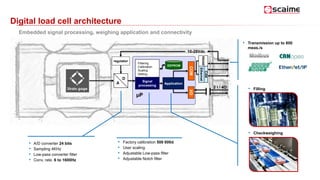

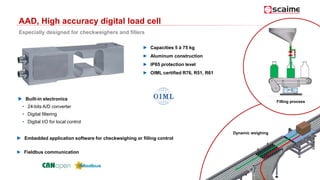

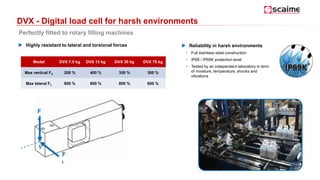

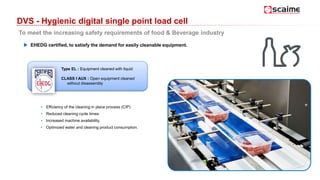

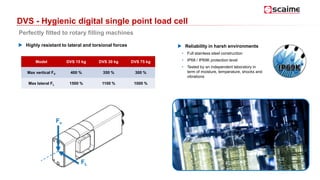

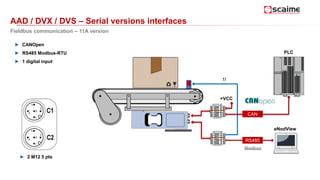

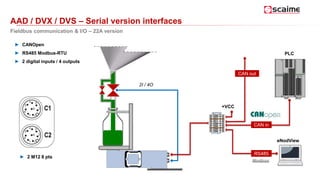

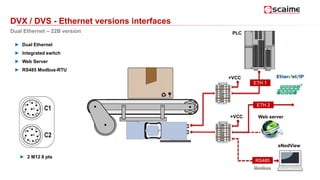

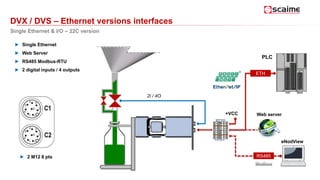

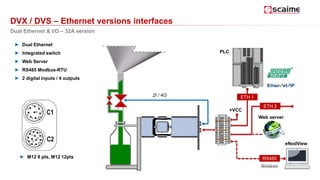

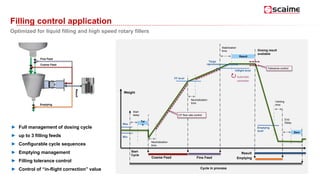

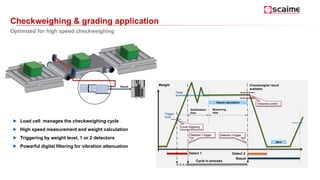

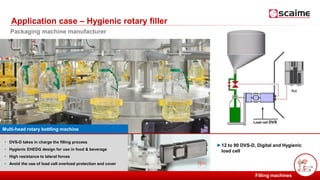

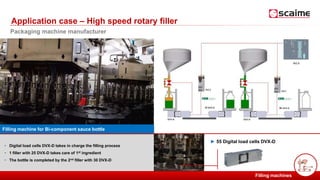

The document presents a range of digital load cells designed for various packaging machine applications, including filling, sorting, and checkweighing. It highlights the specifications, features, and benefits of different load cell models, such as AAD, DVS, and DVX, emphasizing their suitability for harsh and hygienic environments. Additionally, it outlines their advanced communication interfaces and embedded software for efficient process control in food and beverage, industrial, and logistics sectors.