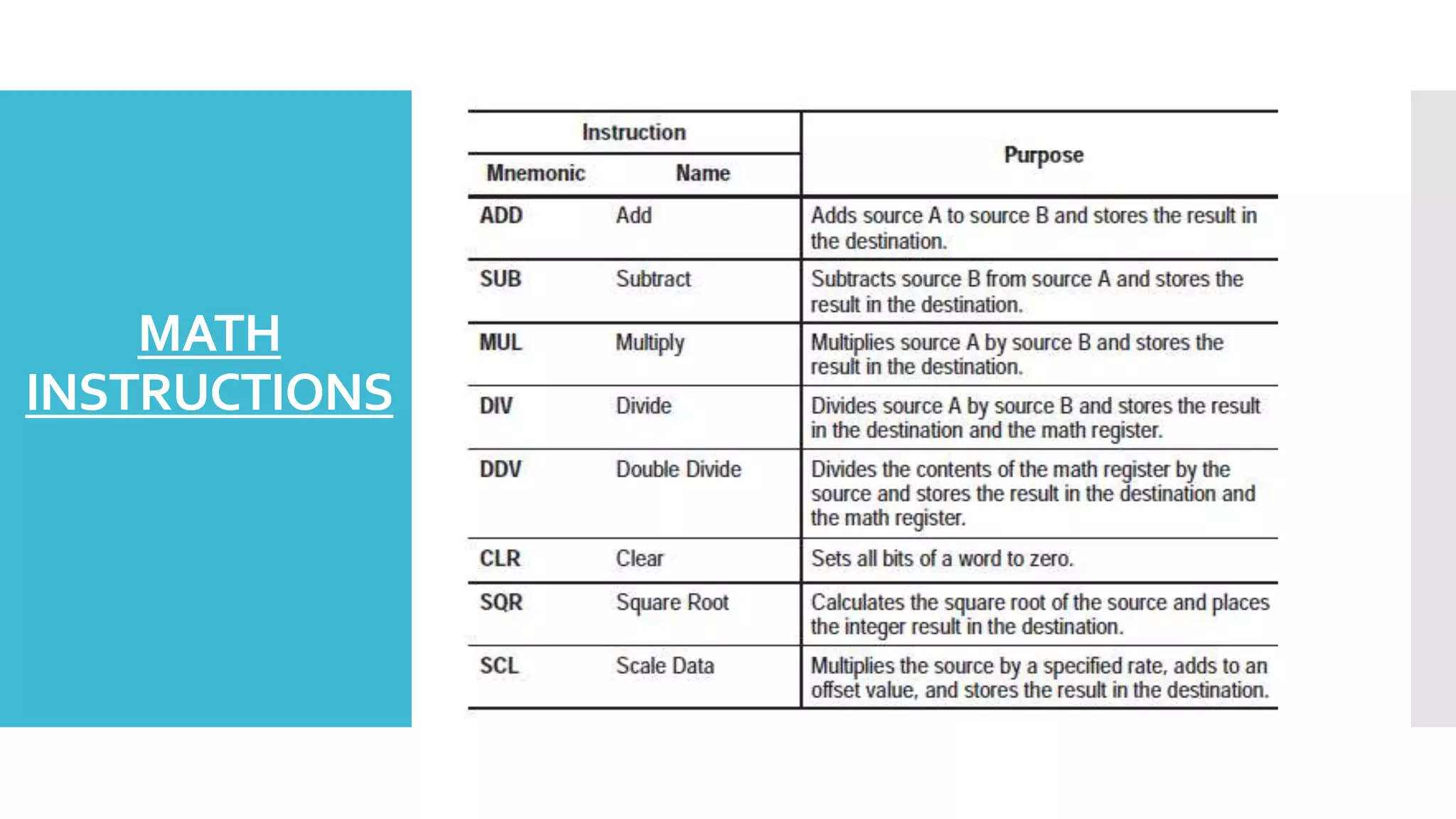

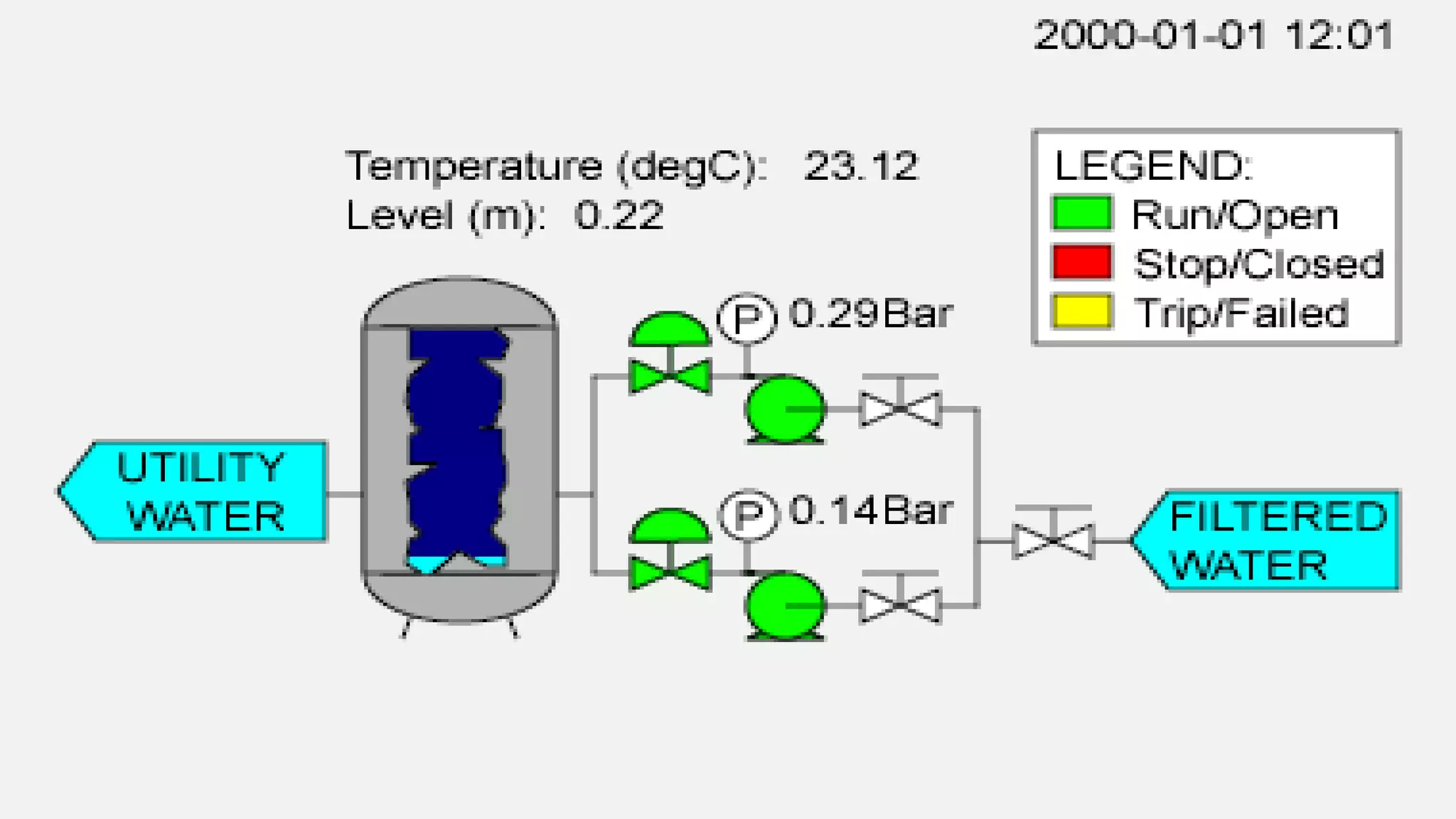

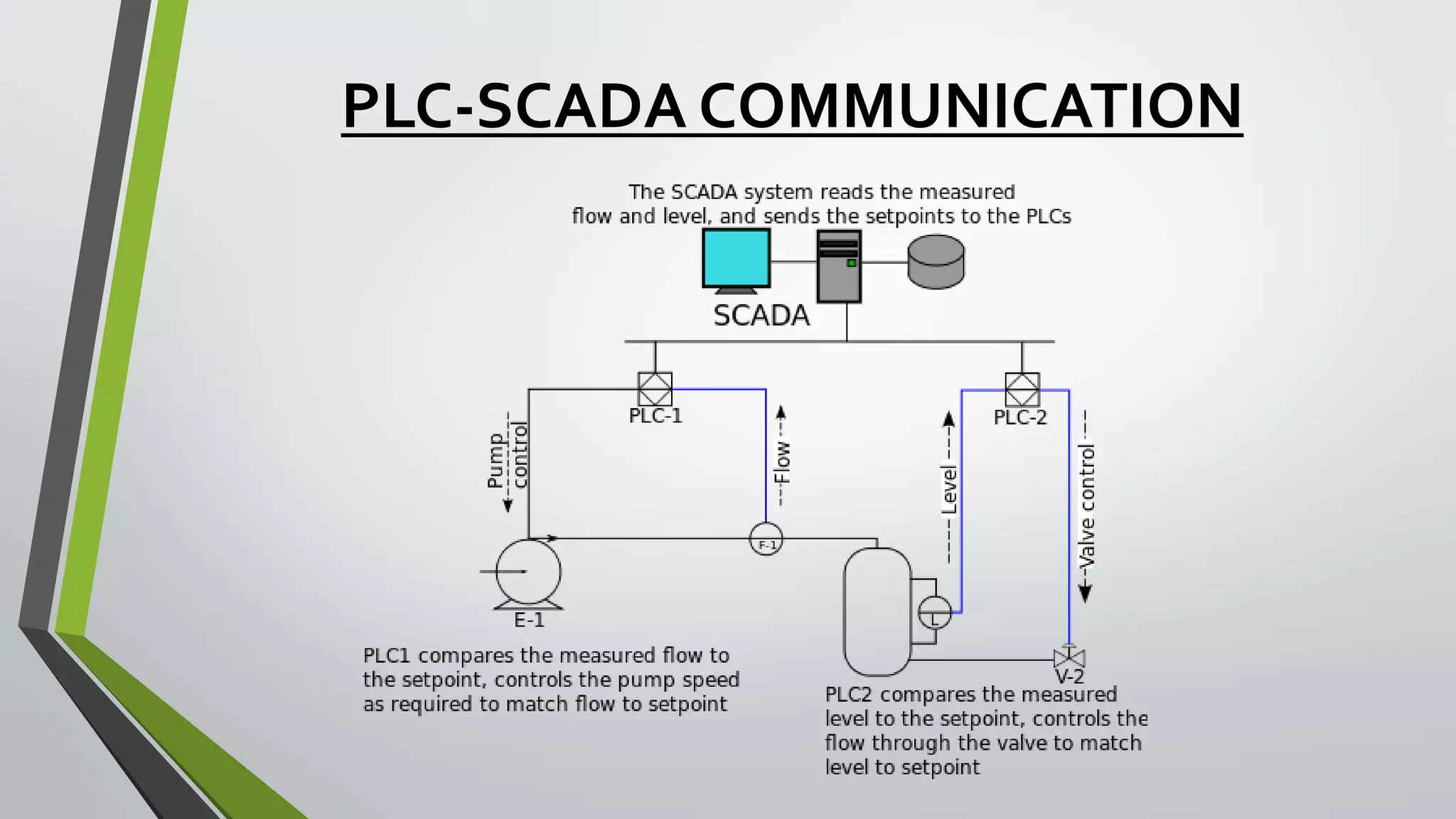

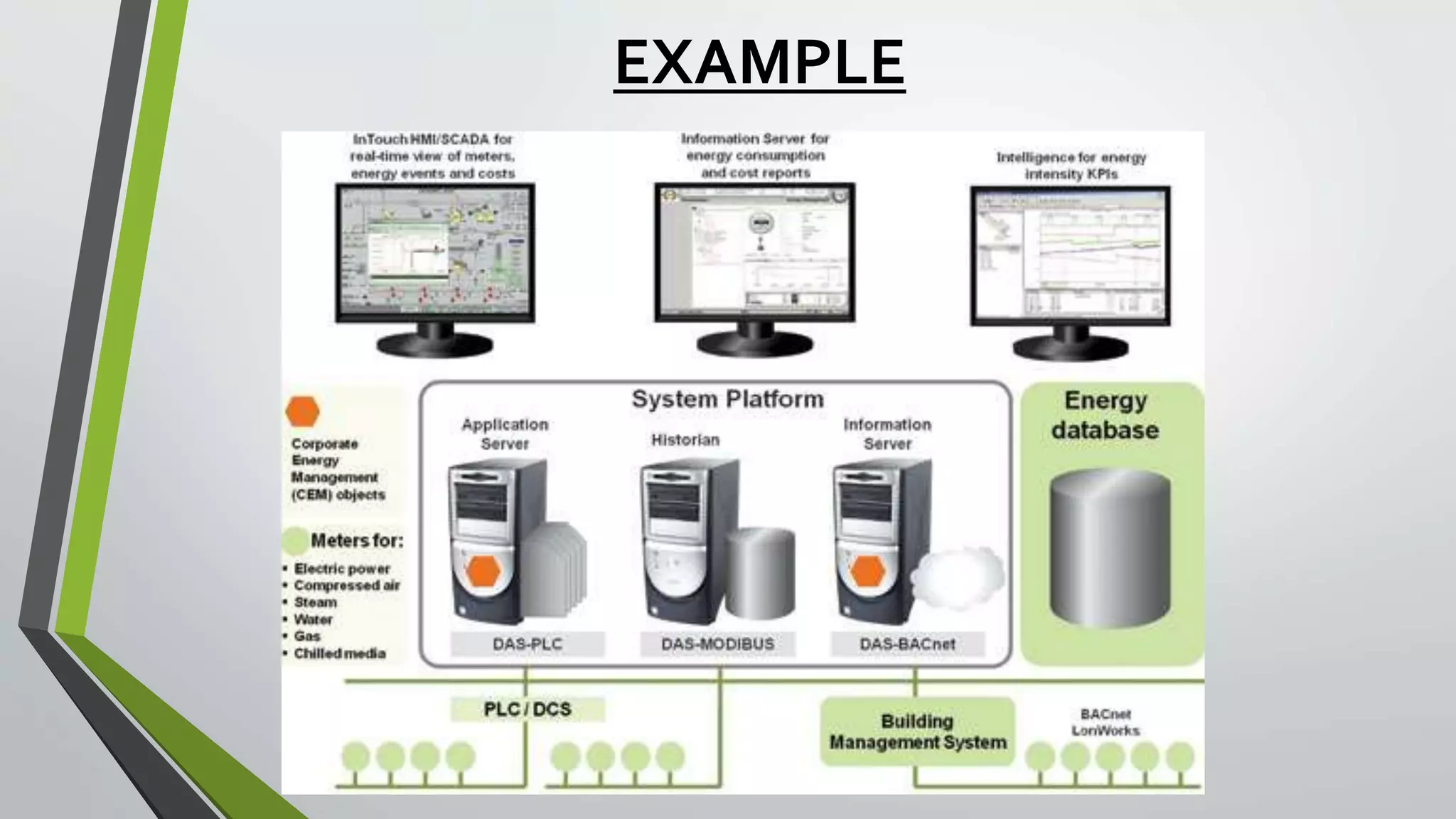

This document provides an overview of programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems for industrial automation. It discusses what automation is and common types of control systems, focusing on PLCs and the Micrologix 1000 PLC in particular. The document outlines PLC hardware, programming, applications, and how PLCs connect and communicate with SCADA software like Intouch Wonderware to allow monitoring and control of industrial processes.