Abrasive and polishing agents/certified fixed orthodontic courses by Indian dental academy

- 1. INDIAN DENTAL ACADEMY Leader in continuing Dental Education

- 2. Contents • Introduction • Definition • Factors affecting the rate of abrasion • Factors affecting the efficiency of abrasion • Design of the abrasive instrument • Types of abrasives • Polishing

- 3. Finishing and polishing :Denture base resins RPD frameworks Gold castings Restorative resins Posterior tooth colored Restorations Porcelain Ceramic restorations and Review of literature Summary Conclusion References

- 4. INTRODUCTION

- 5. DEFINITIONS Abrasion Craig , has defined abrasion as : “A process of wear whereby a hard rough surface ( like a sand paper disk ) or hard irregular shaped particles ( like those in a slurry ) plough grooves in a softer material and cause materials from these grooves to be removed from the surface”. Skinner has stated abrasion to be either a two body process or a three body process.

- 6. Finishing : The term finishing denotes to cut or remove the excess . It is usually performed with coarser abrasives when compared to polishing . Polishing : The use of progressively finer abrasives to remove scratches and give a high shine or luster to the material . To understand this more specifically , the terms such as abrasive wear and erosive wear need more specific understanding .

- 7. Wear : It is a material removal process that can occur whenever surfaces slide against each other . In dentistry , the outermost particle or the surface material of an abrading instrument is referred to as ABRASIVE . The material being abraded is called as Substrate .

- 8. Abrasive wear : Two types – Two Body Wear : Occurs when abrasive particles are firmly bonded to the surface of the abrasive instrument and no other abrasive particles are used eg. A diamond bur abrading a tooth . Three body wear : occurs when the abrasive particles are free to translate and rotate between two surfaces eg. action of prophylaxis paste as they are applied to tooth enamel by a rubber cup .

- 10. Erosive wear : This is caused by hard particles impacting a substrate surface, carried either by a stream of air or a stream of liquid .Erosive wear should be differentiated from chemical erosion more commonly know as acid etching which involves acids and alkalis instead of hard particles to remove the substrate material .

- 11. Factors affecting the rate of abrasion : 1. Concentration of the abrasive particles 2. Size of the particles : expressed in millimeters classified as –fine, medium and coarse. 3. Speed : The faster the speed , faster will be the rate of abrasion. 4. Pressure of the abrasive particles against the surface being abraded : Heavy pressure will lead to formation of deeper scratches and faster removal of the substrate .

- 12. Factors influencing the efficiency of the abrasives : 1. Hardness of the abrasive particle . 2. Rate of movement of the abrasive particles 3. Properties of the material being removed: A brittle material can be abraded rapidly whereas a malleable and ductile material eg. Gold will flow instead of being removed by the abrasive .

- 13. a Cutting operation , a Grinding operation and a Polishing operation Difference Between

- 15. Design of Abrasive Instrument Finishing and polishing devices Abrasive and polishing devicesCutting instruments Loose abrasives Bonded abrasives Coated abrasives

- 16. Loose abrasives or grits : They are derived from abrasive materials that have been crushed and passed through series of mesh screens to obtain different particle sizes- Coarse, medium coarse, medium fine and super fine. Loose abrasive polishing pastes contain a fine particle size distribution of either aluminium oxide or diamond particles dispersed in a water soluble vehicle , such as glycerine.

- 17. Bonded abrasives These consists of abrasive particles incorporated through a binder used for grinding tools. The matrix is usually an elastomeric material such as rubber or silicone compound, but can also be rigid and non elastic in nature. Eg. Bullet or Pointed white stone used at low speed .

- 18. The abrasives are bonded by four methods: 1. Sintering. 2. Vitreous bonding. 3. Resinous bonding. 4. Rubber bonding.

- 20. Coated Abrasives They are usually in the form of a mylar, paper or some other polymeric backing, wherein the abrasive particles are distributed on the surface of the backing or some other symmetric matrix design. The abrasive particles are retained on the surface of the disc or matrix by an adhesive polymeric surface coating or layer. -Aluminium oxide. -silicon carbide. Moisture resistant backings are advantageous as the abrasive stiffness is not reduced by water degradation.

- 21. Air Abrasive Technology As an alternative to the use of rotary cutting, air abrasive systems can deliver a fine, precisely controlled high-pressure stream of 25 to 30um aluminium oxide particles to remove enamel, dentin, and restorative materials. Because air abrasion generates minimal heat or vibration, the potential for tooth chipping or micro fracturing is minimized.

- 22. A controlled delivery of air , water and sodium bicarbonate slurry to remove plaque and stains from tooth surfaces is also employed for Dental Hygiene procedures.

- 23. Skinners has grouped abrasives as Natural abrasives : Arkansas stone Sand Chalk corundum Tripoli Diamond Cuttle Emery Quartz Garnet Kieselguhr Pumice Zirconium silicate Manufactured abrasives : Silicon carbide Aluminum oxide Synthetic diamond Rouge Tin oxide

- 24. 1. Arkansas Stone : Semi-translucent , light grey , siliceous sedimentary rock mended in Arkansas Contains mico-crystalline quartz . Small pieces are attached to metal shanks and trued to various shapes for fine grinding of tooth enamel. 2. Chalk : mineral form of calcite contains calcium carbonate used as a mild abrasive paste to polish teeth enamel , gold fillings ,…

- 25. Corundum : Largely replaced by alpha aluminium oxide due to its various superior physical properties . Available as bonded abrasive and is used primarily to grind metals . Diamond : Transparent colorless mineral composed of carbon called SUPER-ABRASIVE because of its ability to abrade any known substance . Hardest substance known . Used on ceramic and resin based composite materials. Supplied as – bonded abrasive , diamond abrasive pastes , abrasive strips .

- 27. Emery : Consists primarily of a natural oxide of aluminium called corundum .There are various impurities present , such as iron oxide which also act as abrasives .Usually bound to paper discs and can be used on gold or porcelain . Garnet : Includes several minerals , which posses similar physical properties and crystalline form like silicates of Al,Co,Mg, Mn. Is dark red , extremely hard and when fractured during abrasive activity forms sharp chisel shaped plates-thus making garnet an effective abrasive.Usually coated on paper or cloth with a binder. Cuts both metal and porcelain. Denture abrasive discs .

- 28. Pumice : Highly siliceous material of volcanic origin . Suitable for use as an abrasive or a polishing agent according to its particle size .Can be used for many operations from smoothening of denture bases to the polishing of teeth in the mouth . Quartz : The particles are pulverized to form sharp angular particles , which are useful in making coated discs . Used to finish metal alloys and may be used to grind dental enamel .

- 29. Sand : Is an abrasive agent along with other forms of quartz Eg. Sandpaper is coated with a dense crystalline form of quartz called Flint. Flint is a naturally occurring mineral that chips to form sharp cutting edges . It is not as durable or strong as other abrasives , but it is a useful abrasive in the finishing cast gold .Also available a powder in sandblasting equipment .

- 30. Tripoli : Mild abrasive and polishing agent True Tripoli originates from certain porous rocks, first found in Northern Africa near Tripoli , for which it was named . Used for polishing metal alloys and some plastic metals .

- 31. Zirconium silicate : Occurs in nature as Zircon . Is ground to various particle sizes and used as a polishing agent . It is used as a constituent of dental prophylactic pastes and in abrasive impregnated polishing strips and discs . Cuttle : A fine , relatively soft polishing agent made from calcified internal shell of cuttle fish . It is used on paper discs and for delicate operations like polishing of metal margins .

- 32. Kieselguhr : It is composed of siliceous remains of minute aquatic plants know as diatoms . The coarser form is called diatomaceous earth , which is used as a filler in many dental materials . It is an excellent mild abrasive and polishing agent . Precaution should be taken – respiratory silicosis due to long term exposure .

- 33. Manufactured abrasives Silicon carbide : First of the synthetic abrasives to be developed . It is the basic material of corundum Two types are manufactured –green form and blue black form . Cutting efficiency of silicone carbide abrasives is higher as the particles are sharp and break to form new sharp particles . Supplied as an abrasive in coated discs, vitreous and rubber alloys , ceramic and plastic materials . Most of the steel burs employed for the tooth cutting are made of silicon carbide .

- 34. Aluminium Oxide : This is the second synthetic abrasive to be manufactured . Pure aluminium oxide is manufactured from bauxite , an impure aluminium oxide. Extremely fine particles of aluminium can be obtained by a water floation process. In this form it is know as levigated alumina and it is used extensively for polishing metallographic specimens . The forms usually prepared are : Coarse grit aluminium oxide is the abrasive in brown , pink , or coral stones used for finishing metal and ceramic copings . A very fine grit (400) is used for the manufacture white polishing stones, sometimes called Poly stones

- 35. Synthetic diamond : The synthetic or manufactured form of diamond saws, wheels and burs , diamond blocks-used for truing of bonded abrasives . They are used primarily on teeth , ceramic materials .. Rouge: It is a fine red powder composed of iron oxide. Usually employed in cake form It is impregnated on paper or cloth, known as Crocus cloth Excellent polishing agent for gold and noble metal alloys.

- 36. Tin oxide : Also called as Putty powder ,it is used as a polishing agent for teeth and metallic restorations in the mouth It is mixed with water , alcohol or glycerin and used as a paste.

- 37. Polishing Is the production of a smooth mirror like surface without use of any external form. If the size of the abrasive is reduced sufficiently, the scratches finally become extremely fine and may disappear entirely. The surface then acquires a smooth shiny layer referred by Skinner as a POLISH.

- 38. The polished layer is thought of one made up of minute crystals, thus know as the “Micro crystalline layer or Beilby layer” which is easily kept clean and has high corrosion resistance.

- 39. Finishing and polishing of the denture base resin 1.Remove the stone from the denture in small sections. Use a bur or a saw judiciously in removing the stone in sections without damaging the denture . Edentulous casts may have undercut areas and also cast is stronger than the plastic denture . Injudicious prying will result in a broken denture 2.A shell blaster is also helpful in removing stone from the interior of the denture . A pneumatic chisel also aids in removing stone from the denture . 3. After separating the denture the cast , it is ready for finishing and polishing .

- 43. Finishing and polishing the partial denture framework :

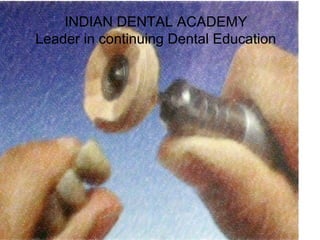

- 51. The technique consists of the following steps 1. Contour with carbide burs, green stones (Silicon Carbide or heatless stones. 2.Finish with pink stones ( Aluminium oxide) or Medium grade abrasive impregnated rubber wheels and points (Brown and Green) 3.Apply fine abrasive impregnated rubber wheels, cups and points ; and if necessary 4.Apply Tripoli or Rouge with rag or leather wheels. Finishing and Polishing of Gold Alloys

- 52. Finishing and polishing of Porcelain Usually two types of kits are available to polish porcelain- 1 Extra oral kits 2. Intra oral kit Examples of extraoral kits : komet/brasseler Dialite Porcelain polishing kit ; Revitalizer (Cosmedent ), Ceramiste Silicon Points (Shofu ).

- 53. These are bonded abrasives and rubber polishing devices that fit straight laboratory handpieces and can operate at higher RPM. The use of diamond polishing paste along with these kits help to produce a polished porcelain surface that is highly smooth and with a surface gloss equivalent to that produced by glazed porcelain.

- 54. Sequence for Extraoral Finishing and Polishing 1. Finishing diamonds, eg. Esthetic Trimming diamonds (Komet/Brasseler), Two Stripper MFS (premier),and T&F and Hybrid points (Shofu) are used dry to adjust and provide gross finishing. 2. Finishing discs or bonded abrasive wheels can also be used , desired for gross adjustment. 3. Rubber porcelain polishing devices are used to pre polish and provide initial polish to the adjusted area.

- 55. 4. Loose abrasive diamond porcelain polishing paste is applied .For example, Porcelize (Cosmedent ), Truluster polishing system (Komet ) ,Two Stripper Mfs Diamond Polishing System (Premier) and Diamond Polish (Ultradent ), using felt wheels and points or a soft using felt wheels and points or a soft Robinson brush on occlusal areas.

- 56. Intra-Oral Polishing Follows similar procedural steps as extra oral polishing. The rationale for the necessity of intraoral porcelain polishing follows from clinical observation that unpolished porcelain can accelerate wear of opposing natural tooth structure and unpolished margins of bonded restorations are more susceptible to inflammation and poor esthetics.

- 57. The Sequence 1.Finishing diamonds. 2.Finishing discs or Enhance disc or Rubber polishing instruments . 3.Diamond polishing paste. -Is also applicable intraorally with some modifications. Diamonds should be used wet to avoid excessive heat. Preferred devices to apply diamond -polishing paste intraorally include enhance polishing cups (Densply) or Robinson brushes.

- 58. Finishing Of All Ceramic Restorations : 1. Broad, relatively flat surfaces are best reduced extra orally with large, smooth-cutting Busch silent- stone, while grooves and ridges are reshaped with smaller pointed diamond stones and green stones. 2. Instruments that have been used on metals should not be used on porcelain. Metal particles become embedded in pores in the porcelain and cause discoloration. 3. When working near an acute edge of porcelain. apply the stone so that it is moving from the edge towards the greater bulk to prevent chipping the fragile edge. This is opposite of the technique used in finishing metal margins.

- 59. 4. Roughened ceramic surfaces are smoothened with clean white stones and polished with rubber wheels of progressively finer grit such as those found in the ceramsite kit is indicated by stripes around the shank of the instrument. No stripe is coarse, one yellow stripe is medium and either two yellow stripes or one white stripe is fine. 5. Pastes containing diamond dusts are available for use on cups and brushes. Porcelain may also be reglazed after it is polished. 6. Final finishing procedures can be accomplished with porcelain polishing agents, including rubberized abrasives and diamond polishing paste. The proximal areas can be finished with finishing strips.

- 60. 5. Pastes containing diamond dusts are available for use on cups and brushes. Porcelain may also be reglazed after it is polished. 6. Final finishing procedures can be accomplished with porcelain polishing agents, including rubberized abrasives and diamond polishing paste. The proximal areas can be finished with finishing strips

- 61. Polishing of teeth : Acrylic resin teeth are polished by the same method as the denture base material. Polishing of porcelain teeth : Since it is more difficult to polish ground porcelain teeth than acrylic teeth, restoring a satisfactory surface requires more effort. 1. Smoothen the surface of ground porcelain teeth with a medium polishing wheel. 2. Smoothen the surface again with a fine polishing wheel .

- 62. 3. Polishing in two directions with a lathe-mounted rag wheel and slurry of flour of pumice. 4. The final polishing is done with a clean lathe- mounted rag wheel and slurry of porcelain finishing polish.

- 63. Finishing and polishing of Restorative Resins : Although one may think that different finishing techniques would be appropriate for posterior and anterior composites, Prattern and Johnson pointed out that no statistically significant difference exists between posterior and anterior materials. Thus, primary considerations for finishing any restoration are based on certain criteria :

- 64. 1. Instrument shape : Anterior finishing : The correct shape for finishing anterior restorations is dependent on the surface being finished. For the labial surface, a long tapered straight edge instrument is preferred, which allows the basic straight shape of the labial surface to be easily contoured. For cervical finishing, a much smaller, but also tapered finishing instrument conforms to the desired straight emergence profile as tooth emerges from the gingival sulcus. For lingual finishing, the rounded, Football shaped instrument can best supply the appropriate curve.

- 65. Posterior finishing : For posterior finishing, 4 instruments can generally finish most composite restorations. The first instrument should be small and thin enough to remove any overhang or excess marginal build up. For this purpose, a 4mm tapered point instrument is best. The basic occlusal anatomy is then placed with the rounded football shaped instrument. Grooves and fissures are next placed using the round end tapered series of diamond or carbide instruments.

- 66. Polishing the posterior composite is easily done using a series of impregnated points (shofu polishing kit) . They must be used in sequence with no band first, followed by yellow and white-banded instruments. Polish and paste can be used in combination with the points or cups.

- 67. Surface of Finishing Instrument Bognosian, Randolph and Jekkals, point out that carbides should not be used at higher speeds when trimming and finishing micro filled composite resins as they tend to disrupt the surface. However high speed finishing with carbide burs on small particle composite resins produces a non disrupted surface that was free from striations and grooves left by diamond.

- 68. Finishing and polishing of Titanium Operations Finishing materials Remarks Removal of Sprue runners ST cutting disk (large) TX cutting disk (thin) Thin Sprue runners (quick cutter) or STM (handtool) Avoid tilting , cool work pieces with water Finishing (Rough) Hard-alloy cutting, mini Hard-alloy cutting, midi Hard-alloy cutting, maxi Hard-alloy cutting, maxi plus Max rotation speed 10,000 per min Low pressure Finishing (fine) Aloxin grinder blue, small, B Aloxin grinder blue, large, C Circular grind on work piece ; Not suitable for surfaces to be coated with ceramics Grinding (fine) Emery cloth - 500 Recommended before rubber polishing Rubber polishing Rubber disks (grey) Rubber disks (red) Rubber disks (red) Rubber disks (red) Use sparingly and without pressure Low rotation speed (danger of overheating) Grey – rough polish Red fine – polish Polishing Large polishing brush Black polishing brushes Small brushes Tiger brilliant, Polishing paste Change direction of polishing frequently Add no more polishing paste for high lusture

- 69. Review of Literature G. Theuniers and M.De Clercq in 1987 made a comparative study of the smoothness of preparation on margins obtained by different finishing procedures .The study compared the finish obtained with a diamond bevel bur, a finishing stone (Dura White), a tungsten-cobalt finishing bur and a tungsten-vanadium finishing bur. The authors concluded 1.A diamond bevel bur creates a relatively rough tooth surface. The best result could be obtained with carbide finishing burs. An intermediate result was obtained with a finishing stone (dura white) 2.The roughness of the surface prepared with diamond burs was directly proportional to the diamond grain size

- 70. 3. Pretreatment with a fine grained diamond bur was necessary. Polishing of the margins was necessary and it could be achieved with a stone (Dura White) or better with finishing burs. 4. Polishing capacity of a bur was enhanced by reduction of rotation speed

- 71. D.A. Felton,et al in 1991 conducted a scanning microscopic analysis on the effect of air abrasives on marginal configurations of PFM alloys. Their investigation qualitatively and quantitatively evaluated the effects of commercially available air abrasives (AL2O3 and glass beads) used for sandblasting on various marginal configurations of 5 metal ceramic alloys.

- 72. The Authors concluded 1.The smaller the margin angle, the greater was the loss of alloy after air abrasion. 2.The abrasion resistance of the alloys investigated generally increased with greater alloy hardness and percent of elongation.

- 73. M.Kern and V.P. Thompson 1994 studied the effect of sandblasting and silica procedures on pure titanium. The study evaluated the effects of sandblasting and costing techniques on volume loss, surface morphology and composition changes in pure titanium. They concluded : 1. Sandblasting plays a critical rolw in bonging of resin to metal by creating a roughened surface that is also changed in composition partially, by the embedding of aluminium particles. 2. Clinical or lab. Sandblasting does not remove a suffucuent volume of surface material as to affect the clinical fit of titanium restorations.

- 74. Jacobi and Shillinburg 1991 compared the abrasiveness of 6 ceramic surfaces and gold .The authors attached a type III gold alloy and 6 different ceramic surfaces in an abrasion machine opposing extracted teeth to determine their relative abrasiveness and resistance to wear Authors found 1. Type III gold was least abrasive. 2. Glazed porcelain was more abrasive than polished porcelain. 3. Dicor shading porcelain had approximately the same abrasiveness as VMK 68 porcelain when glazed.

- 75. 4. Dicor cast ceramic material without shading was the least abrasive ceramic material but the most subjected to wear . 5. The cerammed skin of Dicor cast ceramic material was the most abrasive and wear resistant of the ceramic surfaces.

- 76. Robert C.S. Chen, Daniel C.N. Chan et al 1998 conducted a study of finishing and polishing technique for a composite. The study evaluated and compared 6 finishing and polishing techniques with commonly used materials and methods to identify an effective finishing and polishing technique for microfilled composite restorations. They concluded 1. Soflex disk produced the smoothest polished surface. 2. Finishing and polishing by diamond burs followed with a vivadent polishing point produced the second smoothest polished surface

- 77. 3. A carbide bur followed by a vivadent polishing point and finishing and polishing diamond burs alone, or followed with Den Mat polishing paste produced a relatively smooth surface. 4. Carbide burs followed with Den Mat polishing paste produced the least desirable surface.

- 78. In a study conducted by Dr. Ponnanna A.A. 1999 under the able guidance of Dr. N.P.Patil to evaluate the polished surface characteristics of Co-Cr castings subsequent to finishing and polishing techniques A total no. of 30 disc shaped test specimens of cast Co-Cr alloy were fabricated for the evaluation of surface characteristics They concluded 1. Various finishing and polishing techniques employed for the surface Rx of cast Co-Cr alloys revealed improved surface characteristics using the sequence of sandblasting, coarse grit abrasive, medium grit and the fine grit abrasive.

- 79. 2. Perthometric evaluation of the surface characteristics seems to be a better method of evaluation of finished and polished surface. 3. Loss of weight of metal affecting the physical quality of the alloy can be carefully avoided by judicious sandblasting and application of proper grit of abrasive agents.

- 80. Summary&Conclusion A lot of materials are available commercially to perform finishing and polishing. Discretion on the part of the dentist is necessary to select the right material for that technique. Since each manufacturer advocates his own method, standardization of technique becomes very difficult. Every technique follows the use of abrasive grits in a sequence of coarse to fine to achieve optimal results.

- 81. An optimal application of specific devices for certain restorative materials and specific clinical situations should be considered in order to enhance both longevity and esthetics of the restored teeth. Also due to rapid development in technology, these materials and equipment undergo changes. But one should follow the basic principles of finishing irrespective of the system or product chosen.

- 82. References • Anusavice K.J. “Phillips Science Of Dental Materials” 11th edition, Philadelphia,W.B. Saunders • Aydin A.K. “Evaluation of finishing and polishing techniques on surface roughness of chromium-cobalt castings.”J.P.D.,1991;65:763-767 • Al-Wahadni A.,Martin D.M. “ Glazing and finishing dental porcelain: A literature review”. J.Can.Dent.Asso.,1998;64:580-583. • Chen R.C.S.,Chan K.C. “A quantitative study of finisihng and polishing technique for a composite”.J.P.D.,1988;59:292-297. • Christensen R.P.,Bangereter V.W. ‘Immediate and long term in vivo effects of polishing on enamel and dentin”. J.P.D.,1987;57:150-160.

- 83. • Craig R.G. “Dental Materials, properties and manipulation”. 8th edition ,U.S.A.,Mosby Company, 2004 • Felton D.A.,Bayne S.C.,Karoy B.E. “Effect of air abrasives on marginal configurations of porcelain fused to metal alloys”.J.P.D.,1991;65:38-43. • Goldstein R.E. “Finishing of composites and laminates” DCNA, 1989; 33(2): 305-318. • Goldstein G.R.,Barnard B.R., Pergonda B. “Profilometer, SEM and vsual assessment of porcelain polishing methods”. J.P.D.,1991;65:627-634. • Jacobi R.,Schillinburg H.T. “Acomparison of the abrasiveness of 6 ceramic surfaces and gold”. J.P.D., 1991;66: 303-309.

- 84. • Jeffries S.R. “The art and science of abrasive and finishing and polisjhing in restorative dentistry”. DCNA,1998;42(4): 613-628. • Kern M.,Thompson V.P. “Effect of sandblasting and silicoating procedures on pure titanium”. J.Dent.,1994;22:300-306. • Klusner L.H.,Cartwrught C.B., Chaebeneau G.T. “Polished versus autolglazed porcelain surfaces”.J.P.D.,1982;47:157-162. • Morris F., Brudvik J.S. “Influence of polishing on cast clasp properties”. J.P.D.,1986;55:75-77. • Morrow R.M.,Rhoads J.E., Rudd K.D., “Dental laboratory procedure, removable partial dentures”. 2nd edition, St.Louis, The Mosby company,1986.

- 85. • Morrow R.M., Rudd K.D.,Rhoads J.E. “Dental laboratory procedures, complete dentures”, 2nd edition, St. Louis, The C.V. Mosby company, 1986. • O’Brien W.,Ryge G. “An outline of dental materials and their selection”. W.B. Saunders company,1978. • Ponnanna A.A., N.P.Patil “Evaluation of surface characteristics of Co-Cr castings subsequent to finishing and polishing techniques. • Troxell R.R. “The polishing of gold castings”. J.P.D.,1959; 9 :668-675. • Wiley M.G., Windeler A.S., Barghi N. “Vertical dimension change resulting from polishing and glazing porcelain”. J.P.D.,62:32-34.