CONSTRUCTION MATERIAL

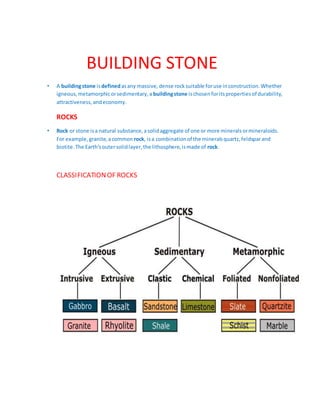

- 1. BUILDING STONE • A buildingstone isdefinedasany massive,dense rocksuitable foruse inconstruction.Whether igneous,metamorphicorsedimentary,a buildingstone ischosenforitspropertiesof durability, attractiveness,andeconomy. ROCKS • Rock or stone isa natural substance,asolidaggregate of one or more mineralsormineraloids. For example,granite,acommon rock, isa combinationof the mineralsquartz,feldsparand biotite.The Earth'soutersolidlayer,the lithosphere,ismade of rock. CLASSIFICATIONOF ROCKS

- 2. Sedimentary Rocks • These rocksget theirname fromthe Latin wordsedimentum whichmeanssettle down. • These rocksare formedbythe settlingdownof sediments. • Sedimentsare the smallerparticles/fragmentsthatare formedbythe breakingdownof rocks whentheyroll down,crackand hit eachother. • These sedimentsare transportedbywind,wateretc. • These sediments;whencompressedandhardened; formsedimentaryrocks. • Sandstone isanexample of sedimentaryrock.It ismade up of grains of sand. • The sedimentaryrocksmayalsocontainfossilsof plants,animalsandothermicro – organisms that once livedonthem. CHEMICAL CLASSIFICATION • Siliciousrocks are those whichhave silicaasthe mainconstituent.The silicainthe free state is calledsandand incombinedstate issilicate. Examples:Granite,Quartzite,Sandstoneetc. • Argillaceousrocks are those whichhave clayor aluminaasthe mainconstituent. Examples:Kaolin,Laterite,Slate etc. Calcareous rocks have calciumcarbonate or lime astheirleadingconstituent.These rocksare readily actedupon byeven dilute HCl. Examples:Limestone andMarble. PHYSICALCLASSIFICATION • Stratifiedrocks are those whichexhibitdistinctlayerswhichcanbe separated.The plane along whichthe separationof the layerscan be carriedout iscalledas the cleavage plane. Examples:Limestone,Slate,Sandstone etc. • Unstratifiedrocks do notshowany signof strata and cannot be easilysplitintothe slabs. Examples:Granite,Trap etc.

- 3. • Foliatedor fragmentedrocks have a tendencytosplituponlyina definite direction.Mostof the metamorphicrockshave a foliatedstructure,exceptforquartzite andmarble whichhave granulose structure. GENARAL CLASSIFICATION OF STONE • MARBLE • KOTA STONE • GRANITE • SANDANDTRAP • BASALTSTONE • SLATES REQUIREMENT OF GOOD BUILDING STONE 1. STRENGTH • Generallymostof the buildingstoneshave highstrengthtoresistthe loadcomingonit. Therefore itisnotof prime concernwhenitcomesto checkthe qualityof stones.Butwhenthe stonesare to be usedinlarge structures,itbecomesnecessarytocheckthe compressive strengthof stones. • Compressive strengthof buildingstonesgenerally fall withinthe range of 60 to 200N/mm2. 2. DURABILITY • Buildingstonesshouldbe capable toresistthe adverse effectsof natural forceslikewind,rain and heat.It mustbe durable andshouldnotdeteriorate due tothe adverse effectsof the above natural forces.

- 4. 3. HARDNESS • Whenstonesare usedinfloors,pavementsorapronsof bridges,theybecome subjectedto wearingandabrasive forcescausedbymovementof menormachine overthem.Soitis requiredtotesthardnessof stone. • Hardnessof stone isdeterminedbyMohsscale. 4. TOUGHNESS • Toughnessof stonesmeansitabilitytoresistimpactforces.Buildingstonesshouldbe tough enoughtosustainstressesdevelopeddue tovibrations.The vibrationsmaybe due tothe machinerymountedoverthemordue to the loadsmovingoverthem.The stone aggregates usedinthe road constructionsshouldbe tough. 5. SPECIFICGRAVITY • The more the specificgravityof stone,the more heavierandstrongerthe stone is. • Therefore stoneshavinghigherspecificgravityvalues shouldbe usedforthe constructionof dams,retainingwalls,docksandharbors.The specificgravityof goodbuildingstone isbetween 2.4 and 2.8. 6. POROSITY AND ABSORPTION • Porosityof buildingstonesdependuponthe mineralconstituentandstructural formationof the parentrock. If stonesusedinbuildingconstructionare porousthenrainwatercan easilyenter intothe pore spaces andcause damage to the stones.Thereforebuildingstone shouldnotbe porous. • 7. DRESSING • Givingrequiredshape tothe stone iscalleddressing.Itshouldbe easytodressso thatthe cost of dressingisreduced.However,the care shouldbe takensothat,thisisnot be at the cost of the requiredstrengthandthe durability. 8. APPEARANCE • In case of the stonesto be usedforface works,where appearance isaprimaryrequirement,its colourand abilitytoreceive polishisanimportantfactor. • Lightcoloredstonesare more preferredthandarkcoloredstonesasthe colourare likelytofade out withtime. 9. SEASONING

- 5. • Good stonesshouldbe free fromthe quarrysap.Lateriticstonesshouldnotbe usedfor6 to 12 monthsafterquarrying.Theyare allowedtogetridof quarry sapby the action of nature.This processof removingquarrysap iscalledseasoning. 10. WORKABILITY • Stone shouldbe workable.Stone issaidtobe workable whenthe workinvolvedinstone working(suchas cutting,dressing&shaping) iseconomical andeasytoconduct. 11. COST • Cost isan importantconsiderationinselectingabuildingmaterial.Proximityof the quarryto buildingsite bringsdownthe costof transportationandhence the costof stonescomesdown. 12. FIRE RESISTANCE • Stonesshouldbe free fromcalciumcarbonate,oxidesof iron,andmineralshavingdifferent coefficientsof thermal expansion.Igneousrockshow markeddisintegrationprincipallybecause of quartzwhichdisintegratesintosmall particlesata temperature of about575°C. Limestone, however,canwithstandalittle highertemperature;i.e.upto800°C afterwhichthey disintegrate. VARIOUS USE OF STONE IN CONSTRUCTION • Sandstone isa popularstone withsculptors. • Good and durable constructionmaterial • Thresholdsandstepsinmanorhouses • War memorialsinthe 19th and 20th centuries • Limestone forburninglime andalsoformanufacture of cement • Limestone asa flux inblastfurnaces • Insulatorsinelectrical appliances

- 6. Quarrying of stones by blasting and its effect on environment • QUARRYING • It isthe processof existingthe stone fromrockswiththe helpof blasting. • Effects • Air Pollution • Noise Pollution • Quarry Waste BRIKS AND TILES • BRICK:- The artificial material of construction in the form of clay blocks of uniform size and shape are known as bricks.A brick isbuildingmaterialused to make walls,pavementsandotherelementsinmasonryconstruction. RAW MATERIAL FORBRICKS 1. Chemical Composition Chemical Required data Explanation SiO2 55~70% Raw material with bigger particle of SiO2 can improve bricks refractoriness, reduce the shrinkage and sensitivitywhen drying; Raw material with smaller particle of SiO2 can let the structure of bricks even and dense. But if the SiO2 is more than 80%, the final finished bricks are easyexpansion and the bending strength will be reduced. If less than 45%, the performance offrost resisting is bad. Fe2O3 2-10% It effects the color of bricks.If the raw material with bigger particle of Fe2O3, there will be brown or black spoton (or in) bricks. Al2O3 10~25% It effects the mechanical strength ofbricks.If the content of Al2O3 is more than 20%, the mechanical strength will improve,butthe burning temperature will increase; if it is less than 10%,the mechanical strength will reduce. CaO <10% It is a kind of co-solventto reduce the refractory degree. If the particle size of CaO is more than 1mm,there will be lime crack for bricks.

- 7. MgO <5% It is also a kind of co-solvent to reduce the refractory degree. But it is not obvious like CaO. The MgSO in raw material can letthe bricks occur scum. LOI 6-8% It is the weightpercentof lostwhen the dried (in 105-110℃) raw material burning in 1000- 1100℃ . It shows the contentof products in gas state (H2O, CO2) and organic material after the raw material is fired and decomposed, then judge whether to pre-burn it or not to let the volume of raw material stable. The Manufacturing of bricks is consists of following processes: 1. Preparation of brick clay 2. Moulding of Bricks 3. Drying 4. Burning of bricks Properties of Good Brick Earth The properties of various ingredients of a good brick earth are discussed below: 1. Alumina It is the principal constituent of every kind of brick earth. It imparts plasticity to the brick earth which is essential for proper moulding of bricks Alumina or Clay in brick earth shrinks and cracks on drying. It also wraps and becomes very hard on burning unless mixed with sand. 2. Silica It exists in brick earth either in chemical composition mixed with clay or sand. Sand alone is infusible but it fuses in the presence of lime and oxide of iron at kiln temperature. Sand or silica in brick earth prevents the shrinkage, cracking and wrapping of bricks it also makes the bricks durable. Exess of silica makes the bricks brittle and weak. 3. Lime A little quantity of lime present in brick earth in a finely and cause the grains of sand to melt. It helps to bind the particles of brick earth together. It also reduces shrinkage of bricks.

- 8. 4. Oxide of Iron A small quantity of oxide of iron present in brick earth also acts as a flux. It helps the grains of sand to melt and binds the particles of clay together. It also provides the required red colour to the bricks on burning. But excess of oxide of iron makes the bricks dark blue. 5. Magnesia Small quantities of magnesia in brick earth makes the brick of yellowish colour and reduces shrinkage. But excess if magnesia leads to be decay of bricks. 6. Manganese The presence of manganese in small quantity in brick earth makes the brick still darker or even black. Properties of Good Brick Earth The properties of various ingredients of a good brick earth are discussed below: PROPERTIESOF CLAY Particle Size Clay has the smallest particle size of any soil type, with individual particles being so small that they can only be viewed by an electron microscope. This allows a large quantity of clay particles to exist in a relatively small space, without the gaps that would normally be present between larger soil particles. This feature plays a large part in clay's smooth texture, because the individual particles are too small to create a rough surface in the clay. Structure Because of the small particle size of clay soils, the structure of clay-heavy soil tends to be very dense. The particles typically bond together, creating a mass of clay that can be hard for plant roots to penetrate. This density is responsible for clay-heavy soil being thicker and heavier than other soil types, and clay soil takes longer to warm up after periods of cold weather. This density also makes clay soils more resistant to erosion than sand or loam-based soils. Organic Content Clay contains very little organic material; you often need to add amendments if you wish to grow plants in clay-heavy soil. Without added organic material, clay-heavy soil typically lacks the nutrients and micronutrients essential for plant growth and photosynthesis. Mineral-heavy clay soils may be alkaline in nature, resulting in the need for additional amendments to balance the soil's pH before planting anything that prefers a neutral pH. It's important to test clay-heavy soil before planting to determine both the soil's pH and whether it lacks important nutrients such as nitrogen, phosphorus and potassium.

- 9. Permeablity and Water-Holding Capacity One of the problems with clay soil is its slow permeability resulting in a very large water-holding capacity. Because the soil particles are small and close together, it takes water much longer to move through clay soil than it does with other soil types. Clay particles then absorb this water, expanding as they do so and further slowing the flow of water through the soil. This not only prevents water from penetrating deep into the soil but can also damage plant roots as the soil particles expand. Identifying Clay There are several tests you can use to identify clay soils. If rubbed between your fingers, a sample of clay soil often feels slick and may stick to your fingers or leave streaks on your skin. Rubbed clay soil often takes on a shiny appearance as well, as opposed to the rough texture you would see with other soils. Clay soils do not crumble well, and a sample of clay can typically be stretched slightly without breaking. When wet, clay soils become slick and sticky; the soil may also allow water to pool briefly before absorption due to the slow permeation. Visually, clay soils seem solid with no clear particles, and may have a distinct red or brown color when compared to the surrounding soil. Moulding of Bricks Giving the required shape to the prepared brick earth is known as moulding of bricks. There are two different ways of moulding. a) Hand moulding b) b) Machine moulding. Hand moulding: This method is adopted when a large and level area of land is available for the purpose. The area of land on which moulding is to be done is levelled, plastered smooth and sprinkled over with sand. .

- 10. Machine moulding: There are a variety of moulding machines and these machines are capable of manufacturing large number of bricks quickly. The bricks moulded in machine have better / sharp edges / smooth surface, stronger than hand moulded bricks etc. Drying Of Bricks: Drying of the bricks at lower temperature is done to strengthen the bricks to have sufficient strength so that they do not crack or crumble while holding and carrying them in hand. Finally bricks are to be stacked in the kiln, but they must possess the sufficient strength to maintain their shape while the transportation and loading operations, so drying of the bricks is important process. Drying of the bricks can be done in two ways: (a) Natural Drying: Natural drying is done by putting the bricks in the under the air circulation, generally avoided to direct Sun-light. (b) Artificial Drying: In artificial burning bricks are put under a temperature of about 120 degrees Celsius in a tunnel like structure where arrangements are there to maintain the temperature.

- 11. Burning Of Bricks Burning of bricks is done in a clamp or kiln. A clamp is a temporary structure whereas kiln is a permanent one. (a) Clamp Burning (b) Kiln Burning Kiln Burning: Kiln is a large oven used for the burning of bricks. Generally coal and other locally available materials like wood, cow dung etc can be used as fuel. They are of two types: (a) Intermittent Kilns. (b) Continuous Kilns. Intermittent Kilns are also the periodic kind of kilns, because in such kilns only one process can take place at one time. Various major processes which takes place in the kilns are: Loading, unloading, Cooling, and Burning of bricks. There are two kind of intermittent kilns: (i) Up-draught Intermittent Kilns (ii) Down draught Intermittent Kilns Down draught kilns are more efficient because the heat is utilized more by moving the hot gases in the larger area of the kiln. In up draught kilns the hot gases are released after they rise up to chimney entrance.

- 12. Continuous Kilns: These kilns are called continuous because all the processes of loading, unloading, cooling,Heating, pre- heating take place simultaneously. They are used when the bricks are demanded in larger scale and in short time. Bricks burning is completed in one day, so it is a fast method of burning. There are two well known continuous kilns: Bull's Trench Kiln: Bull's trench kiln consist of a rectangular, circular or oval plan shape. They are constructed below the ground level by excavating a trench of the required width for the given capacity of brick manufacturing. This Trench is divided generally in 12 chambers so that 2 numbers of cycles of brick burning can take place at the same time for the larger production of the bricks. Or it may happen that one cycle is carried out at one time in all the

- 13. 12 chambers by using a single process in the 2-3 chambers at the same time. The structure is under-ground so the heat is conserved to a large extent so it is more efficient. Once fire is started it constantly travels from one chamber to the other chamber, while other operations like loading, unloading, cooling, burning and preheating taking place simultaneously. Such kilns are generally constructed to have a manufacturing capacity of about 20,000 bricks per day. The drawback of this kiln is that there is not a permanent roof, so it is not easy to manufacture the bricks in the monsoon seasons. Hoffman's Kiln: The main difference between the Bull's trench kiln and the Hoffman kilns are: 1. Hoffman's kiln is an over the ground structure while Bull's Trench Kiln is an underground structure. 2. Hoffman's kiln have a permanent roof while Bull's trench Kiln do not have so it former can be used in 12 months a year to manufacture bricks but later is stopped in the monsoon season.

- 14. Layout Plan Hoffman's kiln is generally circular in plan, and is constructed over the ground. The whole structure is divided into the 12 chambers and all the processes takes place simultaneously like in Bull's trench Kiln. Types of Bricks Bricks can be of many types depending on –

- 15. i. Quality ii. Building Process iii. Manufacturing Method iv. Raw Material v. Using Location vi. Weather-resisting Capability vii. Purpose of Using viii. Shape ix. Region Classification of Bricks Based on Quality On the basis of quality, Bricks are of the following kinds: 1. First Class Brick: The size is standard. The color of these bricks is uniform yellow or red. It is well burnt, regular texture, uniform shape. The absorption capacity is less than 10%, crushing strength is, 280kg/cm2 (mean) where it is 245 kg/cm2 (minimum). It doesn’t have efflorescence. It emits a metallic sound when struck by another similar brick or struck by a hammer. It is hard enough to resist any fingernail expression on the brick surface if one tries to do with a thumbnail. It is free from pebbles, gravels or organic matters. It is generally used- o in a building of long durability, say 100 years o for building exposes to a corrosive environment; o for making coarse aggregates of concrete. o 2. Second Class Brick: The size is standard, color is uniform yellow or red. It is well burnt, slightly over burnt is acceptable. It has regular shape; efflorescence is not appreciable. The absorption capacity is more than 10% but less than 15%. Crushing strength is 175kg/cm2 (mean) where the minimum is 154 kg/cm2 . It emits a metallic sound when struck by another similar brick or struck by a hammer. It is hard enough to resist any fingernail expression on the brick surface if one tries to do with a thumbnail. It is used for the construction of one-storied buildings, temporary shed when intended durability is not more than 15 years. 3. Third Class Brick: The shape and size are not regular. The color is soft and light red colored. It is under burnt, slightly over burnt is acceptable. It has extensive efflorescence. The texture is non-uniform. The absorption capacity is more than 15% but less than 20%. The crushing strength is 140kg/cm2 (mean) where the minimum crushing strength is 105kg/cm2 . It emits a dull or blunt sound when struck by another similar brick or struck by a hammer. It leaves fingernail expression when one tries to do with the thumbnail. Classification of Bricks Based on Building Process On the basis of the building process Bricks are of following kinds:

- 16. 1. Unburnt Bricks: These are half burnt bricks. The color is yellow. The strength is low. They are used as surki in lime terracing. They are used as soiling under RCC footing or basement. Such bricks should not be exposed to rainwater. 2. Burnt Bricks: Burnt bricks are made by burning them in the kiln. First class, Second Class, Third Class bricks are burnt bricks. 3. Over Burnt or Jhama Brick: It is often known as the vitrified brick as it is fired at high temperature and for a longer period of time than conventional bricks. As a result, the shape is distorted. The absorption capacity is high. The strength is higher or equivalent to first class bricks. It is used as lime concrete for the foundation. It is also used as coarse aggregate in the concrete of slab and beam which will not come in contact with water. The common brick tests performed on the field as well as in the laboratory are described below. Compressive Strength Test: ... Water Absorption Test: ... Efflorescence Test: ... Impact Test: ... Dimension Tolerance Test: ... Soundness Test: ... Hardness Test: ... Structure Test: 1. Roofing tiles. These may be flat like slates or may be made to different shapes. Some of the common varieties are discussed below 2. Plain tiles. (measure about 25 cm × 15 cm to 28 cm × 18 cm and from 10 mm to 17 mm thick. These may have a continuous projection at one end or two small projecting nibs (as shown). These nibs should not be less than 2 cm wide cm and 1 cm deep. Camber should be between 5 mm and 10 mm for hand-made tiles. The camber could be reduced for machine.

- 17. 4. Pot tiles. These are semicircular in section and taper along the length (Fig. 3.7.). Diameter at larger end is about 23 cm and at the smaller end it is about 20cm. Rows of these tiles are laid with the concave side up. Then rows of same tiles with convex sides up are laid to cover the adjoining edges of every pair of the previously laid tiles. 5. Allahabad tiles. These consist of two sets of tiles. the lower ones are flat tiles with upturned sides. End widths reduce from 27 cm to 23 cm and the length is about 38 cm. The over tile is half round in section and tapers from 16.5 cm to 12 cm in diameter. Tapper allows the tile in the next course to fit in (Fig. 3.8). Half round tiles are moulded on a potter’s wheel as a round tapering cylindrical tile. Two longitudinal cuts are given to the cylinder while still not dry. With this it is easy to break it into two semicircular tiles after burning. 6. Mangalore tiles. These are flat pattern tiles with suitable key projection. About 16 tiles are required to cover one square metre of roof. Arrangement of Mangalore tiles on a slopping roof . 7. Concrete roofing tiles. Tiles of any shape, size or colour could be made with cement concrete. These are more strong, durable and weather resistant. 8. Flooring tiles or Paying tiles. These are usually thicker than roofing tiles and vary from 15 mm to 30 mm in thickness. Their shapes are square, hexagonal or of any other geometrical pattern and may be coloured, if desired. Depending on properties of clay flooring tiles are classified as class 1, class 2 and class 3 tiles. Maximum water absorption percentages in case of these are 10, 19 and 24 respectively. Minimum average flexural strength kg/cm width in respect of these is 6, 3.5 and 2.5 respectively. 9. Drain tiles. These are curved tiles made in various shapes and sizes to suit the work in which they are to be used. Tiles to be used in the construction of sewage carrying drains should be glazed. Properties of good tiles. Tiles should have the following properties of good tiles : (i) It should be of a regular shape and size. (ii) It should be free from twists, cracks or flaws. (iii) It should be well burnt and have uniform colour. (iv) It should give a clear ringing sound when struck. (v) It should be sound and hard. (vi) Its broken surface should show an even and compact structure

- 18. CEMENT A cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together. Calcium Silicon Aluminum Iron Limestone Clay Clay Clay Marl Marl Shale Iron ore Calcite Sand Fly ash Mill scale Aragonite Shale Aluminum ore refuse Shale Shale Fly ash Blast furnace dust Sea Shells Rice hull ash Cement kiln dust Slag Composition of Cement There are eight major ingredients of cement. The general percentage of these ingredients in cement is given below: Ingredient Percentage in cement Lime 60-65 Silica 17-25 Alumina 3-8 Magnesia 1-3

- 19. Iron oxide 0.5-6 CalciumSulfate 0.1-0.5 SulfurTrioxide 1-3 Alkaline 0-1 FLOW DIAGRAM MANUFACTURING OF CEMENT VARIOUS TYPE OF CEMENT AND THEIR USES 13 Types of Cement and their Uses 1. Ordinary Portland Cement (OPC)

- 20. 2. Portland Pozzolana Cement (PPC) 3. Rapid Hardening Cement 4. Quick setting cement 5. Low Heat Cement 6. Sulphates resisting cement 7. Blast Furnace Slag Cement 8. High Alumina Cement 9. White Cement 10. Coloured cement 11. Air Entraining Cement 12. Expansive cement 13. Hydrographic cement 1. Ordinary Portland Cement (OPC) Ordinary Portland cement is the most widely used type of cement which is suitable for all general concrete construction. It is most widely produced and used type of cement around the world with annual global production of around 3.8 million cubic meters per year. This cement is suitable for all type of concrete construction. 2. Portland Pozzolana Cement (PPC) Portland pozzolana cement is prepared by grinding pozzolanic clinker with Portland cement. It is also produced by adding pozzolana with the addition of gypsum or calcium sulfate or by intimately and uniformly blending portland cement and fine pozzolana. This cement has high resistance to various chemical attacks on concrete compared with ordinary portland cement and thus it is widely used. It is used in marine structures, sewage works, sewage works and for laying concrete under water such as bridges, piers, dams and mass concrete works etc.

- 21. 3. Rapid Hardening Cement Rapid hardening cement attains high strength in early days it is used in concrete where formworks are removed at an early stage and is similar to ordinary portland cement (OPC). This cement has increased lime content and contains higher c3s content and finer grinding which gives greater strength development than OPC at an early stage. The strength of rapid hardening cement at the 3 days is similar to 7 days strength of OPC with the same water- cement ratio. Thus, advantage of this cement is that formwork can be removed earlier which increases the rate of construction and decreases cost of construction by saving formwork cost. Rapid hardening cement is used in prefabricated concrete construction, road works, etc. 4. Quick setting cement The difference between the quick setting cement and rapid hardening cement is that quick setting cement sets earlier while rate of gain of strength is similar to Ordinary Portland Cement, while rapid hardening cement gains strength quickly. Formworks in both cases can be removed earlier. Quick setting cement is used where works is to be completed in very short period and for concreting in static or running water. 5. Low Heat Cement Low heat cement is prepared by maintaining the percentage of tricalcium aluminate below 6% by increasing the proportion of C2S. This makes the concrete to produce low heat of hydration and thus is used in mass concrete construction like gravity dams, as the low heat of hydration prevents the cracking of concrete due to heat.This cement has increased power against sulphates and is less reactive and initial setting time is greater than OPC.

- 22. 6. Sulphates Resisting Cement Sulfate resisting cement is used to reduce the risk of sulphate attack on concrete and thus is used in construction of foundations where soil has high sulphate content. This cement has reduced contents of C3A and C4AF.Sulfate resisting cement is used in construction exposed to severe sulphate action by water and soil in places like canals linings, culverts, retaining walls, siphons etc. 7. Blast Furnace Slag Cement Blast furnace slag cement is obtained by grinding the clinkers with about 60% slag and resembles more or less in properties of Portland cement. It can be used for works economic considerations is predominant. 8. High Alumina Cement High alumina cement is obtained by melting mixture of bauxite and lime and grinding with the clinker. It is a rapid hardening cement with initial and final setting time of about 3.5 and 5 hours respectively. The compressive strength of this cement is very high and more workable than ordinary portland cement and is used in works where concrete is subjected to high temperatures, frost, and acidic action. 9. White Cement It is prepared from raw materials free from Iron oxide and is a type of ordinary portland cement which is white in color. It is costlier and is used for architectural purposes such as precast curtain wall and facing panels, terrazzo surface etc. and for interior and exterior decorative work like external

- 23. renderings of buildings, facing slabs, floorings, ornamental concrete products, paths of gardens, swimming pools etc. 10. Colored cement It is produced by mixing 5- 10% mineral pigments with ordinary cement. They are widely used for decorative works in floors. 11. Air Entraining Cement Air entraining cement is produced by adding indigenous air entraining agents such as resins, glues, sodium salts of sulphates etc. during the grinding of clinker. This type of cement is especially suited to improve the workability with smaller water cement ratio and to improve frost resistance of concrete. 12. Expansive Cement Expansive cement expands slightly with time and does not shrink during and after the time of hardening . This cement is mainly used for grouting anchor bolts and prestressed concrete ducts. 13. Hydrographic cement Hydrographic cement is prepared by mixing water repelling chemicals and has high workability and strength. It has the property of repelling water and is unaffected during monsoon or rains. Hydrophobic cement is mainly used for the

- 24. construction of water structures such dams, water tanks, spillways, water retaining structures etc PROPERTIES OF CEMENT Physical Properties of Cement And Their Testing Different blends of cement used in construction are characterized by their physical properties. Some key parameters control the quality of cement. The physical properties of good cement are based on: Fineness of cement Soundness Consistency Strength Setting time Heat of hydration Loss of ignition Bulk density

- 25. Specific gravity (Relative density) These physical properties are discussed in details in the following segment. Also, you will find the test names associated with these physical properties. Fineness of Cement The size of the particles of the cement is its fineness. The required fineness of good cement is achieved through grinding the clinker in the last step of cement production process. As hydration rate of cement is directly related to the cement particle size, fineness of cement is very important. Soundness of Cement Soundness refers to the ability of cement to not shrink upon hardening. Good quality cement retains its volume after setting without delayed expansion, which is caused by excessive free lime and magnesia. Tests: Unsoundness of cement may appear after several years, so tests for ensuring soundness must be able to determine that potential. Le Chatelier Test This method, done by using Le Chatelier Apparatus, tests the expansion of cement due to lime. Cement paste (normal consistency) is taken between glass slides and submerged in water for 24 hours at 20+1°C. It is taken out to measure the distance between the indicators and then returned under water, brought to boil in 25-30 mins and boiled for an hour. After cooling the device, the distance between indicator points is measured again. In a good quality cement, the distance should not exceed 10 mm. Autoclave Test Cement paste (of normal consistency) is placed in an autoclave (high- pressure steam vessel) and slowly brought to 2.03 MPa, and then kept there for 3 hours. The change in length of the specimen (after gradually bringing the autoclave to room temperature and pressure) is measured and expressed in percentage. The requirement for good quality cement is a maximum of 0.80% autoclave expansion.

- 26. Consistency of Cement The ability of cement paste to flow is consistency. It is measured by Vicat Test. In Vicat Test Cement paste of normal consistency is taken in the Vicat Apparatus. The plunger of the apparatus is brought down to touch the top surface of the cement. The plunger will penetrate the cement up to a certain depth depending on the consistency. A cement is said to have a normal consistency when the plunger penetrates 10±1 mm. Strength of Cement Three types of strength of cement are measured – compressive, tensile and flexural. Various factors affect the strength, such as water-cement ratio, cement-fine aggregate ratio, curing conditions, size and shape of a specimen, the manner of molding and mixing, loading conditions and age. While testing the strength, the following should be considered: Cement mortar strength and cement concrete strength are not directly related. Cement strength is merely a quality control measure. The tests of strength are performed on cement mortar mix, not on cement paste. Cement gains strength over time, so the specific time of performing the test should be mentioned. Compressive Strength It is the most common strength test. A test specimen (50mm) is taken and subjected to a compressive load until failure. The loading sequence must be within 20 seconds and 80 seconds. Setting Time of Cement Cement sets and hardens when water is added. This setting time can vary depending on multiple factors, such as fineness of cement, cement-water ratio, chemical content, and admixtures. Cement used in construction should have an initial setting time that is not too low and a final setting time not too high. Hence, two setting times are measured: Initial set: When the paste begins to stiffen noticeably (typically occurs within 30-45 minutes) Final set: When the cement hardens, being able to sustain some load (occurs below 10 hours) Again, setting time can also be an indicator of hydration rate.

- 27. Heat of Hydration When water is added to cement, the reaction that takes place is called hydration. Hydration generates heat, which can affect the quality of the cement and also be beneficial in maintaining curing temperature during cold weather. On the other hand, when heat generation is high, especially in large structures, it may cause undesired stress. The heat of hydration is affected most by C3S and C3A present in cement, and also by water-cement ratio, fineness and curing temperature. The heat of hydration of Portland cement is calculated by determining the difference between the dry and the partially hydrated cement (obtained by comparing these at 7th and 28th days). Standard Test: Loss of Ignition Heating a cement sample at 900 - 1000°C (that is, until a constant weight is obtained) causes weight loss. This loss of weight upon heating is calculated as loss of ignition. Improper and prolonged storage or adulteration during transport or transfer may lead to pre- hydration and carbonation, both of which might be indicated by increased loss of ignition. Standard Test: Bulk density When cement is mixed with water, the water replaces areas where there would normally be air. Because of that, the bulk density of cement is not very important. Cement has a varying range of density depending on the cement composition percentage. The density of cement may be anywhere from 62 to 78 pounds per cubic foot. Specific Gravity (Relative Density) Specific gravity is generally used in mixture proportioning calculations. Portland cement has a specific gravity of 3.15, but other types of cement (for example, portland-blast-furnace- slag and portland-pozzolan cement) may have specific gravities of about 2.90 Chemical Properties of Cement The raw materials for cement production are limestone (calcium), sand or clay (silicon), bauxite (aluminum) and iron ore, and may include shells, chalk, marl, shale, clay, blast furnace slag, slate. Chemical analysis of cement raw materials provides insight into the chemical properties of cement.

- 28. 1. Tricalcium aluminate (C3A) Low content of C3A makes the cement sulfate-resistant. Gypsum reduces the hydration of C3A, which liberates a lot of heat in the early stages of hydration. C3A does not provide any more than a little amount of strength. Type I cement: contains up to 3.5% SO3 (in cement having more than 8% C3A) Type II cement: contains up to 3% SO3 (in cement having less than 8% C3A) 2. Tricalcium silicate (C3S) C3S causes rapid hydration as well as hardening and is responsible for the cement’s early strength gain an initial setting. 3. Dicalcium silicate (C2S) As opposed to tricalcium silicate, which helps early strength gain, dicalcium silicate in cement helps the strength gain after one week. 4. Ferrite (C4AF) Ferrite is a fluxing agent. It reduces the melting temperature of the raw materials in the kiln from 3,000°F to 2,600°F. Though it hydrates rapidly, it does not contribute much to the strength of the cement. 5. Magnesia (MgO) The manufacturing process of Portland cement uses magnesia as a raw material in dry process plants. An excess amount of magnesia may make the cement unsound and expansive, but a little amount of it can add strength to the cement. Production of MgO-based cement also causes less CO2 emission. All cement is limited to a content of 6% MgO. 6. Sulphur trioxide Sulfur trioxide in excess amount can make cement unsound. 7. Iron oxide/ Ferric oxide Aside from adding strength and hardness, iron oxide or ferric oxide is mainly responsible for the color of the cement. 8. Alkalis The amounts of potassium oxide (K2O) and sodium oxide (Na2O) determine the alkali content of the cement. Cement containing large amounts of alkali can cause some difficulty in regulating the setting time of cement. Low alkali cement, when used with calcium chloride in concrete, can cause discoloration. In slag-lime cement, ground granulated blast furnace slag is not hydraulic on its own but is "activated" by addition of alkalis. There is an optional limit in total alkali content of 0.60%, calculated by the equation Na2O + 0.658 K2O. 9. Free lime Free lime, which is sometimes present in cement, may cause expansion. 10. Silica fumes Silica fume is added to cement concrete in order to improve a variety of properties, especially compressive strength, abrasion resistance and bond strength. Though setting time is prolonged by the addition of silica fume, it can grant exceptionally high strength. Hence, Portland cement containing 5-20% silica fume is usually produced for Portland cement projects that require high strength. 11. Alumina Cement containing high alumina has the ability to withstand frigid temperatures since alumina is chemical-resistant. It also quickens the setting but weakens the cement.

- 29. THANKYOU PREPARED BY WARISH KHAN SUKEDIYA PH.D SCHOLAR