Stress analysis report

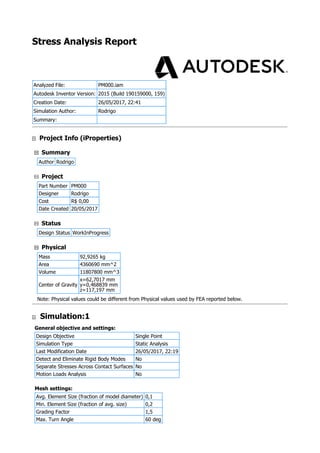

- 1. Stress Analysis Report Analyzed File: PM000.iam Autodesk Inventor Version: 2015 (Build 190159000, 159) Creation Date: 26/05/2017, 22:41 Simulation Author: Rodrigo Summary: Project Info (iProperties) Summary Author Rodrigo Project Part Number PM000 Designer Rodrigo Cost R$ 0,00 Date Created 20/05/2017 Status Design Status WorkInProgress Physical Mass 92,9265 kg Area 4360690 mm^2 Volume 11807800 mm^3 Center of Gravity x=62,7017 mm y=0,468839 mm z=117,197 mm Note: Physical values could be different from Physical values used by FEA reported below. Simulation:1 General objective and settings: Design Objective Single Point Simulation Type Static Analysis Last Modification Date 26/05/2017, 22:19 Detect and Eliminate Rigid Body Modes No Separate Stresses Across Contact Surfaces No Motion Loads Analysis No Mesh settings: Avg. Element Size (fraction of model diameter) 0,1 Min. Element Size (fraction of avg. size) 0,2 Grading Factor 1,5 Max. Turn Angle 60 deg

- 2. Create Curved Mesh Elements No Use part based measure for Assembly mesh Yes Material(s) Name Steel AISI 1020 107 HR General Mass Density 7,87 g/cm^3 Yield Strength 260 MPa Ultimate Tensile Strength 441 MPa Stress Young's Modulus 207 GPa Poisson's Ratio 0,33 ul Shear Modulus 77,8195 GPa Part Name(s) PM028.ipt PM028.ipt PM029.ipt PM029.ipt PM030.ipt PM031.ipt PM035.ipt PM035.ipt PM037.ipt PM037.ipt PM036.ipt PM036.ipt PM034.ipt PM033.ipt PM032.ipt PM032.ipt PM047.ipt PM048.ipt PM049.ipt PM052.ipt PM051.ipt PM054.ipt PM056.ipt PM055.ipt PM055.ipt PM058.ipt PM057.ipt PM059.ipt PM060.ipt PM062.ipt PM063.ipt PM044.ipt PM039.ipt PM039.ipt PM042.ipt PM041.ipt PM040.ipt PM040.ipt PM072.ipt Name AÇO ABNT 1020 General Mass Density 7,87 g/cm^3 Yield Strength 260 MPa Ultimate Tensile Strength 441 MPa Stress Young's Modulus 207 GPa Poisson's Ratio 0,33 ul Shear Modulus 77,8195 GPa Part Name(s) Graxeira M6.ipt Graxeira M6.ipt Graxeira M6.ipt Graxeira M6.ipt PM046.ipt PM050.ipt PM061.ipt Pino R.ipt Graxeira M6.ipt Graxeira M6.ipt

- 3. Create Curved Mesh Elements No Use part based measure for Assembly mesh Yes Material(s) Name Steel AISI 1020 107 HR General Mass Density 7,87 g/cm^3 Yield Strength 260 MPa Ultimate Tensile Strength 441 MPa Stress Young's Modulus 207 GPa Poisson's Ratio 0,33 ul Shear Modulus 77,8195 GPa Part Name(s) PM028.ipt PM028.ipt PM029.ipt PM029.ipt PM030.ipt PM031.ipt PM035.ipt PM035.ipt PM037.ipt PM037.ipt PM036.ipt PM036.ipt PM034.ipt PM033.ipt PM032.ipt PM032.ipt PM047.ipt PM048.ipt PM049.ipt PM052.ipt PM051.ipt PM054.ipt PM056.ipt PM055.ipt PM055.ipt PM058.ipt PM057.ipt PM059.ipt PM060.ipt PM062.ipt PM063.ipt PM044.ipt PM039.ipt PM039.ipt PM042.ipt PM041.ipt PM040.ipt PM040.ipt PM072.ipt Name AÇO ABNT 1020 General Mass Density 7,87 g/cm^3 Yield Strength 260 MPa Ultimate Tensile Strength 441 MPa Stress Young's Modulus 207 GPa Poisson's Ratio 0,33 ul Shear Modulus 77,8195 GPa Part Name(s) Graxeira M6.ipt Graxeira M6.ipt Graxeira M6.ipt Graxeira M6.ipt PM046.ipt PM050.ipt PM061.ipt Pino R.ipt Graxeira M6.ipt Graxeira M6.ipt

- 4. Create Curved Mesh Elements No Use part based measure for Assembly mesh Yes Material(s) Name Steel AISI 1020 107 HR General Mass Density 7,87 g/cm^3 Yield Strength 260 MPa Ultimate Tensile Strength 441 MPa Stress Young's Modulus 207 GPa Poisson's Ratio 0,33 ul Shear Modulus 77,8195 GPa Part Name(s) PM028.ipt PM028.ipt PM029.ipt PM029.ipt PM030.ipt PM031.ipt PM035.ipt PM035.ipt PM037.ipt PM037.ipt PM036.ipt PM036.ipt PM034.ipt PM033.ipt PM032.ipt PM032.ipt PM047.ipt PM048.ipt PM049.ipt PM052.ipt PM051.ipt PM054.ipt PM056.ipt PM055.ipt PM055.ipt PM058.ipt PM057.ipt PM059.ipt PM060.ipt PM062.ipt PM063.ipt PM044.ipt PM039.ipt PM039.ipt PM042.ipt PM041.ipt PM040.ipt PM040.ipt PM072.ipt Name AÇO ABNT 1020 General Mass Density 7,87 g/cm^3 Yield Strength 260 MPa Ultimate Tensile Strength 441 MPa Stress Young's Modulus 207 GPa Poisson's Ratio 0,33 ul Shear Modulus 77,8195 GPa Part Name(s) Graxeira M6.ipt Graxeira M6.ipt Graxeira M6.ipt Graxeira M6.ipt PM046.ipt PM050.ipt PM061.ipt Pino R.ipt Graxeira M6.ipt Graxeira M6.ipt

- 6. Fixed Constraint:2 Constraint Type Fixed Constraint Selected Face(s)

- 7. Contacts (Bonded) Name Part Name(s) Bonded:1 PM027:1/PM028:1 PM071:1 Bonded:2 PM027:1/PM028:1 PM071:2 Bonded:3 PM027:1/PM028:2 PM071:1 Bonded:4 PM027:1/PM028:2 PM071:2 Bonded:5 PM027:1/PM037:1 PM027:1/Graxeira M6:1 Bonded:6 PM027:1/PM037:1 PM071:1 Bonded:7 PM027:1/PM037:2 PM027:1/Graxeira M6:2 Bonded:8 PM027:1/PM037:2 PM071:1 Bonded:9 PM027:1/PM036:1 PM071:2 Bonded:10 PM027:1/PM036:2 PM071:2 Bonded:11 PM027:1/Graxeira M6:1 PM071:1 Bonded:12 PM027:1/Graxeira M6:2 PM071:1 Bonded:13 PM027:1/Graxeira M6:3 PM071:2 Bonded:14 PM027:1/Graxeira M6:4 PM071:2

- 8. Bonded:15 PM045:1/_Weldbead:1 PM045:1/PM046:1 Bonded:17 PM045:1/_Weldbead:1 PM045:1/PM051:1 Bonded:18 PM045:1/_Weldbead:1 PM045:1/PM046:1 Bonded:19 PM045:1/_Weldbead:1 PM045:1/PM046:1 Bonded:20 PM045:1/_Weldbead:1 PM045:1/PM051:1 Bonded:21 PM045:1/_Weldbead:1 PM045:1/PM049:1 Bonded:22 PM045:1/_Weldbead:1 PM045:1/PM050:1 Bonded:23 PM045:1/_Weldbead:1 PM045:1/_Weldbead:1 Bonded:24 PM045:1/_Weldbead:1 PM045:1/_Weldbead:1 Bonded:25 PM045:1/_Weldbead:1 PM045:1/_Weldbead:1 Bonded:26 PM045:1/_Weldbead:1 PM045:1/PM046:1 Bonded:27 PM045:1/_Weldbead:1 PM045:1/PM047:1 Bonded:28 PM045:1/_Weldbead:1 PM045:1/PM046:1 Bonded:29 PM045:1/_Weldbead:1 PM045:1/PM047:1 Bonded:30 PM045:1/_Weldbead:1 PM045:1/PM046:1 Bonded:31 PM045:1/_Weldbead:1 PM045:1/PM049:1 Bonded:32 PM045:1/_Weldbead:1 PM045:1/PM046:1 Bonded:33 PM045:1/_Weldbead:1 PM045:1/PM046:1 Bonded:34 PM045:1/_Weldbead:1 PM045:1/PM046:1 Bonded:35 PM045:1/_Weldbead:1 PM045:1/PM046:1 Bonded:36 PM045:1/_Weldbead:1 PM045:1/PM050:1 Bonded:37 PM045:1/_Weldbead:1 PM045:1/PM048:1 Bonded:38 PM045:1/_Weldbead:1 PM045:1/PM052:1 Bonded:39 PM045:1/_Weldbead:1 PM045:1/PM046:1 Bonded:40 PM045:1/_Weldbead:1 PM045:1/PM048:1 Bonded:41 PM045:1/_Weldbead:1 PM045:1/PM046:1 Bonded:42 PM045:1/_Weldbead:1 PM045:1/PM048:1 Bonded:43 PM045:1/PM051:1 PM071:1 Bonded:44 PM053:1/PM058:1 PM074:1 Bonded:45 PM038:1/PM042:1 PM071:2 Bonded:46 PM038:1/PM040:1 PM071:2

- 9. Bonded:47 PM038:1/PM040:2 PM071:2 Bonded:48 PM071:1 Pino R:2 Bonded:49 PM071:2 Pino R:1 Bonded:50 PM074:1 Pino R:3 Bonded:109 PM027:1/PM028:1 PM027:1/PM031:1 Bonded:110 PM027:1/PM028:1 PM027:1/PM035:2 Bonded:111 PM027:1/PM028:1 PM027:1/PM037:2 Bonded:112 PM027:1/PM028:1 PM027:1/PM036:1 Bonded:113 PM027:1/PM028:2 PM027:1/PM031:1 Bonded:114 PM027:1/PM028:2 PM027:1/PM035:1 Bonded:115 PM027:1/PM028:2 PM027:1/PM037:1 Bonded:116 PM027:1/PM028:2 PM027:1/PM036:2 Bonded:117 PM027:1/PM029:1 PM027:1/PM030:1 Bonded:118 PM027:1/PM029:1 PM027:1/PM035:1 Bonded:119 PM027:1/PM029:2 PM027:1/PM030:1 Bonded:120 PM027:1/PM029:2 PM027:1/PM035:2 Bonded:121 PM027:1/PM031:1 PM027:1/PM034:1 Bonded:122 PM027:1/PM031:1 PM027:1/PM033:1 Bonded:123 PM027:1/PM031:1 PM027:1/PM032:1 Bonded:124 PM027:1/PM031:1 PM027:1/PM032:2 Bonded:125 PM027:1/PM037:1 PM027:1/Graxeira M6:1 Bonded:126 PM027:1/PM037:1 PM045:1/PM051:1 Bonded:127 PM027:1/PM037:2 PM027:1/Graxeira M6:2 Bonded:128 PM027:1/PM037:2 PM045:1/PM051:1 Bonded:129 PM027:1/PM036:1 PM027:1/Graxeira M6:4 Bonded:130 PM027:1/PM036:1 PM038:1/PM040:1 Bonded:131 PM027:1/PM036:2 PM027:1/Graxeira M6:3 Bonded:132 PM027:1/PM036:2 PM038:1/PM040:2 Bonded:139 PM045:1/PM046:1 PM045:1/PM047:1 Bonded:140 PM045:1/PM046:1 PM045:1/PM048:1 Bonded:141

- 10. PM045:1/PM046:1 PM045:1/PM050:1 Bonded:142 PM045:1/PM046:1 PM045:1/PM052:1 Bonded:143 PM045:1/PM046:1 PM045:1/PM051:1 Bonded:144 PM045:1/PM046:1 PM072:1 Bonded:146 PM045:1/PM048:1 PM045:1/PM052:1 Bonded:147 PM045:1/PM050:1 PM053:1/PM063:1 Bonded:148 PM053:1/PM054:1 PM053:1/PM056:1 Bonded:151 PM053:1/PM056:1 PM053:1/PM061:1 Bonded:152 PM053:1/PM056:1 PM053:1/PM057:1 Bonded:153 PM053:1/PM061:1 PM053:1/PM055:1 Bonded:154 PM053:1/PM061:1 PM053:1/PM055:2 Bonded:155 PM053:1/PM055:1 PM053:1/PM062:1 Bonded:156 PM053:1/PM055:2 PM053:1/PM062:1 Bonded:157 PM053:1/PM055:2 PM053:1/PM062:1 Bonded:158 PM053:1/PM058:1 PM053:1/PM057:1 Bonded:159 PM053:1/PM058:1 PM053:1/PM057:1 Bonded:160 PM053:1/PM058:1 PM053:1/PM057:1 Bonded:161 PM053:1/PM058:1 PM053:1/PM060:1 Bonded:162 PM053:1/PM058:1 PM053:1/Graxeira M6:1 Bonded:163 PM053:1/PM058:1 PM053:1/Graxeira M6:2 Bonded:164 PM053:1/PM059:1 PM053:1/PM060:1 Bonded:165 PM053:1/PM062:1 PM053:1/PM063:1 Bonded:166 PM053:1/PM062:1 PM053:1/Pino R:1 Bonded:180 PM038:1/PM044:1 PM038:1/PM043:1 Bonded:181 PM038:1/PM044:1 PM038:1/DIN 963 - replaced by DIN EN ISO 2009 M10 x 25:1 Bonded:182 PM038:1/PM044:1 PM038:1/DIN 963 - replaced by DIN EN ISO 2009 M10 x 25:1 Bonded:183 PM038:1/PM043:1 PM038:1/PM039:1 Bonded:184 PM038:1/PM043:1 PM038:1/PM039:2 Bonded:185 PM038:1/PM043:1 PM038:1/DIN 963 - replaced by DIN EN ISO 2009 M10 x 25:1 Bonded:186 PM038:1/PM043:1 PM038:1/DIN 934 - replaced by DIN EN 24032/28673/28674 M10:1 Bonded:187 PM038:1/PM042:1 PM038:1/PM040:1

- 11. Bonded:188 PM038:1/PM042:1 PM038:1/PM040:2 Bonded:189 PM038:1/PM041:1 PM038:1/PM040:1 Bonded:190 PM038:1/PM041:1 PM038:1/PM040:2 Bonded:191 PM038:1/DIN 963 - replaced by DIN EN ISO 2009 M10 x 25:1 PM038:1/DIN 934 - replaced by DIN EN 24032/28673/28674 M10:1 Bonded:192 PM072:1 PM072:1 Results Reaction Force and Moment on Constraints Constraint Name Reaction Force Reaction Moment Magnitude Component (X,Y,Z) Magnitude Component (X,Y,Z) Fixed Constraint:1 1136,5 N -1132,31 N 96,0009 N m 0 N m 0 N -96,0007 N m 97,51 N 0,208713 N m Fixed Constraint:2 1138,19 N 1133 N 18,6093 N m -0,0534597 N m 0 N -18,6089 N m 108,597 N 0,116817 N m Result Summary Name Minimum Maximum Volume 8883110 mm^3 Mass 35,8983 kg Von Mises Stress 0 MPa 74,5157 MPa 1st Principal Stress -1,58104 MPa 46,6901 MPa 3rd Principal Stress -49,6312 MPa 1,64584 MPa Displacement 0 mm 1,80172 mm Safety Factor 3,4892 ul 15 ul Stress XX -30,0858 MPa 28,8853 MPa Stress XY -22,374 MPa 22,5285 MPa Stress XZ -16,048 MPa 24,8546 MPa Stress YY -43,4792 MPa 42,5824 MPa Stress YZ -28,1971 MPa 27,6777 MPa Stress ZZ -24,7299 MPa 23,8985 MPa X Displacement -0,0476812 mm 0,0560775 mm Y Displacement -0,00530719 mm 0,000202693 mm Z Displacement -1,80135 mm 0,0000846432 mm Equivalent Strain 0 ul 0,00031931 ul 1st Principal Strain -0,00000000015934 ul 0,000281428 ul 3rd Principal Strain -0,0002912 ul 0,0000000000973744 ul Strain XX -0,000167789 ul 0,000165755 ul Strain XY -0,000143755 ul 0,000144748 ul Strain XZ -0,00010311 ul 0,000159694 ul Strain YY -0,000243965 ul 0,000238284 ul Strain YZ -0,00018117 ul 0,000177832 ul Strain ZZ -0,000165039 ul 0,000164161 ul Contact Pressure 0 MPa 179,642 MPa Contact Pressure X -136,621 MPa 112,941 MPa Contact Pressure Y -83,07 MPa 85,1432 MPa

- 12. Contact Pressure Z -100,145 MPa 139,627 MPa Figures Von Mises Stress

- 13. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 14. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 15. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 16. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 17. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 18. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 19. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 20. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 21. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 22. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 23. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 24. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 25. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 26. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 27. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 28. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 29. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 30. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 31. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 32. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 33. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 34. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 35. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 36. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 37. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 38. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)

- 39. PM043.ipt PM071.ipt PM071.ipt Pino R.ipt Pino R.ipt PM074.ipt Pino R.ipt Name Steel, Mild General Mass Density 7,85 g/cm^3 Yield Strength 207 MPa Ultimate Tensile Strength 345 MPa Stress Young's Modulus 220 GPa Poisson's Ratio 0,275 ul Shear Modulus 86,2745 GPa Part Name(s) DIN 963 - replaced by DIN EN ISO 2009 M10 x 25 DIN 934 - replaced by DIN EN 24032/28673/28674 M10 Operating conditions Force:1 Load Type Force Magnitude 200.000 N Vector X 0.000 N Vector Y 0.000 N Vector Z -200.000 N Selected Face(s)