Quality Expert with 22+ Years Experience

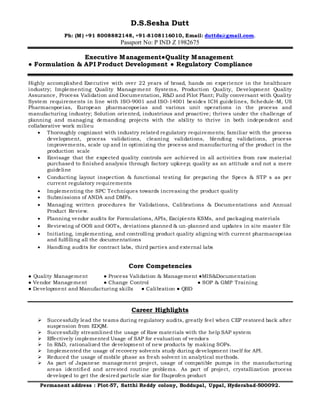

- 1. D.S.Sesha Dutt Ph: (M) +91 8008882148, +91-8108116010, Email: duttds@gmail.com. Passport No: P IND Z 1982675 Permanent address : Plot-57, Satthi Reddy colony, Boddupal, Uppal, Hyderabad-500092. Executive Management●Quality Management ● Formulation & API Product Development ● Regulatory Compliance Highly accomplished Executive with over 22 years of broad, hands on experience in the healthcare industry; Implementing Quality Management Systems, Production Quality, Development Quality Assurance, Process Validation and Documentation, R&D and Pilot Plant; Fully conversant with Quality System requirements in line with ISO-9001 and ISO-14001 besides ICH guidelines, Schedule -M, US Pharmacopoeias, European pharmacopoeias and various unit operations in the process and manufacturing industry; Solution oriented, industrious and proactive; thrives under the challenge of planning and managing demanding projects with the ability to thrive in both independent and collaborative work milieu Thoroughly cognizant with industry related regulatory requirements; familiar with the process development, process validations, cleaning validations, blending validations, process improvements, scale up and in optimizing the process and manufacturing of the product in the production scale Envisage that the expected quality controls are achieved in all activities from raw material purchased to finished analysis through factory upkeep; quality as an attitude a nd not a mere guideline Conducting layout inspection & functional testing for preparing the Specs & STP s as per current regulatory requirements Implementing the SPC Techniques towards increasing the product quality Submissions of ANDA and DMFs. Managing written procedures for Validations, Calibrations & Documentations and Annual Product Review. Planning vendor audits for Formulations, APIs, Excipients KSMs, and packaging materials Reviewing of OOS and OOTs, deviations planned & un-planned and updates in site master file Initiating, implementing, and controlling product quality aligning with current pharmacopeias and fulfilling all the documentations Handling audits for contract labs, third parties and external labs Core Competencies ● Quality Management ● Process Validation & Management ●MIS&Documentation ● Vendor Management ● Change Control ● SOP & GMP Training ● Development and Manufacturing skills ● Calibration ● QBD Career Highlights Successfully lead the teams during regulatory audits, greatly feel when CEP restored back after suspension from EDQM. Successfully streamlined the usage of Raw materials with the help SAP system Effectively implemented Usage of SAP for evaluation of vendors In R&D, rationalized the development of new products by making SOPs. Implemented the usage of recovery solvents study during development itself for API. Reduced the usage of mobile phase as fresh solvent in analytical methods. As part of Japanese management project, usage of compatible pumps in the manufacturing areas identified and arrested routine problems. As part of project, crystallization process developed to get the desired particle size for Ibuprofen product

- 2. D.S.Sesha Dutt Ph: (M) +91 8008882148, +91-8108116010, Email: duttds@gmail.com. Passport No: P IND Z 1982675 Permanent address : Plot-57, Satthi Reddy colony, Boddupal, Uppal, Hyderabad-500092. (Continued….) Reduced the Manufacturing cost for Ibuprofen Reduced the Solvent loss from 25% to 12% during API manufacturing process. Reduced the water consumption by 8% by monitoring and controlling at various stages of API. Development of new product in R&D; Suggested and adopted the recovery solvents usage Establish data from concurrent piloting to adopt in commercial site Yield improvement established for product Ibuprofen Cycle time reduction for Ibuprofen Implemented ICCE(Integrated chemistry and chemical Engineering) project in the process of Ibuprofen on particle size reduction with different RPM’s in crystallizer at nucleation state to avoid milling operation, which in turn reduce the cycle time and environment exposure During new product development(API) in concurrent piloting studied the reaction in different time intervals with different concentrations using TLC method and established optimum cycle time Awareness in, Filtrations – Centrifuges, Nutsch Filter, Leaf Filter, Candle Filter, Micro Filters; Dryers – Tray Driers, FBD, Cone driers; Autoclaves, Scrubbers, Thin Film Evaporator, Liquid-Liquid Extraction Units; Analytical instrument: GC, HPLC etc.,

- 3. D.S.Sesha Dutt Ph: (M) +91 8008882148, +91-8108116010, Email: duttds@gmail.com. Passport No: P IND Z 1982675 Permanent address : Plot-57, Satthi Reddy colony, Boddupal, Uppal, Hyderabad-500092. Employment History Enaltec Labs Pvt Ltd, Mumbai (Since Feb’15-Till date). Deputy General Manager QA (Reporting to Managing Director) Key Deliverables Responsible for API & Formulation Development lab and three manufacturing API sites QMS. Implementation of QMS & QBD effectively in formulation development lab & API R&D Lab. Responsible for new product development in formulation & API R&D, technology transfers to CMOs, auditing & identifying the CMOs, coordinating with clients. Scheduling & performing vendor audits for Key starting materials, External labs and Packing materials, APIs. Successfully lead the entire team for customer audits & local FDA, DSIR. Successfully guided the team for recent USFDA audit happened in Nov 2015. Responsible for, site Management Quality Review with all the departments. Responding to all the customer complaints and regulatory authorities all the time. Ensuring Internal audits as per schedule. Non compliances in the audits discussed in the review meetings to improve the quality Initiating the new SOPs for all the departments as per the current requirement. Supporting the API plants for ensuring the QMS and conducting the trainings Responsible for all customer complaints, recalls and OOS Investigations in the plants. Hetero Drugs Limited, Hyderabad (Since Aug’14-Jan, 15). Deputy General Manager for QA & QC (Reporting to GM CQA) Key Deliverables Key person to initiate QMS effectively in the site. Scheduling & Performing vendor audits for Key starting materials, External labs and Packing materials Successfully lead the entire team for customer audits. Coordinating with CQA departments for Quality Review meetings Corporate Quality Harmonized SOPs implemented. Responsible for, site Management Quality Review with all the departments. Responding to all the customer complaints and regulatory authorities all the time. Ensuring Internal audits as per schedule. Non compliances in the audits discussed in the review meetings to improve the quality Initiating the new SOPs for all the departments as per the current requirement. Involving in the technology transfers of new products to plant. Responsible for all customer complaints, recalls and OOS Investigations.

- 4. D.S.Sesha Dutt Ph: (M) +91 8008882148, +91-8108116010, Email: duttds@gmail.com. Passport No: P IND Z 1982675 Permanent address : Plot-57, Satthi Reddy colony, Boddupal, Uppal, Hyderabad-500092. Food processing unit, Hyderabad (Since Nov’13-Aug’14). Family Started own food processing unit for which supported all administrative and statutory requirements.. Involved in getting all kinds of certifications from local government. Manpower and facility creation. Financial planning and smoothly running the business. Made them aware hygiene and quality requirements. Inventory and budget planning trained. Glochem Industries Limited, Hyderabad (Since Aug’10-Nov’13). General Managerfor CQA & RA (Reporting to Managing Director) Key Deliverables Key person and core member in the organization to design new policies and procedures. Performing vendor audits for Key starting materials, APIs, Excipients, External labs and Packing materials Successfully EDQM CEP restored which was suspended for both the API Units after joining into the organization. Successfully lead the entire team in API Units for FDA, EMA, TGA, KFDA and local WHO GMP audits and customer audits. At the same time took the charge of formulation and successfully achieved MHRA twice, Ukraine FDA and local WHO GMP. Coordinating with plant QA departments through Corporate in Quality Review meetings Corporate Quality Harmonized SOPs designed considering both API & Formulations plants Management Quality Review with all the departments. Corporate quality training for all the plants Responding to all the customer complaints and regulatory authorities all the time. Audits scheduled and performed for internal plants Non compliances in the audits discussed in the review meetings to improve the quality Functioned as one of the key members for supporting R&D and Formulation department during the development of new products Initiating the new SOPs for all the departments as per the current requirement. Involving in the technology transfers of new products to plants Steered functions for supporting formulation department during new product development SAP support to formulation & R&D departments by making relevant SOPs Control of raw material made through SAP, its usage streamlined. In formulation played a key role and lead entire plant. Successfully coordinated for more than 25 products. Regulatory fillings done for API & Formulation successfully.

- 5. D.S.Sesha Dutt Ph: (M) +91 8008882148, +91-8108116010, Email: duttds@gmail.com. Passport No: P IND Z 1982675 Permanent address : Plot-57, Satthi Reddy colony, Boddupal, Uppal, Hyderabad-500092. Torrent Pharmaceuticals Ltd, Ahmadabad (Since Jul’07-Jul’10). Asst General Manager in Corporate Quality Assurance (Reporting to General Manager) Key Deliverables Developed an effective Quality Plan Deployment & measurable objectives for performing vendor audits for Key starting materials, APIs, Formulation, Excipients and Packing materials Facilitated for FDA and customer audits. Active member in FDA audit In Apr’08 Coordinating with plant QA departments through Corporate in Quality Review meetings Corporate Quality core SOPs designed considering both the plants Quality Review with procurement department Corporate quality training for all the plants Responding to all the customer complaints Audits scheduled and performed for internal analytical departments, R&D and plants Non compliances in the audits discussed in the review meetings to improvise the development quality Functioned as one of the key members for supporting formulation development and Medicinal chemistry department (MCD) during the development of new products Responsible for all the new products development reports review Designing the SOPs for MCD (R&D) department as per the current requirement. Involving in the technology transfers of new products to plants Steered functions for supporting formulation department during new product development Developed a robust SAP support to formulation & MCD departments by making relevant SOPs Streamlined: New product development, to mitigate issues of the product during development itself Improvised: Control of raw material made through SAP, its usage streamlined. Successfully identified non moving stocks through SAP and responsibilities allocated in respective plants Audit done for nearly 70 different industries (API, Formulation, Excipients and KSM) to procure the material for regulatory, Rest of the world and domestic markets.

- 6. D.S.Sesha Dutt Ph: (M) +91 8008882148, +91-8108116010, Email: duttds@gmail.com. Passport No: P IND Z 1982675 Permanent address : Plot-57, Satthi Reddy colony, Boddupal, Uppal, Hyderabad-500092. Dr Reddy’s Laboratories Ltd, Hyderabad (Jan’93 – Jun’07). Asst Manager in Development Quality Assurance (Reported to Associate Director) Key Deliverables Functioned as a Development Quality Assurance person in new product development engaged in supervising operations and implementing suggestions as per regulatory compliance Handled all types of validations, Qualifications, Calibrations, Change controls, Complaints SOPs preparation and trainings Involved in FDA and customer audits Involved in review of Annual product reports Provided support to the Technical service department in new product development with respect compliance and operable conditions R&D department with respect to compliance, suggesting the R&D to simulate it to plant conditions Analytical department in developing new methods for new products Online audits, Periodical audits to ensure cGMP, GLP practices are strictly followed Finalized the key starting material as per regulatory requirement and auditing the facilities, creating the documents as per the drug master file Review of technical documents: R&D Development Report, AR&D Method Development Reports and Concurrent Piloting Report, prior to technology transfer to Commercial Sites Coordinated for the: Technology transfers and ensuring the quality of the product at all appropriate phases of drug development starting from development to full-fledged commercialization Submission of DMFs, Technical packages. Approving all quality control Procedures and other quality records. Conducted training classes on cGMP practices as per the pre approved schedule based on training needs to all (R&D, ADL and Pilot Plant) Played a role in following audits: FDA audits, representing R&D and AR&D USFDA audit for Doxzosin Mesylate Facilitated R&D, AR&D, cTSD, RA, SCM, QC and Quality assurance in solving the work place issues, responding to customer queries and regulatory body requirements Process Improvement: Dextromethorphan, Hydrobromide, Propofol, Doxzosin Mesylate and Ibuprofen etc Undertaken scale up and optimization for new products: Olanzapine, Donepezil HCl, Montelukast Sodium, Sumatriptan Oxalate etc. Involved in R&D, made scale up initially , for few products like Flucanazole, Dextromethorphan HBr, Montelukast, Sertraline etc Worked in Pilot plant to study scale up issues, in addition to that worked in commercial manufacturing facility for various products such as Ibuprofen, Sumatripton, Topiramate and Olanzapine among others.

- 7. D.S.Sesha Dutt Ph: (M) +91 8008882148, +91-8108116010, Email: duttds@gmail.com. Passport No: P IND Z 1982675 Permanent address : Plot-57, Satthi Reddy colony, Boddupal, Uppal, Hyderabad-500092. Computer Skills Operating System: MS-DOS, MS-WINDOWS Languages: C, C++. Packages: MS Office Academic Profile M. Sc Tech (Pharmaceutical Chemistry), BITS, Pilani. M.B.A: Marketing Management (Institute of Marketing & Management – Hyderabad). Certifications PG Diploma in Total Quality Management & ISO 9000 (Andhra Pradesh Productivity Council, Hyderabad). PG Diploma in Chemical Analysis & Quality Management (University of Hyderabad). PG Diploma in Information Technology (CMC Limited). PG Diploma in Japanese Management (Shingo Institute of Japanese Management, Hyd). Certification in IPM (World Intellectual Property Organization, Switzerland). Personal Information Date of Birth: 21st February 1969 Languages Known: English, Hindi, Telugu and Kannada (D.S.SESHA DUTT)