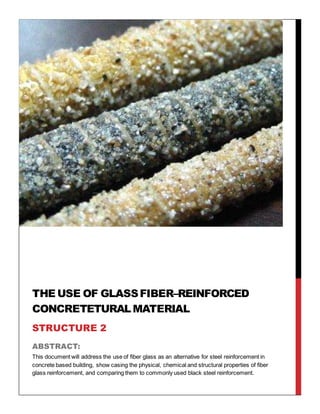

Fiber glass reinforcement

- 1. ABSTRACT: This document will address the use of fiber glass as an alternative for steel reinforcement in concrete based building, show casing the physical, chemical and structural properties of fiber glass reinforcement, and comparing them to commonly used black steel reinforcement. THE USE OF GLASSFIBER–REINFORCED CONCRETETURALMATERIAL STRUCTURE 2

- 2. 1 THE USE OF GLASSFIBER– REINFORCEDCONCRETETURAL MATERIAL STRUCTURE 2 1. INTRUDUCTION: As the lack of steel resource and high cost of infrastructure mount interest in corrosion-resistant reinforcement continually grow, the need for a suitable and available substitute. The potential for using a glass fiber reinforced concrete system was recognized by Russians in the 1940s. The early work on glass fiber reinforced concrete went through major modifications over the next few decades. Many experiments on fiber reinforced concrete with steel fibers and synthetic fibers have Been conducted to obtain fundamental properties of mortar and concrete reinforced with glass fibers, such as tensile and compressive properties. Effect of fiber content on these properties was examined and some problems were theoretically discussed. 2. GFRC HISTORY AND APPLICATION GFRC was originally developed in the 1940’s in Russia, but it wasn’t until the 1970’s that the current form came into widespread use. Commercially, GFRC is used to make large, lightweight panels that are often used as façades. These panels are considered non-structural, in that they are designed to support their own weight plus seismic and wind loadings, much in the way glass window curtain walls are designed. The panels are considered lightweight because of the thinness of the material, not because GFRC concrete has a significantly lower density than normal concrete. On average it weighs about the same as ordinary concrete on a volume basis. Façade panels are normally bonded to a structural steel frame which supports the panel and provides connection points for hanging. GLASS FIBER REINFORCED CONCRETE (GFRC) Is a type of fiber reinforced concrete, mainly used? In exterior building facade panels and as architectural precast concrete. Glass fiber reinforced composite materials consist of high strength glass fiber embedded in a cementation matrix. In this form, both fibers and matrix retain their physical and chemical Identities, yet they produce a combination of properties that cannot be achieved with either of the components acting alone.

- 3. 2 3. GENERAL DATA AND FIBER TYPES In order to make glass fibers resistant to the lime generated during the setting of Portland cement, zirconium is added to the glass mixture composition prior to melting and fiberizing the raw materials. The added zirconium becomes part of the glass fiber molecular structure in the Manufacturing process i.e.; it is not just a protective coating. The minimum zirconium content in the composition for good durability is about 16% by weight. The glass fibers with this zirconium modification are usually referred to as alkali-resistant glass fibers or AR glass fibers. AR glass fibers are chemically stable resisting both alkali and acid conditions. Chemical composition of the AR glass fibers is shown in Table 1 and the physical and mechanical properties in Table 2. Table 1- Chemical composition of AR-glass fibers, percent by weight (PCI MNL-128-01) Table 2- Properties AR-glass fibers (PCI MNL-128-01) 4. PRODUCTION OF GRC Production of GRC with homogeneous characteristics requires a strict quality control, at the production stage and in the final products. The European Standard EN 1169 or the International Glass fiber Reinforced Concrete Association provide fundamental guidance and establish the general rules for production of GRC. There are two main production techniques of GRC. 4.1. Spray Up: The mortar is produced separately from the fibers, which are mixed only at the jet of the spray gun. The glass fiber strands are cut within the spray gun to the required size, typically between 25 mm (0.98 inch) and 40 mm (1.57 inch), and are about 5% of the GRC total weight. The subsequent compaction with a cylindrical roll guarantees the adaptation of GRC to the form, the impregnation of the fibers within the mortar, the removal of the air retained within the mix, and an adequate density. Component AR-glass SiO2 61.0-62.0 Na2O 14.8-15.0 CaO - MgO - K2O 0.0-2.0 Al2O3 0.0-0.8 Fe2O3 - B2O3 - ZrO2 16.7-20.0 TiO2 0.0-0.1 Li2O 0.0-1.0 Property AR-Glass Specific Gravity 2.70-2.74 Tensile Strength, MPa [psi] 1700 [2.5 x 105] Modulus of Elasticity, GPa [psi] 72 [10.4 x 106] Strain at Break, % 2.0

- 4. 3 4.2. Pre-Mixture: Mortar and precut fibers are previously mixed. The quantity of fibers added to the mortar is usually up to 3.5%, in terms of weight, and the length of the fibers is around 12 mm (0.47 inch). Longer fibers lead to an excessive reduction of the mix’s workability. Production with premix GRC may involve several procedures such as injection and vibration, pressing, or shotcreting. 5. STRUCTURAL PROPERTIES OF GFRC GFRC derives its strength from a high dosage of AR glass fibers and a high dosage of acrylic polymer. While compressive strength of GFRC can be quite high (due to low water to cement ratios and high cement contents), it has very high flexural and tensile strength that makes it superior to ordinary concrete. Essentially the high dose of fibers carries the tensile loads and the high polymer content makes the concrete flexible without cracking. 6. ADVANTAGES OF GFRC 6.1. Lightweight GFRC, thin yet strong, weighs 80% to 95% less than solid concrete. This makes it easier and faster to install and reduces the load on the buildings structure. The lighter weight and stronger material also save transport costs, allows more design freedom and, by using less material, reduces environmental impact. 6.2. Superior Strength GFRC is strong. For GFRC panels, this means it has the proven ability to withstand seismic loads and hurricane winds. For architectural elements, stronger means less chance for damage, easier to install and longer lasting. 6.3. Durable GFRC lasts. It is less susceptible to weather erosion and more freeze thaw resistant than conventional concrete. The use of glass fibers for reinforcement rather than steel means it cannot rust and can even be used under salt water and in marine environments. 6.4. Beautiful GFRC provides the look and feel of natural stone, architectural precast concrete, terra cotta, wood or smooth panels. It allows the designer more freedom in shape, color and texture than any material. 6.5. Naturally Friendly to the Environment GFRC has a much lower environmental impact than conventional concrete, stone or other materials. Made with minerals: cement, aggregates, glass fibers and, in some

- 5. 4 cases mineral pigments and special polymers, GFRC is designed to be long lasting and earth friendly. 7. DISADVANTAGES OF FIBERGLASS REINFORCED CONCRETE 7.1. Ductility There is no ductility. Ductility is a solid material’s ability to deform under stress. 7.2. Cost The cost of GFRC is higher than traditional concrete. Due to the fiberglass being inside the concrete and the addition of additives and acrylic co-polymer the price is steeper. 7.3. Self-Mix GFRC is difficult to self-mix. Generally, a contractor will mix and pour or spray this type of concrete. 7.4. Workability Greater reduction of workability. 8. COMPARISON BETWEEN BLACK STEEL AND (GFRP) Black steel is inexpensive and commonly used. It’s a great reinforcement to use if you are not responsible for the long-term maintenance of a concrete structure. 8.1. Tensile & Shear Properties Tensile modulus 6 to 7.2 x 106 psi Modulus of Elasticity > 8000 ksi Compressive strength >60 ksi Transverse Shear strength >20 ksi Table 3- Mechanical Properties 8.2. Bond, CTE & Absorption Bond strength* >1,200 psi / *Grit-Coat >2,200 psi CTE :5.2x 10-6 IN. In./°C Specific gravity <2.0 Yield >100,000 psi Density <0.074 lb/in.3 Water absorption <0.25% Fiber Content >70% Table 4- Corrosion Resistant Chart

- 6. 5 8.3. Fatigue Bridge deck studies simulating heavy traffic over concrete slabs have concluded that properly reinforced GFRP rebar slabs Experience 2.5 times less cracking than steel reinforced slabs Last 20 times longer than steel reinforced slabs when exposed to heavy fatigue loads Researchers believe that this is due to the differences in the modulus of elasticity between GFRP and steel. GFRP has a modulus very similar to concrete. Steel’s modulus is many times higher. Steel is less forgiving than GFRP. Damage occurs to concrete as steel bends within the pour. Table 5- Bridge Deck Slab Exposed To Cyclic Fatigue Loads 8.4. Cost Cost Comparison GFRP to Plain Black Steel October 2009The largest price variance between GFRP and black steel occurs when you compare the lowest grade black steel to rebar GFRP rebar. Depending on volume, a #3 10 mm plain black steel Grade 40 rebar can be 1/3 the cost of a #3 10mm fiberglass rebar. As the diameter of the bars increase this gap narrows to a point where a #8 22 mm plain black steel bar is only slightly less expensive than #8 22 mm fiberglass rebar. In some applications less concrete cover and reduced water proofing costs result in lower initial project cost.

- 7. 6

- 8. 7 9. CONCLUSION: Fiberglass rebar (GFRP) is a cost effective way to: Eliminate fundamental and expensive repair problems created by black steel reinforcement. Maintain cosmetically attractive structures over time (less cracking and ugly rust staining) resulting in higher property resale values. Reduce concrete cover and corrosion protection measures taken to protect black steel rebar. Ensure your structures will last up to 4 times longer eliminating expensive capital expenditures over time. Make slabs exposed to cyclic loads last 20 times longer than steel reinforced slabs. Fiber reinforcement is a common method to increase the mechanical properties of materials. GFRC does not replace reinforced concrete when true load carrying capacity is required. It’s best used for complex, three dimensional shells where loads are light. Generally fibers do not increase the flexural strength of concrete, and so cannot replace moment resisting or structural steel reinforcement. 9.1. REFRENCES Introduction to GFRC (Glass Fiber Reinforced Concrete) / Jeffrey Girard GFRC – 30 Years of High Fiber Cement Composite Applications Worldwide / Graham T Gilbert NRC Research Press / David T. Johnson and Shamim A. Sheikh Mechanical Properties of Glass Fiber Reinforced Concrete / Muna M .Abdullah & Eman K.Jallo THE USE OF GLASS FIBER–REINFORCED CONCRETE AS A STRUCTURAL MATERIAL / J.P.J.G. Ferreira and F.A.B. Branco Sustainable Concrete Solutions / FRP Distributors Inc.

- 9. 8 CONTENTS Abstract:...................................................................................................................................................... 0 1. Intruduction: ......................................................................................................................................... 1 2. GFRC History and Application ............................................................................................................ 1 3. General Data and Fiber Types ............................................................................................................ 2 4. PRODUCTION OF GRC ..................................................................................................................... 2 4.1. Spray Up:...................................................................................................................................... 2 4.2. Pre-Mixture:.................................................................................................................................. 3 5. Structural Properties of GFRC ............................................................................................................ 3 6. Advantages of GFRC........................................................................................................................... 3 6.1. Lightweight ................................................................................................................................... 3 6.2. Superior Strength ......................................................................................................................... 3 6.3. Durable......................................................................................................................................... 3 6.4. Beautiful........................................................................................................................................ 3 6.5. Naturally Friendly to the Environment.......................................................................................... 3 7. Disadvantages of Fiberglass Reinforced Concrete ............................................................................ 4 7.1. Ductility......................................................................................................................................... 4 7.2. Cost.............................................................................................................................................. 4 7.3. Self-Mix......................................................................................................................................... 4 7.4. Workability.................................................................................................................................... 4 8. Comparison between Black Steel And (GFrp) .................................................................................... 4 8.1. Tensile & Shear Properties .......................................................................................................... 4 8.2. Bond, CTE & Absorption.............................................................................................................. 4 8.3. Fatigue.......................................................................................................................................... 5 8.4. Cost.............................................................................................................................................. 5 9. Conclusion:.......................................................................................................................................... 7 9.1. Refrences......................................................................................................................................... 7 Done By: Saad Dahleh