YAMATO MACHINES

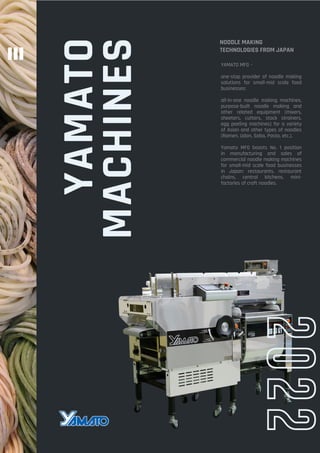

- 1. YAMATO MACHINES 2022 NOODLE MAKING TECHNOLOGIES FROM JAPAN YAMATO MFG – one-stop provider of noodle making solutions for small-mid scale food businesses: all-in-one noodle making machines, purpose-built noodle making and other related equipment (mixers, sheeters, cutters, stock strainers, egg peeling machines) for a variety of Asian and other types of noodles (Ramen, Udon, Soba, Pasta, etc.). Yamato MFG boasts No. 1 position in manufacturing and sales of commercial noodle making machines for small-mid scale food businesses in Japan: restaurants, restaurant chains, central kitchens, mini- factories of craft noodles.

- 2. WE ARE ALL ABOUT OUR CUSTOMERS’ LONG TERM SUCCESS Providingreliableandsafeequipmentforproduction of noodle products of the best quality Helping our customers achieve long term success in noodle business Popularizing Japanese noodle culture across the world OUR MISSION Biography: Kaoru Fujii - May 1948. Born in Sakaide City (Japan, Kagawa pref.) - March 1968. Graduated from the National Institute of Technology Kagawa College. - April 1968. Started work at Kawasaki Heavy Industries (assigned to Aircraft design bureau, Fuselage section: in charge of the “Phantom” airplane License production) - April 1971. Assigned to the Design section of the Ship building division (in charge of designing an engine room for 200 000 ton tanker ship) - October 1975. Left Kawasaki Heavy Industries, and established his own company (precursor of the current YAMATO MFG) - January 1984. Founded Sansyo Co., Ltd Kaoru Fujii is an author of many books on noodle cuisine and noodle business management, he has been featured in a number of high-profile business TV shows in Japan, and is famous for his professional advice to prospective and existing entrepreneurs. Yamato MFG Co. Ltd., CEO Sansyo Co. Ltd., CEO

- 3. YAMATO PHILOSOPHY COMMITMENT TO CUSTOMER SUCCESS YAMATO HISTORY COMPANY PROFILE — Throughout its more than 4 decades long history Yamato has achieved a position of No 1 manufacturer of special equipment for small-mid scale commercial production of craft noodles. Together with its sister company Sansyo Yamato is constantly engaged in scientific and practical research of noodle quality, always striving to improve design, safety, productivity, durability and ergonomics of its machines. At the same time, the Noodle Schools organized by Yamato - both in-person and online - have served as a starting point in carreers of many successful noodle restaurateurs and business owners both in Japan and worldwide. Success of our clients is our success. We do not sell just machines – we sell technical solutions to our customers’ problems, working closely with each of them to offer the best possible equipment for their current and future needs. CEO: Kaoru Fujii Capital: 90,000,000 JPY Founded: April 1, 1980 Field of business: Design, manufacturing and sales of noodle making equipment for Ramen, Udon, Soba and other types of noodles. In-person and online noodle cuisine schools. Noodle business consulting. NOODLE MAKING MACHINES/ OTHER FOOD EQUIPMENT NOODLE CUISINE SCHOOLS Yamato manufactures a variety of noodle making machines for Jap- anese ramen, udon, soba and other types of noodles for small-mid size commercial production. Yamato machines are designed based on deep and scientifically-founded understanding of ingredients’ qualities and characteristics. Machines are safe, versatile, durable, ergonomic, and easy to use. Yamato also makes other types of re- lated equipment for noodle businesses (automatic soup strainers, soft-boiled egg peelers, etc.). Yamato offers professional business-oriented Noodle Schools for ramen, udon and soba cuisines both in-person (Japan) and online. Intensive full-immersion courses allow to master noodle cuisines in a short time. Yamato web-site and other online platforms also offer a wide range of relevant information on noodle production, recipes, and noodle business management. RESEARCH LAB R&D, FACTORY, TECHNICAL SUPPORT Knowledge is power. A special research lab allows Yamato to study properties of wheat and other ingredients to ensure its equipment is capable of producing noodles of the best quaility, and the reci- pes it teaches at its school make the most delicious noodle dishes. Yamato is a full cycle manufacturing company. Yamato noodle machines are designed and manufactured by Yamato itself, and undergo the most thorough and rigorous quality controls before being shipped to customers across the world. The machines are also tested if they can produce noodles according to customers' specifications. Multilingual Tech support department offers its services 7/24/365. Free guidance on maintenance and servicing is available.

- 4. Yamato is all about customer success. Since most of our customers are food businesses making their own noodles even a shortest down time can mean loss of revenues. That is why we want to make sure our customers’ machines are always running smoothly and efficiently producing noodles of the best quality. Yamato offers support to all its customers, no matter how long they have owned their machines or wherever in the world they are using them. Quality starts with good design. Yamato noodle machines are designed based on thorough understanding of ingredients, and the quailities that make the best noodles. Quality of machines is ensured during assembling where each screw, bolt and nut is given proper attention, and all parts are finely tuned and attached to where they should be. Quality is tested before shipping - with each and every machine being checked both for mechanical quality, and the quality of noodles it produces. Quality is maintained through care and correct operation based on user manuals, servicing instructions, and guidance from Yamato technical staff on how to properly operate the equipment, how make sure it does not break, or what to do when it does. For Yamato machines, break downs are rare, and 99% of them can be easily solved by adjustment / part replacement. In addition to our HQ in Kagawa Japan, Yamato has local branches in Singapore, Netherlands, South Korea and USA where our staff or our partners do their utmost efforts to keep your machines running. CUSTOMER SUPPORT 365 DAYS A YEAR, MAINTENANCE/SERVICE DEPT. SUPPORT is not only technical. With over 40 years of experience, Yamato has accumulated much knowledge on how to create and operate successful noodle specialty businesses. Yamato Noodle Schools focuse on teaching future noodle shop owners and chefs about what it takes to have a successful business, as well as provide a unique opportunity to experience automatic noodle making, and gain comprehensive expertise in homemade noodles. Yamato Noodle Schools - both in-person and online - offer a comprehensive curriculum that includes both theoretical and practical aspects, enabling its graduates to become top noodle masters knowledgeable enough not only to make and cook standard noodle dishes, but also to create their own original recipes and menus, always staying ahead of the competition. ※September 2022

- 5. SERIES NOODLE MACHINES “Richmen” is a name for the series of Rolling-type commercial noodle machines designed and manufactured by Yamato. These machines are used in restaurants, restaurant chains and other types of food businesses specializing in fresh craft noodles. Richmen noodle machines are safe, durable, and very easy to use to produce a variety of noodles (e.g. Ramen etc). The name “Richmen” is combined from two words: “MEN” meaning “noodles” in Japanese, and “RICH” that reflects the ability to produce fresh noodles with excellent taste and texture. RICHMEN

- 6. RICHMEN GOLD RICHMEN GOLD less effort, more productivity! Decades of noodle science and centuries of noodle making traditions have been condensed into 1 machine. Powerful, easy to use, and safe. With RICHMEN GOLD anyone can be a top-level noodle master. RICHMEN GOLD is equipped with a truly revolutionary automatic dough feeding and rolling system. It's design is based on deep scientific understanding of physical properties of ingredients, and allows perfect automation regardless of the type of noodles produced. An all-in-one machine combining mixing, pressing and cutting functions, and equipped with an automatic flour duster and dough conveyor. At the time of release it was the first noodle machine for commercial small-mid scale production with a touch screen display for information and control. Compared to the legacy RICHMEN TYPE I model, the productivity of RICHMEN GOLD is 1.7 times higher. Also: Infrared sensors in the rollers compartment prevent injuries on every stage of dough sheet production. Cutter compartment sensor prevents machine from operating if the cutter cover is not closed. Mixer tank lid sensor won't allow the mixer to run if the lid is not properly closed. Improved safety “ With this machine any of my staff can make great noodles like an experienced noodle master” (models for European and North American markets available) lower height for easier operation improved mixer for better dough quality automatic dough conveyor intelligent dough feeding system additional safety sensors ergonomic design for easier handling improved cutter position for faster and more effortless work Flour duster — Automatically sprinkles flour during sheeting and cutting stages. Flour goes directly onto conveyor for less waste and easier cleaning. Touch panel — For displaying all relevant informa- tion and changing the settings. Rolling pin rails — Instead of lifting pins with heavy dough - now you can simply slide them where necessary depending on the operation stage. Easy noodle length adjustment — For changing noodle length during the cutting stage. A craft noodle factory in one small room - effortless operation - short learning curve - small footprint - absolute safety RICHMEN GOLD combines all functions and complexities of noodle making in one machine!

- 7. 12 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 13 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 12 13 The Gold series is a milestone in the evolution of the Yamato noodle machines! Yamato always listens to wishes and demands of its customers, and strives to make its machines as easy to use, safe and productive as possible. Easy maintenance Mixer cleaning is very easy - simply put wet sponges inside the tank, and run the machine. After about 10 minutes, wipe the surfaces with a cloth, and disinfect. Cleaning of roller scrapers and trays is also very easy, and can be safely done on a regular basis by operators. 机器名称 RICHMEN GOLD RICHMEN GOLD CE规格 RICHMEN GOLD UL规格 型号 LMA552310 LMACE LMAUS 外形尺寸 W 1,350 x D645 x H 1,000mm W 1,350 x D645 x H 1,000mm W 1,350 x D645 x H 1,000mm 最大功耗 1.80/1.73kw 50/60Hz 单相100v 1.80/1.73kw 50/60Hz 单相100v 1.80/1.73kw 50/60Hz 单相100v 重量 约350kg 约350kg 约350kg 规 格 搅拌机 最大10kg(面粉重量) 最大10kg(面粉重量) 最大10kg(面粉重量) 辊筒宽度 230 mm 230 mm 230 mm 辊筒直径 163 mm (5.4寸) 163 mm (5.4寸) 163 mm (5.4寸) 生产效率 150~200份 /小时 150~200份 /小时 150~200份 /小时 Improved mixer tank design for optimal optimal mixing operation mixing operation Dough mixing quality directly affects the final quality of noodles. Yamato engineers and food technologists created a shape for the most optimal mixing performance. Less effort, better noodles with automatic dough feeder Specifications Machine name RICHMEN GOLD RICHMEN GOLD CE (EU) RICHMEN GOLD US (NA) Model LMA552310 LMA5523CE LMA552310US Dimensions W 1,350×D645×H1,000 W 1,350 x D645 x H 1,000mm W 1,350 x D645 x H 1,000mm Power supply 1.2kw 50/60Hz (1 phase 100V) 1.2kw 50Hz (1 phase 230V) 1.2kw 60Hz (1 phase 115V) Weight ~350kg ~350kg ~350kg mixer 10kg (flour weight) 10kg (flour weight) 10kg (flour weight) rollers width 230 mm 230 mm 230 mm rollers diam. 163 mm 163 mm 163 mm productivity 100~150 portions / hour 100~150 portions / hour 100~150 portions / hour Richmen Gold High-performance all-in-one noodle machine ▶ touch screen ▶ optimized height ▶ automatic conveyor ▶ rolling pin rails ※Specifications for the 100V model Now you do not need to spend your time and effort to push dough mix through Rollers - an intelligent automatic conveyor mechanism will do it instead. Infrared light-curtain for failure-proof safety Infrared light-curtain for failure-proof safety Advanced safety sensors cover an area above the rollers to prevent hands or foreign objects from getting caught between them. The system is non-intrusive and reliable. Ergonomic and intelligent design for easier and faster cutting Cutting mechanism of the legacy models was re-designed to allow changing the cutting speed and noodle length during operation.

- 8. Noodle sheeter+cutter More efficiency. More productivity High production capacity. Easy operation Richmen Gold II is optimized for high production capacity. Mixing is done using a separate stand-alone 25 kg (flour weight) mixer unit. This solution is ideal for medium to large scale restaurants or small noodle factories. Richmen Gold II has enough production capacity to process dough volume from 2 sepa- rate 25 kg mixers, making this com- bination a real mini-factory that can be installed and operated in 1 small room. For specialty noodle shops its outstanding speed and ease of use allow to produce enough noodles in a short time, helping to reduce labor cost. Food service businesses often experience a problem of staff shortage because the job is hard while profit margins may not be high enough to pay higher wages. This makes it difficult to make noodles in-house even if the business has a noodle machine. Great ergonomics, high automation and outstanding production capacity of Richmen Gold II allow to produce high quality noodles quickly and in large quantities. Fully digital ROLLER GAP ADJUSTMENT Standard physical roller gap ad- justment handle has been replaced by a digitally controlled automatic motor-operated system. ・Zero dead space The areas around the shaft are embossed to ensure more thor- ough mixing (by preventing accumulation of dough particles). ・Lower position, bigger opening Compared to legacy models, the Silky Mixer’s height was low- ered by 14cm, while the opening was made wider by 11cm. RICHMEN GOLD II Automatic DOUGH FEEDING Easy to use TOUCH SCREEN PANEL Instead of having to feed dough between rollers by hand, Richmen Gold II is equipped with an intel- ligent conveyor that does it auto- matically. Intuitive and effortless operation with a touch screen panel. SILKY MIXER M25B MOST ADVANCED NOODLE MIXER (purchased separately) IT ALL STARTS WITH MIXING! “Silky Mixer” - perfect companion to the Richmen Gold II Optimal shape, optimal number of rotations for the best dough and noodle quality ・Homogeneous hydration Number of watering holes, their position and size have been decided based on thorough research of properties and charac- teristics of flour and other noodle ingredients ・Adjustable rotation frequency The mixer is equipped with a frequency converter to change the number of mixing revolutions according to the condition of dough.

- 9. YAMATONOODLE.COM 16 Automatic dough feeding system The machine is equipped with with a mechanism that detects the amount of dough on the conveyor, and optimizes the feeding speed based on the type of dough being made at the moment. Digital roller gap adjustment In Richmen Gold II, the evolution of noodle making technologies made a quantum leap by getting rid of the physical handle altogether! A truly revolutionary solution to make work even more easier. Failure proof safety system The more powerful the machine, the more important safety is. The most dangerous part of a noodle maker is the roller unit. Richmen Gold II is equipped with an infrared sensor safety system to protect operators from injuries. High performance, versatility In combination with the Silky Mixer, this machine helps to achieve high production volume of craft-quality noodles - ramen, pasta, as well as certain varieties of Udon and Soba. All new, powerful, high performance, noodle machine with greater ease of use RICHMEN GOLD II Full digital control! Revolution in noodle making for restaurants and mini-factories of CRAFT noodles less effort - more productivity RUN YOUR BUSINESS - LEAVE NOODLE MAKING TO RICHMEN GOLD II LONG or SHORT Specifications RICHMEN GOLD II Model LSB7723 Dimensions W1,470×D674×H900 Power supply 1.36kw (3 phase 200V) Weight ~340kg mixer no (purchased separately) rollers width 230 mm rollers diam 210 mm productivity 250~350 portions /hour noodle length freely adjustable during cutting ※100V model

- 10. 18 19 SYSTEM 1 // FLOUR DUSTER Similar to noodles made by hand, machine-made noodles also need to be sprinked with flour to prevent them from sticking. Richmen 1 is equipped with a device to do this automatically. RICHMEN TYPE I Richmen series noodle machines The RICHMEN I model is a compact, durable all-in-one noodle machine, and it has been the best-selling model of Yamato machines across the world. With a built-in 10kg mixer, it is a perfect fit for small - medium-scale restaurants. Although it does not have the modern features of the Gold series, it is a true "classic" because of its robust design, high noodle quality, and outstanding track record. SYSTEM 2 // ROLLERS A pair of powerful rollers for passing dough between them. Used for sheeting (making a dough sheet from dough mix) and thinning of dough. A safety grid above the rollers protects operators from injuries. Better usability and convenience with a foot switch that can temporarily stop the rollers during the operation. SYSTEM 3 // CUTTER A built-in cutting mechanism allows to cut dough sheet into noodles of desired size, shape, and batch weight. A great variety of replaceable cutters of different types and sizes is available. SYSTEM 4 // PRECISION ROLLER GAP ADJUSTMENT The adjustment system allows to set the distance between rollers with precision up to 1 mm. Adjustment is done easily using only one handle. Current roller gap can be viewed on a dial indicator. SYSTEM 5 // MIXER Richmen Type 1 is equipped with a 10 kg (flour weight) dough mixer. The mixer is easy to use, powerful, hygeinic, and can be cleaned simply by putting wet sponges inside, and running it for ~10 minutes. SYSTEM 6 // DOUGH TRAY The dough tray can be detached from the machine, and placed under the mixer. When mixing is finished, dough can be transfered directly into the tray by tilting the mixing tank. Dough mix can be directly fed between the rollers from the tray. models for European and North American markets available YAMATONOODLE.COM YAMATONOODLE.COM

- 11. 20 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 21 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 20 21 ALL-IN-ONE NOODLE MACHINE Specifications RICHMEN TYPE I RICHMEN TYPE I CE (Europe) RICHMEN TYPE I US (NA) Model YLM10062I LM10062ICE LM10062IUS Dimensions W 1,110 x D765 x H 1,320mm W1,224 x D690 x H 1,168 W 1,525 x D730 x H 1,168 Power supply 1.24/1.12kW 50/60Hz (1 phase 100V) 0.880kW 50Hz ±1% (1 phase 230V±10%) 0.855kW 60Hz (1 phase 115V) Weight ~270kg ~290kg ~270kg mixer 10kg max (flour weight) 10kg max (flour weight) 10kg max (flour weight) roller width 210 mm 210 mm 210 mm roller diam. 163 mm 163 mm 163 mm productivity 100 portions / hour 100 portions / hour 100 portions / hour RICHMEN: NOODLE MAKING PROCESS Rough sheeting Dough mix is passed between two powerful rollers which are set apart at an optimal distance, and apply appro- priate amount of force depending on dough hydration. First combination At this stage the rough dough sheet is split in two halves, overlayed and passed through a narrower gap to form one sheet which is more firm and elastic. Second combination One combination strengthens dough sheet, but two is even better! Such noodles are more able to maintain their texture during storage and cooking. Thinning After the second combination, dough sheet is thinned down to a desired thickness. This is done gradually through several repetitions to preserve gluten structures. Cutting Once dough sheet has been thinned, a simple turn of the lever will direct it into a cutter installed in the machine. Richmen machines can make a great variety of different noodles. Yamato believes that dough resting and aging (maturing) are crucial processes to ensure outstanding noodle quality. That is why dough trays of Richmen Series noodle machines can be easily detached from the main unit to allow operator to effortlessly handle the dough. Resting and aging prevent noodles from breaking or getting soggy, and allows them to maintain their texture for a long time. Noodle making using Richmen machines is based on careful development of gluten structures - a secret key to truly delicious noodles. Dough resting - for better noodles NSF, UL, CSA, CE certified (models for European and North American markets are available) Dough mixing The shape of the mixer tank, mixing rods and the number of rotations ensure that gluten structures are thoroughly developed in the dough for outstanding noodle quality. THE SECRET OF GOOD NOODLES: GLUTEN DEVELOPMENT Mixing wheat flour with water produces gluten structures, which play an important role in overall noodle quality, including such properties as elasticity. To make the gluten structures firm and robust, it is necessary to repeat the process of applying pressure and relaxing them several times (as if working out muscles). The design and operation of the Richmen series noodle machines is based on science and deep understanding of ingredients’ properties. ※Specifications for the 100V

- 12. yamatonoodle.com yamatonoodle.com 22 23 RICHMEN TYPE II Richmen series noodle machines Operators: 1-2 Output: 200-300 portions / hour of Ramen, Pasta, etc. MIXER M25 YAMATO MIXER M25 was designed to achieve the same dough and noodle quality as hand-made varieties. Mixer tank shape, number and rotation frequency of pins - each component ensures the perfect balance between mixing time, speed and intensity. RICHMEN II machines meet various global safety standards (CE, NSF/ANSI8, CSA, UL763 certification), which means they can be used in the U.S., Canada, EU member countries, and other parts of the world. RICHMEN II + M25/M25B - low footprint, high productivity for your restaurant, restaurant chain or noodle factory ※230V model ※Appearance of models for different regions may differ Models for European and North American markets are available. Suitable for central kitchens, small noodle factories or restaurant chains. The RICHMEN II model has no built-in mixer. We recommend using it with a 25 kg stand-alone mixer (M25 or M25B models) to achieve its full pro- ductivity potential.

- 13. 24 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 25 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 24 25 Mediumsizenoodlemachine formaximumproductivity RICHMEN TYPE II Dedicated function design Purpose-built structure allows to boost the output of each function increasing the overall productivity. SHEETER+CUTTER NOODLEMACHINE RICHMEN II is a machine built for sheeting and cutting functions. Compared to RICHMEN I model, its bigger rollers make it more powerful and increase its productivity. Certified by major safety stan- dards (CE, NSF, CSA, UL), RICHMEN TYPE II is kitchen-legal all over the world. Easy to use noodle length adjustment function High capacity dough tray A noodle tray for larger volume of dough helps to ensure higher processing capacity and productivity. Accessory conveyor All RICHMEN TYPE II machines are equipped with a conveyor for easier cutting and higher output. Safety features Sensor-operated safety features ensure operators are protected from injuries while using the machine. Machine name RICHMEN TYPE II RICHMEN TYPE II CE (EU) RICHMEN TYPE II UL (NA) Model YLM10062I LM10062ICE LM10062IUS Dimensions W 1,324 x D758 x H 1,350mm W 1,380 x D795 x H 1,405mm W 1,350 x D645 x H 1,000mm Power supply 0.85kw 50/60Hz (3 phase 200V) 0.85kw 50/60Hz (1 phase 230V) 0.85kw 50/60Hz (3 phase 230V) Weight ~360kg ~360kg ~360kg mixer 10kg max (flour weight) 10kg max (flour weight) 10kg max (flour weight) roller width 210 mm 230 mm 230 mm roller diam. 163 mm 163 mm 163 mm productivity 150~200 portions / hour 150~200 portions / hour 150~200 portions / hour ※models for different regions may have dif- ferent appearance

- 14. CE CERTIFIED MODELS FOR EUROPE STANDARD MODELS (100V) Suitable for non-EU, non-North American countries (use of an electric transformer may be needed). CSA/UL/NSF CE CERTIFIED MODELS FOR NORTH AMERICA RICHMEN series noodle machines are compliant with global safety and quality standards Richmen has been one of the first Japanese noodle machines to obtain most major international safety certifications, such as CE, UL, SA, NSF, etc., as well as several patents for safety features. It is the most widely known Japanese noodle machine brand in the world. Richmen machines have been shipped to more than 60 countries around the world. 26 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 27 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 26 27 RICHMEN TYPE I Machine name RICHMEN GOLD RICHMEN GOLD II RICHMEN TYPE I RICHMEN TYPE II Model YLMA552310 YLSB7723 YLM10062I YLS082I Dimensions W 1,350 x D 645 x H 1,000 W 1,350 x D 645 x H 1,000 W1,110 x D765 x H 1,320 W1,324 x D758 x H 1,350 Power supply 1.80/1.73kW (1 phase 100V) 1.36kW (3 phase 200V) 1.24 / 1.12kW (1 phase 100V) 0.85kW (3 phase 200V) Weight ~350kg ~350kg ~270kg ~360kg mixer 10kg — 10kg — roller width 230mm 230mm 210mm 230mm roller diam. 163mm 210mm 163mm 210mm productivity ~100 - 150 portions/hour ~250 - 350 portions/hour ~100 portions/hour ~200 - 300 portions/hour touch panel 〇 〇 — — auto gap adjustment — 〇 — — auto dough feeder 〇 〇 — — conveyor 〇 〇 — 〇 Features • Height reduced by > 10 cm for better ergonomics • More space under the machine • Improved mixer perfor- mance • Automatic dough feeder • Additional safety sensors • Guide rails for easier trans- fer of rolling pins • Dusting on the conveyor belt for less loss and bet- ter hygiene • More convenient and ergo- nomic cutting position • Mixer-less model of the Gold series • + Bigger rollers • + Automatic roller gap adjustment for reduced workload • + Ability to produce noodles without dough sheet combination (depending on noodle variety) other 25kg mixer purchased separately 25kg mixer purchased separately 变 RICHMEN TYPE I CE RICHMEN TYPE I US RICHMEN TYPE II RICHMEN TYPE II CE Depending on the applicable standards and regions of use, machine appearance may change. Basic functionality is the same for 100V, CE or US models. Machine name RICHMEN GOLD RICHMEN GOLD II RICHMEN TYPE I RICHMEN TYPE II Model LMA552310US under development LM10062IUS LS082IUS Dimensions W 1,350 x D 645 x H 1,000 W 1,525 x D730 x H 1,168 W1,1380 x D795 x H 1,168 Power supply 1.2kw 60Hz (1 phase 115V) 0.855kW 60Hz (1 phase 115V) 0.85kW 60Hz (3 phase 230V) Weight ~350kg ~270kg ~360kg mixer 10kg 10kg — roller width 230mm 210mm 230mm roller diam. 163mm 163mm 210mm productivity 100 - 150 portions/hour 100 portions/hour 200 - 300 portions/hour Machine name RICHMEN GOLD RICHMEN GOLD II RICHMEN TYPE I RICHMEN TYPE II Model LMA552310CE under development LM10062ICE LS082ICE Dimensions W 1,350 x D 645 x H 1,000 W1,2240 x D690 x H 1,168 W1,380 x D795 x H 1,168 Power supply 1.2kw 50Hz (1 phase 230V) 0.880kW 50Hz ±1% (1 phase 230V±10%) 0.85kW 50Hz (1 phase 230V ) Weight ~350kg ~290kg ~360kg mixer 10kg 10kg — roller width 230mm 210mm 230mm roller diam. 163mm 163mm 210mm productivity 100 - 150 portions / hour 100 portions / hour 200 - 300 portions / hour

- 15. 28 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 29 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 28 29 Easily change the size and shape of noodles by changing the cutter you use. From thin and hard Hakata-style noodles to thick, chewy Tsukemen noodles, flat noodles, round noodles, square noodles... And by attaching special rubber accessories to the cutter, you can make "instant ramen"-style wavy noodles - only much fresher, and without any additives! Cutters are very easy to install and remove. Richmen series noodle machines allow to adjust the speed of cutting, as well as length and shape of noodles. Cutter examples No.11 Groove width 2.7mm Variety of cutters for variety of noodles No.20 Groove width: 1.5mm No.6 Groove width: 5mm (depicted: pasta noodles with natural coloring agents added) (depicted: standard wavy noodles, chili powder noodles) (depicted: noodles with sesame seeds, whole wheat Tsukemen noodles) Yamato noodle making machines can bring more added value to noodles. Make craft noodles - give your customers the value they would be willing to reward your business for! Yamato provides free instruction on how to operate the machines, as well as multilingual technical support to ensure that every customer has their machines up and running wherever in the world they are. Infinite varieties of noodles with Yamato noodle machines By using different dough recipes (hydration level, ingredients, aging, etc.), production methods (number of dough sheet combinations, final thickness, dusting, etc.) and cutters (of different sizes and shapes) you can produce almost unlimited number of noodle varieties. ※possible varieties of noodles are not limited by the examples above cutter width thickness cutter width thickness No.6 5.0 mm 3.4 mm No.8 1.7 mm 1.5 mm No.8 4.0 mm 3.4 mm No.20 1.5 mm 1.3 mm No.10 3.0 mm 2.6 mm No.22 1.4 mm 1.2 mm No.12 2.5 mm 2.2 mm No.24 1.3 mm 1.1 mm No.14 2.2 mm 1.9 mm No.26 1.2 mm 1.0 mm No.16 2.0 mm 1.7 mm No.28 1.1 mm 0.9 mm ※square/round shapes are available; can be used with wavy attachments Cutter size/Noodle size reference table cutter:square #25 hydration:27% noodle width:1.15mm Hakata Tonkotsu style cutter:square #18 hydration:33% noodle width:1.67mm Ie-kei style short boiling time, thin, hard texture, low hydration, square, for soup dishes, wheat flavor medium boiling time, medium thickness, medium hydration, reverse-cut, for soup dishes medium boiling time, medium thickness, medium hydration, wavy, elastic, chewy, for soup dishes cutter:square #18 hydration:38% noodle width:1.67mm Miso ramen cutter:square #16 hydration:33% noodle width:1.88mm Jiro ramen style medium boiling time, medium thickness, medium hydration, reverse-cut cutter:square #22 hydration:32% noodle width:1.36mm Tokyo ramen medium boiling time, thin, square, medium hydration, for soup dishes cutter:square #20 hydration:35% noodle width:1.5mm Tori Paitan style medium boiling time, medium thickness, medium hydration, square, chewy, for soup dishes cutter:square #12 hydration:40% noodle width:2.5mm Fish Tsukemen long boiling time, medium thickness, high hydration, elastic, chewy, for tsukemen cutter:square #16 hydration:39% noodle width:1.88mm Mazemen long boiling time, medium thickness, high hydration, elastic, chewy, for mazemen cutter:square #16 hydration:40% noodle width:1.88mm Hand pressed medium boiling time, thin, square, high hydration, absorbs soup, wavy, elastic, chewy cutter:square #12 hydration:38% noodle width:2.5mm Kitakata ramen long boiling time, medium thickness, high hydration, elastic, chewy, for tsukemen, absorb soup, for soup dishes/ tsukemen/mazemen cutter:square #24 hydration:40% noodle width:1.25mm Hokkaido ramen medium boiling time, thin, square, high hydration, absorb soup, smooth surface, for soup dishes cutter:square #12 hydration:40% noodle width:2.5mm Tsukemen long boiling time, medium thickness, high hydration, elastic, chewy, for mazemen/ tsukemen

- 16. UDON NOODLE MAKING MACHINES By scientifically analyzing and quantifying all the processes involved in making udon noodles using traditional methods by hand, Yamato has developed this noodle making machine for udon and other types of high hydration noodles. SHINUCHI allows anyone to make artisan-quality udon noodles easily and safely, using just one machine that needs only a small room to instal and operate. SHINUCHI MAKE YOURSELF A NOODLE MASTER with SHINUCHI

- 17. 32 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 33 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 32 33 YAMATO UDON MACHINES ROLLERS A PAIR OF ROLLERS FOR STRETCHING AND THINNING DOUGH SHEETS WITH A 12-STAGE THICKNESS ADJUSTING SYSTEM SHINUCHI • full production cycle • no noodle making experience needed • high productivity (~250 portions/hour) • small foot-print for in-store use • multiple safety devices • hygienic materials The machine is designed to be very small and compact, allowing it to be installed even in locations with very little space. With its stylish and beautiful appearance, it is perfect for displaying in front of customers, to let them directly see the noodle making process, which not only ensures the quality of noodles, but also en- hances the entertainment aspect of eating experience. MIXER BUILT IN MIXING UNIT FOR 12.5 KG FLOUR WEIGHT PRESS POWERFUL PRESSING UNIT TO PROCESS DOUGH MIX INTO SOLID DOUGH BLOCKS CUTTER AUTOMATIC CUTTING UNIT WITH ADJUSTABLE CUTTING WIDTH number one udon noodle making machine in Japan--- Until Yamato has developed SHINUCHI most udon professionals and connois- seurs were totally convinced that real udon can only be made by hand. But the advent of SHINUCHI has changed everything. The taste, firmness, smooth- ness, elasticity - everything that makes authentic udon noodles so special were not only replicated - they were consum- mated and perfected. Now SHINUCHI is used in the most popular and successful udon res- taurants in Japan and other countries. The latest iteration in the SHINUCHI series - model S-1284 - is a product of more than 4 decades of dedicated research, trial and error, and hard work of Yamato and its engineers to make a perfect udon machine.

- 18. 34 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 35 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 34 35 SHINUCHI mixer’s structure and functionality are designed to produce dough similar to the one produced by hand kneading MIXING 1ST RESTING PRESSING 2ND RESTING THINNING CUTTING Letting the dough rest after mixing is very im- portant (this reduces the tension of gluten structures, and re- leases air bubbles inside the dough) At this stage dough lumps are pressed into solid blocks. SHI- NUCHI press produces the same authentic quality as tradi- tional masters who make dough by stepping on it over bamboo mats Right after pressing, dough is still not ready to be made into noodles. By resting/maturing it overnight we make it more ro- bust through enzyme acitivity to ensure better noodle quality After the second resting the dough is ready to be thinned down for cutting. To ensure thinning is done gradually and with precision, SHINUCHI has a 12-stage gap adjustment sys- tem, retractable table and a thickness measuring device On the final stage, the dough sheet is placed on a conveyor, sent into an automatic cutter; after cutting noodles are automati- cally stacked onto a tray. ARTISAN QUALITY of MACHINE MADE NOODLES Udon hand-making methods have been thoroughly analyzed and incorporated into the functionality and production processes of SHINUCHI. Machine name Super SHINUCHI Super SHINUCHI CE Super SHINUCHI US WAKADAISHO model SB1284AS SB1284CE S1284US WB874AS dimensions W 1,355 x D 880 x H 1,365 W1,350 x D810 x H 1,420 W1,345 x D870 x H 1,431 W1,120 x D840 x H 1,330 Power supply 1.51 kW 50/60Hz (1 phase100V) 1.51kW (3 phase 400V) 1.53kW (3 phase 230V) 1.16kW 50/60Hz (100V) weight ~470kg ~470kg ~470kg ~400kg mixer 12.5kg 12.5kg 12.5kg 8kg roller width 800mm 800mm 800mm 700mm productivity ~250 - 300 portions/hour ~250 - 300 portions/hour 250 - 300 portions/hour ~150 - 200portions/hour All-in-one machine for Udon and other types of high-hydra- tion noodles UL, NSF/ANSI, CSA, CE certified models available 真 SHINUCHI models 打 ※the drawing is for the CE-certified model / appearance and dimensions of models for other markets may differ SHINUCHI has been developed by Kaoru Fujii, the founder of Yamato, who analyzed the process of making authentic udon noodles from an engineer's point of view, and replicated them in a single machine.

- 19. 36 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 37 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 36 37 SOBA NOODLE MAKING MACHINE BANDOTARO In contrast to Ramen and Udon brought to Japan from China, the tradition of making Soba noodles has originated in Japan, and still plays a very important role in Japanese cuisine. Unlike wheat used for Ramen and Udon, Soba is made from buckwheat that contains no gluten, and for this reason is very difficult to make into noodles. In the past, Soba noodle making was possible only through manual production by experienced Soba masters who would have spent years if not decades to learn the art and skills of Soba making. With Bandotaro anyone can be a Soba noodle master, and produce top-quality authentic Japanese Soba noodles with ease, speed, and in quantities enough to satisfy needs of a small-mid scale noodle specialy shop.

- 20. 39 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 39 BANDOTARO FOR SOBA AND OTHER TYPES OF HIGH HYDRATION NOODLES Special 8KG SOBA MIXER The mixer is designed to produce dough from buckwheat flour through gradual granulation for uniform hy- dration and structural integrity of noodles. Mixing speed can be ad- justed. Hand-made style 12 STAGE ROLLER Bandotaro is equipped with a spe- cially designed 12-stage adjustable roller unit for gradual thinning of dough sheets to create authentic texture of Japanese Soba. A vertical automatic cutter with ad- justable cutting width can cut dough sheets at an angle - a style similar to the one used by Soba making artisans. Any variety of authentic hand-made style Japanese Soba noodles can be made on just one ma- chine: from the most common“NIHACHI”(20% wheat / 80% buckwheat ratio) to “JUUWARI”(100% non- extrusion type buckwheat flour noodles) Considering general popularity of Japanese cuisine worldwide, but already high competition among such widely known dishes as sushi or ramen, authentic Japanese buckwheat Soba noodles offer food businesses across the world another great opportunity to tap into the vast commercial potential of Japanese food. Although other types of noodles such as Ramen and Udon are popular too, it is Soba that is considered the soul of Japanese noodle tradition. In addition to its nutritional and dietary value, as well as its unique taste and aroma, Soba eating has a lot of cultural siginificance for Japanese people. —— BANDOTARO is an all-in-one full production cycle machine designed to make authentic hand-made style Soba noodles from scratch - even varieties produced exclusively from buckwheat flour (i.e. "JUUWARI SOBA") - something ONLY Bandotaro is capable of. Original SOBA CUTTING BLADE

- 21. 40 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 41 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 40 41 Buckwheat dough mixing Flour is put into the mixer tank, and mixed without water for 1 minute. Then 1/2 of water is added, and mixed for 3 minutes. After that, the remaining water is added little by little judging by the dough condition. 12-STAGE ROLLERS [Dough formation: granulation through agitation] Machine name BANDOTARO BANDOTARO US model MXB584AS MXA884US dimensions W 1,190 x D 965 x H 1,386 W1,190 x D965 x H 1,473 Power supply 50/60Hz 1.44kW (1 phase 100V) 60 Hz 1.59kW (3 phase 230V) weight ~520kg ~530kg mixer 8kg 8kg rollers width 800mm 800mm cut width 420mm 420mm productivity ~200 portions/hour ~200 portions/hour • no experience or expertise in noodle making required • high productivity (200 portions of craft quality noodles) • Small footprint for easy in-store placement • Multiple safety devices • Hygienic materials • Ability to produce a variety of other high-hydration noodles Number 1 choice for Soba noodle restaurants in Japan BANDOTARO - a dedicated noodle master at the service of your food service business Roller unit design allows to thin down the dough gradually resembling the process of manual production. 3 pin rolling process automatic rolling automatiic winding 12 stage gap rolling direction Based on the same principles and processes as used for production of hand-made Soba noodles ※100V model

- 22. LABOR-SAVING / COST-EFFECTIVE SINGLE TASK MACHINES In addition to noodle-making machines, Yamato has developed a variety of equipment for noodle food service industry to solve the problems of heavy workloads and high labor costs. Yamato single task machines save time, and reduce cost, making businesses more profitable and successful.

- 23. FEATURES • Automatic shell removal (for hard and soft boiled eggs) • Fast speed (1 egg / 6 seconds) • Greatly reduced loss rate compared to hand peeling • Hygienic materials / conformity with worldwide safety standards the machine performs best with eggs of required size and freshness following proper boiling and cooling procedures is recommended for better peeling performance While peeling machines for hard boiled eggs have been around for decades, no one before Yamato has succeeded in creating one for SOFT BOILED eggs (i.e. eggs cooked for 6-8 minutes) which are one of the mainstays of Ramen cusine. One of the problems that exists in food service industry is the occasional inconsistency of taste and texture depending on a person in charge of cooking. In Ramen restaurants this can manifest itself in their soups tasting differently when it is made by different employees who may strain the stock with varying thoroughness and intensity. This can also affect the restaurants’ bottom lines when significant volumes of high cost stock is wasted during straining/filtering process. RICHSOUP can not only solve these problems, but improve the quality of stock as well making its texture more creamy and smooth. Centrifugal separation method for better taste and texture Two times faster compared to manual straining High output capacity (*straining 60L of density 8 pork stock in 5 minutes) 20% more yield compared to manual straining Easy and intuitive operation Safety features RICHSOUP IS MAINLY DESIGNED TO PROCESS ANIMAL- BASED TYPES OF STOCK. CONSULT FOR ADDITIONAL INFORMATION ON STRAINING OTHER TYPES. Examples of stock that can be processed using RICHSOUP : 1.High/low density pork stock 2. High density seafood stock 3.High/low density chicken stock Golden Egg is a tabletop machine that automatically peels the shells of boiled eggs. This is the only machine in the world that is capable of peeling not only hard boiled but soft boiled eggs (with runny yolks) as well!!! Yamato engineers dedicated much time and effort on researching egg properties, as well as developing the functionality and design of the GOLDEN EGG machine. The machine can be disassembled for easy cleaning. RICHSOUP can be used for major Ramen sock varieties (i.e. chicken, pork). 44 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 45 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 44 45 GOLDEN EGG shell peeling machine for hard AND soft boiled eggs TMW01 Perforated lid Stock is poured into the strainer through a lid with holes big enough to allow most of the volume, but small to prevent large bones from getting inside. RICHSOUP stock straining machine SK20 Machine casing Hygienic materials, safety functions, small footprint. Automatic feeding Standard size tray for 20 eggs. Automatic egg feeding device. Low-engagement operation. Shell removing Automatic shell removing system of co-rotating spiked shafts for fast and clean shelling. Discharge chute Peeled eggs are continuously discharged automatically. No engagement by the operator is required. Removable scrapers Different varieties of stock have different texture and viscosity that require using different scrapers. RICHSOUP has scrapers for light and thick varieties of stock. Adjustable speed controller Straining speed can be controlled for more operational flexibility, and to accomodate different stock types and varieties. Emergency stop button Operation of the machine can be discontinued immediately by pressing the emergency stop button. This ensures safety of operation. HOT HOT model dimensions power weight TMW01 W210×D500×H400 100V 14/KG TMW01CE W210×D500×H400 230V 14/KG TMW01US W210×D500×H400 115V 14/KG model dimensions power weight SK20 W410×D530×H900 100V 43/KG SK20CE W410×D530×H900 230V 43/KG SK20US W410×D530×H900 115V 43/KG

- 24. 46 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 47 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 46 47 mixing capacity: 25kg / flour weight Yamato believes that dough mixing quality depends on whether the mixer can evenly and equally distribute all amount water throught all flour particles - this is exactly what SILKY MIXER was designed to achieve with perfection. SILKY MIXER model: M25B dimension: W1,000×D560×H1,045 power supply:3 phase 200v 1.5KW weight:140kg NEW SILKY MIXER M25B THE MOST ADVANCED DOUGH MIXER FOR HIGH QUALITY FRESH CRAFT NOODLES Less tension / Better hydration Concave tank shape Upward pin rota- tion Zero dead-zone structure All stainless-steel frame Outstanding hygiene and durability with a frame made fully of high quality stainless steel. Bare-bone structure for easier cleaning, Lower height and wider opening compared to legacy models for better usability. Convenient to use dough trays on casters for easy dough handling and storing. • Anti-clumping shape of the tank • Watering lid for homogenous hydration • Hygienic materials • Optimal number of pin rotations for better mixing quality • Better ergonomics with lower height • Safety sensors aging machine for Ramen and Udon dough NETARO MODELS: YYA6、 YYA12、 YYA18 water quality is one of the biggest factors in ensuring good noodle quality; using soft water is recommended as minerals in hard water interfere with dough formation and noodle cooking WATER SOFTENER MODELS: NR3、 NR6 used for placing rolling pins for dough aging or during noodle making; variants for 3 and 6 pins are available ROLLING PIN RACK MODELS: M25CE、 M25US dough quality greatly affects noodle quality; in addition to many factors that play their roles during dough making such as quality of ingredients, humidity, temperature etc., dough production equipment is one of the most important among them; M25 series design, operation and functionality ensure outstanding dough quality for Ramen, Pasta, Udon and other varieites of noodles. STAND-ALONE MIXER MODELS: YYA6、 YYA12、 YYA18 Can be used with RICHMEN series noodle machines for efficient production of dough for gyoza wrappers GYOZA DRUM SIZE: 60MM~120MM cutting molds for gyoza dumpling wrappers GYOZA MOLD MODELS: RR17、 RR34 equipped with thermostat, these machines are used to keep noodle dough at constant temperature for a set period of time One of the problems of mixers with conventional design was insufficient stirring of dough mass at the bottom of a mixer tank which can cause lumping, and result in poor noodle quality. By having it pins rotate upwards SILKY MIXER ensures most optimal mixing conditions and thorough hydration. Mixer tank shape for reduced gluten stress and better hydration Direct drive system adopted in the SILKY MIXER design allows for more efficient transmission of torque from motor to the shaft, and a longer service life due to fewer moving parts.

- 25. YAMATO NOODLE SCHOOL RAMEN SCHOOL 48 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 49 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 48 49 — — With over 20 years of offering professional Ramen cuisine courses Yamato has accumulated a great amount of experience and expertise, as well as hundreds of noodle and soup recipes which it is ready to share with its students, and keep sharing with its graduates. YAMATO RAMEN SCHOOL - ONCE A STUDENT - ALWAYS A CUSTOMER FULL IMMERSION INTENSIVE COURSE - ALL THEORY AND PRACTICE OF JAPANESE NOODLE CUISINE AND BUSINESS Day 1: business seminar / noodle making The course starts with learning basic information about noodle ingredients and noodle making practices, as well as a lecture on Ramen business management. Day 2: Base stock making A day-long practical cooking session where students can learn and experience how to make different varieties of Ramen base stock (ingredients, cooking methods, etc.) Day 3: Fish/Veg base stock; Side dishes; Oils Broaden your expertise with learning how to make base stock from fish (“uo-dashi”), vegetables and fruit. Learn how to make Char Siu meats, and Flavor Oils. Day 4: Soup blending Learn how different components of Ramen soup are combined together, and practice as much as you can to create your own original recipe. Day 5: Side dishes / Graduation dish practice Learn how to make Ramen side dishes such as pan-fried gyoza; design your graduation dish, and calculate its commercial viability. Day 6: Mockup Ramen restaurant (preparation, opera- tion, cooking, serving). Creation and presenta- tion of a graduation dish. | CURRICULUM INDUSTRY No. 1 professional RAMEN courses FLAVOR OILS DISH PLATING CHAR SIU MOTODARE SOUP BLENDING GRADUATION DISH BASE STOCK (TONKOTSU etc.) GARNISHES BUSINESS LECTURE MOCKUP RESTAURANT Our curriculum does not teach by feel and intuition - the instruction is based on numbers (grams, minutes etc.) and rigorous definitions. This not only allows our program to be learned by a person with any back- ground, but for the content to be easily applied to local conditions and ingredients, enabling students to de- velop their original recipes and menues. DIGITAL COOKING — for precision and ease of localization RAMEN SCHOOL for ramen chefs and ramen business owners Successful food service business rests on two founda- tions: good food and robust business practices. Yamato Ramen School emphasizes both aspects - which is why so many our graduates become so successful in Ramen industry. 01 6 DAYS COURSE TO CREATE YOUR IDEAL RAMEN FROM SCRATCH — Professional Yamato Ramen school teaches not only ready to use recipes but the fundamental principles they are founded on as well. NOODLE MAKING 02 START A NOVICE - FINISH A PRO — Whether you are an established professional who wants to improve your skills or a novice with 0 experience, the highly experienced team of Yamato Ramen School staff will help you be- come a noodle master in only 6 days. It all starts with the goal - learning how to create your ideal and perfect Ramen that is not only tasty but also commercially viable, can be made using your local in- gredients, and be popular among your customers. Dur- ing the 6 day-long intensitve Ramen course students learn and practice all aspects of Ramen cuisine through theory classes and hands-on cooking sessions together with their classmates (up to 8 students per class) - for better educational synergy and a more fulfilling learn- ing experience achieved through positive interaction with likeminded people united by a common interest and motivation.

- 26. The ultimate goal of this course is to provide students with all the knowledge and skills necessary for them to succesfully create and run their own food service busi- nesses based on Udon noodles. Our students are established or aspiring Udon cuisine chefs and entrepreneurs interested in working with Udon noodles. Our school adopts a digital cooking approach that allows to learn quickly, and be able to use that knowledge to create one’s own original recipes and menus. 50 Yamato Noodle | contact@yamatomfg.com | yamatonoodle.com 51 Yamato Noodle | contact@eyamatomfg.com | yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com yamatonoodle.com contact@yamatonoodle.com 50 51 In order for each student to learn, absorb and retain as much as they can from the course, we limit the maxi- mum number of students to 8 per course. Each student is given full attention of the School staff, and can also interact with other participants to enrich their learning experi- ence and further expand their culinary horizon. Yamato Udon School curriculum is based on learning fundamental principles of Udon cuisine, and using this knowledge to develop one’s original recipes based on principles of digital cooking. Yamato Udon School curriculum gives equal emphasis both to traditional and novel varieties of Udon dishes. However, regardless of whether the recipes students learn are old or new - they are based on using only natural ingredients and seasonings. 5 DAYS INTENSIVE UDON COURSE Professional Udon cuisine course Yamato Udon School is located in Kagawa Prefecture, Japan, which is also known as "Udon Prefecture". It is the most famous Udon producing area in Japan. Despite its small size, there are more than 700 udon restaurants in Kagawa prefecture. Visiting local Udon restaurants is one of the biggest tourist attractions. Fierce competition makes every restaurant strive to improve the quality of its products. Naturally, this makes Kagawa the best place in Japan to learn authentic Udon cuisine. Although originally introduced from China, now Udon noodles are as part of "WASHOKU" (Japanese food) as any other famous dish such as Sushi or Ramen. Udon cuisine has already achieved much popularity around the world with many famous Udon restaurants in different countries. The knowledge, skills, expertise and experience one can gain at Yamato Udon school would allow them to fully capitalize on the great business potential of Udon cuisine anywhere in the world. Make yourself a true Udon master in just 5 days! Day 1: Udon noodle making / Management lecture Studying everything about Udon noodles: ingredients (water, flour, etc.), Udon making equipment, Udon making methods. Day 2: Soup / broth making Learning how to prepare various types of “Dashi” (Udon broth), seasonings, and how to properly boil Udon noodles. Day 3: Tempura and other Udon side dishes Tempura is the most commonly used Udon side dish: learn how to make batter, select, prepare and cook ingre- dients in different styles. Day 4: Side dish practice / Plating training Side dishes are great revenue sources for Udon restau- rants - learning how to make them is given great empha- sis in Yamato Udon school curriculum. Day 5: Mockup Udon shop / Graduation dish The value of a dish is determined not only how it tastes but how it looks as well - learn Udon plating techniques from the best professionals. | UDON SCHOOL CURRICULUM YAMATO NOODLE SCHOOL UDON SCHOOL NOODLE MAKING DASHI SIDE DISHES GRADUATION DISH MOCKUP RESTAURANT PLANTING TEMPURA

- 27. While headquartered in Japan, Yamato is a multinational company with a network of local branches across the world, and a multilingual staff speaking Japanese, English, Chinese, Korean, Spanish, Vietnamese, Russian, Hindu, Dutch, Burmese, Thai, Bangla, and Malay. F.A.Q. 1 After sale service / Customer support The standard warranty period for Yamato equipment is1 year (from the date of delivery). During this period, we are responsible for free repair if any problems occur under conditions of normal use. Experience shows that cases requiring technical support are rare, and most of them can be resolved by adjustment / replacement of parts (from spare parts kits supplied with machines). This is done either by customers, or by a staff dispatched by Yamato. After the warranty ends Yamato supports customers with spare parts and all necessary technical infor- mation required to solve any technical issue. 2 Power supply specifications Most types of Yamato equipment have models that can work in electric grids with 220-230V or 115-120V voltage. The models share the same functionality, though certain external features may be different. 3 Equipment service life Under normal use conditions, and with attention to daily maintenance and proper care, most standard models of noodle making machines can be used for a period of about 10 years (may vary depending on average opera- tion time per day). There are examples of Yamato machines remaining operational for several decades. 4 How long will it take to receive the machine after purchase All Yamato machines are made to order (we also adjust them to particular customer recipes / specifications). The average assembling time is several weeks - 1 month. Lead time for shipping from Japan and delivery varies depending on the destination and transportation method. YAMATO-EUROPE BOLSTOEN 2 E (BGG) 1046 AT Amsterdam, Netherlands Our distributors in different countries Yamato Global sales Track Record 57 Warren Street, New York, NY 10007 United States - Korin Japanese Trading Corp #201-6741 Cariboo Rd, Burnaby V3N 4A3 Canada Canada - PureRange Enterprises Ltd. 北京市朝阳区顺南大街16号,嘉美中心写字楼1101 China - 华珊尚国际商贸有限公司 11 bis rue Moulin David, 17540 Le Gue D’Allere France - Sushi Robots Km. 19, East Service Road, Barangay San Martin de Porres, Paranaque, 1700 Metro Philippines - JCG Marketing Group, Inc. Jl. Gandaria I, No. 330, Kebayoran Baru, Jakarta Selatan Indonesia - PT. Gastro Gizi Sarana Teuku Cik Ditiro 16 Jakarta, 10350. Indonesia Indonesia - Rotaryana Prima, PT 408台中市南屯區工業區21路41-1號 Taiwan - 苗林行 Miaolin Foods Germany 53604 Bad Honnef Berck-sur-Mer-Str. 9 Germany - ALGO GMBH Russia 129337 Moscow, Krasnaya Sosna St. 20/1, 2F. 23/1 Russia - Svoi Proekt LLC HEADQUARTERS OF YAMATO IN JAPAN 37-4 Hamasanbanchō, Utazu-chō, Ayauta- gun, Kagawa-ken, 769-0203 Throughout history we have supplied our equipment to customers from more than 60 countries across the world YAMATO DREAM STUDIO IN SEOUL 40-13, Garak-dong, Songpa-gu, Seoul 138- 160, Korea +82-2-3412-3661 MAKE THE BEST NOODLES WITH YAMATO NOODLE MAKING EQUIPMENT NOODLE MAKING SCHOOLS NOODLE BUSINESS CONSULTING With 4 decades of designing and manufacturing commercial noodle making equipment for food service industry, and 2 decades of offering professional noodle cuisine schools, Yamato is best positioned to ensure your success in noodle business. Our dedicated multilingual team of engineers, instructors and noodle industry professionals can provide you with all the necessary tools, methods and other expertise necessary to succeed in opening your own specialty noodle shop, noodle dish delivery business, or a craft noodle factory. Yamato boasts a customer support department operating 24/7/365 always ready to help our customers wherever they are in the world. Yamato MFG offices

- 28. YAMATO MFG.CO.,Ltd. +81 (877) 85 6168 contact@yamatomfg.com 37-4 Hamasanbancho,Utazu-cho,Ayauta- gun,Kawaga-ken,Japan yamatonoodle.com