Zulfiqar Ali's CV for electrical and instrumentation positions

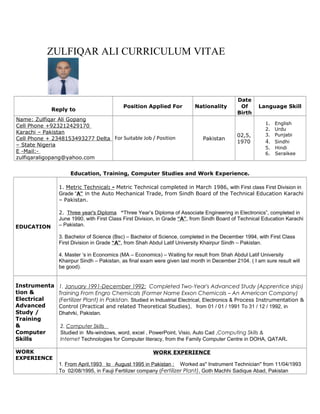

- 1. ZULFIQAR ALI CURRICULUM VITAE Reply to Position Applied For Nationality Date Of Birth Language Skill Name: Zulfiqar Ali Gopang Cell Phone +923212429170 Karachi – Pakistan Cell Phone + 2348153493277 Delta – State Nigeria E -Mail:- zulfiqaraligopang@yahoo.com For Suitable Job / Position Pakistan 02,5, 1970 1. English 2. Urdu 3. Punjabi 4. Sindhi 5. Hindi 6. Seraikee Education, Training, Computer Studies and Work Experience. EDUCATION 1. Metric Technical: - Metric Technical completed in March 1986, with First class First Division in Grade “A” in the Auto Mechanical Trade, from Sindh Board of the Technical Education Karachi – Pakistan. 2. Three year's Diploma “Three Year’s Diploma of Associate Engineering in Electronics”, completed in June 1990, with First Class First Division, in Grade “A”, from Sindh Board of Technical Education Karachi – Pakistan. 3. Bachelor of Science (Bsc) – Bachelor of Science, completed in the December 1994, with First Class First Division in Grade “A”, from Shah Abdul Latif University Khairpur Sindh – Pakistan. 4. Master ‘s in Economics (MA – Economics) – Waiting for result from Shah Abdul Latif University Khairpur Sindh – Pakistan, as final exam were given last month in December 2104. ( I am sure result will be good). Instrumenta tion & Electrical Advanced Study / Training & Computer Skills 1. January 1991-December 1992: Completed Two-Year's Advanced Study (Apprentice ship) Training From Engro Chemicals (Former Name Exxon Chemicals – An American Company) (Fertilizer Plant) in Pakistan. Studied in Industrial Electrical, Electronics & Process Instrumentation & Control (Practical and related Theoretical Studies), from 01 / 01 / 1991 To 31 / 12 / 1992, in Dhahrki, Pakistan. 2. Computer Skills Studied in Ms-windows, word, excel , PowerPoint, Visio, Auto Cad ,Computing Skills & Internet Technologies for Computer literacy, from the Family Computer Centre in DOHA, QATAR. WORK EXPERIENCE WORK EXPERIENCE 1. From April,1993 to August 1995 in Pakistan : Worked as" Instrument Technician" from 11/04/1993 To 02/08/1995, in Fauji Fertilizer company (Fertilizer Plant), Goth Machhi Sadique Abad, Pakistan

- 2. 2. From August 1995 to February,1996 in Pakistan : Worked as "Commissioning Instrument Technician" from 05/08/1995 To 02/02/1996, with Fillippo Fochi Energia,Italia, (An Italian Company) in Qadirpur Gas Field,Ghotki,Pakistan. 3. From February 1996 to February 1998 in Pakistan: Worked as" Instrument Technician" from 04/02/1996 To 20/02/1998 , with Oil and Gas Development Corporation (O.G.D.C) Pakistan, in Qadirpur Gas Field, Ghotki, Pakistan. 4. From April 1998 to October 2006 in QATAR (Middle East): Worked as Senior Electrical & Instrument Shift Lead Technician (Supervisor), in Qatar Petrochemical Company (QAPCO), in Qatar, from 24 / 04 / 1998 To October 2006. 5. From November 2006 to October 2008 in Nigeria (Africa): Worked as International Electrical & Instrument Supervisor at Off Shore Gas Field. (100 MM SCFD, Cryogenic Gas Plant in Caw Thorne River Channel), River State, Port Harcourt Nigeria Africa, on 6x4 on / off rotation base With an American company EXTERRAN (Exterran Eastern Hemisphere FZE, Dubai - UAE). From November 2006 to October 2008. 6. From November 2008 to February 2010 Oman (Middle East): Worked as International Electrical & Instrument Supervisor in Oman, and were Supervising two gas fields at same time, first one was, Shams Central Processing Plant 100 MMSCFD and the 2nd one was, Daleel Cryogenic Gas Plant 20MMSCFD, On Shore Gas fields near Iberi city, on 6x4 on / off rotation base with an American company EXTERRAN (Exterran Eastern Hemisphere FZE, Dubai - UAE). From November 2008 to February 2010. 7. From March 2010 to July 2011 in Gabon (West Africa):- Worked as International Electrical & Instrument Supervisor at Waxy Crude Oil Production Facility and Gas Compression for Artificial Lift, Exterran / Shell Koula Permanent Production Facilities Project, 80 km south-east of Port Gentil city in GABON – West Africa, on 6x4 on /off rotation base with an American company EXTERRAN (Exterran Eastern Hemisphere FZE, Dubai - UAE). From March 2010 to September 2011. 8. From August 2011 to November 30, 2012 in Pakistan :- Worked with HasTech Engineering Group, as Electrical & Instrument Contractor / Instrument Site / Field Supervisor for the Industrial Electrical equipments & Control Instrumentation’s Installation, Commissioning, Maintenance, Breakdown / Shutdown, critical trouble shootings, including the all kind of Electrical & control Instrumentation jobs for the Furnaces, Boiler’s, Compressors, Gas Turbines, Generators, Turbo-Expander/Compressors, Analyzers and control room instrumentation for Oil & Gas Sector including Petrochemical plants, Fertilizer Plant's, Gas processing Plants, Gas Cryogenic Plants (On Shore & Off Shore Gas Fields), Oil Refineries and Power Generation Plants. From 1st August 2011 to 30th November 2012. 9. From April 2013 to till present date in Nigeria :- Presently working as Operations Support & Maintenance Manager in INTER-GLOBAL PROCUREMENT ENGINEERING SERVICES LIMITED (I.G.P.E.S), Port Harcourt, Nigeria.(Oil & Gas Sector), as I am fully responsible to produce crude oil production ( 50,000 bbl/day) for our client, Nigeria Petroleum Development Corporation (N.P.D.C) from OML – 30 site, as in the OLM – 30 operations, we are operating 8 flow stations & 4 Gas Lift Compressor stations (Olomoro Flow Station & Gas

- 3. Lift Compressor Station, Affiesere Flow Station & Gas Lift Compressor station, Kokori Flow Station & Gas Lift Compressor Station, Uzere Flow Station & Gas Lift Compressor Station, Oweh Flow Station, Eriemu Flow Station. Evwerni flow Station & Oroni Flow Station, as all these stations are located in the circle of 50 km of the Oleh city in Delta State in Nigeria – Africa. 10. Special Achievement – Worked as Construction Manager from March 2014 to September 2014 & build a Amukpe Gas Lift Compressor Station, in Amukpe village near Warri City, for our client Seplat Petroleum Development Company Nigeria Ltd, where Caterpillar’s 4 Gas Engines (G3516 B) with respective Ariel Compressor, respective Fuel Gas system , Ingersoll Rand Air Compressor Package (utility control system) were installed, project were commissioned safely within time frame & hand over to the client safely, during the project work, I was fully responsible & supervised all kind of the project work, including Electrical, Instrument, Mechanical, Piping, Welding, HSE & Logistic Issues and as well as for QA/QC project documents, Project safely & successfully were completed and commissioned in September 2014. Special Note – Well Familiar with Gas Lift Compression Process Philosophy. (Capable to handle/solve all kind of the process related issues). INDUSTRIAL TRAININGStions Industrial Trainings Obtained. • Basics of Supervision. • Safety Training. • HSE Course • First Aid Course • H2S Course • Sulpher Loading Safety Course • Fire Fighting Course • DCS over View. • Environmental Awareness course. • DCS Basic Course. • Oscilloscopes & Recorders. • ISO - 9000 (Training for ISO-9000 for Quality control). • Safety & Firefighting (Training in Safety & Firefighting Deptt: Fire & Gas Leak Drill, Breathing Apparatus handling & using Procedures). • PLC (Training for Siemens, Hima & Allen Bradley PLCs). • Electrical Safety Course. • Introduction to Automatic Control. • Tailor made electrical course for Automation Shift Technician. • Sulpher Loading System (PLC control system for solid sulphur loading from jetty to ships). • Variable Speed Drive (Electrical Motor for Extruder Machine) Specific. • Simovert Master drives Cu2/Cuvc Training. • Level Measurement (Advanced). • Simocode - DP Introduction Course. • Advanced training for Pressure, Level, flow & Temperature Controls. • CMMS (Training for Computerized Material Management System).

- 4. • RECIPROCATIONG COMPRESSOR OPERATION AND MAINTENANCE FROM DRESSER – RAND ASIA PACIFIC PRODUCT TRAINING DEPARTMENT KOULALUMPUR MALAYSIA IN NOVEMBER 2010. • CENTRIFUGAL COMPRESSOR OPERATION AND MAINTENANCE FROM DRESSER – RAND ASIA PACIFIC PRODUCT TRAINING DEPARTMENT KOULALUMPUR MALAYSIA IN DECEMBER 2010. On Line Training courses obtained. Skills BPR2 – Process Control Modes BPR3 – Process Characteristics BPR4 – Process Variables MLU2 – Lube Oil–Equipment & Procedures MTR8 – Motor Controls-Installing/Troubleshooting VBR2 – Machine Vibration: Basic Theory RWB1 – Dresser Rand–Recip Compressor Major Components RWB5 – Dresser Rand–Recip Compressor Frame Lube RWB10 – Dresser Rand Recip Compressor Divider Block Cylinder & Packing Lubrication EWB10 – Dresser Rand Pre-Ignition Detonation Safety SSLKEFV – Small Spills & Leaks LOT9EFV – Lock out Tag Out –Lightning in a Bottle HYDSEFV – Hydrogen Sulfide/Sulphur Dioxide HZ18EFV – Global Harmonization Hazard Communication BEN0EFV – Benzene: Knowledge is Power & Safety FOLLOWING INDUSTRIAL TRAININGS GIVEN TO NIGERIAN ENGINEERS. Industrial Trainings Given To Local Nigerian National Engineers in Off Shore Gas Field, in Caw Thorne Channel Cryogenic Gas Plant, Near – Port Harcourt River State Nigeria. Instrument/Electrical Crew Consisting on the 10 Local National Nigerian Engineers). As It’s the part of the my job responsibilities, to improve the skill level of the local Nigerian national Engineers (Instrumentation/Electrical Crew), according to the plant work requirements and request, from local Nigerian national engineers, arranged and given following mentioned all trainings in detail, to the 10 local Nigerian national Engineers (Instrument/Electrical crew) for the following mentioned all Instrument / electrical Control equipments. 1. Programmable Logic Controller. (PLC) This Training session was consisting on the complete introduction and understanding with Digital Logic Gates (AND Gate, OR Gate, XOR Gate, NAND Gate, NOR Gate, XNOR gate, Buffer Gate and Inverting Buffer Gate) and Introduction and understanding with PLC, Ladder Logic, PLC Connections, Ladder Logic Inputs, Ladder Logic Outputs. PLC Programming and PLC Operation and PLC problems and Practice on the Simulator (Software). 2. IR-522 Combustible Hydrocarbon Sensor 0 – 100% LEL (Detcon Microsoft). CH4 - Gas Detector. This Training session was consisting on the complete ,Description, Principle OF Operation, Application, Specifications, Operating Software, Installation, Startup, Calibration, Status OF Programming, Calibration level, and RS-485 ID, Program Features, Display Contrast Adjustment, Optical Sensor Replacement

- 5. Procedure, Trouble Shooting Guidance, Software Flow Chart and Spare Parts List for the IR-522 Combustible Hydrocarbon Sensor 0 – 100% Lower Explosive Limit (Detcon - Microsoft). 3. Rosemount 3095 Multivariable Transmitter. This training was consisting on the complete calibration procedure for the Rosemount 3095- MV- Transmitter, including, Static Pressure sensor, Absolute / Gage Pressure Calibration, Differential Pressure Calibration, Temperature Sensor Calibration and Analog out put Trim, for the Transmitter. Also it’s included with 375 Hart Communicator’s Software Menu Tree for the Rosemount 3095 Multivariable Transmitter. 4. DANIEL SENIOR ORIFICE FITTING. The training session for the DANIEL SENIOR ORIFICE FITTING, was include and covering following all topics in details. General Introduction, Description, Specifications and spare parts list. Installation, Preliminary Steps, Daniel senior Orifice Fitting Installation, Line Pressure Test and Orifice Plate Installation procedure . Maintenance Procedure in normal condition. Daniel Senior Orifice Plate Insertion, removal and Lubrication Procedure. Supplemental Information for Recommended Spare Parts for one year operation period and Lubrication Information and also about the Screw and Stud Torque table information. 5. NORRISEAL SERIES-2700-A CONTROL VALVES. This Training session was consisting on the complete introduction and understanding with Norriseal’s Control Valves Series2700A, including Introduction, Scope, Description. Valve Identification, Valve Installation, Valve Maintenance and Calibration, Actuator Disassembly and Re-Assembly, Valve Disassembly and Re-assembly (Plug Control Trim, Reduced Plug Trim, Cage Control Trim, and Reduced Cage Trim). Trim Inspection and Restoration. Replacement of Teflon V-Ring Packing and Valve Compression Pacing. Packing Lubrication. Repair Kits, Stem Travel and Maintenance Schedule, Lapping Compounds. Bolt Torque for CSTL and SST Bodies. Trouble Shooting. Configurations, Valve Specifications, Model Codes and How to Order. (Ordering Procedure). 6. Moisture Monitor Series 35. (Moisture Analyzer, Panametrics). This Training session was consisting on the complete introduction and understanding with Moisture Monitor Series 35. (Moisture Analyzer ,Parametric), including Feature and Capabilities, Installation, Operation, Trouble Shooting and Maintenance, Specifications, Data Information Sheet and Spare Parts List. Career Summary I am having more than 20 year's international hand-on working experience in Petrochemical plant, Fertilizer Plant's, Gas processing Plants, Gas Cryogenic Plants (On Shore & Off Shore Gas Fields) in the area of Industrial Electrical & Instrumentation & Control systems, as worked in Pakistan, Qatar, Nigeria, Oman and in Gabon countries. Practically well familiar with the Air Compressor Control systems / Packages and control instrumentation for the all kinds of the Gas Turbines. Generators, Boilers, Furnaces, Compressors, Turbo-Expander/Compressors, control room instrumentation , DCS (TDC3000” Distributed Control System), PLC (HIMA PLC, SIEMEN PLC, SIMATIC S-5 & S-7 ) Allen Bradley PLC (PLC-5,SLC 500) Dos & Window Base and SCADA control systems, Wonder ware Process Graphics (Smart symbols manager, In Touch 8.9),Gas Analyzers including Gas chromatograph analyzer, H2s Analyzers, Moisture Analyzers, PH Meter Analyzers and Bentley Nevada Vibration Monitoring System (Bentley Nevada Series 7200, 3300) & Speed Control Systems .. Fire and Gas Detection systems, as well as instrument Related Portable & Bench Mounted Test/calibration Equipments including Hart Communicator(Rosemount) (Model (275,375) Communicator that Provide Communication Link to all Hart, Compatible & Microprocessors base Instruments. Well familiar with Ex-Protection classification and with Lockout/Tag out procedure and capable to supervise for the all kinds of main contractor, sub-contractors and the different vendor representatives work and capable for the

- 6. scheduling / planning annual leaves and emergency leaves for the staff. Capable to use Field Laptop Computers for PLC including Allen Bradley and Siemens Simatic S-5 / S7 & Fujitsu Field PGs. Capable for the trouble for motor control systems and electrical isolation and energizing the circuit breakers ( Contactors ) from the respective substations. Having excellent English language skills for the technical communications and reports. Capable on working with Digital Governor controls, PLC systems, Microprocessor controls and various conventional pneumatic & electronic Instruments, all of which require the ability to read & understanding engineering drawings such as P & IDs, loop drawing, ladder logic and block & functional diagrams and capable to perform preventive, corrective and troubleshooting maintenance, and testing of all Plant Instrument Process Monitoring, Control Protective Equipments and to perform preventive, corrective and diagnostic maintenance on the process control systems and control loops and capable to remove, dismantle, overhaul/repair and install electrical, pneumatic, electronic & hydraulic control system such as motors, electrical control wiring system, control valves and actuators, recorders, measuring and recording instruments in the field or in the workshop and control room / rack room and capable to perform preventive and emergency maintenance on all equipment on site, as well as during machine scheduled or unscheduled shutdowns and to perform modification of control circuits and/or control loops as per the plant change request and update all related plant drawings to reflect the actual changes and capable to assist other sections such as process, electrical, mechanical and workshop in the repair and troubleshooting of their instrument and electronic related systems and test equipment and capable to perform upgrade and retrofitting of new control instruments to the existing panels in the field and main control rooms and capable to comply with all company Health, Safety and Environment as well as Work Permit, policies and procedures and capable to input data into CMMS / MAXIMO maintenance system, such as work order activities, materials and spares, failure reports and manpower statistics and capable to perform regular calibration and maintenance of all safety, fire and gas equipment such as gas monitors, H2S monitors, smoke detectors and heat detectors etc, and capable to train and develop the assigned staff or local Nationals and capable to troubleshoot, repair, calibrate and test various types of process control loop / instruments and relay logic, which pneumatic, electrical and electronic and microprocessor based instruments. Well on hand working experienced with following mentioned rotating equipment, regarding Normal operations, preventive, corrective, break down and overhauling maintenance activities and as well as for respective spare parts / inventory issue. • Caterpillar G3516ULB/Ariel JGT/4 (Ariel Gas Lift Compressor with Caterpillar Gas Engine G – 3516) • Waukesha L7042GSI / Thomassen C203, ( Thomassen Gas Lift Compressor with Waukesha Engine) • Waukesha L7042GSI / DR 3RDS-3(Dresser Rand Gas Lift Compressor with Waukesha Engine) • Waukesha 7042 GSI/ DR 4RDS-3 (Dresser Rand Gas Lift Compressor with Waukesha Engine) • Caterpillar G3412 / Sulzer MSD-D4 ( Crude Oil Centrifugal Export Pump with Caterpillar Gas Engine G - 3412) • Caterpillar G3412 / Sulzer MSD-D5(Crude Oil Centrifugal Export Pump with Caterpillar Gas Engine G - 3412) • Caterpillar G3408 / National Oil Well (Crude Oil PD Export Pump with Caterpillar Gas Engine G - 3408). • Caterpillar G3306 / FWI 6070 ( Crude Oil PD Export Pump with Caterpillar Gas Engine G - 3406) • Solar Turbine/UCPump, (Crude Oil Solar Turbine Pump). • Loher Elect Motor/Byron Jackson ( Crude Oil Transfer Pump) • Caterpillar D3304 / SR4 (Generator with Caterpillar Diesel Engine G – 3304) • Caterpillar D3406 /SR4 (Generator with Caterpillar Diesel Engine – D3406) • Caterpillar G3306 /SR4 (Generator with Caterpillar Gas Engine G – 3306)

- 7. • Caterpillar G3408 / SR4 (Generator with Caterpillar Gas Engine G – 3408 ) • Caterpillar G3412 / SR4 ( Generator with Caterpillar Gas Engine G – 3412) • Caterpillar G3512 / SR4 ( Generator with Caterpillar Gas engine G 3512) • Caterpillar Model C15 / SR4 ( Generator with Caterpillar Diesel Engine ) • Ingersoll Rand UP5-18 ( Instrument Air Compressor) • Ingersoll Rand T-15 ( Instrument Air Compressor) • Ingersoll Rand 10T ( Instrument Air Compressor) • Ingersoll Rand 30T ( Instrument Air Compressor) • DEUTZAG/Atlas Copco ( Instrument Air Compressor) Objective: - Looking for a suitable and challenging job which suits my profile and utilizes my extensive leading potential, as I am Self-motivated, visionary professional with more than 20 Year's international on hand working experience in Electrical & control Instrumentation, as worked in Petrochemical plants, Fertilizer Plant's, Gas processing Plants, Gas Cryogenic Plants (On Shore & Off Shore Gas Fields / Plants).Waiting to hear good news from your side. Thanks Availability: -- Immediately. Thanks & Best Regard’s Zulfiqar Ali. Cell # +923212429170 Karachi – Pakistan. Cell # + 2348153493277 Delta – State Nigeria. E -Mail:- zulfiqaraligopang@yahoo.com