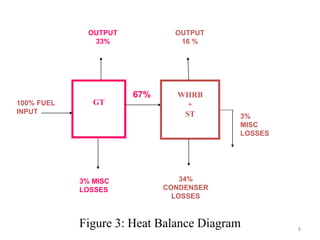

This presentation provides an overview of power generation at NTPC's Anta power plant. It discusses the key components of a combined cycle power plant, including the gas turbine, waste heat recovery boiler, and steam turbine. It also explains the basic processes involved, such as the Brayton cycle for gas turbines and Rankine cycle for steam turbines. The presentation aims to educate about how NTPC generates reliable power through an efficient combined cycle process that integrates gas and steam turbines to maximize energy output.