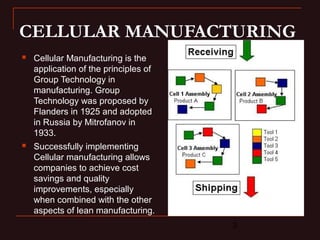

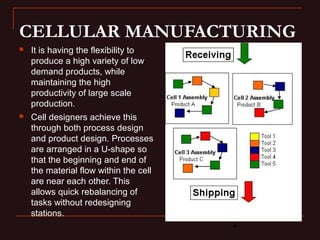

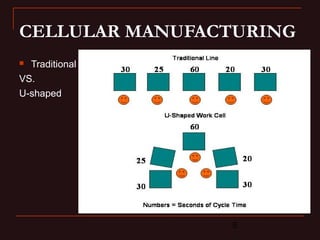

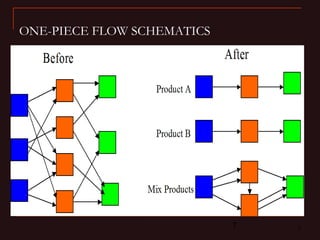

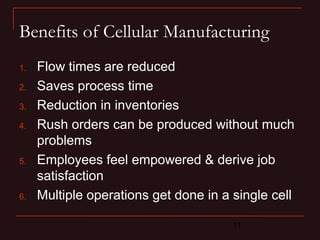

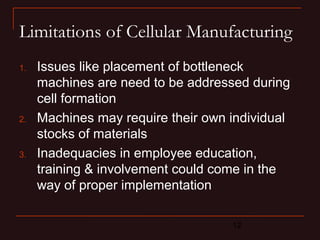

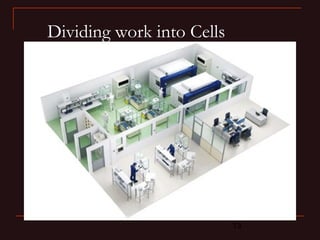

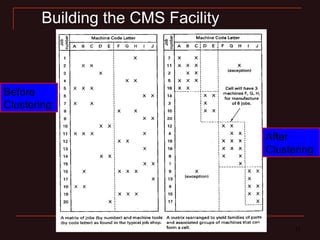

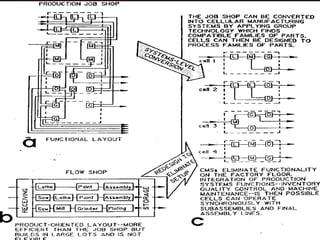

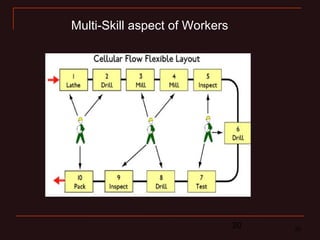

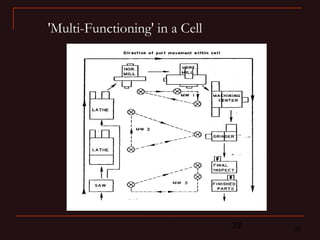

This document discusses cellular manufacturing. Cellular manufacturing groups similar parts that require common processing steps into manufacturing cells. Within each cell, the equipment and workstations are arranged closely together in the sequence of processing steps. This cellular layout aims to promote continuous one-piece flow and reduce waste such as transportation time between steps. Operators are cross-trained to run multiple machines within a cell flexibly. The goals of cellular manufacturing include improved productivity, flexibility, and reduced lead times and inventories.