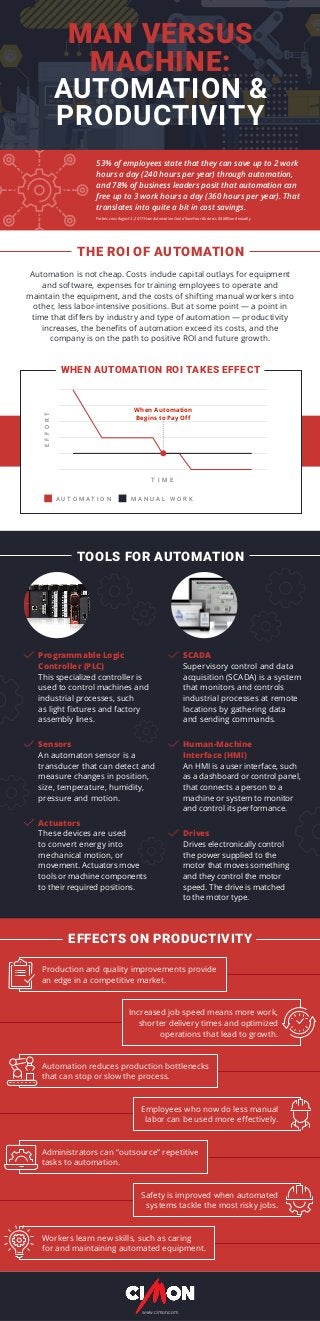

Man vs. Machine: Automation & Productivity

- 1. MAN VERSUS MACHINE: AUTOMATION & PRODUCTIVITY Automation is not cheap. Costs include capital outlays for equipment and software, expenses for training employees to operate and maintain the equipment, and the costs of shifting manual workers into other, less labor-intensive positions. But at some point — a point in time that differs by industry and type of automation — productivity increases, the benefits of automation exceed its costs, and the company is on the path to positive ROI and future growth. THE ROI OF AUTOMATION EFFORT T I M E WHEN AUTOMATION ROI TAKES EFFECT When Automation Begins to Pay Off A U T O M A T I O N M A N U A L W O R K TOOLS FOR AUTOMATION EFFECTS ON PRODUCTIVITY www.cimon.com Programmable Logic Controller (PLC) This specialized controller is used to control machines and industrial processes, such as light fixtures and factory assembly lines. Sensors An automaton sensor is a transducer that can detect and measure changes in position, size, temperature, humidity, pressure and motion. Actuators These devices are used to convert energy into mechanical motion, or movement. Actuators move tools or machine components to their required positions. SCADA Supervisory control and data acquisition (SCADA) is a system that monitors and controls industrial processes at remote locations by gathering data and sending commands. Human-Machine Interface (HMI) An HMI is a user interface, such as a dashboard or control panel, that connects a person to a machine or system to monitor and control its performance. Drives Drives electronically control the power supplied to the motor that moves something and they control the motor speed. The drive is matched to the motor type. Production and quality improvements provide an edge in a competitive market. Increased job speed means more work, shorter delivery times and optimized operations that lead to growth. Automation reduces production bottlenecks that can stop or slow the process. Employees who now do less manual labor can be used more effectively. Administrators can “outsource” repetitive tasks to automation. Safety is improved when automated systems tackle the most risky jobs. Workers learn new skills, such as caring for and maintaining automated equipment. 53% of employees state that they can save up to 2 work hours a day (240 hours per year) through automation, and 78% of business leaders posit that automation can free up to 3 work hours a day (360 hours per year). That translates into quite a bit in cost savings. Forbes.com: August 3, 2017: How Automation Could Save Your Business $4 Million Annually