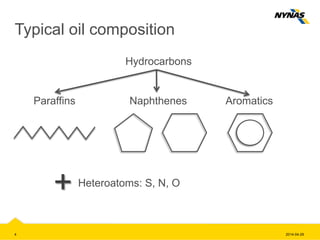

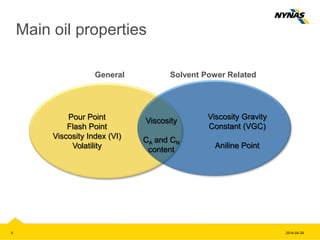

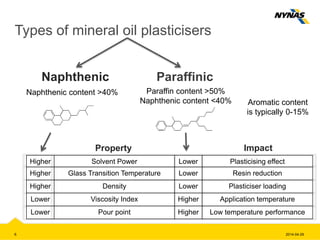

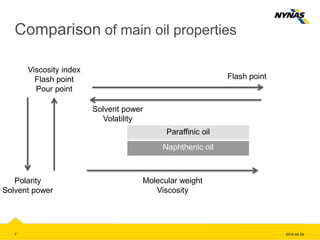

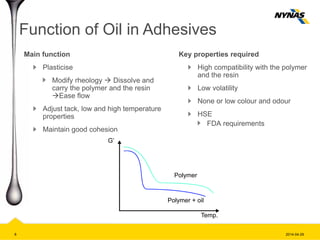

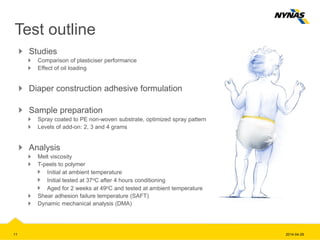

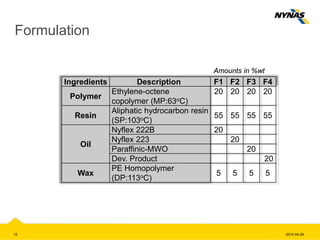

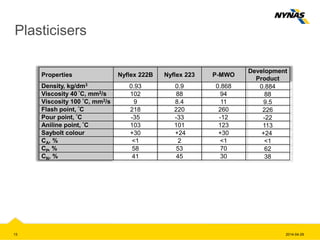

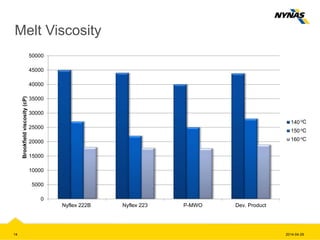

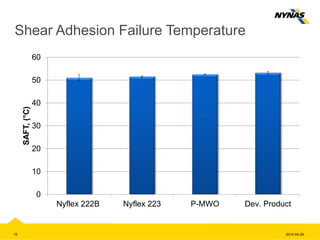

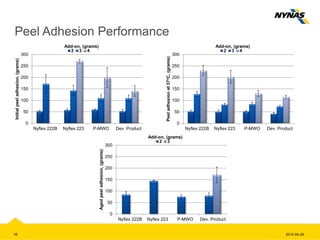

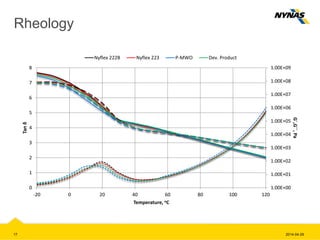

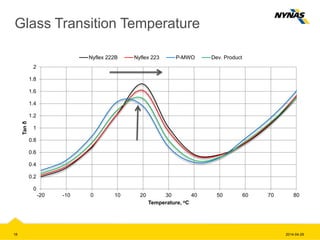

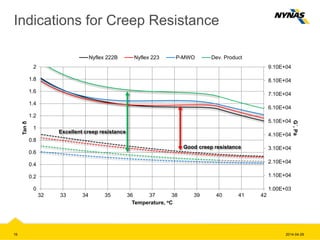

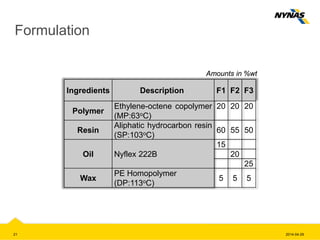

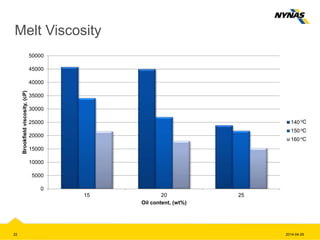

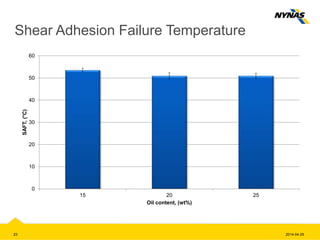

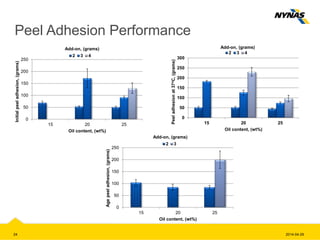

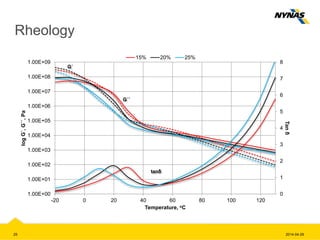

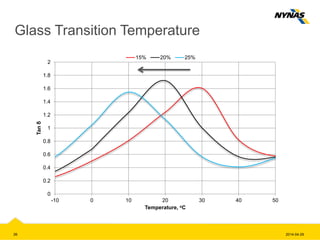

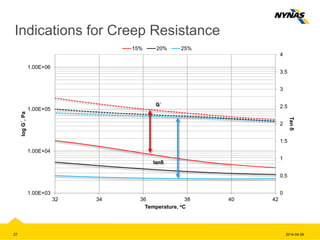

This document summarizes a presentation given by Dr. Peter Kaali on the use of highly refined mineral oil plasticizers in polyolefin-based hot melt adhesives. It discusses the composition, properties, and types of mineral oils used as plasticizers. It then compares the performance of paraffinic and naphthenic oils as plasticizers in hot melt adhesives, including their effect on melt viscosity, peel adhesion, shear adhesion failure temperature, and creep resistance. The document finds that naphthenic oils perform similarly or better than paraffinic oils as plasticizers, providing benefits such as high solvency and compatibility. It is feasible to increase the oil content to 20-25% to decrease the amount