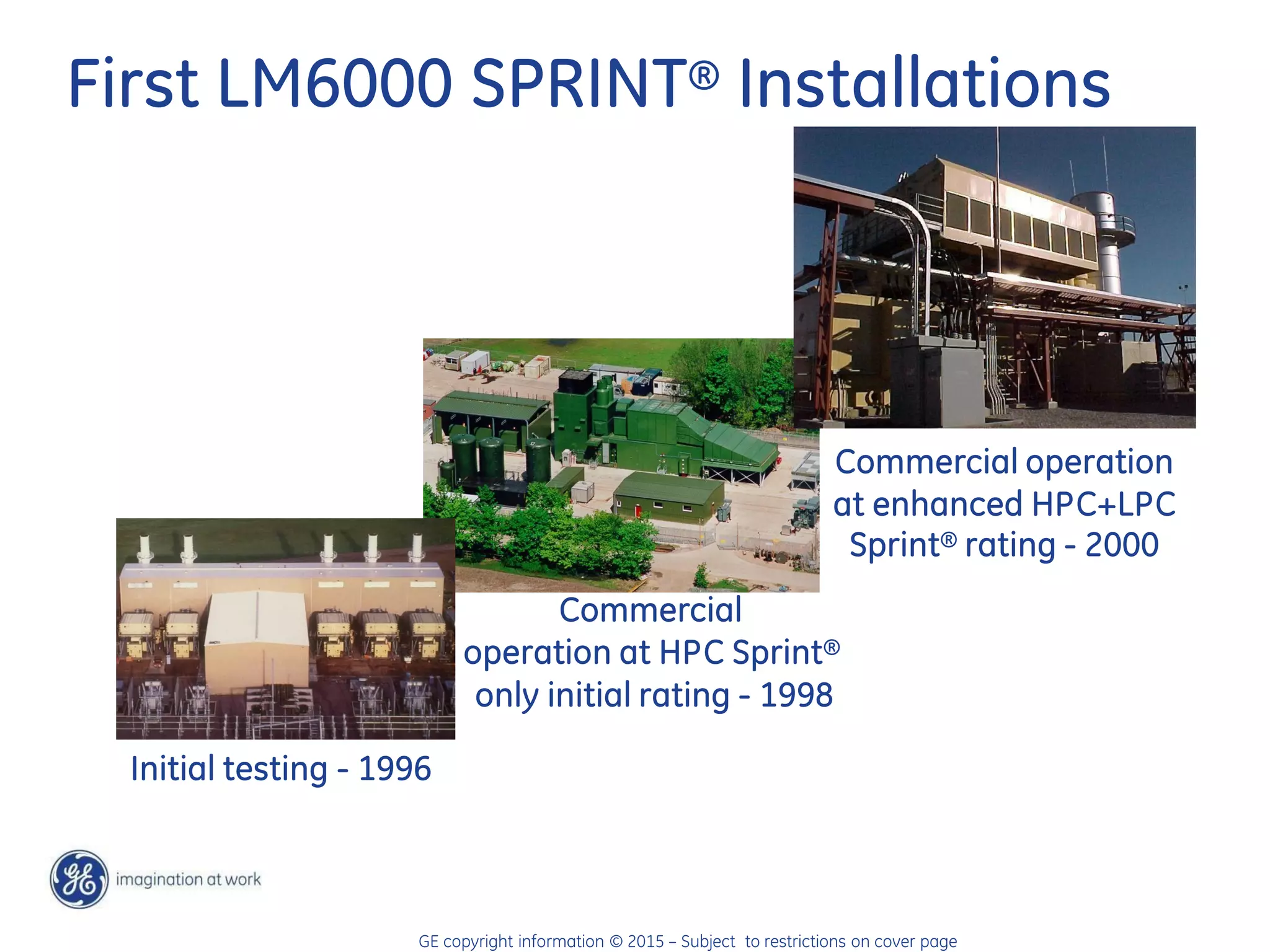

1) The LM6000 gas turbine can be upgraded with SPRINT technology to increase power output and efficiency.

2) SPRINT stands for SPRay INTercooling and increases power by injecting water into the compressor, allowing the engine to run at higher temperatures and mass flows.

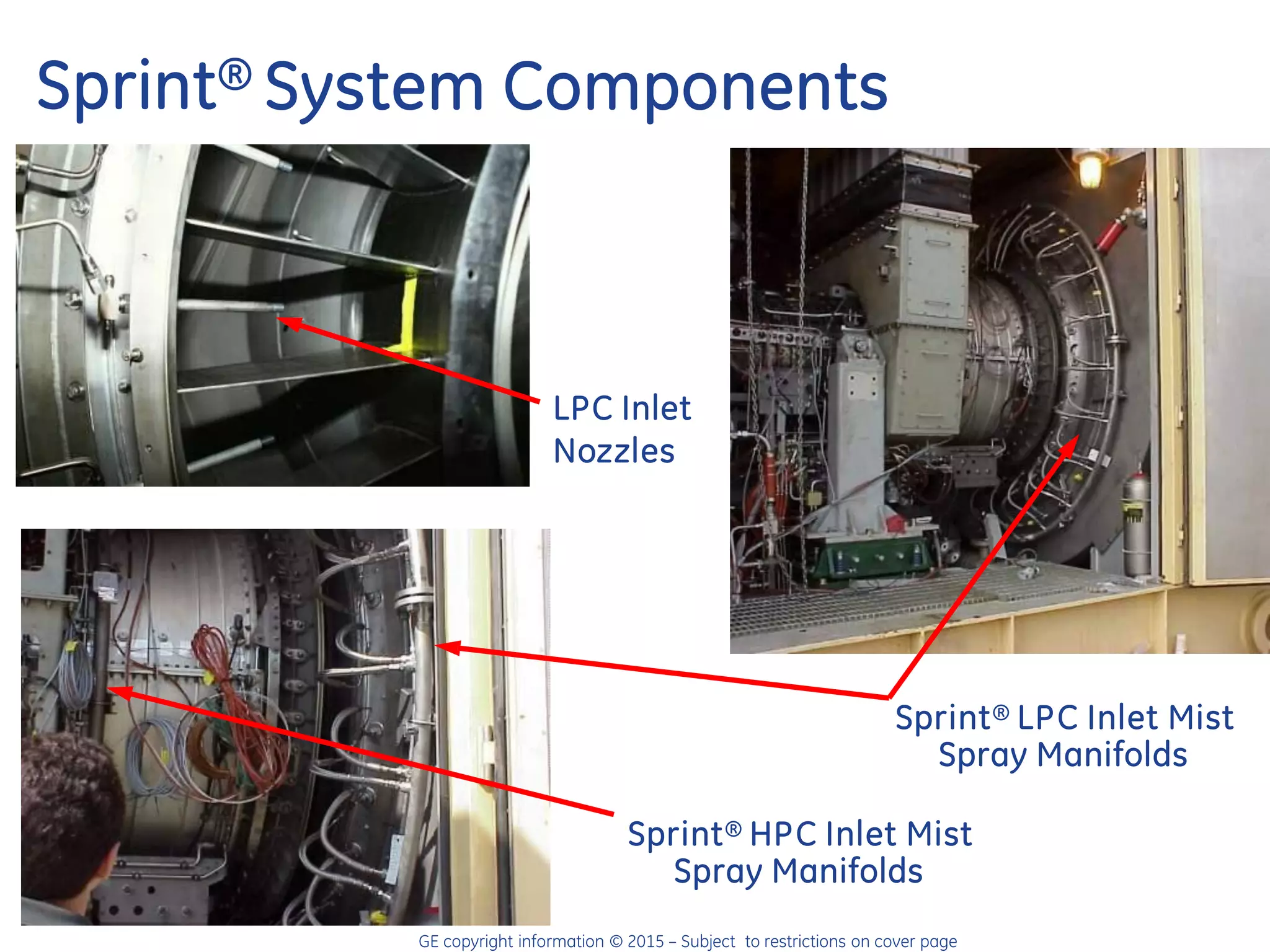

3) SPRINT installation involves adding water and air manifolds and nozzles to inject an atomized water spray into the low and high pressure compressors. This can increase output by up to 7MW depending on ambient conditions.