Heidelberg's greatest gift: Wide-format leverage

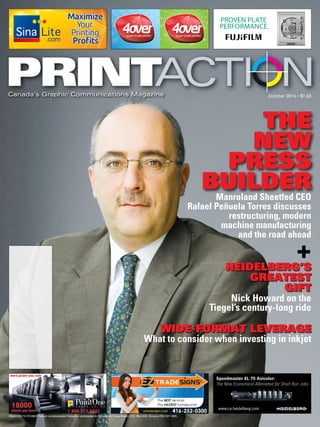

- 1. .com Maximize Your Printing Prots Maximize Your Printing Prots 18000 sheets per hour www.point-one.com 1.866.717.5722 Proven Plate Performance. Speedmaster XL 75 Anicolor: The New Economical Alternative for Short Run Jobs www.ca.heidelberg.com 4OverLug_PA_July.indd 1 2014-06-26 8:58 AM PM40065710 R10907 Return undeliverable Canadian addresses to Circulation Department: P.O. Box 530, Simcoe ON N3Y 4N5 Canada’s Graphic Communications Magazine The New Press BuilderManroland Sheetfed CEO Rafael Peñuela Torres discusses restructuring, modern machine manufacturing and the road ahead Nick Howard on the Tiegel’s century-long ride What to consider when investing in inkjet + heidelBerg’s greaTesT gifT wide-formaT leverage October 2014 • $7.50

- 2. 12 • PRINTACTION • OCTOBER 2014 I n late-July, I had the opportunity to interview Rafael PeñuelaTorres,Chief ExecutiveOfficerof Manroland Sheetfed GmbH in Offenbach, Germany. A polyglot born in Spain, educated in Economics in Germany, and employed in the printing industry since 1992, Peñuela took charge of Manroland’s Spanish organization in 1999. By 2003, he was managing the company’s Western Eu- ropean market and by 2006 Manroland Sheetfed sales worldwide. Following Manroland Sheetfed’s takeover by an British industrial conglomerate controlled by Tony Langley, Peñuela Torres temporarily shared the role of Managing Director of Service and Sales with a col- league until 2013, when he became Manroland Sheetfed’s sole CEO. In our interview, Peñuela Torres, 54, candidly discusses Manroland’s change of direction after its 2011 insolvency and 2012 acquisition by Langley Holdings PLC. He de- scribes several aspects of the company’s restructuring ef- forts, working through Germany’s tough labour laws. Peñuela Torres offers analyses of how dramatically the offset equipment and printing markets have changed since being hard hit by the global financial crisis of 2008. He also divulges how Manroland Sheetfed’s research-and-de- velopment division is currently adapting its printing machines to meet a whole new set of customer needs and expectations. Victoria Gaitskell: What do you consider to be the most important sheetfed-offset technology your company has introduced over the past five years or so – and why? PeñuelaTorres:For decades,Manroland has been leading the development of new technologies for offset printing – although not all these developments have been commer- cially successful.For example,in 2000 we launched the DI- COweb plateless press, enabling a digital changeover from job to job in less than 10 minutes. It was amazing technol- ogy for the time, but it was not a commercial success, be- cause the cost was much too high. In 2009, we developed the world’s largest perfector, the Roland 900 XXL, to serve the demand for high-volume book printing. It allowed offset printers to produce 64 A4 pages in one pass,enabling them to compete with web pro- cess productivity. But after commercial and editorial printers took a hit in the 2008 financial crisis, the demand for this technology was greatly reduced. Press productivity is only important if customers have jobs for it. So some of our new devel- opments did not succeed because of the wrong timing or costs. But many others were successful because they were ex- actly what our customers wanted: In 2003, for example, we built the Roland 500, the first press to print 18,000 sheets perhour;andtimehasproventhatthisinnovationinspeed was the right trend for our market. We also launched an InlineFoiler that can print cold foil in one pass on a conventional press. Although at first it proved popular, it generated complaints that the process wasted too much very expensive foil; so later we developed an indexing function to reduce waste in the inline process by up to 50 percent. This is an example of how we are try- ing increasingly to generate value for our customers by our technology. Our innovations have not only taken the form of heavy metal, but also the integration of software processes into a single electronic workflow, as we achieved in our Printnet network management system. In 2006, we launched the Roland 700 DirectDrive. The DirectDrivetechnologyallowedcustomerstochangeplates simultaneously while the press is washing the cylinders, al- lowing for zero plate-changing time. Since then many of our competitors have introduced similar technology, and so far it forms the biggest step towards a significant reduc- tion of make-ready time. Peñuela Torres continues to discuss R&D… PT: Among these successful technologies, I can’t identify one single development as the most important; but I can say that many of our recent developments have focused on increasing automation and reducing make-ready time, rather than on increasing press speed.One reason is that in today’s world we have discovered that speed is not the issue for our customers.The general trend is that run lengths are becoming shorter, so increasing press speed does not really help. A precondition for the improvements we introduce now is not just that they satisfy our R&D people but that they satisfy our customers. Since 2008, it has been increasingly difficult for Man- roland and our competitors to sell the same amount of equipment we used to sell. The market has shrunk by 50 percent because print shops are disappearing or merging, so less demand for machinery exists. Customers are also running machinery for longer than planned.Theaverageageof apressnowis13years,and our customers’ requirements and business models are chang- ing rapidly; so we are developing new technology like the InlineFoiler in a way that allows customers to add it on throughupgradesorretrofitstogetdifferentorbettervalue out of their existing press. In addition to shortening make-ready, another of our R&D goals is to make it easier to handle a press by creat- ing an easier interface with the user. Our customers are finding it more and more difficult to obtain highly skilled operators to run presses, because fewer of these operators are available; so we are spending a lot of brainpower and resources to make it easier to operate our technology.Espe- cially because runs are becoming shorter,automation plays a tremendous role. The New Press Builder by VicToria GaiTskell Half of Manroland Sheetfed’s 1,800 employees work in the press maker’s Offenbach plant, while the other half are spread out across the printing world. Rafael Peñuela Torres, CEO of Manroland Sheetfed, discusses restructuring, the state of the printing market, modern machine manufacturing and the road ahead

- 3. 14 • PRINTACTION • OCTOBER 2014 Since skilled labour is critical to the manufac- ture of high-performance presses: What was the size of the labour force in your three manufac- turing plants before restructuring and what is it now in your single plant after restructuring? PT: You are correct – Skilled labour is crucial for press manufacturers. Manroland decided years ago and con- firmed under Langley its plan not to do any manufactur- ing outside of Germany. One reason is that, although we realize many skilled people work outside of Germany, in other countries we find it more difficult to find the right number of them with expertise in all the different disci- plines we need to build a press. In the insolvency, we lost 50 percent of our workforce. Beforehand we had roughly 4,300 employees and we have 1,800 today.Of these,900 work in the German factory and the other 900 take care of our markets and aftermarket ser- vices in various parts of the world. How did you select which workers to keep and which to downsize? PT:I don’t know if you are aware of it,but German labour laws require a company undergoing massive restructuring to apply for approval on who goes and stays via a so-called social plan. The government works with unions to establish criteria for this process. Workers are assigned points based on fac- tors like seniority, age and family situation. Adding up the points results in a pre-selection of employees who have to leave the company. Because the point system gives prefer- ence to older workers with seniority and families,normally you have to ask younger people,sometimes with promising talent, to leave the company – which happened in our case. Sometimes, if you have certain workers with critical ex- pertise,you can offer a successful argument here and there to avoid the social plan and keep them on board. But we had only a short time to discuss the plan with the union and workers council during the last week of insolvency. I don’t know if the results were right or wrong, but we tried to do our best. With a reduced workforce, how are you en- suring your machinery continues to be of high quality? PT: We are still continuing to fine tune our human re- sources management strategy after restructuring. Langley was convinced that with our remaining capabilities we are still able to keep our whole production portfolio. Not one press was eliminated. This challenge has required us to cross-train people who were specialists before. For exam- ple, experts on 700 perfectors have also become qualified to handle 500 perfectors. It was quite a challenge, especially for the first six months of 2012; but now we have a more flexible work- force of people who can change from one model to anoth- er on the production line and still maintain high-quality standards. The employees say they are happy with the new system,because they have acquired more skills and are do- ing work that is more challenging and less routine. In 2012, I was concerned that we would not be able to manage the whole portfolio with a reduced workforce; but in fact the presses we ship out today are costing less overall after delivery. This fact proves that we have been able to manage with half our original workforce and achieve an even better result in terms of quality. With restructuring behind you, what is the big- gest challenge facing your company today? PT: After the Langley takeover, our immediate challenge was to serve customers as well as before,or even better,de- spite having reduced resources.Even before then,the com- pany had experienced different phases of restructuring, but it was only because of the insolvency that we became aware that our old culture and huge-corporation mental- ity were responsible for the insolvency itself. We had be- come too heavy, too bureaucratic, too self-confident that we couldn’t fail, and too slow in managing, reacting to the market, and responding to our customers. Our new shareholder Tony Langley knew we needed to change our attitude first. During the first year, he spent three days a week helping to transform us into a mittel- stand [German for middle-sized] company with a hands- on attitude and quicker response times. Now the biggest challenge is to keep this new culture as part of our daily business and avoid falling back into the old ways.Especially in the last two years,when profits have been better than expected, it creates the expectation of go- ing back to the good old days when salaries were higher and expenses less controlled. It’s an issue I need to keep an eye on. Why should new sheetfed-offset presses con- tinue to interest commercial printers in North America, one of the world’s most mature print- ing markets? PT: Commercial printers in industrialized Western coun- tries are in a different position than commercial printers in China,India,and Latin America,where other electronic media are still less widespread and print is still the main transmitter of commercial messages. In North America and other Western economies, the commercial sheet- fed-offset print segment has suffered more since the 2008 financial crisis because it must defend its position against electronic media and digital print. But after 20 years, digital printing is still far from dom- inating the market. It still represents one single digit of to- tal printed volume, although the marketing noise is very loud and gives the impression that digital is dominating. In reality it will take years for digital to achieve a bigger percentage than what they have today,because the cost per copy is high for digital and many enhancements, such as UV and foil coating, are not available in digital. I think for many,many years sheetfed offset will remain the dominat- ing technology. It may be less loud and less sexy, but for sure it is the best way to print massive volumes of sheets of cardboard or paper for packaging or commercial print. When it comes to cost-per-copy for industrial volumes, no method is cheaper. Today, we see Western commercial printers finding new business models to stay in the mar- ket or even grow by adding value to commercial print and escape from the commodity print market. We see more and more commercial sheetfed-offset printers who have managed to find their own niche by focusing on a specif- ic application, or way of adding value, or way of servicing customers. For example, sheetfed offset is still the most used meth- od to print business cards, and it also lets printers develop workflows to produce simple products for customers on 24-hours’ demand. So today’s successful business models include Web-to-print production of business cards and other simple products, printed with the highest efficiency at an unbeatable price. What is the best advice you can share with the many small- to mid-sized commercial printers in Canada who continue to rely on sheetfed offset as their primary production process? PT:I’mnottheguytogiveadvicetoprinters.Theyarepro- fessionals who know best what they have to do. But one thing I know from observation is that it is cru- cial for printers to identify and follow the right model for their business. They need know what they can do better than others. Basically they have a choice between two ways of mov- ing forward: One is to find a way to be different from their competitors with a different product or a different approach to customers through their services, response time, flexibility of workflow, or other factors. The second way is to achieve excellence by increasing productivity and reducing the cost per copy; for example, by using a large commercial press to produce large volumes with good or good-enough quality. The right business model can be either mass productivity or differentiation. Rafael PeñuelaTorres, Chief Executive Officer, Manroland Sheetfed GmbH. Manroland R&D focuses on make-ready rather than press speed. One of Manroland’s skilled German workers prepares a 900 press unit.