Unit iii 8 feb

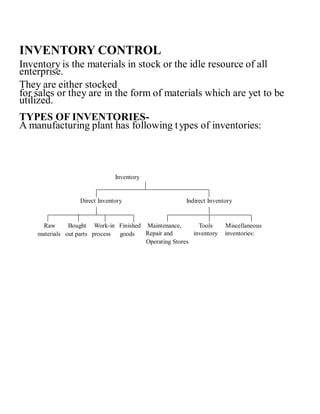

- 1. INVENTORY CONTROL Inventory is the materials in stock or the idle resource of all enterprise. They are either stocked for sales or they are in the form of materials which are yet to be utilized. TYPES OF INVENTORIES- A manufacturing plant has following types of inventories: Inventory Direct Inventory Indirect Inventory Raw Bought Work-in Finished Maintenance, Repair and Operating Stores Tools inventory Miscellaneous inventories:materials out parts process goods

- 2. Direct Inventory: Direct inventory is that inventory which becomes the part of the final product. e.g. Pipes, Channels in a fabricated item; cloth thread and buttons etc. in a readymade garment. Indirect Inventory: Indirect inventory is that inventory which does not become a part of the final product. e.g. Stationery items, oil and lubricant for the machine etc. (i) Raw materials: are those which have not undergone any operation since they are received from the suppliers such as pipes, channels etc. (ii) Bought out parts: are finished parts, subassemblies purchased from outside as per the company‟s specifications. (iii) Work-in-process inventories (WIP): are semi-finished products at the various stages of manufacture. (iv) Finished goods inventories: are the completed products ready for dispatch. (v) Maintenance, Repair and Operating Stores: are consumed in the production process, such as oil, grease etc. (vi) Tools inventory: such as standard tools and special tools. (vii) Miscellaneous inventories: are office stationeries and other consumable stores.

- 3. 2. Maintain smooth and efficient production flow. 3. Take advantage of quantity discounts. 4. Utilize the advantage of price fluctuations. 5. Have effective utilization of men and machinery. 6. Guard against scarcity of materials in the market. Need of Inventories Inventories are needed to:

- 4. PROCUREMENTAND CONSUMPTION CYCLE Let us assume that a material is consumed at an uniform rate throughout th4e year. Let the quantity of butter stock kept in the stores I „B‟ units. When ordered, the material is received in one lot. For the above conditions, the consumption and procurement cycle is shown in the figure . SafetyStock Lead Time Procurement and Consumption Cycle ( Dr. S. Seetharaman) In the beginning, the stock of quantity Q is available. It is consumed at uniform rate. So the level of stock goes on reducing. When the stock reaches the reorder level (C), action is taken for purchase. The quantity ordered will be equal to EOQ. The stock goes on reducing. When the stock reaches the safety stock level (B) , the material is received in a lot. So the total stock increases to the original level. From the figure we can see that Reorder level= Safety stock + Lead time consumption. Even when the supplier does not supply the material in time, production will not be affected for want of material. This is because; material can be issued from the safety stock. This is shown in the figures by the line DD. Minimum Stock or Buffer Stock or Safety Stock The buffer stock is the minimum quantity of stock which should be available in the stores. This stock is kept as a reserve for emergency use. When the material is not received in time from/the supplier the buffer stock can be used. In figure 8.3 the buffer stock is shown as B units. The quantity of buffer stock in stores depends upon the following: 1. Reliability of the supplier. 2. Transporting facilities. 3. Fluctuations in the rate of consumption of material. Re order Level

- 5. Lead Time This is also known as procurement time. This is the total time taken from the time stores sends its purchase requisition to the purchase department, to the time the material is taken into stock in the stores. Lead time includes the time taken for the following activities. 1. Sending the purchase requisition by stores department. 2. Calling for quotation and approval. 3. Placing the purchase order. 4. Delivery time taken by the supplier. 5. Transportation of material. 6. Receiving material at the company. 7. Inspection of material received. 8. Entering the material into stock. Reorder Level This is the level of stock in stores at which a purchase requisition is placed to procure material. The reorder level is minimum stock plus the lead time requirement. When this level is reached, the store keeper sends a purchase requisition to the purchase department. In figure the reorder level is C

- 6. 1. Static Inventory Models: It is applicable where only one order can be placed, due to perishable or seasonal nature of items (Coolers, Fidge, Umbrellas). 2. Dynamic Inventory Model: In this repeat order can be placed Further classified into two:- a) Deterministic Model: These models are based on the assumption that the demand as well as lead time are deterministic. b) Probabilistic Models: These models take into account the variation in demand and lead time of an item. INVENTORYCOSTS INVENTORY MODELS The inventory control models are based on different types of inventory costs. These costs can be grouped as follows: (1) Purchase cost: is unit purchasing cost for availing the price discount and is expressed in Rs. Per unit. (2) Capital cost: is the amount of capital not available for other purchases. (3) Ordering cost: This cost includes the expenses on the following functions: (i) Calling quotations. (ii) Processing quotations. (iii) Placing purchase orders. (iv) Receiving and inspection of materials. (v) Verifying and payment of bills. vi) Order incidental charges, etc.

- 7. If Co is the cost of placing an order, D is the annual demand, and Q is the ordered quantity Then no. of orders placed in a year = D/Q, Total Ordering cost for the year = Co x D/Q Ordering quantity Inventory carrying costs or holding costs: This cost includes the following expenses: (i) Insurance of goods during storage. (ii) Storage and handling within stores. (iii) Obsolescence and depreciation. (iv) Deterioration. (v) Taxes. (vi) Interest, etc. This cost varies between 10% to 20% of the product cost. Carrying cost are directly proportional to ordered Quantity and expressed as percentage of unit cost. If Cu is the purchase cost per unit, and “i” is the carrying cost in percentage per unit Then Annual cost per unit = Cu . i Annual carrying cost = Cu x i x Q/2 Ordered Quantity Shortage Cost: It is due to item needed not being in stock. The shortage costs include backorder costs, loss of future sales, loss of customer goodwill, etc.

- 8. Economic Ordered Quantity (EOQ) Economic ordered quantity is that quantity which minimizes the total cost. The total cost is the sum of fixed cost and variable cost. Fixed cost is independent of ordered quantity while variable cost is dependent on ordered quantity. Inventory Model Considering Quantity Discount The basic EOQ model is based on the assumption that the price per unit is fixed irrespective of the order quantity .Sometimes suppliers offer quantity discount if large quantities are purchased. Quantity discount reduce the material cost and procurement cost but increase the inventory carrying cost. MATERIALPURCHAGE Material management consists of process of integrating the activities involved in acquisition and utilization of materials required in the production of final product. Purchasing is the first phase of material management. Purchasing is responsible for getting the right material, from right place, in right quantity, at right time and at right price. Purchase Procedure The purchase procedure consists of the following stages: 1. Receipt and analysis of requirements from different departments and processing the requisitions. 2. Selection and location of potential suppliers. 3. Request, receipt and analysis of quotations. 4. Placing of orders. 5. Expediting and following of purchase orders. 6. Verification of vender‟s invoices for payments after processing discrepancies and rejection. 7. Closing of completed orders and maintenance of records. Methods of Purchasing The following are some popular methods of purchasing: 1. Purchasing according to requirements-Hand to mouth purchasing. 2. Purchasing for some specified future period. 3.Market purchasing. 4. Rate contract purchasing. 5. Central purchase organization. 6. Rate contract through D.G.S. and D. 1. Hand to Mouth Purchase: used in a job order system, material requirement is worked out after receipts of order. No inventory is kept. This system has the advantage of less capital requirements. 2. Purchasing for Specified Future Period: There are standard items which are consumed regularly. The volume of consumption is low and price fluctuation is not much. These items are purchased and are available as soon as some order is received. 3. Market Purchasing: Market purchasing helps to take advantage of price fluctuations. The purchasing is related to price fluctuations and not production needs. There can be loss to the organization if price fluctuation assessment is wrong.

- 9. 4. Rate Contract Purchasing: The organization enters into agreement with various vendors to supply goods in future periodically on rate contract basis. This method is used for purchase of large quantities of basic raw materials, like coal, pig iron, paints, cables, etc. 5.Central Purchase Organization: Large government and private organizations have central purchase system. The requirements from various departments, shops and sections are collected. The central purchase can be carried out at cheap rates and better bargain. 6. Rate Contract through D.G.S. and D.: The various government departments and other firms can place orders for the supply of requisite materials at the contract rates approved by D.G.S. and D. STORE KEEPING Storekeeping is the physical storage of goods and materials. The main objectives of storekeeping are: 1. To make available a balanced flow or raw materials, components, tools, equipments and other goods necessary to meet operational requirements. 2. To level out irregularities in purchasing. 3. To offset delays in transportation. 4. To provide maintenance materials, spare parts and general stores as required. 5. To add flexibility to production schedule. 6. Permit quarterly purchases which bring lower prices. 7. To ensure right time delivery of finished goods to the customer. The stores control the stocks and ensure availability of right amount of materials at right time. The manufacturing departments are not involved with the stock control. FUNCTIONS OF STORES DEPARTMENT The following are the main functions and duties of stores department. 1. Identification: Preparation of a code or vocabulary identifying and standardizing of all stocks. This can be done in collaboration with design, planning and purchase departments. 2. Receipt: Acceptance of all materials and components used in the organization for manufacturing, maintenance, office, capital goods and finished products. 3. Inspection: Inspection of all incoming consignments for quality either by inspection department or stores department. 4. Issue and Despatch: Receiving demands, selecting the items and handling over to users. Also packing of items and loading of vehicle with goods for delivery. 5 Stock Records: Preparation of documents for recording of individual receipts, issues and balance of stock on day-to-day basis. 6. Stores Accounting: Process of recording details of stocks movement and balance in valuses. This can be done either by finance department or stores department. 7. Stock Control: Continuously arranging issues a receipts to ensure stock balances are adequate to support the current rate of consumption. 8. Stock Taking: Physical verification of quantities and conditions of goods in store houses and stock yards. 9. Storage: Management of store houses and stock yards to ensure proper handling, storage, safe custody and protection of stock CODIFICATIONAND STANDARDIZATION

- 10. Standardization Standards are documents containing a set of conditions to be fulfilled. These are technical publications stating the manufacturing of materials and produces, their measurement, testing and description. Industrial standardization is used: i. ii. iii. iv. To achieve interchangeability or parts. To lay down the standards of performance of men, materials and tools. To reduce a line of product to a fixed form, size and characteristics. To establish standards of excellence and quality of materials. The standards may be formulated at the following levels: i. ii. iii. iv. v. Individual standards for a dam, house, building, furniture. Companystandards for design, purchase and manufacture of a product. Industry standards for a trade or profession. National standards within a country, i.e., ISI. International standards between independent sovereign nations, i.e., ISO. Types of Standards 1. 2. 3. 4. 5. 6. Dimensional standards to ensure interchangeability of parts. Material standards for specification of raw material. Quality/Performance standards of finished products. Technical terms and symbols for a common technical language. Code of practice for operation and maintenance, i. e. , turbines, transformers etc. Safely standards for men, machines and materials, i.e., Boiler Code, FactoryAct, 1948. Advantages of Standards The following advantages can be achieved by standardization in different fields. 1. 2. 3. 4. 5. 6. 7. Purchasing of materials, parts and supplies. Engineering practices and procedures. Manufacturing processes. Marketing: Sales procedures and techniques. Office management: standard office procedures and practices. Top management: standard policies. Sales: Export market. Codification Allocation of symbols for correct classification is called codification. Codes are identification marks, symbols or references used for classification. Basic Requirements 1. 2. 3. 4. 5. Code should be as simple as possible. Use numerals for codes, i.e., telephone numbers. Codes should be unique. Coding and decoding should be easily understandable. Codes should be flexible to meet future alterations. Coding Systems The coding may be done in one of the following steps: 1. Serially: A serial identification register is prepared. 2. Sequentially: The codes are given in blocks and in sorted form. Metal sheets: 10,000 to 19999 Nuts and bolts: 20,000 to 29999

- 11. ABC Analysis divides inventory into three groups in terms of %age of no. of items and % age of total value. It is based on Pareto Analysis. In this system important items (high value items) are grouped in A, While trivial (low usage value) items are grouped in C and the remaining middle level items are considered B items. The inventory is controlled on the principle of “Management By Exception”, i.e. rigorous control over A items and routine loose control over C items, and moderate control over B items. The items are classified by virtue of their uses ABC Analysis:

- 12. Category %age of items (approx.) 10% 20% 70% %age value (approx.) 70% 20% 10% A High value items B Medium value items C Low value items Steps in ABC analysis: 1. 2. 3. 4. 5. 6. Calculate annul usage in units for each item. Calculate annual usage of each item in terms of Rupees. Rank the item from highest annual usage to lowest annual usage in Rupees. Compute total value. Find %age of high, medium and low valued items. A graph can be plotted between %age useful of on X axis and %age of total value of item on Y axis. Controlling of A, B and C items S. No. A Class items B Class items C Class items High consumption Value Moderate control Low consumption Value 1. Very strict control Moderate control Low control 2. No safety stock Low safetystock High safety stock 3. Frequent ordering Once in a week Bulk ordering once in 6 months 4. Weekly control Statement Monthly control reports Quarterly control report 5. Maximum efforts of reduce lead time Moderate efforts Minimum clerical efforts 6. Controlled by top management Controlled by middle level management Controlled by lower level management

- 13. Application of ABC Analysis: Various stages where it can be applied are 1) 2) 3) 4) 5) Information of items which required higher degree of control To evolve reordering strategy Priority treatments to different items Determination of safety stock of limits Stock records

- 14. VED Analysis: Applicable incase of classification of spare parts. The spares are divided in three categories of importance of functional utility. V stands for vital items without which production will come to a halt. If these items go out stock there will be loss of production. E stands for those items which are essential, without which efficiency of equipment will be affected. Non availability of which will result in temporary loss of productivity. D stands for desirable items. The remaining items which do not cause any immediate loss of production fall under this category. SED Analysis: This is based on the availability position of each item. “S”- refers to scarce items, which are short in supply. This includes imported items. “E”- refers to easily available items. These items are available locally. “D”- refers to difficult items, which cannot be procured easily. May not be locally available, Ltd. no. of suppliers, Quality suppliers difficult to get. item. FSN Analysis: This analysis is based on movement or rate of consumption of each “F” refers to fast moving items. The items which have a high rate of consumption “S” refers to slow moving items, the items which are moving at a steady rate of consumption. “N” refers to non moving items which have no consumption during say one year.

- 15. JUST- IN- TIME (JIT) PRODUCTION The Just-In-Time (JIT) production concept was developed in Japan by Toyota to eliminate waste of materials, machines, capital, manpower and inventory throughout the manufacturing system. Toyota Motor Company identifies following types of wastes as being the targets of continuous improvement in production processes by attending to these wastes improvement is achieved. The wastes are: (1) Waste of Overproduction: Make only what is needed now. (2) Waste of Waiting: Eliminate through synchronizing work flow as much as possible and balance uneven load. (3) Waste of Transportation: Establish layouts and locations to make transport and handling unnecessary. (4) Waste of Processing Itself: The first question why this part or product should be made at all, then why each process is necessary.

- 16. (5) Waste of Stocks: Reduce by shortening setup times and reducing lead times. Reducing all other wastes reduces waste of stocks. (6) Waste of Motion: Study motion for economy and consistency. First improve the motions, then mechanize or automate. (7) Waste of Making Defective Products: At each process accept no defects and make no defects. JIT has the following aims: a) b) c) d) Purchase supplies just – in- time to be used. Produce parts just-in –time to be made into sub-assemblies. Produce sub-assemblies just-in-time to be assembled into finished products. Produce finished products just-in –time to the sold. Object of JIT 1. In conventional manufacturing, parts are produced and purchased in batches to serve as inventory to be used whenever necessary. This approach is a Push system. JIT is a Pull system. The parts are produced or purchased to planned orders. Production or delivery of parts matches the demand with zero inventories. Workers inspect parts, monitor product quality, correct defects immediately. Worker, engineer and manager work in a team to quickly solve any problem that may occur during production or assembly. This eliminates further processing of defective parts. 2. 3. 4. Advantages of JIT 1. 2. 3. 4. Low inventory carrying cost. Fast detection and correction of defects, low scrap loss. Reduced inspection and rework of parts. High quality parts at low cost. Results of JIT Implementation 1. Reduction in product cost of 20-40%. 2. Reduction in inventory by 60-80%. 3. Rejection chances less than 10%. 4. Reduction in lead time. 5. Reduction in rejection or warranty cost of 50%. 6. Increase in indirect labour productivity by 60%.

- 17. SUPPLYCHAIN MANAGEMENT SCOPE OF SCM Supply chain consists of network of organizations that connects supplies and customers through manufactures. The coordination components of the supply chain includes the following: Procurement of materials called Source. Manufacture of finished goods called Make. Logistics of flow of materials and goods called Move. Warehousing called Store. Marketing called sell. A supply chain produces value in the form of physical products and services in the hands of users. A generic structure of a supply chain is shown in Fig.

- 18. Distributor Retailer Contractor ManufacturerSupplier Assembler Retailer C & F Agent Supplier Supplier Retailer = Supply Chain Component = Inventory Stockpile = Material Flow The scope of supply chain management (SCM) consists of the following:1. 2. 3. 4. BENEFITS AND RISKS OF SCM Main objective of SCM is to optimize the overall performance of the entire network of supply chain. All the components of supply chain have their own short-term, and long-term objectives and their operating decisions are based on these objectives. Therefore, it is very important to align the overall strategic goal of entire supply chain. Benefits of SCM The benefits of SCM may be listed as follows: 1. 2. Integrated view of enterprise resources and constraints. Improved channel efficiency by sharing information between suppliers and customers. Reduced inventory levels and production costs. Extension of organizational control beyond company‟s boundaries. High return on investment on developing and implementing the system. 3. 4. 5. Risks of SCM SubSupplier Supply chain management is the management of all components and activities of the supply chain. Supply chain management coordinates the activities of material suppliers, production system, distribution, services and customers which are linked together by feed-forward flow of information and feed-back flow of materials. Supply chain management provides a framework forthe integration of information, material and finance of an enterprise, right from suppliers to customers. Supply chain management is a part of ERP software solution, internal business practices, and tightly managed trading partner relationship.

- 19. There can be following risks of SCM: 1. 2. 3. 4. 5. 6. 7. Poor implementation due to enlargement of scope. Information access and security. Supply chain interruptions. Undirectional loss of bargaining power. Training and change management. System management. Challenge of developing trust and managing the inter organizational dependencies. Comparison of ERPand SCM Concept of Value Chain: Supply Chain or value chain makes the production system an extended enterprise. The vendors are treated as part of the extended enterprise. The enterprise can be divided in to two segments of Primary activities and supportive activities Primary Activities in Supply Chain There are five primary activities namely, in-bound logistics, operations, out- bound logistics, marketing & sales, and services. (i) Inbound Logistics Involves raw material handling and warehousing. (ii) Operations: The processing of raw material is performed so that it may change its original shape, form feature etc. (iii) Out-Bound Logistics: involves warehousing and distribution of finished products. Out- bound logistics lead to delivery. This is additional value. (iv) Marketing and Sales: have advertising, promotion, pricing, and channel relations. Marketing the finished products to customer. (v) Services: Services are comprised of installation, repair and replacement. The five primary activities are arranged sequentially. A sequential of these primary activities can result in profits. Sl. No. ERP SCM 1. 2. 3. 4. 5. 6. Primary function is generate data It is the body of an enterprise ERP systems are linear It generates data It excels in the transaction management. It links processes only within the organization Primary function is to take decisions from data. It is the brain of an enterprise SCM is constraints based and optimized. The system is optimized from data generated by ERP. It affords forecasting and decision support. It links organizations of the entire supply chain.

- 20. Support or Secondary Activities in Supply Chain: Porter‟s value chain model for a manufacturing firm having the five primary activities are supported by four secondar y activities. These are: (i) Firm Infrastructure: It involves general management, accounting, strategic planning and control, finance and communication system. (ii) Human Resource Management: It is basically recruitment, manpower development, training and managing personnel. etc. (iii) Technology Development: It involves improvement in product, improvement in process, improvement in system and R&D etc. (iv) Procurement: It is basically purchase of raw material procuring machines, and supplies etc. These secondar y activities can support one or more or all primar y activities and can also support each other for an effective value chain.