Analysis of machining parameters using MQL condition

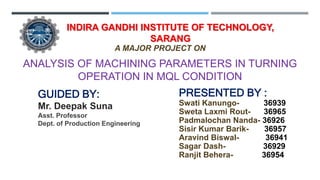

- 1. ANALYSIS OF MACHINING PARAMETERS IN TURNING OPERATION IN MQL CONDITION GUIDED BY: Mr. Deepak Suna Asst. Professor Dept. of Production Engineering PRESENTED BY : Swati Kanungo- 36939 Sweta Laxmi Rout- 36965 Padmalochan Nanda- 36926 Sisir Kumar Barik- 36957 Aravind Biswal- 36941 Sagar Dash- 36929 Ranjit Behera- 36954 INDIRA GANDHI INSTITUTE OF TECHNOLOGY, SARANG A MAJOR PROJECT ON

- 2. CONTENTS INTRODUCTION PURPOSE LITERATURE REVIEW OBJECTIVE MATERIAL SELECTION METHODOLOGY MQL IN TURNING OPERATION RESULTS AND DISCUSSION CONCLUSION WORKING VIDEO OF MQL FUTURE SCOPE REFERENCE

- 3. INTRODUCTION MACHINING IS THE WIDE SPREAD METAL SHAPING PROCESS, IT CONSIST RAPID WEAR RATE OF CUTTING TOOLS DUE TO HIGH CUTTING TEMPERATURE GENERATED DURING THE PROCESS. THUS EFFECTIVE CONTROL OF THE HEAT GENERATED DURING MACHINING IS ESSENTIAL TO ENSURE GOOD WORK QUALITY. DIFFERENT CUTTING FLUIDS ARE APPLIED TO AVOID THE PROBLEM; HOWEVER CONVENTIONAL CUTTING FLUIDS ARE RESTRICTED DUE TO THEIR HARMFUL HEALTH AND ENVIRONMENTAL IMPACTS. THE NECESSITY TO MACHINE USING LESS HARMFUL CUTTING FLUIDS HAS LED THE RESEARCHER TO DEVELOP NEW CUTTING FLUIDS WHICH ARE LESS HARM AND THE RESULT OF INVESTIGATION CAME UP WITH A NEW SYSTEM CALLED MINIMUM QUANTITY LUBRICATION (MQL) MINIMUM QUANTITY LUBRICATION REFERS TO USE SMALL AMOUNT OF CUTTING FLUID, WHICH IS ABOUT 1000 TIMES LESS THAN THAT OF CONVENTIONAL CUTTING FLUIDS.

- 4. LUBRICATION IS THE PROCESS OR TECHNIQUE OF USING A LUBRICANT TO REDUCE FRICTION AND WEAR & TEAR IN A CONTACT BETWEEN TWO SURFACES. MQL: IT IS A PROCESS OF PROVIDING LUBRICANT IN VARIOUS MACHINING PROCESS IN MINIMUM QUANTITY. DUE TO MINIMUM QUANTITY LUBRICATION, LUBRICATING FLUID CAN BE REDUCED SIGNIFICANT TIMES THAN CONVENTIONAL LUBRICATION PROCESS. THE INTERFACE BETWEEN TOOL AND WORKPIECE IS COATED WITH HIGH QUALITY OF LUBRICANT THAT IS DELIVERED IN ATOMIZED SPRAY TO ACHIEVE LUBRICATION PROPERTIES. WHAT IS MQL?

- 5. PURPOSE IN ALL MACHINING PROCESSES, TOOL WEAR IS A NATURAL PHENOMENON AND IT LEADS TO TOOL FAILURE. THE GROWING DEMANDS FOR HIGH PRODUCTIVITY OF MACHINING NEED USE OF HIGH CUTTING VELOCITY AND FEED RATE. SUCH MACHINING INHERENTLY PRODUCES HIGH CUTTING TEMPERATURE, WHICH NOT ONLY REDUCES TOOL LIFE BUT ALSO IMPROVES THE PRODUCT QUALITY. METAL CUTTING FLUIDS CHANGES THE PERFORMANCE OF MACHINING OPERATIONS BECAUSE OF THEIR LUBRICATION, COOLING, AND CHIP FLUSHING FUNCTIONS BUT THE USE OF CUTTING FLUID HAS BECOME MORE PROBLEMATIC IN TERMS OF BOTH EMPLOYEE HEALTH AND ENVIRONMENTAL POLLUTION.

- 6. THE OTHER ADVANTAGE OF STUDYING THE VARIOUS MACHINING PROCESS USING MQL SYSTEM IS TO : EASILY AVAILABLE AND LOW COST TECHNOLOGY. NEED OF SUCH IMPROVED SYSTEM IN THIS GENERATION. DEVELOP TECHNICAL SKILLS. IMPROVE MACHINING CHARACTERISTICS. UTILIZE NATURAL RESOURCES IN LUBRICATION FIELD. PROVIDE POLLUTION FREE LUBRICANTS FOR THE INDUSTRIES .

- 7. TYPES OF LUBRICATION BASICALLY THERE ARE THREE TYPES OF LUBRICATION SYSTEMS FLOODED LUBRICATION DRY LUBRICATION MINIMUM QUANTITY LUBRICATION

- 8. DRY LUBRICATION : DRY LUBRICATION IS LUBRICATION IN WHICH USE OF CUTTING OIL IS TOTALLY PROHIBITED. THIS TYPES OF LUBRICATION IS GENERALLY USED WHERE MATERIAL REMOVAL RATE IS VERY LESS. FLOODED TYPE: FLOODED TYPE OF LUBRICATION SYSTEM IS WHAT WE SEE REGULARLY IN OUR INDUSTRIES.IN FLOODED TYPE OF LUBRICATING SYSTEM ,LARGE AMOUNT OF CUTTING FLUID IS SUBJECTED TOWARDS THE WORKPIECE FOR ITS COOLING ACTIONS . MINIMUM QUANTITY LUBRICATION (MQL): THE LUBRICATION TECHNIQUE USES MUCH LESS AMOUNT TO CUTTING FLUID AS COMPARED TO COVENTIONAL SYSTEM.

- 9. LITERATURE REVIEW SL NO. AUTHOR YEAR JOURNAL NAME FINDINGS 1 N.R. Dhar , M.amruzzaman, Mahiuddin Ahmed 2005 Effect of minimum quantity lubrication (MQL) on tool wear and surface roughness in turning AISI-4340 steel Material:- Aisi-4340-steel PARMAETERS:-Tool wear , surface roughness CUTTING TOOL:- Carbide Findings:-The cutting performance of MQL machining is better than that of dry and conventional machining with flood cutting fluid supply because MQL provides the benefits mainly by reducing the cutting temperature, which improves the chip–tool interaction and maintains sharpness of the cutting edges. 2 B. Tasdelena, T. Wikblomb, S. Ekeredc 2007 Studies on minimum quantity lubrication (MQL) and air cooling at drilling Drill body:-Coro drill 880-D1900L25-03 Inserts:- GM 1044 (centrum), GM 4024 (periphery) Cutting speed:-155m/min Feed rate:-0.11mm/rev Hole depth:-33mm Findings:- • The highest wear both for center and periphery inserts was observed using emulsion, followed by air and MQL assisted machining. • The highest cooling ability of emulsion is probably the reason for the excessive tool wear located in the middle of the

- 10. 3 M.M.A. Khana, M.A.H. Mithua, N.R. Dharb 2007 Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil- based cutting fluid Material:- AISI 9310 steel Machine tool:- Lathe Machine, 15 hp CUTTING TOOL:- Uncoated carbide, SNMG 120408 (P-30 grade) Findings:- MQL provided significant improvements expectedly, though in varying degree, in respect of chip formation modes, tool wear and surface finish throughout the range of Vc and so undertaken mainly due to reduction in the average chip–tool interface temperature. Wet cooling by soluble oil could not control the cutting temperature appreciably and its effectiveness decreased further with the increase in cutting velocity and feed rate. 4 Murat Sarıkaya, Abdulkadir Güllü 2006 Multi-response optimization of minimum quantity lubrication parameters using Taguchi-based grey relational analysis in turning of difficult-to-cut alloy Haynes 25 Inserts:- Uncoated carbide, SNMG 120408-QM (S-15 grade) Cutting speed:-155m/min Cutting speed (Vc) :-30, 40, 50 m/min Feed rate (f):- 0.15 mm/rev Depth of cut :- 1mm Material removal rate (MRR):-7500 mm3 Tool Holder :- PSBNR2020K12 Findings:- The highest wear both for center and periphery inserts was observed using emulsion, followed by air and MQL assisted machining. The highest cooling ability of emulsion is probably the reason for the excessive tool wear located in the middle of the contact zone.

- 11. OBJECTIVE IN THIS PROJECT WE ARE GOING TO INVESTIGATE THE ROLE OF MQL ON TOOL WEAR AND SURFACE ROUGHNESS IN TURNING OPERATION AT INDUSTRIAL SPEED-FEED COMBINATION. AIM OF THIS EXPERIMENT IS TO MEASURE SURFACE ROUGHNESS, TOOL WEAR AND CUTTING TEMPERATURE IN DRY CONDITION , FLOODED CONDITION AND MQL CONDITION.

- 12. MATERIAL SELECTION LUBRICANT: LUBRICANT OIL- 40 GRADE MATERIAL: 6061 ALUMINIUM ALLOY, Ø25.7 × 150mm DENSITY OF 6061 ALUMINIUM ALLOY – 2.7 g/cm3 CUTTING TOOL(INSERT): HSS MACHINE: LATHE , PATHAK INDUSTRIES OPERATION: TURNING CUTTING ENVIRONMENT: DRY, FLOODED, MQL COMPONENT Al Si Mg Cr Cu COMPOSITION (Wt. %) 97.9 0.6 1.0 0.2 0.28 6061 Al Alloy

- 13. INPUT PARAMETERS CUTTING VELOCITY FEED RATE DEPTH OF CUT CUTTING TEMPERATURE TOOL WEAR SURFACE ROUGHNESS OUTPUT PARAMETERS

- 14. METHODOLOGY THE MQL NEEDS TO BE SUPPLY AT HIGH PRESSURE AND IMPINGED AT HIGH SPEED THROUGH THE NOZZLE AT THE CUTTING ZONE. CONSIDERING THE CONDITIONS REQUIRED FOR THE PRESENT EXPERIMENTAL WORK AN UNINTERRUPTED SUPPLY OF MQL AT CONSTANT PRESSURE OVER A REASONABLY LONG CUT . A MQL DELIVERY SYSTEM WILL BE DESIGNED, FABRICATED AND USED. THE SCHEMATIC VIEW OF THE MQL SET UP IS SHOWN IN FIG. 1 THE THIN BUT HIGH VELOCITY STREAM OF MQL WILL PROJECTED FROM A NOZZLE ALONG THE CUTTING EDGE OF THE INSERT, AS INDICATED IN A FRAME WITHIN FIG. 1 , SO THAT THE COOLANT REACHES AS CLOSE TO THE CHIP–TOOL AND THE WORK–TOOL INTERFACES AS POSSIBLE.

- 16. THE REFERENCE PHOTOGRAPHIC VIEW OF THE EXPERIMENTAL SET-UP IS SHOWN IN FIG. 2. & FIG. 3 THE MQL JET WILL BE USED MAINLY TO TARGET THE RAKE AND FLANK SURFACE AND TO PROTECT THE AUXILIARY FLANK TO ENABLE BETTER DIMENSIONAL ACCURACY. MQL IS EXPECTED TO PROVIDE SOME FAVOURABLE EFFECTS MAINLY THROUGH REDUCTION IN CUTTING TEMPERATURE. THE SIMPLE DIGITAL THERMOMETER WILL EMPLOYED TO MEASURE THE AVERAGE CUTTING TEMPERATURE DURING TURNING AT DIFFERENT VC COMBINATIONS BY THE HSS INSERT UNDER DRY, WET AND MQL CONDITIONS. ROUGHNESS TESTER WILL BE EMPLOYED TO MEASURE THE SURFACE ROUGHNESS OF THE MACHINED WORKPIECE OF DRY, FLOODED & MQL CONDITION AND CUTTING FORCE WILL BE MEASURED BY USING DYNAMOMETER.

- 17. MQL IN TURNING OPERATION TURNING IS A MACHINING PROCESS IN WHICH NON-ROTARY CUTTING TOOL DESCRIBES HELICAL PATH WHILE THE WORKPIECE ROTATES. THE EFFECTS OF CUT, FEED RATE AND CUTTING SPEED WERE STUDIED FOR THE TOOL WEAR AND SURFACE FINISH. MIXING CHAMBER Fig-2 OUTLET INLET (2) COMPRESSOR

- 18. NOZZLE COMPRESS OR COOLANT RESORVIOR PUMP Fig-3 LATHE MACHINE (MT LAB) DEPT. OF PRODUCTION ENGG

- 19. EXPERIMENTAL INVESTIGATION EXPERIMENTS HAVE BEEN CARRIED OUT BY PLAIN TURNING A 25.7MM DIAMETER AND 150MM LONG ROD OF ALLUMINIUM IN A POWERFUL AND RIGID LATHE (PATHAKMACHINE COMPANY) AT INDUSTRIAL SPEED-FEED COMBINATION UNDER DRY, WET AND MINIMUM QUANTITY LUBRICATION CONDITIONS. THE EXPERIMENTAL CONDITIONS ARE GIVEN IN Table-1

- 20. EXPERIMENTAL CONDITION ENVIRONMENT CUTTING VELOCITY VC [in terms of N] (in RPM) FEED RATE S0 (in mm/sec) DEPTH OF CUT (in mm) DRY 230 0.19 0.5 310 0.28 0.5 500 0.38 0.5 FLOODED 230 0.19 0.5 310 0.28 0.5 500 0.38 0.5 MQL 230 0.19 0.5 310 0.28 0.5 500 0.38 0.5 Table-

- 21. RESULTS AND DISCUSSION EFFECT ON CUTTING TEMPERATURE EFFECT ON TOOL WEAR EFFECT ON SURFACE ROUGHNESS

- 22. EFFECT ON CUTTING TEMPERATURE DURING MACHINING OF ANY DUCTILE MATERIALS, HEAT IS GENERATED AT THE (I) PRIMARY DEFORMATION ZONE DUE TO SHEAR AND PLASTIC DEFORMATION, (II) CHIP–TOOL INTERFACE DUE TO SECONDARY DEFORMATION AND SLIDING AND (III) WORK–TOOL INTERFACES DUE TO RUBBING. ALL SUCH HEAT SOURCES PRODUCE MAXIMUM TEMPERATURE AT THE CHIP–TOOL INTERFACE, WHICH SUBSTANTIALLY INFLUENCE THE CHIP FORMATION MODE, CUTTING FORCES AND TOOL LIFE. CONVENTIONAL CUTTING FLUID APPLICATION MAY, TO SOME EXTENT, COOL THE TOOL AND THE JOB IN BULK BUT CANNOT COOL AND LUBRICATE EFFECTIVELY AT THE CHIP–TOOL INTERFACE WHERE THE TEMPERATURE IS MAXIMUM.

- 23. IT WAS OBSERVED THAT THE MQL JET IN ITS PRESENT WAY OF APPLICATION ENABLED REDUCTION OF THE AVERAGE CUTTING TEMPERATURE BY ABOUT 5–10% DEPENDING UPON THE LEVELS OF THE PROCESS PARAMETERS. EVEN SUCH APPARENTLY SMALL REDUCTION IN THE CUTTING TEMPERATURE IS EXPECTED TO HAVE SOME FAVOURABLE INFLUENCE ON OTHER MACHINABILITY INDICES. THE EXPERIMENTAL OBSERVED DATA WAS PRESENTAED IN GRAPHICAL FORM .

- 24. A GRAPHICAL REPRESENTATION BETWEEN CUTTING TEMPERATURE & CUTTING VELOCITY IN THREE DIFFERENT CONDITION

- 25. EFFECT ON TOOL WEAR DURING MACHING, CUTTING TOOLS REMOVES MATERIAL FROM THE COMPONENT TO ACHIEVE THE REQUIRED SHAPE, DIMENSION AND SURFACE ROUGHNESS(FINISH). HOWEVER WEAR OCCUR DURING THE CUTTING ACTION, AND IT ULTIMATELY RESULT IN THE FAILURE OF THE CUTTING TOOL. THE CHANGE OF SHAPE OF THE TOOL FROM ITS ORIGINAL SHAPE , DURING MACHINING, RESULTING FROM GRADUAL LOSS OF TOOL MATERIAL .THIS IS KNOWN AS TOOL WEAR IN MACHINING. ANOTHER IMPORTANT TOOL WEAR CRITERIA IS AVEARGE AUXILIARY FLANK WEAR WHICH GOVERNS THE SURFACE FINISH ON THE JOB AS WELL AS DIMENSIONAL ACCURACY. IRREGULAR AND HIGHER AUXILIARY FLANK WEAR LEADS TO POOR SURFACE FINISH AND DIMENSIONAL INACCURACY. THE APPLICATION MQL HAS EXPECTED TO PROVIDE BETTER SURFACE FINISH.

- 26. THE TOOL WEAR IS MORE ON DRY CONDITION AND GRADUALLY DECREASE IN FLOODED AND MQL CONDITION.THE REASON BEHIND IT IS REDUCTION IN TEMPERATURE, BECAUSE OF THAT GROWTH OF TOOL WEAR DECREASES AND TOOL LIFE WOULD INCREASES OR MUCH HIGHER IF MQL IS PROPERLY APPLIED. USUALLY UNDER DRY ENVIRONMENTS ABRASIVE SCRATCH MARKS APPEARED IN THE INSERT, THERE MAY BE SOME PLASTIC DEFORMATION OCCUR UNDER SAME CONDITION WHICH IS REDUCED UNDER APPLICATION OF FLOODED AND MQL nitial wt. of tool=69.70g Final wt. of tool=69.41g Initial wt. of tool=69.41g Final wt. of tool=69.37g Initial wt. of tool=69.37g Final wt. of tool=69.34g DRY CONDITION FLOODED CONDITION MQL CONDITION

- 27. EFFECT ON SURFACE ROUGHNESS ROUGHNESS IS A MEASUREMENT OF THE SMALL SCALE VARIATION IN THE HEIGHT OF PHYSICAL SURFACE. IT CONSIST OF SURFACE IRREGULARITIES WHICH RESULTS FROM THE VARIOUS MACHINING PROCESS. THESE IRREGULARITY COMBINE TO FORM SURFACE TEXTURE. THIS IS IN CONTRAST OF LARGE SCALE VARIATIONS, WHICH MAY BE EITHER PART OF THE GEOMETRY OF THE SURFACE OR UNWANTED ‘WAVINESS’. SURFACE FINISH IS AN IMPORTANT INDEX OF MACHINABILITY BECAUSE PERFORMANCE AND SERVICE LIFE OF MACHINED COMPONENTS ARE OFTEN AFFECTED BY SURFACE FINISH AND EXTENT OF RESIDUAL STRESS & PRESSURE PRESENT ON SURFACE.

- 29. THE MAJOR CAUSE BEHIND DEVELOPMENT OF SURFACE ROUGHNESS IN CONTINUOUS MACHINING PROCESS LIKE TURNING OF DUCTILE MATERIAL ARE: i. REGULAR FEED MARKS LEFT BY THE TOOL TIP ON THE FINISHED SURFACE . ii. IRREGULAR DEFORMATION OF THE AUXILIARY CUTTING EDGE AT THE TOOL TIP DUE TO CHIPPING, FRACTURING AND WEAR. iii. VIBRATION ON MACHINING SYSYTEM. iv. BUILT-UP-EDGE FORMATION. IN MQL CONDITION TOOL/FLANK WEAR ON AUXILIARY CUTTING EDGE IS REDUCED, SO SURFACE ROUGHNESS IS EXPECTED TO INCREASE UNDER MQL CONDITION.

- 30. CONCLUSIONS BASED ON THE PRESENT EXPERIMENTAL INVESTIGATION THE FOLLOWING CONCLUSIONS CAN BE MADE: THE CUTTING PERFORMANCE OF MQL-MACHINING IS BETTER THAN THAT OF DRY AND CONVENTIONAL MACHINIG ALSO THE MACHINABILITY OF THE WORK HAS A SIGNIFICANT IMPROVED. MQL PROVIDE BENEFITS MAINLY BY REDUCING THE CUTTING TEMPERATURE, WHICH IMPROVES THE CHIP TOOL INTERACTION AND MAINTAINS THE WORK CONDITION EASE FOR FURTHER MACHINING. MQL JET PROVIDE REDUCED TOOL WEAR , IMPROVED TOOL LIFE AS COMPARED TO DRY AND FLOODED CONDITION. MQL IMPROVES AND ENHANCES THE PRODUCTIVITY AND REDUCED THE COST OF COOLANT ALLOWING HIGHER CUTTING VELOCITY AND FEED.

- 31. Final machined workpiece a b c a. DRY CONDITION b. FLOODED CONDITION c. MQL CONDITION Dt. 11/04/2021 Dt. 11/04/2021 MT LAB (PE DEPT.)

- 33. FUTURE SCOPE MQL TECHNOLOGY HAS A GREAT POTENTIAL TO PERFORM WELL IN THE EXPERIMENTAL ENDEAVOR, HERE, WE FOUND A FEW GAPS IN THE PREVIOUS LITERATURE AND PROPOSE THESE GAPS AS THE FUTURE SCOPE OF THE STUDY, WHICH IS LISTED BELOW: INTRODUCTION OF NANO PARTICLES IN LUBRICATION PROCESS AND NEW DEVELOPMENT OF MQL TECHNOLOGY USING NANOFLUIDS FOR SUSTAINABLE CUTTING PROCESSES HAS A POTENTIAL FOR FUTURE STUDIES. A FIELD SURVEY IS REQUIRED TO BE PUBLISHED ON THE ACTUAL INDUSTRIAL APPLICATION OF MQL. FOR THIS PURPOSE, THE LIFE CYCLE ASSESMENT WOULD BE A GOOD CHOICE. STUDY OF THE DROPLET DYNAMICS OF MQL BASE FLUID WILL BE A NEW RESEARCH DIMENSION. HERE, THE THERMAL ANALYSIS NEEDS TO BE INCORPORATED WITH SUSTAINABILITY ANALYSIS FOR GREEN MANUFACTURING TECHNOLOGY. LASTLY, THE ADVENT OF ADVANCED COMPUTATIONAL ALGORITHMS AND DATA SCIENCE DEMAND TO BE INTEGRATED WITH MQL ASSISTED MACHINING, AND MQL CONTROL PARAMETERS SO THAT INTELLIGENT AND SMART MANUFACTURING CAN BE DEVISED FOR INDUSTRY 4.0. STUDIES ARE REQUIRED IN THIS FIELD.

- 34. REFERENCES Studies on minimum quantity lubrication (MQL)and air cooling at drilling. B. Tasdelena,∗, T. Wikblomb, S. Ekeredc Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil-based cutting fluid. M.M.A. Khana,∗, M.A.H. Mithua, N.R. Dharb Multi-response optimization of minimum quantity lubrication parameters using Taguchi-based grey relational analysis in turning of difficult-to-cut alloy Haynes. 25 Murat Sarıkaya a, *, Abdulkadir Güllü b Comparison among different vegetable fluids used in minimum quantity lubrication systems in the tapping process of cast aluminum alloy Sergio Luiz Moni Ribeiro Filho, Jessica Tito Vieira, Juliano Aparecido de Oliveira, Etory Madrilles Arruda, Lincoln Cardoso Brand~ao* Experimental evaluation of the lubrication performance of mixtures of castor oil with other vegetable oils in MQL grinding of nickel-based Alloy Shuming Guo, Changhe Li*, Yanbin Zhang, Yaogang Wang, Benkai Li, Min Yang, Xianpeng Zhang, Guotao Liu Study of specific energy and friction coefficient in minimum quantity lubrication grinding using oil- based nanolubricants Parash Kalita a, Ajay P. Malshea,∗, S. Arun Kumarb, V.G. Yoganathb, T. Gurumurthyb

- 35. THANK YOU