USPTO Patent for an Ag Robot to process soil

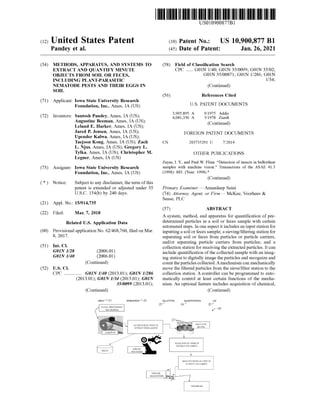

- 1. USO10900877B1 (12) United States Patent Pandey et al. (10) Patent No.: US 10,900,877 B1 (45) Date of Patent: Jan. 26, 2021 (54) METHODS, APPARATUS, AND SYSTEMS TO EXTRACT AND QUANTIFY MINUTE OBJECTS FROM SOIL OR FECES, INCLUDING PLANT-PARASITIC NEMATODE PESTS AND THEIR EGGS IN SOIL (58) Field of Classification Search CPC ...... GOIN 1/40; GOIN 35/0099; GOIN 35/02; GOIN 35/00871 ; GOIN 1/286; GOIN 1/34; (Continued) (56) References Cited (71) Applicant: Iowa State University Research Foundation, Inc., Ames, IA (US) U.S. PATENT DOCUMENTS 3,905,895 A 4,081,356 A 9/1975 Addis 3/1978 Zierdt (Continued) FOREIGN PATENT DOCUMENTS (72) Inventors: Santosh Pandey, Ames, IA (US); Augustine Beeman, Ames, IA (US); Leland E. Harker, Ames, IA (US); Jared P. Jensen, Ames, IA (US); Upender Kalwa, Ames, IA (US); Taejoon Kong, Ames, IA (US); Zach L. Njus, Ames, IA (US); Gregory L. Tylka, Ames, IA (US); Christopher M. Legner, Ames, IA (US) CN 203735291 U 7/2014 OTHER PUBLICATIONS (73) Assignee: Iowa State University Research Foundation, Inc., Ames, IA (US) Zayas, I. Y., and Paul W. Flinn. “ Detection of insects in bulkwheat samples with machine vision.” Transactions of the ASAE 41.3 (1998): 883. (Year: 1998).* (Continued) ( * ) Notice: Subject to any disclaimer, the term ofthis patent is extended or adjusted under 35 U.S.C. 154(b) by 240 days. Primary Examiner Amandeep Saini (74) Attorney, Agent, or Firm — McKee, Voorhees & Sease, PLC (21) Appl. No.: 15 /914,735 (22) Filed: Mar. 7, 2018 (60) Related U.S. Application Data Provisional application No. 62/468,760, filed on Mar. 8, 2017. (51) Int. Cl. GOIN 1/28 GOIN 1/40 (2006.01) (2006.01) (Continued) (57) ABSTRACT A system , method, and apparatus for quantification of pre determined particles in a soil or feces sample with certain automated steps. In one aspect it includes aninput station for inputting a soil or feces sample; a sieving/filtering station for separating soil or feces from particles or particle carriers, and/or separating particle carriers from particles; and a collection station forreceiving the extractedparticles. It can include quantification ofthe collected sample with an imag ing stationto digitally image theparticles andrecognize and counttheparticles collected.Amechanism canmechanically move the filtered particles from the sieve/filter station to the collection station. A controller can be programmed to auto matically control at least certain functions of the mecha nism. An optional feature includes acquisition of chemical, (Continued) (52) U.S. CI. ??? GOIN 1/40 (2013.01); GOIN 1/286 (2013.01); GOIN 1/34 (2013.01); GOIN 35/0099 (2013.01); (Continued ) INPUT- 21 EXTRACTION - 22 COLLECTION USE QUANTIFICATION 24 PLOKAL, PREPREPARED SOX, SAMPLES OS EXTRACTION OFTEMS OF INTEREST FROM SAMOLE MUO-STEP S @VING CONVEYOTE COLLECTION OF TEMS OF INTEPESTOR SUS $ 71 WASTE POSITIONER QUANTIFICATION OF ITEMS OF TEROSTOR SUKSET IVACING RECOGN::ON FURTHER USE

- 2. US 10,900,877 B1 Page 2 biological, physical, or other parameters ofthe sample with oneormore sensorspositionedorpositionableatthe sample. 25 Claims, 47 Drawing Sheets (9 of 47 Drawing Sheet(s) Filed in Color) 5,526,705 A 6,202,829 B1 6,331,438 B1 7,123,750 B2 7,788,970 B2 7,830,504 B2 9,110,240 B2 2004/0005714 Al 2012/0202715 A1 * 6/1996 Skotnikov et al. 3/2001 Van Dyke, Jr. et al. 12/2001 Aylott et al. 10/2006 Lu et al. 9/2010 Hitt et al. 11/2010 Deppermann et al. 8/2015 Gill et al. 1/2004 Safar et al. 8/2012 Partida -Sanchez BOIL 3/50255 506/23 OTHER PUBLICATIONS (51) Int. Ci. G06K 9/32 (2006.01) G06T 7700 (2017.01) GOIN 1/34 (2006.01 ) GOIN 35/00 (2006.01) GOIN 35/02 (2006.01) G06K 9700 (2006.01) G05B 19/402 (2006.01) (52) U.S. CI. CPC GOIN 35/00871 (2013.01); GOIN 35/02 (2013.01); G05B 19/402 (2013.01); G06K 9/00134 (2013.01); G06K 9/3233 (2013.01); GO6T 770012 (2013.01); GOIN 2001/2866 (2013.01); G05B 2219/23416 (2013.01); G06T 2207/10016 (2013.01); G06T2207/10056 (2013.01); G06T2207/30188 (2013.01); G06T 2207/30242 (2013.01 ) (58) Field of Classification Search CPC GOIN 2001/2866; G06K 9/00134; G06K 9/3233; G05B 19/402; GO5B 2219/23416; G06T 7/0012; G06T 2207/30188; G06T 2207/10056; GO6T 2207/30242; G06T 2207/10016 USPC 382/110 See application file for complete search history. Syed, Farhan Abbas. Development of an automated system for extraction and quantification ofsoybean cystnematode (SCN) eggs and cysts. Diss. 2015. (Year: 2015).* Winfield, A.L. et al., “ A Column Elutriator for Extracting Cyst Nematodes and Other Small Invertebrates from Soil Samples”, Association ofApplied Biologists, pp. 223-231. 1987. Adamchuk, V.I. et al., “ On- The-Go Soil Sensors for Precision Agriculture", Computers and Electronics in Agriculture, pp. 71-91. Mar. 8, 2004. Byrd, Jr., D. W. et al., “Two Semi-Automatic Elutriators for Extracting Nematodes and Certain Fungi From Soil”, Journal of Nematology, vol. 8, No. 3, pp. 206-212. Jan. 16, 1976 . Faghihi, J. et al., “An Efficient New Device to Release Eggs From Heterodera Glycines”, Journal ofNematology 32 (4): pp. 411-413. 2000. Turntable Bearing Kit - VEX Robotics, https://www.vexrobotics. com /276-1810.html, pp. 1-3, retrieved from internet on Feb. 22, 2018. HumboldtManufacturing — ASTM Sieves, https://www.humboldtmfg. com /sieves.html, pp. 1-2, retrieved from internet on Mar. 7, 2018. Syed, Farhan, “Development of an Automated System for Extrac tion and Quantification ofSoybean CystNematode (SCN) Eggs and Cysts”, Grad Student Thesis, pp. 1-86. 2015. Gerdemann, J. W., “Relation of a Large Soil-Borne Spore to Phycomycetous Mycorrhizal Infections”, Mycological Society of America, vol. 47, No. 5, pp. 619-632. 1955. CN2037352910, English machine translation of part of China patent publication, 1 page, published on Jul. 30, 2014. Soil Sensor Types and Technologies, http://soilsensor.com/soil sensor-types, pp. 1-6, retrieved from internet on Mar. 8, 2018. (56) References Cited U.S. PATENT DOCUMENTS 5,063,026 A 5,222,605 A * 11/1991 Wong 6/1993 Pogue B07B 1/38 209/239 * cited by examiner

- 3. U.S. Patent Jan. 26, 2021 Sheet 1 of 47 US 10,900,877 B1 12 female teses G azad temale) Peluale adult juveniles Swollen juvenile

- 4. U.S. Patent ( a ) Mason City ( NC ) Arkgton ( NB ) Jan. 26, 2021 ( MS ) uogoury pypes Sheet 2 of 47 10 US 10,900,877 B1 FIG . 1B

- 5. INPUT 21 EXTRACTION 22 TIFICA 23 24 25 PLURALPREPREPAREDSOIL SAMPLES U.S. Patent 27 EXTRACTION OF ITEMS OF MULTI - STEP SIEVING CONVEYOR Jan. 26, 2021 COLLECTION OF ITEMS OFINTEREST ( OR SUBSET ) WASTE ROBOTICPOSITIONER Sheet 3 of 47 QUANTIFICATIONOFITEMSOFINTEREST ( OR SUBSET ) RECOGNITION US 10,900,877 B1 FURTHER USE FIG . 2A

- 6. U.S. Patent Jan. 26, 2021 Sheet 4 of 47 US 10,900,877 B1 26 80 INPUT (SAMPLES) CONTROL SYSTEM AVO 28 180/190 EXTRACTION STATION EXTRACTION OF TEMS OF INTEREST FROM SAMPLE 29 QUANTIFICATION STATION QUANTIFICATION OF ITEMS OF INTEREST (OR SUBSET) QUTPUT OF QUANTIFICATION (FOR FURTHER USE) FIG. 2B

- 7. 30A 30 PREPAREPLURALSAMPLES U.S. Patent GRIND ? No VBRATE ? No RINSE ? NO - REPOSITION ? CONVEYSAMPLE ( S ) Yes Yes Yes Yes 300 30E 300 30F Jan. 26, 2021 30B VIBRATE RINSE REPOSITION SAMPLE Yes 30G Sheet 5 of 47 CONTINUESIEVING ? COLLECTITEMS OF INTEREST NO 30L REPOSITIONSIEVES CONVEY ITEMSOF INTEREST COUNT ITEMSOF INTEREST 301 301 US 10,900,877 B1 30K RINSE USEDSIEVES COMMUNICATEDQUANTIFICATION REMOVEWASTE FIG . 3A

- 8. 32 INPUTCONVEYORMOTOR ( S ) GRINDERMOTOR VIBRATORMOTOR( ON / OFF ) GRIPPERMOTOR( OPEN / CLOSE ) U.S. Patent ( GRIND ) PRESSURIZEDWATERSOURCE STATE POST MOTOR( ROTATION ) GRINDERMOTOR( UP / DOWN ) GRIPPERPOST MOTOR( UP / DOWN ) WATERVAUVE ( S ) ( OPEN / CLOSE ) Jan. 26, 2021 GRIPPERPOST MOTOR( ROTATION ) GRIPPERMOTOR( TILT ) CONTROLLER ( AUTOMATED - ORDER / TIMING AND FUNCTIONS ) STAGE POSTMOTOR( UP / DOWN ) Sheet 6 of 47 RING SPRAYER BAR CODE READER OUTPUTCONVEYORMOTOR ( S ) INTERNET PC IMAGERECOGNITIONSOFTWARE TABLET OR SMART REMOTECOMPUTER / SERVER US 10,900,877 B1 DIGITALIMAGER PHONE FIG . 3B

- 9. U.S. Patent Jan. 26, 2021 Sheet 7 of 47 US 10,900,877 B1 Home 56 60 DRAIN PAN 52

- 10. U.S. Patent Jan. 26, 2021 Sheet 8 of 47 US 10,900,877 B1 40 MMT @ 98888888 0 0 0 0 0 0 0 0 0 0 0 0 0 04 60 52 wey - o o OOOOOOOOOO O OOOOOOOOOOOO · 0 0 0 0 0 0 0 0 o OOOOOOOOOOOO O O 0 Q o Q Q A 0 o 9 ? ? FIG . 4B

- 11. U.S. Patent Jan. 26, 2021 Sheet 9 of 47 US 10,900,877 B1 70 80 62 ?

- 12. U.S. Patent Jan. 26, 2021 Sheet 10 of 47 US 10,900,877 B1 80 60 52 56 50

- 13. U.S. Patent Jan. 26, 2021 Sheet 11 of 47 US 10,900,877 B1 53 OPEN/CLOSE 56 ROTATE FIG . 5A

- 14. U.S. Patent Jan. 26, 2021 Sheet 12 of 47 US 10,900,877 B1 50 PRESSURIZED 80 UP/DOWN 52 LU 56 55

- 15. U.S. Patent Jan. 26, 2021 Sheet 13 of 47 US 10,900,877 B1 OPENG OPEN/CLOSE FIG . 5C ?GC -571 57L 58 -59 FIG. 5D

- 16. U.S. Patent Jan. 26, 2021 Sheet 14 of 47 US 10,900,877 B1 I 63 64(2) 64(1) 64 (3) 62T a 62M 2 62B 64(4) ROTATE FIG. 6A

- 17. U.S. Patent Jan. 26, 2021 Sheet 15 of 47 US 10,900,877 B1 63 62 T 62 M ? 62 B FIG. 6B

- 18. U.S. Patent Jan. 26, 2021 Sheet 16 of 47 US 10,900,877 B1 70 72 73 ROTATE FIG . 7A

- 19. U.S. Patent Jan. 26, 2021 Sheet 17 of 47 US 10,900,877 B1 - 70 o O UP/DOWN 72 73 FIG . 7B

- 20. U.S. Patent Jan. 26, 2021 Sheet 18 of 47 US 10,900,877 B1 FIG . 8A

- 21. U.S. Patent 81 COMPUTERSOFTWARE COMPUTERBOARD Jan. 26, 2021 STAGEPOST GRIPPERPOST GRIPPER GRINDER WATERVALVES Sheet 19 of 47 UP / ROTATE ROTATE OPENCLOSE GRINDON / OFF OPENCLOSE FIG . 8B US 10,900,877 B1

- 22. InputSample SieveWasher 1 U.S. Patent Grinder Grinder Grinder 204 20 607 601 200 200t Jan. 26, 2021 T 500 Sheet 20 of 47 Grinder Grinder 201 20 ? 201 F 60 200 200 500 with eggs 500 portofolium modelului OutputSample US 10,900,877 B1 FIG . 9A

- 23. U.S. Patent Jan. 26, 2021 Sheet 21 of 47 US 10,900,877 B1 Input Sample Grinder 27(# 20) 627 27 (# 60) 27(# 200) 62M 27(# 500) FIG. 9B

- 24. U.S. Patent Jan. 26, 2021 Sheet 22 of 47 US 10,900,877 B1 Grinder Sieve Washer 52 # 20 FIRST SIEVING ACTION #500 FIG. 9C

- 25. U.S. Patent Jan. 26, 2021 Sheet 23 of 47 US 10,900,877 B1 Grinder Pad 72 # 20 #60 with Cysts 627 # 60 Moved By Gripper 56 PPT *** 3 } 62M #500 62B FIG.9D

- 26. U.S. Patent Jan. 26, 2021 Sheet 24 of 47 US 10,900,877 B1 Grinder 70 UP/DOWN . #20m ?? { 760 with Cysts SECOND SIEVING ACTION # 200 ~ # 500

- 27. U.S. Patent Jan. 26, 2021 Sheet 25 of 47 US 10,900,877 B1 Grinder *20 # 200 SIEVING ACTION #500 FIG. 9F

- 28. U.S. Patent Jan. 26, 2021 Sheet 26 of 47 US 10,900,877 B1 Grinder #20 SIEVED PRODUCT #500 with eggs * 200 #500 Moved and Tipped by Gripper 56 * | 1 OutputSample FIG. OG

- 29. U.S. Patent Jan. 26, 2021 Sheet 27 of 47 US 10,900,877 B1 Start Density gradient Centrifugation of collectedsample 102 Scanner imaging Lensless Imaging Quantification method ? Stain the solution Load the solution and initiate solution flow in the device Transfer to a substrate placed on a scanner Record the video, apply reconstruction technique Record the final particle count End Scan the substrate and splitthe image into blocks Open reconstructed video 3 Yes 3 $ Read a block Read two successive frarnes Is there another frame/block ? 5 Convert the colorspace apply colorthresholds Applybackground subtraction Add Nioop to the total particle count Nioop - Nioop - 1 No Identifyall objects, set Nioop =0 Select an object Isthere another object? Extract parameters of an object(size, shape) Does it match aparticle of interest? Yes FIG . 10

- 30. U.S. Patent Jan. 26, 2021 Sheet 28 of 47 US 10,900,877 B1 01 A

- 31. U.S. Patent Jan. 26, 2021 Sheet 29 of 47 US 10,900,877 B1 117 X 323 ) FIG . 11B 116

- 32. U.S. Patent Jan. 26, 2021 Sheet 30 of 47 US 10,900,877 B1 120 110 (PRIOR TO DENSITY SEPARATION) 110 (AFTERDENSITY SEPARATION) 116 (SAMPLE FROM 111) 116 (SAMPLE FROM 112) 116 (SAMPLE FROM 113) r444 and FIG. 12C M Hair I FIG. 12D FIG. 12E FIG. 12F

- 33. U.S. Patent Jan. 26, 2021 Sheet 31 of 47 US 10,900,877 B1 130 1 - Bottom 1 we Top Ege recovery ratio - * -Interface 1 W W % Optiprep solution FIG. 13

- 34. U.S. Patent Jan. 26, 2021 Sheet 32 of 47 US 10,900,877 B1 140A Error in 40% Interface SoftwareCounts 5 Manual Counts Error in 80% Interface SoftwareCounts Hilities 5 Manual Counts

- 35. U.S. Patent Jan. 26, 2021 Sheet 33 of 47 US 10,900,877 B1 Error in 60% Interface SoftwareCounts W! Manual Counts Error in 50 % Interface SoftwareCounts melulupoepooor! Manual Counts FIG . 14D

- 36. U.S. Patent Jan. 26, 2021 Sheet 34 of 47 US 10,900,877 B1 151) 154A THE FLIER PAPER WI DIGITAL SCANNER 153 154B FIG. 15A

- 37. U.S. Patent Jan. 26, 2021 Sheet 35 of 47 US 10,900,877 B1 SCANNER HOUSING 158 DIGITAL SCANNER COMPUTERWITH IMAGEACQUISITIONAND FILTERPAPER WTHSCH EGGS

- 38. U.S. Patent Jan. 26, 2021 Sheet 36 of 47 US 10,900,877 B1 12 9001793 m 700 actual size ( um ) 2? 500 14 100 soybean corn potato cereal FIG . 16A

- 39. U.S. Patent Jan. 26, 2021 Sheet 37 of 47 US 10,900,877 B1 160 Imaging nematodes 16 -162 -163 FIG . 16B

- 40. U.S. Patent Jan. 26, 2021 Sheet 38 of 47 US 10,900,877 B1 Separation of SOK eos from a cleaner suspensionafts sucroseseparation step. 116' FIG . 16C GEOW ::: ligitimating School CMTV3:5W **:> ( 109 :05ste 165 FIG. 160

- 41. U.S. Patent Jan. 26, 2021 Sheet 39 of 47 US 10,900,877 B1 174 173A 173B FIG . 17A 2 . 2 172

- 42. U.S. Patent Jan. 26, 2021 Sheet 40 of 47 US 10,900,877 B1 179A 179B -175 00 . : . . . 178 17 -------.............................. FIG . 17B 36:28 . 177mmy 176

- 43. U.S. Patent Jan. 26, 2021 Sheet 41 of 47 US 10,900,877 B1 180A 176 n D1 E1 VIDEO FRAME 1 AT IMAGING LOCATION

- 44. U.S. Patent Jan. 26, 2021 Sheet 42 of 47 US 10,900,877 B1 180B E3 01 E2 03 D2 E1 VIDEO FRAME 2 FIG. 18B

- 45. U.S. Patent Jan. 26, 2021 Sheet 43 of 47 US 10,900,877 B1 180C E3 Dm E2 03 D1 En D2 £ 1 VIDEO FRAME 3

- 46. U.S. Patent Jan. 26, 2021 Sheet 44 of 47 US 10,900,877 B1 180D E3 Om 1 03 En 02 VIDEO FRAME 4 FIG . 18D

- 47. 191 190 192 LIGHT U.S. Patent SOURCE SYRINGES 3X3 195 Jan. 26, 2021 3X3 FLOWOUT C6 C3 09 016 019 194 C5 C8 Sheet 45 of 47 D3 018 D15 C1 01.1 014 017 3X3 FLOWIN 176 177 COMPUTER 3X3OUTTOIMAGERECONSTRUCTION 196 US 10,900,877 B1 198 FIG . 19

- 48. U.S. Patent Jan. 26, 2021 Sheet 46 of 47 US 10,900,877 B1 Sensor 204B Sensor 2044 Sensor2040 Sensor204E Sensor 204D 56 203 208 202 207 209 Sensor Circuit 205A 3 Sensor Circuit 205B } Sensor Circuit 2050 } Sensor Circuit 205D } Sensor Circuit 205E { FIG . 20A

- 49. U.S. Patent Jan. 26, 2021 Sheet 47 of 47 US 10,900,877 B1 200 204A 1 www Sensor Circuit 205A FIG. 20B

- 50. US 10,900,877 B1 1 2 METHODS, APPARATUS, AND SYSTEMS TO volume of soil, the difficulty is (a) identifying whether EXTRACT AND QUANTIFY MINUTE infestation has occurred and then (b) what severity. One OBJECTS FROM SOIL OR FECES, cannot tell from simply looking at the soil, as the organisms INCLUDING PLANT-PARASITIC are beneath the top of the soil. Also, quantification or NEMATODE PESTS AND THEIR EGGS IN 5 severity cannot be accurately determined from simply look SOIL ing at plants growing in the soil. Decisions as to treatment or strategies of remediation CROSS-REFERENCE TO RELATED require a reasonable quantification ofinfestation severity to APPLICATIONS be practical and effective. In other words, a producer could 10 prophylactically apply chemicals to the soil, or utilize spe This application claims the benefit of Provisional Appli cific SCN -resistant seed coatings, varieties or GMO seeds. cation U.S. Ser. No. 62/468,760, filed on Mar. 8, 2017, But this might utilize quantities not needed and incur which is herein incorporated by reference in its entirety. substantial unneeded expense or may result in ineffective treatmentinterms oflevel ofchemicals ortype ofseedused. GOVERNMENT RIGHTS 15 Another remediation technique is crop rotation for the field of interest between different growing seasons. This invention was made with government support under The dilemma is made worse by the fact that SCN is NATIONAL SCIENCE FOUNDATION GRANT No. becoming increasingly resistant to GMO engineered seed. DB11556370. The Government has certain rights in the Therefore, a better understanding of where infestation has invention. 20 expandedto geographically andits severity wouldbehighly valuable to the agricultural community. It could help on a I. BACKGROUND OF THE INVENTION macro-scale with remedial strategies. Thus, individual pro ducers addressing their specific SCN problems, to regional A. Field of the Invention or even worldwide organizations or governments, face 25 increasing pressure because of the expanding infestations Thepresent inventionrelatesto extractingrelatively small geographically and increasing resistance to typical treat objects ororganisms ofinterest from a startingmixture, such ments. See, e.g. FIG. 1B. as a soil or feces sample, and to apparatus, systems, and As can be appreciated, the small size ofthe SCN organ methods of automating at least certain steps in not only ism, as well as its entrainment in soil, make both extraction extraction, but in input, collection, and quantification ofthe 30 and quantification not just difficult, but unpredictable. extracted items of interest for further use. In one example, Manual soil sampling from a field, manual sieving of the the items of interest are plant-parasitic nematodes of field sample through increasingly fine mesh sizes to extract eggs, crops that can be sampled with a mixture ofsoil and debris and then quantification ofnumber of SCN eggs per sample froma field andfurtheruse ofcollectedandquantifieditems by suchthings as visual ormanual counting is laborious and ofinterestto assist inmaking informed decisions onhow to 35 error-prone. Considering the increasingincidence of infes manage the organisms and/or crops in the sampled field . tationandneedformorequantifiable, quickerunderstanding Those skilled in the art will appreciate that at least aspects of severity of infestation, such manual procedures become ofthe disclosed invention may be applied to different items almost untenable. of interest. Therefore, the invention is not necessarily lim- A conventional way of estimating nematode population itedtonematodes,soilorfeces samples, orquantificationfor 40 density froma soil sampleis to gatherfieldsoil samples and remedial purposes. send them to a remote laboratory for analysis prior to the growing season. There the sample is sub -divided into sub B. Problems in the State of the Art samples of known volume. A sieving process is conducted manually on selected sub-samples to try to extract the Extraction ofrelatively small objects or organisms from a 45 relevant forms ofthe nematodepests, whether egg, worm , or soil or feces sample has numerous challenges. For example, cyst stage from the sub-sample known volume of soil. Pest the organism of interest can be in different stages of devel- population density estimates forthe field are made manually opment. The soil or feces sample vary drastically in char- counting what the worker decides are pests in the sub acteristics suchasparticularsizedistribution, debris, organic sample andthenrelatingthat countto apestdensityestimate and inorganic matter, etc. Inparticular, the organisms canbe 50 pervolume ofsoil. This canbe extrapolatedinto anestimate hard to distinguish from other components and other organ- correlated to whether pest density needs remediation. isms in the sample. The foregoing technique relies heavily on human manual Take the case of soybean cyst nematodes. They can exist actions andjudgements. As such, it is susceptible to human in egg, juvenile worm , or egg-filled cyst form in soil. Each error, as well as resource costs and limitations related to state varies in size and shape (see ref. nos. 10, 12, 14 and 16 55 labor and time. It also requires substantial targeted training in FIG. 1A). Soil from field -to- field, and sometimes within of the workers. a single field, can vary in texture, moisture, make-up, and Therefore, the inventors have identified room for otherorganisms and organic and inorganic components. improvement in this technical area. Soybean cyst nematodes (SCN) can cause substantial There is a need for more automated, quicker, repeatable, yield decrease. Yield reduction typically is related to nema- 60 andprecise extraction ofnematode eggs and cysts, andtheir todeeggs andcystspopulationdensity (ornumber) inafield. quantification. There is the need for a system that can Knowledge ofestimated population density at the appropri- operate away from laboratory settings and, as such, can be ate time ortimes, with sufficient accuracy, can at least allow substantially portable and robust. the chance ofmeaningful remedial actions. However, there are many challenges. The small scale of As is well knownin soybeanproductionagriculture, SCN 65 nematode eggs (e.g., microscale) presents technological is the number one yield loss. While it has been demonstrated hurdles to not only identifying them but handling them in that yield loss is proportional to number of SCN eggs per machine-based fashion. Technological hurdles include

- 51. 25 30 US 10,900,877 B1 3 4 variation and content of soil sample. Most samples contain g. Portability of system. Can be carried and moved to not only any nematodes but other organisms along with dirt different laboratory or non-laboratory settings or in particles. Also, the soil in the sample can vary by compo- farm fields or other locations to perform functions on sition (clay, loam , etc.) but also textures, particle sizes, not the soil or feces sample in a preferred location by the to mention debris (e.g. organic trash, rocks, etc.). These 5 user or group of users. types of factors make it difficult to differentiate objects of h. Speed. Can quantify a plurality of samples in much interest from all else. Unpredictability results from both the quickertime-frame thanpresent techniques.Aspects of foregoing challenges, andalso because designfactors canbe the invention can be implemented in single sample antagonistic withone another.Forexample, betterextraction serial processing or high -throughput plural parallel of such small objects tends to require more steps and more 10 sample processing. time. But a need in this area is more efficient extraction i. Repeatability. Can be set up over a variety of different techniques. Similarly, better automatic identification and sample make-ups and conditions to produce repeatable countingtendto suggesthighercostandcomplexity.Butthis results. is antagonistic with economical solutions. j. Precision and accuracy. As will be explained further It will be further appreciated that analogous challenges 15 below, absolute precision and accuracy is not required can exist regarding other items of interest. For example, for benefits. But repeatability and accuracy within a there are other organisms that lay their eggs in soil or feces certain acceptable margin of error can be sufficient. It of which efficient, economical, and accurate population is to be understood that the present invention can density estimation would be useful. Some are parasitic. address and take advantage ofthat. Others are non-parasitic or beneficial. There can be other 20 k. Macro- or micro -data. As will be appreciated, the objects of interest in feces. But quantification could be increasing pressure at addressing problems discussed beneficial, including for pest management and for research herein, exists over a range of scales. On one hand, purposes. Still further, there are other relatively small items individual producers orresearchers wouldliketo better that could benefit from a more efficient and economical quantify soil or feces samples not only at one sample extraction, collection, and/or quantification. location but in as many per field or location as is practical. Modern precision agricultural application SUMMARY OF THE INVENTION and planting equipment allow on-the-go adjustment of chemical application rate or seed selection which can A. Objects, Features and Advantages of the be changed across a single field. Knowing ifinfestation Invention levels differ in the same field can be meaningful as far as cost ofmaterials. On the other hand, the ability to It is therefore a principal object, feature, or advantage of have a technique that is repeatable, accurate within the present invention to improve over or solve problems and needed margin of error, and precise within the margin deficiencies in the state -of-the-art. of error can allow gathering of data on a more macro Other objects, features, and advantages of the invention 35 scale. Use of multiple systems across wide range of include a system, methods, or apparatus as above described geographical areas can gather such informationin a which provide one or more ofthe following: consistent manner. Such information can be reliably a. Efficiency. Does not require transport of samples to correlated in a data sense to help understand the SCN dedicatedlaboratory,which is many times remotefrom problem and generate solutions regionally and world sample site, or necessarily require advanced or highly 40 wide. Modern animal science could likewise benefit specialized training from such systems in similar ways by gaining infor b. Economy. Does not require high priced components, a mation from quantifying small organisms in feces lab setting or specialized training. samples. c. Throughput. Can allow at least substantially efficient 1. Startingunpurified sample.Aspects oftheinventioncan automated movement through the system for good 45 be used with a dirty sample, in the sense it does not throughput of plural samples, while keeping track of require substantial, costly, complex pre-processing of each for documentation and identification purposes. the sample to remove substantially all impurities or This can relate to speed per sample, or cumulative irrelevant substances. number ofprocessed samples per unit time. d. Uniformity of results. By reducing sources of human 50 B. Aspects of the Invention error, and by consistent mechanized, automated func tions, inconsistencies can be reduced, and results A first aspect of the present invention relates to a highly obtained more consistently for improved comparisons flexible, highly adaptable substantially automated system between samples from the same field to samples from and method of extracting, collecting, and/or quantifying different fields. 55 relatively small items of interest to improve over highly e. Effectiveness. High control ofextraction functions can manual techniques that require substantial technical training improve extraction of relevant items and thus quanti- ofworkers. In particular, this aspect ofthe invention pres fication ofthe same. ents a basic framework or functional technique to not only f. Flexibility ofImplementationandUse. Allows multiple fosterrelatively highthroughput, highly controllable, highly functions with same basic systems so that different 60 adjustable extraction, but also collection and/or quantifica items of relevance can be extracted and quantified. tion, which allows the designer to apply these aspects to a Different processes, different order of processes, and variety ofpossible tasks. For example, one implementation sequence ofprocesses allows for application to differ- is improved efficiency inextractingrelatively small items of ent target items ofrelevance or different treatments of interest from a mixture. Alternatively, the system and suchtargets. Essentiallythe systemcanbereconfigured 65 method could be used for collection and quantification of as to when, where, what, how, and why certain func- relatively small items of interest. An intelligent, program tions occur but all within the same basic system. mable controller can orchestrate different operations to

- 52. US 10,900,877 B1 5 6 effectuate the desired operations to achieve such results. and any items of extracted from it between input to and Examples of controllable functions are translation between output from the system to maintain correlation of samples. operational stations, multiple steps for extraction, acquisi- A further aspect of the invention applies the concepts tion of automated counting of the items of interest, and above to a single soil sample for quantifying nematodes in communication and storage ofthe quantification for subse- 5 any of its life stages, including eggs, worms, and cysts. quent use. Such uses can include, but are not limited to, A further aspect of the invention applies the concepts decisions related to the quantification, research purposes, or above to a single feces sample for quantifying organisms in other. it. Another aspect ofthe invention comprises a comprehen Afurtheraspect ofthe inventionprovides efficientparallel sive automated system and method of providing multiple 10 processing of many samples. samples to an input station, serially extracting items of BRIEF DESCRIPTION OF THE DRAWINGS interest from each sample, collecting the extracted items of interest from each sample, and quantifying the number of items of interest in each collection in a continuous or 15 executedincolor.Copies ofthispatentorpatent application Thepatentorapplicationfile contains atleastone drawing semi-continuous efficient manner. In one implementation, a publication with color drawing(s) will be provided by the conveying sub-system presents samples sequentially to an Office upon request and payment ofthe necessary fee. input station. Amechanized positioner guides a first sample FIGS. 1A-B are diagrammatic views and illustrations of through one or more extraction functions at an extraction background information regarding SCN. station. Examples of the extraction functions can include, 20 FIG. 2A is a high-level diagrammatic flowchart of a but are not limited to, separating the items of interest from methodology using the system of FIG. 2B according to an at least other constituent materials in the sample by one or exemplary embodiment ofthe invention. more filtering or sieving steps.Additionally, extraction func- FIG. 2B is a high-level diagram ofa system and its major tions can also include further operations on the extracted components according to one exemplary embodiment ofthe items. One example is grinding the items to separate con- 25 invention. stituent parts ofthe items ofinterest, such as to release eggs FIG. 3Ais a flowchart ofa method ofoperation according from cysts. Another example is use of fluids to assist in to a first specific embodiment of the present invention. separation ofobjects ofinterest orcleaning the sub-systems. FIG. 3B is a diagrammatic view of an apparatus and Quantification can include further operations on extracted systemcomponentsto practicethemethodology ofFIG. 3A. items ofinterest to prepare for evaluation at a quantification 30 FIG. 4Ais a perspective assembled view ofan extraction station. Examples include but are not limited to moving station of FIG. 2A in one specific implementation and extracted items to a rotational or centrifugation separation embodiment. device to concentrate the items ofinterest in preparation of FIGS. 4B, 4C, and 4D are front, side, and inviews ofFIG. imaging. Quantification can then be done by digital imaging 4A. and using image recognition software to identify and count 35 FIG. 5A is an isolated, enlarged perspective ofa robotic, the items of interest automatically. The count can be com- multiple-degree freedom ofmovement subassembly ofFIG. municated to an intelligent programmable processor where 4A, namely a combined robotic gripper tool and washing the count can be used, stored, or manipulated according to tool according to the system of FIG. 4A. need or desire. Second and succeeding samples can be then FIG. 5B is a front elevation of FIG. 5A. processed serially in a similar manner. FIGS. 5C and D are perspective isolated views of the Another aspect ofthe invention comprises different tech- gripper tool of FIGS. 5A and B from two perspectives. niques of quantifying extracted objects of interest. In one FIGS. 6A and B are enlarged isolated perspective and example, image recognition of a digital image of a static front plan elevation views of a turntable assembly of the sample from a scanned -based digital imager is used to system of FIG. 4A according to a specific exemplary identifyandcountobjects ofinterestbasedondifferentiating 45 embodiment. characteristics, such as size, shape and color. In another FIGS. 7Aand B are enlarged isolatedperspective and side example, image reconstruction of digital video of a sample views ofa grinding tool according to a specific embodiment entrained in a flowing liquid from a lens-less digital video of the system of FIG. 4A. imager is used to identify and count objects ofinterest. FIG. 8A is a perspective, isolated view of a control In a further aspect ofthe invention, a specific application 50 subsystem and circuit arrangement for the system of FIG. can include an automatedextractionofitems ofinterest from 4A. FIG. 8B is a diagrammatic view of the functional a starting sample mixture by directing the mixture through attributes of software used with the control subsystem of at least two sieves. Each sieve may have pores of different FIG. 8Arelativeto operationofthe extraction stationofFIG. sizes. This aspect involves filtering the sample mixture in a 4A. first sieve and collecting what passes the first sieve in a 55 FIG. 9A is a simplified diagrammatic illustration of a lower sieve, andthen either collecting what is not passedby sequence ofoperations for extracting SCN eggs from a soil the second sieve or actuating further processing steps. The sample using the station of FIG. 4A. FIGS. 9B-G are extraction can include automated ancillary functions such as isolated views of each ofthe sequence ofthe steps of FIG. vibration, rinsing, ortipping ofone ormultiple sieves, either 9A. sequentially or in parallel. In one embodiment, a robotic 60 FIG. 10 is a flowchart ofpossible functional operations of hand can be automatically controlled relative to the sieves, the quantification station ofFIG. 2B according to a specific actuators can be automatically controlled for vibration of embodiment of the invention. sieves or the entire extraction system, and valves automati- FIG. 11A is an enlarged diagrammatic view ofa vial used cally controlled for rinsing action of sieves or the entire in anoptional technique forseparating by density SCN eggs extraction system . A programmable controller can coordi- 65 from other materials in solution prior to quantification by nate timing and sequence of operations. The system can any of the techniques of FIG. 10, including showing how further include techniques to maintain identity of a sample density separation through centrifuging occurs. 40

- 53. 20 US 10,900,877 B1 7 8 FIG. 11B is a perspective view of a stack of filter paper aspects ofthe invention canbe a subset or even one ofthose disks for receiving a sample for quantification, with dia- functions, depending on need or desire. For example, grammatic isolated illustration ofone such disk with super- aspects of the invention can relate simply to extraction. posedimagingzones orblockswhenscanning a static digital Other aspects can be limited to collection or quantification. image ofthe surface ofthe disk used for imaging extracted 5 eggs fromthemiddle density-separatedvolume ofFIG. 11A, B. Generalized Example deposited on the filter paper, for quantification of eggs according to an exemplary embodiment ofthe invention. Ageneralizedexampleofamethod(indicatedgenerallyat FIGS. 12A-F are photos and graphs showing proof of reference no. 20) and system (generally at 26) according to concept of effective separation of SCN eggs in the centri- 10 aspects of the invention is illustrated at FIGS. 2A and 2B. fuged vials of FIG. 11A. FIGS. 2A and 2B show at its highest level, aspects ofthe FIG. 13 is a graph showing proofofconcept ofconsistent invention can include on a functional level. One or more of recovery ofSCN density-separated eggs from other portions efficient extraction and/or quantification of an unknown of the solution in the vial of FIG. 11A. quantity ofminute objects ofinterest can be accomplished, FIGS. 14A-D are graphs showing proof of concept of 15 including from a relatively dirty starting raw sample. Auto using imaging recognition software for counting SCN eggs mation or semi-automation can be applied to one or more of on the filter paper ofFIG. 11B compared to manual counts. these. While specific embodiments are described in relation FIG. 15Ais a high-level flow chart ofquantificationusing to soybean or other nematodes, the invention is not neces the filterpaper ofFIG. 11B witha digital scanner and image sarily limited to those items of interest. recognition software, according to one option in FIG. 10. FIG. 2A shows the basic methodology. One or more raw FIG. 15B is a diagrammatic example of one possible samples are prepared (see step 21). In the example of imaging subsystemforimagingfilterpapers ofFIG. 11B and nematodes, this can involve a soil sample obtained from a then processing with image recognition software for count- field. Thus, it is "dirty" in the sense that it contains the ing SCN eggs on filter paper as in FIG. 15A. objects ofinterest to be quantified (e.g. SCNs or its cysts or FIGS. 16A-D are illustrations and color photos showing 25 eggs) but entrained in a substantialamount of objects or shapes that are typical regarding SCN life stages and tech- substances not ofinterest (e.g. dirt, otherorganisms, debris). niques forsamplepreparationfor imagingand countingwith It can be diluted or otherwise prepared for further process image recognition software technique of FIGS. 15A-B. ing. But in one aspect, it does not need to be purified in the FIG. 17A is a flowchart depiction ofan alternative tech- sense ofsubstantially separating the objects ofinterest from nique ofSCN egg quantification in FIG . 10, namely use of 30 all else. In the case offeces, it can be obtained from a field, microfluidics and lens-less video imaging capture offlowing an animal confinement, or otherwise. eggs in solution with an illumination source for diffraction- An identification designation can be given to the sample. based image reconstruction and object-of-interest identifi- In one example an identification number can be assigned. cation. That number could be encoded in a bar code or other FIG. 17B is a diagram of one hardware set up for the 35 machine-readableformona samplecontainer.Techniquesto technique ofFIG. 17A. do so are well-known to those skilled in this area of FIGS. 18A-D are simplified and highly diagrammatic technology. Sample(s) can be presented for processing illustrations of video capture with the technique of FIGS. including by mechanized conveyance or otherwise. 17A -B to obtain a count of SCN eggs in a flowing sample 1. Extraction solution. In this generalized embodiment, an extraction function FIG. 19 is a diagram of an automated sample parallel- involves at least two separation or filtering steps. In the case processing option according to another example of the ofnematodes, it caninvolve a first sievingwitha sievemesh invention. size effective to pass nematodes in whatever stage (eggs, FIGS. 20A and B are perspective and side elevation worms, cysts) through to a second sieve. As explained views, respectively, of an optimal sensor tool that can be 45 further later,the second sieve is selectedbased onwhat item used in the other embodiments of the invention. of interest and/or what stage of development of items of interest is desired to be collected. DETAILED DESCRIPTION OF EXEMPLARY In the case ofnematode eggs, the sieving may include a EMBODIMENTS OF THE INVENTION grinding step to rupture or force the eggs in cysts to be 50 released through a second sieve to a third sieve. In the case A. Overview ofworms, the second sieve may have a mesh size to collect them and no third sieve is needed. Inthe case ofcysts,it may For a better understanding of the invention, several be that only two sieves are needed. examples of forms or embodiments the invention can take One aspect of the generalized embodiment is that the will now be described in detail.These examples are neither 55 paradigm provides the designer/userwith high flexibility in inclusive nor exclusive of all forms and embodiments. As selecting and adjusting the system to meet different require will be appreciated by those skilled in this technical area, ments, with the advantages of automation at acceptable variations and options are possible. levels of precision and accuracy, and further on a cost The examples will focus on soybean nematodes and their effectivebasis at least comparedto conventional techniques. cysts and eggs as the items of interest to be extracted, 60 As in the above example, the extraction (step 22) is adjust collected, and/or quantified. As will be appreciated, the ablebasedonwhatneeds to be filteredaccordingto different invention is not so limited. Application ofthe techniques of goals. Inthe nematode implementation, this involves two or the invention can be applied in analogous ways to other more sieves 27. In some applications it might be just one items of interest. sieve. Automatic actions are controlled to cause the starting The examples will be focused on a substantially compre- 65 raw (“dirty”) sample mixture through a first filtering step at hensive automated system for extraction, collection, and/or least at one sieve and collection ofwhat passes through on quantification of items of interest. As will be appreciated, another. Further filtering through still smaller mesh-size 40

- 54. US 10,900,877 B1 9 10 sieves is possible. This processing can include controlled In one embodiment, the static image is acquired by a movement of the sieves both in position relative to other flat-bed digital scanner. This can include using built-in components of the system or relative to space generally zooming capabilities of the scanner to zoom in on the (translation in XYZ directions to different position, or tilt- surface for higher magnification to promote better image ing, vibration, or other). 5 recognition. This could include scanning the surface at the As shown in FIG. 2A, the items of interest can be zoomed setting to acquire individual areas or blocks ofthe collected after the extraction (step 23). Such collection can surface, each which could be evaluated by the software. be a result ofthe extraction steps. For example, after sieving, Alternatively, or in combination, the imager could have a items ofinterest can collect on top ofa sieve. In some uses, digital zoom function that could be employed after a digital thecollecteditemsofinterest cansimplybeused for further 10 imageofatleastpartofthesurface (or allofit)isacquired. research (e.g. biological research regarding nematodes). That digital zoom could magnify discrete portions of the image to promote better image recognition of objects of Optionally, a variety ofpost-collection steps are possible. interest. The count would accumulate over the entire surface One example is to collect the contents of a sieve and then area to produce a quantification oftotal estimated nematode further process that collected intermediate product. For 15 eggs in the sample from the static sample. example, items ofinterest in the intermediate product could Another technique for imaging is a video, acquired by a be quantified. Non-limiting examples include substantially lens-less digital sensor component, ofthe extracted sample automated quantification (see FIG. 2A, step 24). One places in solution flowing past the sensor. With an appropriate the intermediate product on a filter paper, plastic sheet, illumination source and optical set-up, inexpensive, small counting slide, or other substrate, and uses image recogni- 20 form factor lens-free Talbot-effect interference patterns can tion to count items of interest recognized on the substrate. be captured by the sensor. The interference patterns caused Another moves the intermediate product past or through by non -transparent objects in the flow can be compared some type of sensor configured to differentiate and count across several frames ofcapturedvideo. The software would items of interest. Non-limiting examples includemicroflu- be pre-programmed to either identify diffraction patterns idic flow past a video imager with image reconstruction 25 indicative ofan object ofinterest and count them or recon identification ofitems or interest in the video or use offlow struct a truer optical image from the interference pattern and cytometry techniques to singulate andcount items ofinterest use more typical image recognition to count. The count in a flow. Furtheroptions can include techniques to improve would accumulate over the entire sample flow to produce a onthe intermediate product.Non-limiting examples include quantification oftotal estimated SCN eggs (orother objects purificationstepstopromoteagreaterpercentageofitemsof 30 of-interest) from the sample. interestrelativeto otherparticles inthe intermediateproduct FIG. 2B indicates that a final quantification ofthe items before counting. This can include, inter alia, shaking, cen- of interest can be then communicated automatically for trifuging, rotating, heating, or otherwise manipulating (in- further use (step 25). Examples include digital storage for cluding by automated techniques) to further separate, iso- later access. Another is transfer of information over a late, concentrate, ordistributethe extracteditems ofinterest. 35 communications network (including wide-area networks There are also enhancements possible regarding any carrier like the Internet or local networks). In the example of fluids, surfactants or detergents combined with the items of nematodes, the quantificationcanbe correlatedwitha begin interest, along with hydrophobic coating the inner walls of ning soil sample, the count converted into an estimate of container and mechanical agitation to avoid clumping ofthe population density of nematode eggs and cysts per unit items of interest. Examples will be discussed herein. 40 volume soil for the field sampled, and the further action As illustrated in FIGS. 2A and 2B, different stations and involve a recommendation for remedial action for that field components can effectuate the method steps. An extraction to reduce the effect of that density of nematodes on crop station 28 can include robotic or automated motion control. growth and production. An intelligent controller 80 (with software) can instruct The method can include additional automated steps. One system operation. Further intelligent devices (e.g. tablets or 45 is control over waste or non -relevant components of the smart phones) can communicate with the main controller. A sample (see FIG. 2A). Automated actions can be pro quantification 24 (FIG. 2A) byvarious possible components grammed to move such substances to a waste location. at a quantification station 29 (FIG. 2B) can produce a Additionally, automation can be controlled to present, quantification count ofitems ofinterest in a highly flexible, sequentially and serially to the input, plural pre-prepared efficient, and effective manner. 50 samples for processing. Such steps can allow high through 2. Quantification put by allowing automated processing of samples on a Asshown in FIGS. 2A and2B, substantially automated continuous, even around-the-clock basis, if desired. Alter quantification ofthe extracted items ofinterest in the inter- natively, parallel processing ofsamples is possible applying mediate product can take different forms. One example is aspects of extraction and/or quantification according to the transfer ofitems ofinterest fromthe extraction step or steps 55 exemplary embodiments. Examples ofthese techniques are to then digitally image them . Image recognition or recon- available commercially from a variety of sources and are struction software canbe usedto identify andcount what are well-known to those skilled in this technical area. considered by the software to fit the profile orparameters of FIG. 2B is a block diagram for a generalized system an item of interest. This could be by shape, size, color, or according to aspects of the invention. As indicated, the other parameters or combinations ofparameters. 60 system can include the following stations: As will be further discussed, digital imaging can be Input station for presenting one or more pre-prepared implemented in different ways and techniques. One is by samples. distributing an extracted sample across the surface of a Extraction station 28 - for automated separation ofitems substrate and acquiring a static digital image ofthat surface ofinterest ofeach sample, and for collection in useful form by a digital scanner. The image can be evaluated by image 65 of extracted items of interest. recognition pre-programmed to identify objects of interest Quantification station 29 for in some fashion quantify and count them . ing the items of interest as a raw quantity or in correlation

- 55. US 10,900,877 B1 11 12 with other relevant information. One example is computa- actuators to accomplishneededmovement, timing, andother tion ofan estimate ofdensity ofnematode eggs and cysts per functions. The designer would have to coordinate them as unit volume of soil. needed or desired. It is to be appreciatedthatthe system ofFIG. 2B does not FIGS. 3Aand B are overall schematics ofone example of necessarily require all stations to be automated. For 5 methodology (FIG. 3A) and system (FIG. 3B) that can be example, there could be tasks which simply take advantage used with this specific embodiment. They show diagram of automated extraction. One specific example is simply matically one example ofthe overall control and actuation extracting nematode worms from a mixture for research system for automated operation ofthis embodiment. As will purposes without quantifying their number in the sample. be appreciated, the specific components andtheir set-up and As will be appreciated bythose skilled in the art, auto- 10 interconnection can be adjusted by the system designer mated or semi-automatedtracking ofa soil or feces sample, according to needed functions. through the extraction station and then to the quantification In this example, the system controls not only a robotic station, can take a variety of forms. In some embodiments, gripperarmthathas multiple degrees freedom ofmovement, simply by nature ofknown sequence and timing of actions but also a water rinsing sub -system and a rotatable turntable through the stations, a soil or feces sample in can be 15 with multiple levels. There is also an available grinder that correlated to the quantification measurement out. The sys- can be translated towards a sieve screen (or sieve screen tem is simply reset for the next sample. translatedto the grinder) androtatedforgrinding actionnear Onthe other hand, a variety of known commercially the sieve screen. available technologies could be used. For example, a bar A computer is shown connected to the controller and code on a containerwiththe first ofsoil or feces sample can 20 includes imager control as well as image recognition pro be scanned and entered into the control system . Once the cessing, digital storage, or communication to other devices, results of the extraction station are collected into a second including remote computers or devices. container, a bar code or other identifier can be tracked or As will be appreciated by those skilled in the art, assigned to correlate it to the input soil or feces sample appended FIGS. 3A and 3B schematically depict non-lim barcode. This cancontinuethroughthequantificationstation 25 iting examples ofthe overallcontrol system (s)andmethod and be correlated to a numerical quantification value that steps that are possible with this embodiment. As shown in would match an SCN infestation characterization to that FIG. 3A, some type of programmable controller 180 (e.g. original soil or feces sample. That can be communicated, Arduino UNO Controller board for NEMA 17 stepper stored, displayed, printed out, etc. motor) can be programmed to control timing and actuation Still further, even more automated identification and 30 ofa variety ofcomponents. In this example, there could be tracking systems can be used. Those systems are quite timing of operation of conveyors, both input and output. advanced and available in a variety oftesting or automated There is timing and sequencing ofturntable(s) and gripper, systems. For example, when testing a plurality ofbiological as well as several degrees freedom of movement of the samples with multi-well titrator trays, such automated com- gripper to allow movement of sieves in three dimensions. ponents such as pipettes and othermaterial handling com- 35 The system can control spraying by controlling fluid ponents can correlate an input sample to output data for that valve(s), as well as vibration by a motor or actuator ifused. sample which can be utilized according to need or desire of Still further, the control system could sense and read the designer. identification information about samples. Such techniques As indicated in the generalized example of FIGS. 2A-B, arewell-known. It canutilizeanintelligentdevice andwired discrete parts ofthe overall system 26 or method 20 could 40 or wireless communications (e.g. PC, laptop, tablet, smart be implemented in certain situations. For example, as indi- phone, or other) or use the controller to control and process cated earlier, just the extraction station 28 and functions 22 digital imaging and image recognition at the imaging sta could be used for extraction of items of interest from a tion. Finally, optionally, the quantification calculated from complex starting sample, even if the quantification station image recognition counting can be stored or communicated 29 or functions 24 are not used. Similarly, different extrac- 45 for further use. tion systems or functions could benefit from just the quan FIG. 3A shows in flow chart form , one non-limiting tification system or functions of the generalized example. methodaccordingto inventionwhichmakes the systemvery But, as can be appreciated, combining the extraction and flexible in its application. For example, some processes quantification functions can result in benefits. require one sieving step and then collection. But others 50 require a second orthird sieving step (with different sieves). C. Specific Example 1 There couldbe repeats ormore sieving steps. Also, grinding is not needed in all applications. For example, grinding is One exemplary embodiment according to at least some of needed only when an egg count is desired where the cysts the aspects ofthe present invention are set forth below. The are ruptured to release the eggs. Vibration and rinsing ofan description outlines both apparatus and methods but also 55 individual sieve or multiple sieves is optional and is needed some ofthe practical considerations with respect to extract- to enhance the extraction process and clean the sieves when ing, collecting, and/or quantifying soybean nematodes in desired. This illustrates that the system could be pro egg, cyst, or worm form in comparison to conventional grammed and configured easily for different sequences, techniques. number, andtypes ofprocessing steps according to desire or 1. Overall Functions/Components of Specific Embodi- 60 need. ment 1 (FIGS. 3A-B) FIG. 3B shows diagrammatically one non-limiting hard FIGS. 3A and 3B illustrate diagrammatically examples of ware combination to effectuate at least the method 30A-L of some of the automation requirements of the system and FIG. 3A. Variations are, of course, possible. method of FIGS. 2A and 2B, such as might be applied to FIGS. 4A-D show, from different perspectives, one nematodes in a specific implementation of the generalized 65 example of an assembled embodiment 40 for an extraction invention discussed above. For example, one or more pro- station according to relevant components 32 in FIG. 3B. grammable controllers would be needed to control different Then, FIGS. 5A-E, 6A-B, 7A-B, and 8A-B illustrate with

- 56. 5 asin US 10,900,877 B1 13 14 more detail the gripper, washer, turntable, grinder, and designed components, each having functionalities to pro control sections of station 40. mote the process. Motion control is through an effective yet Further illustrations of how the Specific Embodiment 1 flexible manner. canbe operated, including in an automatic mode, are shown 2. Extraction Station 100 Assembled (FIGS. 4A-D) at FIGS. 9A-G. The nematode egg extraction instrument 40 canbebroken a) Method ofFIG. 3AApplied to Extraction ofSCN Eggs down into a number of subsystems including linear motor from a Soil Sample sub -systems, gripper arm , washing tool, a set of rotational FIG. 3A is a highly schematic depiction of examples of stage platforms, and grinder tool. FIGS. 4A-D shows the automatically controlled functions for extractionand collec locations of these individual subsystems and how they fit tionstepsaccordingto onewaythatSpecific Embodiment1 10 into theoverallinstrument40. Thelinearmotor subsystems can be configured and operated. As will be discussed in control both the vertical motion of the combined gripper/ detail later, this automated control can be applied tomotion washing tools and their planar rotation, allowing for sieves controlledhandlingofstandard-sized sieves. Oneexampleis as follows. to bemovedverticallyto newpositions andthewashing tool Asample is introduced(step 30A) to afirst#20 sieve (e.g., 15 to access and operate at any ofthose position. The gripper ~800 um openings). The #20 sieve is selected to pass cysts arm assists in this process by grabbing a cylindrical object, and some ofthe dirtby gravity and, optionally, waterrinsing any ofthe sieves, in its fingers and holding it while the (step 30C) and/or vibration (step 30E) from a soil sample linear systems carries out the transfer between turntable onto a #60 sieve (~300 um openings) beneath but block stages. Each turntable stage can contain four sieve retainer larger particles and debris.This isafirst purification or 20 positions (could bemore or less) allowing for up to four extraction step (step 30B) for soybean cyst nematodes. different sieves or the same or different types to be housed Afterapre-selectedtime, the gripperautomaticallymoves on each level of the instrument's stage subsystem . These and grabs the #60 sieve, and automatically moves it into a stages can then rotate to the gripper or washing tool vertical position (step 30F) where a grinder can automatically be axis independent of each other increasing the versatility of converged towards the top ofthe small #60 sieve to gently 25 the instrument as a whole. grind (step 30D) the cysts. This action releases and pushes FIG. 4A illustrates a specific, non-limiting embodiment eggs from the cysts through the small #60 sieve to drop by 40 of the extraction station 28 of FIG. 2B. Its major gravity (and optionally with vibration and/or water assis- subsystems are as follows. tance) onto the top of a #200 sieve (~100 um openings) A framework 41, including a base or floor, has a length , below it. The #200 is sized to block larger debris than the 30 width, andheightthatcanbereasonablyportableandrobust. eggs but allow the chance for smaller items (and any water) In one example it is table-top scale. This would allow the to pass through (step 30G). This essentially is trying to entire integrated extraction station 40 to be mobile such as purify the sample at this point down to just eggs and debris on a pickup truck orthe like. It couldbe taken directly to the of similar or smaller size. At that point the gripper can field from which soil samples are obtained. Of course, can manipulate the #200 sieve and pour its contents to a collec- 35 be scaled up or down depending a need or desire. tionfunnel orconduitforquantification, orfurtherfilteronto The materials used for frame 41 can vary. One example an even smaller sieve (e.g. #500), approx. 20 um openings, for beams is Aluminum Extrusion 10 Series, Part #: 1010-S and the eggs (which are on the order of less than 100 um from 80/20 Inc. of Columbia City, Ind. (USA). See https:// dia.). 8020.net/shop/1010-s.html (incorporated by reference As will be appreciated, this schematic shows the flexibil- 40 herein). Beams are connected by 10 Series 3 Way-Squared ity ofthe embodiment. It canbe varied as to what size sieves Corner Connectors, Part #: 4042 from 80/20 Inc. See https:// and mesh pores are desired, how many sieving steps, when 8020.net/4042.html (incorporated by reference herein). and how to collect, and whether to add ancillary steps such FIGS. 4B-D show various view angles of extraction as grinding. Rinsing and vibration are examples of others. station40 ofFIG. 4A.Aswillbeappreciatedbythose skilled An example of sieves is U.S.A. Standard ASTM Sieves 45 in the art, extraction station 40, in an integrated fashion, Series (e.g. 6 " dia.) available from Humboldt Mfg. Co., provides not only high flexibility but specific functionalities Elgin, Ill., USA. to enhance speed, accuracy, repeatability, and precision of Counting/quantification (step 30H) and storage/commu- extracting SCN eggs from a raw soil sample. As will be nication (step 301) of the count can occur, if desired. further appreciated, variations obvious to those skilled inthe Waste removal (step 30J), rinsing ofall used sieves (step 50 art will be included within this example. The arrangement, 30K) and repositioning of sieves (step 30L) can reset the specific tools, specific operationparameters can be set up as system for a next sample. desired or needed by the designer. b) Apparatus of FIG. 3B Applied to Extraction of SCN Details about each sub system ortool in extraction station Eggs from a Soil Sample 40 follow . FIG. 3B is a block diagram depiction ofone configuration 55 3. Vertical andRotational Control Features ofGripperand of automated control for the processing of FIG. 3A. It Washing Tools (FIGS. 5A-B) illustrates how a programmable control board, by appropri- a. Function ate programming, can control motors which perform the The fundamental functionalities ofcombined gripper and different automatic steps described above. It will be appre- washing tools 50 ofFIGS. 5Aand B are in multiple degree ciatedthat different configurations are possible according to 60 freedomofmovementbymotioncontrol to move sieves and need or desire. to wash sieves. As will be appreciated by details regarding each of the Using motion control, combined tool 50 is positioned in component parts of extraction instrument 40 later in this frame 41 at the periphery of multilevel rotatable turn table description, the fundamental aspect of instrument 40 is the 60. It can interact with any level and position turn table 60, ability to automate sieving actionon araw sampleto extract 65 as well as grab a sieve or sieve-sized container with a raw extremely small items ofinterest for further use. Extraction sample at input andretrieve a sieve andunloaditto an output instrument 40 does this with a combination of carefully container or location.

- 57. US 10,900,877 B1 15 16 b. Apparatus to that action. The designer has flexibility such as building One non-limiting example of combined tool 50 is shown into washing tool 52 custom spray patterns for achieving at FIGS. 5A-H. Variations are possible. needed functions, use ofwater pressure to power rotation of Vertical motion control is accomplished by mounting the the spray arm , and optimized spray pattern forboth rotation combined tool 50 on a linear bearing that moves with the 5 and spray coverage for best results. screw nut of a lead screw or ball screw in a vertical post Controller/software 80 can operate appropriate valving along axis 53. from a pressurized water source to spin spray arm 54. This Non-limiting examples ofprincipal components to allow can enhance a washing action relative to a raw soil sample vertical motion control are as follows: to promote passage ofcysts and eggs through a first sieve of Vertical Linear Motion Control of Both Gripper/Washer 10 #20 mesh size. The washing action of the rotating arm 54 Tool Combination and Turntable. can continually try to influence that action, as well as wash Lead Screw. Part #:634052 from Servocity. Thread Size: off the sides of both the sieve and the hood, to attempt to 8 mm. Length: 24".See URL: https://www.servocity- move all cysts andeggs intheraw sampleto andthroughthe .com /lead-screws# 371 = 326 first sieve, to improve the accuracy of the ultimate quanti Linear Bearing. Part #6415 from 80/20 Inc. See https:// 15 fication. In other words, the design ofwashing tool 52 not 8020.net/shop/6415.html (incorporated byer reference only helps separate, in a first stage, the materials that are or herein ). include the SCN eggs from larger particles, but also ensure Set Screw Shaft, Part #: 625224 from Servocity. Bore: 5 that the whole raw sample is processed at this sieve to mm to 5 mm. See https://www.servocity.com/set- recover as many of the eggs as possible (e.g. not leave a screw -shaft-couplers. 20 significant number stuck to the side ofthe sieve or hood, or NEMA 17 Stepping Motor. Step angle: 1.8º. onthe sieve screen ). Without the same, some canbe retained As can be seen at FIGS. 4A-D, this allows access either along the sieve walls or not pass through the sieves. of the tools to any level of the turn table. As can be further appreciated, washing tool 52 can be c. Features used in other ways. For example, it can provide washing Rotation of the combined tools 50 about axis 53 is 25 action to other sieves to further influence sieving action and accomplished with a rotary geared bearing with onboard promote full collection of articles of interest. motor mounted on the linear bearing that supports both the But furthermore, because station 40 can be used to tools 52 and 56 of combined tool 50. An example is Vex efficiently process, in a serial manner, multiple different turntable bearing kit. See https//www.vexrobotics.com /276- samples, washing tool 52 can also be used to clean or wash 1810.html. This allows eitherthe gripper orwashing tool to 30 out sieves after they are used and prepare them for a next address the turntable at any level or other locations on frame sample. For example, after a first soil sample is processed 41. witha set ofsieves, eachcouldbe serially movedby gripper Therefore, as canbe seen in FIGS. 5Aand B, there is both arm 56 to a position on turntable 50 accessible by washing up/down motion control ofthe combined tool 50 as well as tool 52, andthenproceedto wash each (including by tipping rotational motion control. 35 if needed), to help reset that set of sieves by removing Motion control motors can be operatively connected to artifacts from the last sample which could contaminate the control circuit 80 and, via software, respond to a prepro- next sample, before using the same sieves for the next grammed sequence ofmotion instructions for desired rota- sample. tion and vertical movement. These motions can be con- 5. Gripper Tool Features FIGS. 5C-D trolled to approximately an acceptable degree of precision 40 a. Function for these functions in a repeatable manner. The fundamental use of gripper tool 56 is movement of 4. Washing Tool Features FIGS. 5A-D sieves to, within, and from station 40. Importantly, with a. Functions particular reference to FIGS. 5C and D, an additional The primary function of washing tool 52 is to present freedom ofmovement with motion control is built-in to tool water to any sieve at any accessible location oftool 50. This 45 56. allows not only assistance in sieving actionby moving water It canberotatedaroundahorizontal axis 59 foressentially through material on a sieve but can also help wash offsieve a tilt function. sidewalls during sieving so that items ofinterest are not left Thus, it also has open/close motion control of its jaws behind. Furthermore, it can be utilized to clean out used aroundjaw axes 57 R and L. This allows gripping but also sieves in preparation for processing ofthe next sample. 50 other such things as oscillation during sieving or washing, b. Apparatus dumping or pouring, or otherwise. As shown in FIGS. 5A and B, washing tool 52, in this b. Apparatus embodiment, includes basically a hood enclosing a spray Thejaws oftool 56 are supported on meshed gears, each arm 54. As diagrammatically illustrated in FIG. 5A, spray ofwhich rotates around an axis 57 R or L. A motor driven arm 54 would be in fluid communication with a source of 55 shaft connected to one ofthe gears allows motion control of pressurized water. On/off and flow rates can be controlled one gear. Because they are meshed, they work together, and through control circuit 80. Tubing would be long enough to oppositely, for the open/closemovement. allow for up/down and rotation of tool 52. Tool 56 is carried on a base mounted on gear 58 that c. Features rotates around axis 59 relative to the linear bearing that The washing tool canhave a diameterthat fits over any of 60 moves up and down the vertical post of the combined tool the sieves' upper lip to retain spray when installed over a 50. By motor and drive gear attached to that linear bearing sieve. (see FIGS. 5C and D), the larger gear 58 responds to rotate Nozzles 55 (FIG. 5B) on a spray arm can be designed to thewhole grippertool 56 aroundaxis 59 forthetilt function. direct a spray pattern that, by reaction forces on the interior It can include 360° rotation in either direction. ofthe hood, causes arm 54 to spin on its own. This can also 65 c. Features distribute the spray in an effective pattern to continuously Inside profiles of the gripper jaws are specifically cleanthe sieve sides. Spray arm 54 freely rotates inresponse designed with a wavy profile to help center a sieve that is

- 58. 10 15 30 US 10,900,877 B1 17 18 grasped by the gripper. Minor variations in sieve diameters c. Features are possible. Most sieves have a top edge lip that would Each level 62 has multiple receivers designed to each allow the gripper arms to open and that close around the receive and hold a sieve 27. In this example there are four diameter ofthe sieve body, while the larger diametertop lip differentreceivers 64 pertray 62. That canvary andbemore is a mechanical stop against the sieve falling through those 5 or less than four. Each level thus can hold four sieves in this closed arms when sufficiently closed. embodiment. But it is noted that not all receivers need to The gripperjaws can open sufficientlyto laterallypass by holda sieve for a cycle ofoperation ofextraction station40. the greatest diameter of the sieve and then close to gently Thejaws ofeach receiver 64 are fixed to allow a sieve to surround a sieve yet retain it for vertical movement or be dropped vertically into the complementary space ofeach tipping purposes. The jaws are then reopened to slide pass receiver. the greatest diameter of the sieve and release it in a given As can be appreciated, the number of levels 62 and the position. numberofreceivers64 canvaryaccordingtoneedordesire. Non -limiting examples ofcomponents that can be usedto In this example, three levels are used with four sieve implement the foregoing for gripper 56 are as follows: receivers each, which is deemed sufficient for processing 1.00 " Bore 32 Pitch Aluminum Hub Gears. Part #: 615234 SCN cysts and eggs according to the present embodiment. from Servocity. Diameter: 3.125". Number of Teeth: As can be further appreciated, each receiver 64 and each 100. See https://www.servocity.com/32p-1-00-bore level 62 cooperates with gripper tool 56 such that any aluminum -hub-gears (incorporated by reference receiver 64 canberotatedto have its center axis alignedwith herein 20 the center axis between the gripperjaws when gripper tool Motor. S3305 Servo from Servocity. Specifications: 56 is appropriately rotated. This allows gripper tool 56 to Dimensions: 1.6 "x0.8 "x1.5" (41x20x38 mm ). Product place orremove a sieve from any receiver 64 from any level Weight: 1.64 oz. (46.5 g). Output Shaft Style: 25 Tooth 62 by correlated vertical movement and rotation of the (3F) Spline. Voltage Range: 4.8V-6.0V. Stall Torque whole turntable 50. (4.8V): 99 oz/ in. (7.1kg.cm ). Stall Torque (6.0V): 124 25 Likewise, washing tool 52 can be operatively positioned oz/in . (8.9 kg:cm ). PulseAmplitude: 3-5V. MotorType: on center to any receiver 64. 3 Pole Ferrite. Potentiometer Drive: Indirect Drive Output Shaft Support: Dual Ball Bearings. See: https:// Non-limiting examples ofcomponents that canbe usedto www.servocity.com/s3305-servo (incorporated by ref achieve the foregoing functions include: erence herein ). Turntable Stage System 1/4 " Stainless Steel Precision Shaft. Part #: 634160 from Motor. Vex Robotics, 2 -wire Vex Motor 393. See https:// Servocity. Length: 2". See: https://www.servocity.com/ www.vexrobotics.com/motors. html (incorporated by 0-250-1-4-stainless-steel-precision-shafting#371=246 reference herein). Specifications: Free Speed:100 rpm . 5 mm Bore 32 Pitch, 16T Shaft Mount Pinion Gear. Part Stall Torque:1.67 N-m (14.76 in-lbs). Stall Current: #: 615342 from Servocity. Number of Teeth: 16. See 35 4.8A. Free Current:0.37A . https://www.servocity.com/5 mm-bore-32p-16t-shaft mount-pinion -gears. Vex Turntable Bearing Kit. See https://www.vexrobotics. com /276-1810.html Swivel Hub. https://www.servocity.com/swivel-hub. 0.770" Pattern Set Screw Hubs. Bore: 14". https://www.s- Used in: Linear Motor System, Turntable Stage System ervocity.com/770-set-screw-hubs 7. Grinder Tool Features FIGS. 7A - B 12" Bore 32 Pitch Aluminum Hub Gear. Part #: 615190 a. Functions from Servocity. Diameter: 1.5". Number of Teeth : 48. https://www.servocity.com/32-pitch-50-bore-alumi- The primary functions ofgrinder 70 are to provide rotary num -hub-gears. press action on top of material on a sieve. In the specific As will be appreciated, the open/close and tilt functions 45 exampleofSCN, itis particularlyvaluableininfluencingthe can be accomplished in other ways. bursting of the cysts to release their eggs. By bringing a 6. Turntable Stages Features FIGS. 6A-B rotating grinding pad 72 towards the sieve screen, calibrated a. Function to come no closer than a minimum distance, the rotary Theprimary function ofturntable 60 is to providevertical grinding andup-and -downpressing action onthe cysts have co-location of sets of sieves of increasinglysmaller screen 50 been found to promote such egg release. size. To do so, turntable 60 is designedto rotateplural levels In the present embodiment, grinding system 70 can both 62 T, M, and B (FIG. 6B) around a vertical axis 63. As will provide grinding pad rotary motion around axis 73. But it be discussed below, programmed sequenced operation, by can also, through a gearing arrangement, provide up/down motion control, allows manipulation ofa set ofsieves 27 for movement of pad 72. this purpose. b. Apparatus b. Apparatus The nonlimiting example of a turntable in FIGS. 6A and As indicated in FIGS. 7A and B, both rotation and B shows how each level 62 can be mounted on its own linear up/down movement of pad 72 are accomplished through bearing along vertical post. In a similar fashion to up/down mechanical means. A motor provides rotary action that can movementofcombinedtool 50 onitsverticalpost, asimilar 60 beconvertedbygearingtothepadrotation. Itcan also have rotary geared and motorized bearing could be operatively a controlledup and downtravel range. This canbe calibrated installed onthe linearbearing at each level 62. Motors could relative to a grinding vertical axis generally along 73 to turn the entire combination in synchronization. Alterna automatically move down into a sievebutnot getcloserthan a minimum distance. tively, each level 62 could have independent rotation. FIG. 6A shows this embodiment has four sieve receiving 65 One non-limiting example is utilization of essentially a jaw sets 64 (1)-(4) at each level 62. Eachreceiver 64 is sized drill press. This provides both rotary and up/down move to receive and hold a sieve 27. ment at its working tool end. 40 55