Internal combution of Engine (two stroke and four stroke)

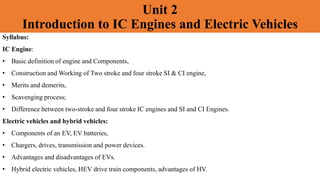

- 1. Unit 2 Introduction to IC Engines and Electric Vehicles Syllabus: IC Engine: • Basic definition of engine and Components, • Construction and Working of Two stroke and four stroke SI & CI engine, • Merits and demerits, • Scavenging process; • Difference between two-stroke and four stroke IC engines and SI and CI Engines. Electric vehicles and hybrid vehicles: • Components of an EV, EV batteries, • Chargers, drives, transmission and power devices. • Advantages and disadvantages of EVs. • Hybrid electric vehicles, HEV drive train components, advantages of HV.

- 2. HEAT ENGINE • It is a device which converts heat energy into mechanical energy. • The heat is obtained from the combustion of fuel which may be coal, petrol, diesel and some gases. Heat engine may be classified into two main categories:- 1. External combustion engine 2. Internal combustion engine.

- 3. External combustion engine: • In this engine, the products of combustion of air and fuel transfer heat to a second fluid which is the working fluid of the cycle. Examples: • In the steam engine or a steam turbine plant. • The heat engine, in which the combustion takes place inside the cylinder and the heat energy of the flue gas is converted into mechanical energy, is known as Internal Combustion Engine (I.C. Engine). • Petrol & Diesel engines are examples of internal combustion engine, where the working fluid is a mixture of air and fuel Internal combustion engine

- 4. Comparison between external combustion engine and internal combustion engine External combustion engine Internal combustion engine Combustion of air-fuel is outside the engine cylinder Combustion of air-fuel is inside the engine cylinder The engines are running smoothly and silently due to outside combustion Very noisy operated engine Working pressure and temperature inside the engine cylinder is low; hence ordinary alloys are used for the manufacture of engine Working pressure and temperature inside the engine cylinder is very much high; hence special alloys are used Lower efficiency about 15-20% Higher efficiency about 35-40% High starting torque IC engines are not self-starting It can use cheaper fuels including solid fuels High grade fuels are used with proper filtration

- 5. Components of an I.C. Engine Cylinder: • It is a hollow cylindrical structure closed at one end with the cylinder head. • The combustion of the fuel takes place inside the cylinder. • This is known as the heart of the engine. Cylinder Head: • It covers one end of the cylinder and consists of valves/ports and spark plug/injector. Piston: • It is a cylindrical component which is fitted perfectly inside the cylinder providing a gas-tight space with the piston rings and the lubricant. • The main function of the piston is to transfer the power produced by combustion of the fuel to the crankshaft.

- 6. Piston Rings: • The outer periphery of the piston is provided with several grooves into which piston rings are fitted. • The function of the piston ring is to compress the air or air-fuel mixture and collect the surplus lubricating oil on the liner surface Connecting Rod: • It connects the piston and the crankshaft. • One end, called the small end, is connected to the gudgeon pin located in the piston and the other end, called big end, is connected to crank pin. • The function of the connecting rod is to transfer the reciprocating motion of the piston into rotary motion of the crankshaft. Crankshaft: It is principal rotating part of the engine which controls the sequence of reciprocating motion of the pistons. Valves: Normally, the two valves are used for each cylinder, which may be of mushroom shaped poppet type.

- 7. Spark Plug: • In an S.I engine, a spark plug is located near the top of the cylinder and initiates the combustion of the fuel. Crankcase: • It consists of a cylinder, piston, and crankshaft. It helps in lubrication of different parts of the engine. Flywheel: • It is a heavy wheel mounted on the crankshaft to minimize the cyclic variations in speed. It absorbs the energy during the power stroke and releases it during the non-power stroke. Crankshaft: • It is principal rotating part of the engine which controls the sequence of reciprocating motion of the pistons. It consists of several bearings and crank pins. Carburetor: Carburetor is a device which is used to control the fuel qualitatively in an S.I engine. Fuel Pump and Injector Unit: • This unit is used in C.I. engines (nowadays injection system is also used in S.I. engine as multi- point fuel injection, MPFI). • Its function is to supply the fuel to injector under pressure which consists of one or more orifices through which the fuel is sprayed into the cylinder.

- 8. Terminology used in IC engine: A. Cylinder Bore (d): • The nominal inner diameter of a cylinder is called a cylinder bore which is designated by an English letter ‘d’ and expressed in millimeter (mm). B. Piston Area (A): • The area of the inner diameter of a cylinder is known as piston area. It is measured in terms of a square centimeter (cm2) or square millimeter (mm2). C. Stroke (L): • The axial distance for which a piston moves inside a cylinder in one stroke is known as stroke or stroke length which is designated by an English letter ‘L’ and measured in terms of a millimeter (mm). D. Dead Centers: • The positions of the piston, at the moments when the direction of the piston motion is reversed are known as dead centers. • There are two dead centers—Top dead center (TDC) and Bottom dead center (BDC). • The farthest position of the piston head from the crankshaft is known as TDC and nearest position of the piston head from the crankshaft is known as BDC

- 10. E. Displacement/Stroke/Swept Volume (Vs): • The nominal volume swept by the working piston when traveling from one dead center to the other is called the displacement volume. It is expressed in terms of a cubic centimeter (cc) F. Clearance Volume (Vc): • The nominal volume of the combustion chamber above the piston when it is at the at the TDC is known as clearance volume (Vc) and is expressed in cc. G. Compression Ratio (rv): • It is the ratio of the total cylinder volume when the piston is at BDC to the clearance volume.

- 11. Classification of I.C. engines There are several bases for classification of I.C. Engines, some of the important bases can be explained as: • Number of strokes per cycle • Nature of thermodynamic cycle • Ignition systems • Fuel used • Arrangement of cylinder • Cooling systems • Fuel supply systems

- 12. Working principle of I.C. engines • I.C. Engines can be classified as four-stroke engines (4S) and two-stroke engines (2s). • In four-stroke engines, the thermodynamic cycle is completed in four strokes of the piston or two revolutions of the crankshaft whereas. • In two-stroke engines, the thermodynamic cycle is completed in two strokes of the piston or one revolution of the crankshaft. 1. Four-stroke Spark Ignition (S.I.) Engine • In this engine, the cycle of operations is completed in 4-strokes of the piston or two revolutions of the crankshaft. • During the 4-strokes, there are four processes to be completed, viz., • 1. Suction stroke, 2. Compression stroke, 3. Combustion or power stroke , 4. Exhaust stroke. • Each stroke consists of 180° rotation of he crankshaft and hence a 4-strokes cycle is completed in two revolutions of the crankshaft.

- 13. Suction Stroke (0-1): • It starts when the piston is at TDC and about to move downward, the inlet valve is open, and the exhaust valve is closed. • Due to suction created by the piston movement towards BDC, air-fuel mixture enters into the cylinder, and the suction ends when the piston reaches the BDC. Compression Stroke (1-2): • At the end of the suction stroke, the inlet valve is closed and the piston moves towards TDC. • In this stroke, both the valves, inlet and exhaust are closed; compression of the air-fuel mixture filled in the cylinder starts from BDC and ends at TDC. • At the end of compression and at constant volume (2-3), sparking starts at the spark plug and instantaneously burning takes place in the compressed air-fuel mixture. • Pressure and temperature are increased to the maximum limit.

- 14. Power Stroke (3-4): • The high pressure developed due to combustion of fuel forces the piston towards BDC. • The power is transferred to the crankshaft. • Pressure and temperature decrease during the stroke. • In this stroke, both the valves are closed. Exhaust Stroke (4-1): • At the end of expansion or power stroke, the exhaust valve opens and the inlet valve remains closed. • Piston moves towards TDC and exhaust gas is forced to escape into the atmosphere through the exhaust valve.

- 15. P-V Diagram for Otto Cycle

- 16. Four-stroke Compression Ignition (C.I.) Engine • The four-stroke compression ignition (C.I. Engine) operates at a much higher compression ratio. • The compression ratio of S.I. Engine varies from 6 to 10 whereas in C.I. Engines it ranges from 16 to 20.. • In this engine, a fuel pump and injector are used to inject the fuel at high pressure. • The ignition system of the C.I. Engine is completely different from S.I. engine as no spark plug and carburetor are required.

- 17. Suction Stroke: • In this stroke, the piston moves from TDC to BDC and air is sucked alone as the vacuum is created inside the cylinder by the piston movement. • During suction inlet valve is open and exhaust valve remains closed. Compression Stroke: • Both the valves are closed during the stroke and air is compressed into the clearance volume by the piston movement from BDC to TDC. • At the end of compression at constant pressure fuel is injected. • Due to high pressure and temperature, fuel starts to ignite automatically as temperature of the air is increased to the flash point of the fuel

- 18. Expansion or Power Stroke: • Fuel injection starts nearly at the end of the compression stroke. • Heat is assumed to have been added at constant pressure. • After the injection of the fuel is completed (after cut-off) the combustion products expand. • Both valves remain closed during the expansion stroke. Exhaust Stroke: • The exhaust valve is open and the inlet valve is closed during the stroke. • The movement of the piston from BDC to TDC pushes the product of combustion and disposed into the atmosphere through the exhaust valve

- 19. P-V Diagram for Diesel Cycle

- 20. Two-stroke Spark Ignition Engine • A two-stroke engine is a type of internal combustion engine that completes a power cycle with two strokes of the piston during only one crankshaft revolution. • The cycle is completed in two-stroke i.e., one revolution of the crankshaft. The different parts are listed as follows: •Piston: The piston moves by the forces generated by the combustion of the gasses. •Crankshaft: It is connected to the pistons and converts the reciprocal motion of the pistons into the rotational motion. •Connecting Rod: It connects the piston head to the crankshaft. •Inlet Port: It is the opening for fuel and air mixture to come inside the piston chamber. •Exhaust Port: It is the opening for the exhaust fumes which opens during the downstroke. •Spark Plug: Spark plug is the device inside the piston chamber that causes the combustion of the fuel-air mixture.

- 22. (1) Upward stroke of the piston (Suction + compression) • When the piston moves from BDC to TDC the inlet port opens and the fresh air-fuel mixture enters easily due to less pressure inside the crankcase(cylinder). • During this, the transfer port remains closed. But as soon as the piston reaches TDC, the air-fuel mixture which already present in TDC compressed and the spark plug ignites the compressed fuel. (2) Downward stroke or Power Stroke (Expansion + Exhaust) • Due to high pressure in TDC, the piston moves from TDC to BDC. • The Inlet port will be closed and the exhaust port will be open. Transfer port also opens. • Now, the fresh air-fuel mixture moves upwards through the transfer port and the exhaust gases move outward. • When the piston moves TDC to BDC pressure inside the crankcase increases, due to which fresh air-fuel mixture comes above the piston through the transfer port and pushes the exhaust gases due to which exhaust gases exit through the exhaust port.

- 23. Comparison Between Four-stroke and Two-stroke Engines Four-stroke Engines Two-stroke Engines 1 One power stroke is obtained in two revolutions of the crankshaft One power stroke is obtained in one revolution of the crankshaft 2 The power produced from same size engine is less than two-stroke engine due to one power stroke in two revolutions of the crankshaft. he power produced from same size engine is more than the four-stroke engine due to one power stroke in each revolution of the crankshaft. 3 It consists of valves and valve actuating mechanism such as cam, camshaft, rocker arm, spring, valve, and valve seat. It has ports in place of valves 4 It has a higher thermal efficiency due to complete combustion of the fuel. t has a lower thermal efficiency due to the partial wastage of fuel through the exhaust port and incomplete combustion. 5 Turning moment is not so uniform during all the four strokes and hence, the heavier flywheel is required. Comparatively, turning moment is more uniform and hence lighter flywheel can be employed.

- 24. Comparison Between S.I. and C.I. Engines S.I. Engines C.I. Engines 1 It is based on Otto cycle or constant volume heat addition and rejection cycle. It is based on a Diesel cycle or constant pressure heat addition and constant volume heat rejection 2 A high volatile and high self-ignition temperature fuel, i.e., gasoline is used. Comparatively low volatile and low self-ignition temperature fuel, i.e., diesel is used 3 A carburetor is necessary to provide the mixture. A fuel pump and injector units are used. 4 For combustion of the charge, it requires an ignition system with a spark plug in the combustion chamber. Autoignition occurs due to the high-temperature of air resulting from high-compression. 5 Compression ratio ranges from 6 to 10. 6. Compression ratio ranges from 16 to 20. 6 A gaseous mixture of fuel and air is inducted during the suction stroke. Fuel is injected at high pressure at the end of compression stroke.

- 25. Advantages of 2-Stroke Engine 1.More power per weight –They can produce more power compared to their weight than many other engine types. This makes them ideal for lightweight, high-speed vehicles. 2.Simple mechanical design – Their design is straightforward, with fewer moving parts. This less complex structure is easier to understand and work with, making them a favorite among DIY enthusiasts. 3.Lower cost of production – When it comes to production, these engines are cheaper to make. This is due to their simple structure, requiring fewer components and less assembly time. 4.No need for valve system – Valves do not require in two stroke engine. Without the need for valves, the design and operation of these engines become even simpler. 5.Easier to maintain – Maintenance is also less with two-stroke engines.

- 26. Disadvantages of 2 Stroke Engine • Burn more fuel – Two stroke engines tend to consume more fuel compared to their four-stroke counterparts, leading to increased operational costs. • Less efficient – They are less efficient as they generate power once every two strokes, which can lead to wasted energy. • High pollution levels – These engines are known to produce high pollution levels, as they release more unburned fuel into the environment. • Requires frequent maintenance – Frequent maintenance is needed for two-stroke engines due to their design and operation, increasing upkeep time and costs. • Shorter lifespan – Lastly, the lifespan of a two-stroke engine is generally shorter because of the constant high-speed operation, causing quicker wear and tear.

- 27. Scavenging Process • Scavenging is the process of removing exhaust gases from a cylinder and replacing them with fresh air. • This process is important for the combustion of fuel inside the engine cylinder. Types of Scavenging in Engine 1. Crossflow Scavenging 2. Loop Scavenging 3. Uniflow scavenging

- 28. Crossflow Scavenging • Crossflow cylinder heads are used by most modern 2-stroke engines, whereby the intake ports are located on one side of the combustion chamber and the exhaust ports are on the other side. • The momentum of the gases assists in scavenging during the 'overlap' phase (when the intake and exhaust valves are simultaneously open). Loop scavenging. • In this method, the inlet and outlet ports are situated on the same side of the engine cylinder. • The intake port is larger to accommodate a greater volume of charge, while the smaller exhaust port. • Highly effective at high engine speeds, less efficient at low speeds. Uniflow scavenging • Uniflow scavenging is a design in which the fresh intake charge and exhaust gases flow in the same direction. • In this method, the fresh charge, while entering from one side (or sometimes two sides) of the engine cylinder pushes out the gases through the exit valve situated on the top of the cylinder. • This requires that the intake and exhaust ports be at opposite ends of the cylinder.