The house of lean v3.6 ELG

•

16 likes•10,261 views

Summary of Lean Manufacturing/Management V3.6 (2016) Updated V3.7(2018): https://www.slideshare.net/enateduardo/the-house-of-lean-v37-elg https://www.amazon.co.uk/dp/1973409771 https://www.amazon.com/dp/1973409771 https://www.amazon.es/dp/1521901864

Report

Share

Report

Share

Download to read offline

Recommended

Hoshin Kanri Strategy Deployment by Operational Excellence Consulting

Hoshin Kanri Strategy Deployment by Operational Excellence ConsultingOperational Excellence Consulting

More Related Content

What's hot

Hoshin Kanri Strategy Deployment by Operational Excellence Consulting

Hoshin Kanri Strategy Deployment by Operational Excellence ConsultingOperational Excellence Consulting

What's hot (20)

Lean Manufacturing : Concept & Overview nkchawla@gmail.com

Lean Manufacturing : Concept & Overview nkchawla@gmail.com

Hoshin Kanri Strategy Deployment by Operational Excellence Consulting

Hoshin Kanri Strategy Deployment by Operational Excellence Consulting

Viewers also liked

Viewers also liked (20)

Gestión de Fábrica-2 El Despliegue y el Control de la Política Corporativa

Gestión de Fábrica-2 El Despliegue y el Control de la Política Corporativa

Graficas de control por atributo y por variable [autoguardado]![Graficas de control por atributo y por variable [autoguardado]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Graficas de control por atributo y por variable [autoguardado]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Graficas de control por atributo y por variable [autoguardado]

Factory management-1 The Corporate Constitution and Management Framework

Factory management-1 The Corporate Constitution and Management Framework

Metodología para Implantación de un Sistema Lean Mfg.

Metodología para Implantación de un Sistema Lean Mfg.

Launch Of Clara Club Lean Automotive Rhone Alpes 24 Nov 2005

Launch Of Clara Club Lean Automotive Rhone Alpes 24 Nov 2005

More from Eduardo L. Garcia

More from Eduardo L. Garcia (20)

TPM-15 Cost Reduction 3 and Consultancy Job (contnuation).pdf

TPM-15 Cost Reduction 3 and Consultancy Job (contnuation).pdf

TPM-15 Reducción de Costes y El Trabajo de Consultoría (contnuación).pdf

TPM-15 Reducción de Costes y El Trabajo de Consultoría (contnuación).pdf

TPM-12, El teletrabajo y Los 3 mayores malentendidos

TPM-12, El teletrabajo y Los 3 mayores malentendidos

TPM-12, Teleworking & The three major misunderstandings in Factory Management

TPM-12, Teleworking & The three major misunderstandings in Factory Management

8 wastes in Lean Management / 8 desperdicios en Lean management

8 wastes in Lean Management / 8 desperdicios en Lean management

Recently uploaded

Enjoy ➥8448380779▻ Call Girls In Sector 18 Noida Escorts Delhi NCR

Enjoy ➥8448380779▻ Call Girls In Sector 18 Noida Escorts Delhi NCRStunning ➥8448380779▻ Call Girls In Hauz Khas Delhi NCR

No-1 Call Girls In Goa 93193 VIP 73153 Escort service In North Goa Panaji, Ca...

No-1 Call Girls In Goa 93193 VIP 73153 Escort service In North Goa Panaji, Ca...Call girls in Goa, +91 9319373153 Escort Service in North Goa

Recently uploaded (20)

Islamabad Escorts | Call 03070433345 | Escort Service in Islamabad

Islamabad Escorts | Call 03070433345 | Escort Service in Islamabad

Call Us 📲8800102216📞 Call Girls In DLF City Gurgaon

Call Us 📲8800102216📞 Call Girls In DLF City Gurgaon

(Best) ENJOY Call Girls in Faridabad Ex | 8377087607

(Best) ENJOY Call Girls in Faridabad Ex | 8377087607

8447779800, Low rate Call girls in Shivaji Enclave Delhi NCR

8447779800, Low rate Call girls in Shivaji Enclave Delhi NCR

Ms Motilal Padampat Sugar Mills vs. State of Uttar Pradesh & Ors. - A Milesto...

Ms Motilal Padampat Sugar Mills vs. State of Uttar Pradesh & Ors. - A Milesto...

Japan IT Week 2024 Brochure by 47Billion (English)

Japan IT Week 2024 Brochure by 47Billion (English)

Enjoy ➥8448380779▻ Call Girls In Sector 18 Noida Escorts Delhi NCR

Enjoy ➥8448380779▻ Call Girls In Sector 18 Noida Escorts Delhi NCR

8447779800, Low rate Call girls in Saket Delhi NCR

8447779800, Low rate Call girls in Saket Delhi NCR

8447779800, Low rate Call girls in New Ashok Nagar Delhi NCR

8447779800, Low rate Call girls in New Ashok Nagar Delhi NCR

No-1 Call Girls In Goa 93193 VIP 73153 Escort service In North Goa Panaji, Ca...

No-1 Call Girls In Goa 93193 VIP 73153 Escort service In North Goa Panaji, Ca...

Pitch Deck Teardown: Geodesic.Life's $500k Pre-seed deck

Pitch Deck Teardown: Geodesic.Life's $500k Pre-seed deck

The house of lean v3.6 ELG

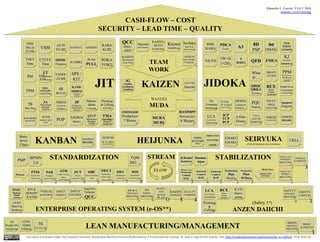

- 1. HEIJUNKA CASH-FLOW – COST SECURITY – LEAD TIME – QUALITY JIT JIDOKA STANDARDIZATION STABILIZATION ENTERPRISE OPERATING SYSTEM (e-OS**) LEAN MANUFACTURING/MANAGEMENT TEAM WORK (WASTES) MUDA PDCA Cycle FMEAPOKA YOKE QFD A3 QRQC QRKA Q-Chart 5 WHYS ISHI- KAWA 8D PSP · IT’S & · IT’S NOT · IN/OUT BOX ONE POINT LESSON BRAIN STORM … 6σ DMAIC KJ METHOD MINDMAP POKER ESTIMATION ANDON BOARD PM TAKT Time TPM ONE PIECE FLOW ANDON CYCLE Time JUNJI INSPECTION NEXT 5S Pika-Pika PUSH PULL ICP TCP PCP VSM SCRUM SCALABLE DEVELOPMENT SMED Uchi-Soto Dandori ·ASAKAY Dayly-Huddle ·YUICHI POP 4R RULES 3A Allocation Amount Article PTSS Process Time Study Sheet QCC JISHU- KEN JUNDATE JUNBIKI TIMWOOD Production 7 Wastes KAMI- SHIBAI CARDS & TABLE MIZU- SUMASHI DandoriMan KAIZEN- BLITZ KAIKAKU Shijonka polyvalence Soifuku Idea from empowerment 5ZEROs theory KATAZUKE AKAFUDA SPS / KIT 6-Hats Disney LT LTEfficiency LTStandard KANBAN SEIRYUKA (Cells & Machinery easy to relocate) PRODUCTION INVENTORY SALES 5W+H (+2H) YAMA- KUZUSHI DAILY MURA MURI (Safety 1st) ANZEN DAIICHI PQC Diagram Kaizen OutOfLine 3G Gemba Genbutsu Genjitsu *VISUAL CONTROL DAILY TARGET DAYLY CONTROL PRODUC- TION /ACTION PLAN KPI & HOSHIN KANRI BMC Business Model Canvas AS IS TO BE KAIZEN PROGRESS Chart/Table PPM POTENTIAL PROBLEMS MAP All People’sPa rticipation LONG TERM VISION KPI DAILY MEETING KPI & Q MONTHLY MEETING FAULT TREE ANALYSIS PARETO & Correlation ANALYSIS RCE Root Cause Analysis TQM ISO… Suggestion Scheme QCC What IF… SAFETY MONTHLY MEETING RCE Root Cause Analysis BPMN 2.0 PMP PRODUCTION MONTHLY MEETING PRODUCTION WEEKLY MEETING QUALITY COMITEE SAFETY COMITEE Production COMITEE DESING THINKING TOOLS… MVP Minimum Product Viable MGMT. COMETEE MGMT. MONTHLY MEETING 3S CS, ES, SS KAIZEN COMITEE 1 2 3 45 1 2 3 45 6 CHAKU CHAKU YAMA- ZUMI KARA KURI LCA Low Cost Automation 3P Production Preparation Process OJT/TWI Hancho CELL LCA Live Cycle Assessment Burn- down Chart Ji Koutei Kanketsu ILUO Matrix (STM) PCT Process Capability Table SWCT Standardized Work Combi- nation Table SOS Standardized Operation Sheet PAB Production Analysis Board STM Skills Training Matrix ILUO Matrix OBC Operator Balance Chart SWC Standardized Work Chart KANBAN BOARDs 1 2 3 4 5 6 7 8 Handan- kijun Process Spaghetti Diagram SIPOC Diagram Production Plan 30 Days 1 Production Plan Weekly 2 Production Control DAY 3 Forward Control DAY 4 Machinery/Line Production Control DAY 5 PRODUCTION CONTROL* 7 RAMMPP Bureaucracy 6 Wastes KAIZEN HEIJUNKA LEAN Start-Up Technics CIA’s LIST OF PHOENIX Moon- shine Concept TMA Therbligs Motion Analysis This work is licensed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/. (ELG 2016 ©) Pointing & Calling Pointing & Calling A3/A2 The Trimming Technique Ø VA/VE Eduardo L. García. V3.6 © 2016 linkedin.com/in/edulgg STREAM FLOW